Zane Laser akan Dutse

Duk Game da Shafukan Keɓaɓɓu ne & Haɗin Tunani

Laser Engraving Stone: ƙwararre da cancanta

Don taron karawa juna sani, lokaci ya yi da za a saka hannun jari a cikin injin zanen Laser don fadada kasuwancin ku.

Zanen Laser akan dutse yana ƙara ƙarin ƙima ta hanyar zaɓin ƙirar mutum ɗaya. Ko da don ƙananan samar da tsari, da CO2 Laser da fiber Laser na iya haifar da m da dindindin gyare-gyare.

Ko yumbu, dutse na halitta, granite, slate, marmara, basalt, lave stone, pebbles, fale-falen buraka, ko tubalin, Laser zai ba da sakamako mai bambanta ta halitta.

Haɗe tare da fenti ko lacquer, za a iya gabatar da kyautar zanen dutse da kyau. Kuna iya yin rubutu mai sauƙi ko haruffa cikin sauƙi kamar cikakkun hotuna ko ma hotuna!

Laser don sassaƙa dutse

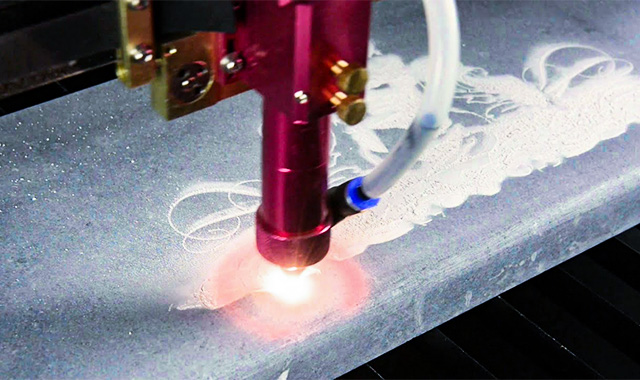

Lokacin amfani da fasahar Laser CO2 don sassaƙa dutse, katakon Laser yana cire saman saman daga zaɓaɓɓen nau'in dutse.

Alamar Laser za ta haifar da ƙananan ƙwayoyin cuta a cikin kayan, samar da alamomi masu haske da matte, yayin da dutsen da aka zana Laser ya sami tagomashin mutane tare da alheri mai kyau.

Yana da ka'ida ta gaba ɗaya cewa duhun rigar gem ɗin, mafi daidai tasirin sakamako kuma mafi girman bambanci.

Sakamakon ya yi kama da rubutun da aka samar ta hanyar etching ko yashi.

Koyaya, ya bambanta da waɗannan hanyoyin, ana sarrafa kayan kai tsaye a cikin zanen Laser, wanda shine dalilin da yasa ba kwa buƙatar samfuri da aka riga aka tsara.

Bugu da kari, fasahar Laser ta MimoWork ta dace da sarrafa kayan aiki na kauri daban-daban, kuma saboda kula da layinsa mai kyau, har ma ya dace da zana ƙananan abubuwa.

Tips da dabaru Lokacin Laser sassaƙa Dutse

Farawa da dutsen zanen Laser na iya jin ɗan ban tsoro, amma tare da ƴan tukwici da dabaru, zaku kasance da kyau akan hanyar ku don ƙirƙirar guda masu ban sha'awa.

1. Tsaftace saman

Na farko, koyaushe farawa da wuri mai tsabta.

Kura da tarkace na iya shafar ingancin zanen ku, don haka ba wa dutsen ku goge mai kyau.

2. Tsarin Da Ya dace

Na gaba, la'akari da ƙirar ku.

Mafi sauƙi, ƙira masu ƙarfin hali sukan haifar da sakamako mafi kyau fiye da ƙira.

3. Koyaushe Gwaji Farko

Gwada saitunan ku a kan gungu.

Kafin nutsewa cikin yanki na ƙarshe don tabbatar da cewa kuna da cikakkiyar saurin gudu da matakan ƙarfi.

4. Cika da Paint Contrasting

Ba wai kawai yana haskaka ƙirar ku ba amma kuma yana ƙara ƙwanƙwasa launi wanda zai iya sa yanki ya yi fice. A ƙarshe, kada ku ji tsoron gwaji. Kowane dutse yana da nasa hali, kuma gano abin da ke aiki mafi kyau zai iya haifar da wasu abubuwa na musamman na gaske!

