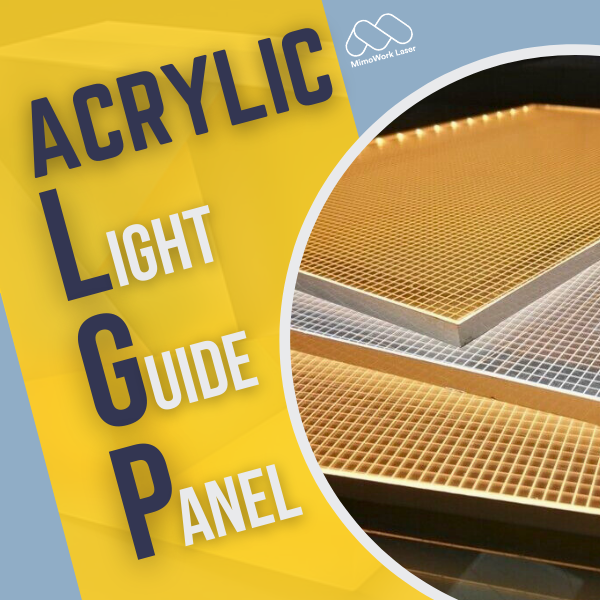

Acrylic LGP (Panel Jagoran Haske)

Acrylic LGP: M, Tsare-tsare da Dorewa

Duk da yake acrylic ne sau da yawa hade da yankan, mutane da yawa mamaki ko shi ma iya zama Laser etched.

Labari mai dadi shineiya, hakika yana yiwuwa a yi amfani da laser etch acrylic!

Teburin Abun Ciki:

1. Za a iya Laser Etch Acrylic?

Laser CO2 na iya yin vapor daidai daidai da cire siraran acrylic don barin a bayan alamomin da aka zana.

Yana aiki a cikin kewayon tsayin infrared na 10.6 μm, wanda ke ba da izinisosai sha ba tare da yawa tunani.

Tsarin etching yana aiki ta hanyar jagorantar madaidaicin katako na Laser CO2 akan farfajiyar acrylic.

Zafin zafi daga katako yana haifar da kayan acrylic a cikin yankin da aka yi niyya don rushewa da tururi.

Wannan yana kawar da ɗan ƙaramin filastik, yana barin bayan ƙira, rubutu, ko tsari.

Kwararren CO2 Laser na iya samar da sauƙietching high ƙuduria kan zanen gado na acrylic da sanduna.

2. Menene Acrylic shine mafi kyawun Laser Etching?

Ba duk zanen gadon acrylic ba ne aka ƙirƙira daidai lokacin da etched Laser. Abun da ke ciki da kauri na kayan yana shafar ingancin etching da sauri.

Anan akwai wasu abubuwan da yakamata kuyi la'akari yayin zabar mafi kyawun acrylic don etching laser:

1. Cast Acrylic Sheetssukan fi tsafta kuma sun fi juriya ga narkewa ko ƙonewa idan aka kwatanta da extruded acrylic.

2. Siraran Acrylic Sheetskamar 3-5mm ne mai kyau misali kauri kewayon. Koyaya, kauri a ƙarƙashin 2mm yana haɗarin narkewa ko ƙonewa.

3. Fitowar gani, Acrylic mara launiyana samar da mafi kyawun layi da rubutu. Guji acrylics masu launi, masu launi, ko madubi waɗanda zasu iya haifar da rashin daidaituwa.

4. High-Grade Acrylic ba tare da Additiveskamar masu kare UV ko suturar antistatic zai haifar da mafi tsabta gefuna fiye da ƙananan maki.

5. Smooth, Glossy Acrylic SurfacesAn fi so fiye da rubutun rubutu ko matte gama wanda zai iya haifar da gefuna bayan etching.

Bi waɗannan jagororin kayan za su tabbatar da ayyukan etching na Laser ɗin ku na acrylic sun fito daki-daki da ƙwararru-neman kowane lokaci.

KOYAUSHE gwada samfurin guda na farko don bugawa a cikin saitunan laser dama.

3. Haske Jagora Panel Laser Etching/Dotting

Daya na kowa aikace-aikace na Laser etching acrylic ne samar dahaske jagora bangarori, kuma ake kiradot matrix panels.

Wadannan acrylic zanen gado suna da wanitsararrun ƙananan ɗigo ko makidaidai wanda aka rubuta a cikin su don ƙirƙirar alamu, zane-zane, ko hotuna masu cikakken launi lokacinbacklit tare da LEDs.

Laser dotting acrylic haske jagororin tayidama abũbuwan amfãniakan fasahar bugu na allo na gargajiya ko fasahar bugu.

Yana bayar daƙudiri mai kaifi ƙasa zuwa girman dige 0.1mmkuma yana iya sanya dige-dige a cikin rikitattun alamu ko gradients.

Hakanan yana ba da damarcanje-canjen ƙira da sauri da kuma samar da gajeriyar aiki akan buƙata.

Don ɗigon Laser jagorar haske na acrylic, an tsara tsarin laser CO2 don yin raster a duk faɗin takaddar a cikin haɗin gwiwar XY, harbi.matsananci-gajeren bugun jini a kowane wuri "pixel" manufa.

The mayar da hankali Laser makamashiyana yin ramuka masu girman micrometer ko dimplesta hanyar am kaurina acrylic.

Ta hanyar sarrafa wutar lantarki ta Laser, tsawon lokacin bugun jini da ɗigogi, za a iya samun zurfin zurfafa ɗigo daban-daban don samar da matakai daban-daban na ƙarfin hasken da ake watsawa.

Bayan aiki, kwamitin yana shirye don mayar da haske da haskaka tsarin da aka saka.

Dot matrix acrylic yana neman haɓaka amfani a cikin sigina, hasken gine-gine, har ma da nunin na'urorin lantarki.

Tare da saurinsa da daidaito, aikin laser yana buɗe sabbin damar haɓaka don ƙirar jagorar haske da ƙirar masana'anta.

Ana amfani da Etching Laser galibi don Sa hannu, Nuni, da Sauran Aikace-aikace

Muna farin cikin fara ku nan take

4. Amfanin Laser Etching Acrylic

Akwai fa'idodi da yawa don amfani da Laser don ƙirƙira ƙira da rubutu akan acrylic idan aka kwatanta da sauran hanyoyin yin alama:

1. Daidaituwa da Kudi

Laser CO2 yana ba da damar etching cikakkun bayanai masu rikitarwa, layi, haruffa, da tambura tare da ƙuduri zuwa 0.1 mm ko ƙarami,ba za a iya cimma bata wasu matakai.

2. Tsari mara Tuntuɓi

Tun da Laser etching ne ahanyar da ba ta sadarwa ba, yana kawar da buƙatar rufe fuska, wankan sinadarai, ko matsa lamba wanda zai iya lalata sassa masu laushi.

3. Dorewa

Alamomin acrylic Laser Etched suna jure wa bayyanar muhalli kuma suna da dorewa sosai. Alamun zaibaya dushewa, karce, ko buƙatar sake aikace-aikacekamar bugu ko fenti.

4. Sassaucin Zane

Tare da laser etching