Nunin Bidiyo: Laser Engraving Slate Coaster

Kuna son ƙarin koyo Game daRa'ayoyin sassaƙa Dutse?

Me yasa Amfani da Dutsen Zane Laser (Granite, Slate, da sauransu)

• Tsari mai sauƙi

Zane-zanen Laser baya buƙatar kayan aiki, kuma baya buƙatar samar da samfuri.

Kawai ƙirƙirar ƙirar da kuke so a cikin shirin zane, sannan aika shi zuwa laser ta hanyar buga umarni.

Misali, ba kamar niƙa ba, ba a buƙatar kayan aiki na musamman don nau'ikan dutse daban-daban, kauri ko ƙira.

Wannan yana nufin ba za ku ɓata lokaci don sake haɗawa ba.

• Babu Kudaden Kayan aiki da Tausasawa akan Kayan

Tun da Laser engraving na dutse ba lamba, wannan shi ne musamman m tsari.

Dutsen ba ya buƙatar gyarawa a wurin, wanda ke nufin cewa saman kayan bai lalace ba kuma babu kayan aiki.

Kulawa mai tsada ko sabbin sayayya ba zai jawo kowane farashi ba.

• Samfura mai sassauƙa

Laser ya dace da kusan kowane saman abu, kauri ko siffar. Kawai shigo da zane-zane don kammala aiki ta atomatik.

• Madaidaicin sakamako

Ko da yake etching da engraving ayyuka ne na hannu kuma koyaushe akwai wani takamaiman matakin rashin daidaito, MimoWork's injin yankan Laser na atomatik yana da alaƙa da babban maimaitawa a matakin inganci iri ɗaya.

Ko da cikakkun bayanai za a iya samar da su daidai.

Na'urar sassaƙa dutse da aka ba da shawarar

• Ƙarfin Laser: 100W/150W/300W

Wurin Aiki: 1300mm * 900mm (51.2 "* 35.4")

CO2 Vs Fiber: Don Dutsen Zane Laser

Lokacin da yazo don zaɓar madaidaicin laser don zanen dutse, muhawarar sau da yawa takan tashi zuwa CO2 vs. fiber Laser. Kowannensu yana da ƙarfinsa, kuma sanin wanda za ku zaɓa zai iya haifar da duk wani bambanci a cikin kwarewar zanen ku.

CO2 LaserZane Dutse

CO2 Laser ne tafi-zuwa zabi ga mafi dutse engraving ayyukan.

Suna aiki na musamman da kyau akan kayan kamar granite, marmara, da slate.

Tsawon tsayin zafin laser na CO2 yana ba su damar vaporize saman dutsen, wanda ke haifar da santsi, zane-zane daki-daki.

Ƙari ga haka, sun kasance sun fi araha da sauƙin samu!

Fiber LaserZane Dutse

A daya hannun kuma, fiber Laser na samun karbuwa, musamman ga masu neman zana abubuwa masu wuya kamar karafa ko yumbu.

Duk da yake fiber Laser na iya ɗaukar dutse, gabaɗaya sun fi dacewa da yin alama fiye da zane mai zurfi.

Idan kuna shirin yin aiki da farko da dutse, CO2 lasers zai iya zama mafi kyawun fare ku.

A ƙarshe, zaɓin da ya dace ya dogara da takamaiman bukatunku da nau'ikan ayyukan da kuke tunani. Don haka ko kuna ƙera kyaututtukan zuciya ko kayan ado na musamman, duniyar dutsen zanen Laser tana cike da yuwuwar mara iyaka - kawai jiran taɓawar ku!

Yadda za a Zaba Laser Marking Machine?

Shiga cikin cikakken jagora akan zabar na'ura mai alamar Laser a cikin wannan bidiyo mai ba da labari inda muke magance yawancin tambayoyin abokin ciniki.

Koyi game da zaɓin girman da ya dace don na'ura mai sanya alama ta Laser, fahimtar alaƙa tsakanin girman ƙirar da wurin kallon Galvo na injin, da karɓar shawarwari masu mahimmanci don sakamako mafi kyau.

Bidiyon kuma yana nuna shahararrun haɓakawa waɗanda abokan ciniki suka sami fa'ida, suna ba da misalai da cikakkun bayanai game da yadda waɗannan haɓakawa zasu iya tasiri ga zaɓin na'urar yin alama ta Laser.

Wani nau'in Duwatsu ne za a iya sassaƙa shi da injin Laser?

• yumbu da ain

• Basalt

• Granite

• Dutsen farar ƙasa

• Marmara

• Duwatsu

• Lu'ulu'u na gishiri

• Dutsen Sand

• Slate

Wadanne Duwatsu Za'a iya Zana Laser Tare da Babban Sakamako?

Idan ya zo ga zane-zane na Laser, ba duka duwatsu ne aka halicce su daidai ba. Wasu duwatsun suna da sauƙin gafartawa kuma suna ba da sakamako mafi kyau fiye da wasu.

Granite

Granite babban ɗan takara ne-ƙarfin sa da kyakkyawan hatsi sun sa ya zama cikakke don ƙira mai rikitarwa.

Marmara

Marmara, tare da kyakkyawar jijiyar sa, na iya ƙara taɓar da kyau ga kowane zane.

Slate

Sannan akwai slate, wanda bai kamata a manta da shi ba! Filayensa mai santsi yana ba da damar ƙwanƙwasa, zane-zane, yana mai da shi abin da aka fi so don sigina da kayan ado na gida.

Dutsen Kogin

Kuma kada mu manta game da duwatsun kogi! Suna kawo dabi'a na dabi'a, rustic kuma suna da ban mamaki don kyaututtuka na sirri. Ka tuna kawai, maɓallin don babban sakamako yana daidaita nau'in dutse tare da zane-don haka zaɓi da hikima!

Menene Koyaushe Siyar da Sauri don Dutsen Ƙarƙashin Laser?

Idan kun taɓa yin yawo ta hanyar fasahar fasaha ko kantin kayan ado na gida, ƙila kun lura cewa abubuwan da aka zana na dutse sukan tashi daga kan ɗakunan ajiya.

Me ya sa ba za su iya jurewa ba?

Yana iya zama irin halayensu na musamman, kyawawan dabi'un dutse, ko kuma watakila taɓawar jin daɗi da ta fito daga zanen al'ada.

Ka yi tunani game da shi: dutsen da aka zana da kyau zai iya zama kyauta mai ban sha'awa, abin tunawa da za a iya mantawa da shi, ko ma wani yanki mai ban sha'awa na fasahar lambu.

Abubuwa kamar duwatsun tunawa da keɓaɓɓu, alamomin dabbobi na al'ada, ko ma duwatsun lambu na ado sun kasance masu saurin siyarwa.

Suna hulɗa da mutane a matakin sirri.

Bayan haka, wa ba zai so wani yanki na nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau’in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in nau'in) yana nuna soyayya, ƙwaƙwalwar ajiya, ko jin daɗin sa?

Don haka, idan kuna la'akari da nutsewa cikin duniyar zanen Laser, ku tuna: taɓawar sirri da haɗin kai sune abokan ku mafi kyau a cikin wannan kasuwancin!

Tambayoyin Da Aka Yawaita Game Da Laser Egraving Stone

1. Nawa ne Kudin sassaƙa Dutse?

Farashin na iyabambanta kadan!

Idan kana amfani da sabis na ƙwararru, ƙila kana kallon ko'ina daga $50 zuwa dala ɗari da yawa, ya danganta da girman da wuyar zanen.

Idan kana tunanin yin shi da kanka, na'ura mai kyau Laser engraving inji yana da wani zuba jari, amma tunanin duk keɓaɓɓen kyaututtuka da kayan ado za ka iya ƙirƙirar!

2. Abin da Laser ne Mafi kyau ga sassaƙa Dutse?

Don yawancin ayyukan sassaƙa duwatsu,CO2 Laser shine abokin ku mafi kyau.

Suna da yawa, abokantaka masu amfani, kuma suna yin abubuwan al'ajabi akan kayan kamar granite da marmara. Idan kana neman zana kayan aiki masu wuya, Laser fiber na iya zama zaɓi, amma don aikin dutse na gaba ɗaya, tsaya tare da CO2!

3. Har yaushe Zane-zanen Dutse Zai Dawwama?

Zane-zanen dutse suna da yawagina don dawwama!

Tare da kulawa mai kyau, zane-zanenku na iya ɗaukar shekaru da yawa, idan ba haka ba. Tun da dutse abu ne mai ɗorewa, zane-zane ya kasance cikakke ko da lokacin da aka fallasa su ga abubuwa. Kawai kiyaye shi da tsabta kuma ba tare da tarkace ba don kiyaye kyawunsa!

4. Menene Mafi Sauƙin Dutse don Rubuta?

Ana la'akari da Slate sau da yawamafi sauƙin dutse don sassaƙawa.

Fuskar sa mai santsi yana ba da damar ƙirƙira ƙira, yana mai da shi abin da aka fi so ga masu farawa. Granite da marmara suma zaɓuɓɓuka ne masu kyau, amma slate yana nuna ya zama mai gafartawa idan kun fara farawa.

5. An sassaƙa Laser na Headstones?

Yawancin duwatsun kai yanzu an zana Laser, baiwa iyalai dama don ƙara abubuwan taɓawa da ƙira masu rikitarwa.

Hanya ce mai kyau don tunawa da ƙaunatattuna da ƙirƙirar yabo mai ɗorewa wanda ke nuna halayensu.

6. Menene Matakai na Laser Engraving Stone?

Zane dutse wani ɗan tsari ne, amma ana iya yinsa gaba ɗaya!Ga takaitaccen bayani:

Laser sassaƙa Dutse:Matakin Shiri

1. Zabi Dutsen ku:Zaɓi dutsen da ke magana da ku - granite, marmara, ko slate duk manyan zaɓuɓɓuka ne.

2. Zana Kayan Aikinku:Ƙirƙiri ko zaɓi ƙirar da kuke so. Ci gaba da sauƙi don sakamako mafi kyau!

3. Shirya Dutse:Tsaftace saman don cire duk wata ƙura ko tarkace.

4. Saita Injin ku:Daidaita saitunan laser ku bisa nau'in dutse da ƙira.

5. Gudun Gwaji:Koyaushe yi zanen gwaji a kan guntun guntun farko da farko.

Laser sassaƙa Dutse:Engrave & Bayan-Tsarin

6. Rubuta:Da zarar kun shirya, ci gaba da zana gwanin aikinku!

7. Gamawa:Tsaftace dutsen kuma la'akari da ƙara bambancin fenti don haskaka ƙirar ku.

Kuma a can kuna da shi! Tare da ɗan ƙaramin aiki, zaku ƙirƙira zane-zanen dutse masu ban sha'awa cikin ɗan lokaci.

Zafafan batutuwa game da zanen Laser

# Nawa Ina Bukatar Zuba Jari Akan Na'urar Laser?

# Zan iya ganin Wasu Samfurori don sassaƙa dutse?

# Menene Hankali & Nasihu don Yin Aiki da Injin Zana Laser?

Samun Tambayoyi game da Laser Egraving Stone?

FAQ

CO2 Laser engravers (misali, Flatbed Laser Cutter 140) sun dace da mafi yawan duwatsu kamar granite, marmara, da slate, saboda tsayin tsayinsu yana vaporize saman saman sumul don cikakkun zane-zane. Fiber Laser aiki amma sun fi dacewa don yin alama fiye da zane mai zurfi, dacewa da kayan aiki masu wuya kamar yumbu. MimoWork's CO2 model tare da 100-300W ikon rike da duwatsu daban-daban, daga dutsen dutse zuwa kauri mai kauri, yana sa su zama masu dacewa ga masu sha'awar sha'awa da ƙwararru.

Zane-zanen Laser akan dutse yana da matuƙar ɗorewa, dawwama shekaru masu yawa-har ma a waje. Ƙarfin asali na dutse yana kare ƙira daga lalacewa, yayin da madaidaicin laser ke haifar da zurfi, alamomi na dindindin. Dutsen kai, alal misali, sun dogara da zane-zanen Laser don dawwamammiyar haraji, kamar yadda tsarin ke yin tsayayya da yanayin yanayi, dusashewa, ko zazzagewa. Tsaftacewa na yau da kullun (don guje wa tarkace tarkace) yana taimakawa wajen kiyaye tsabta akan lokaci.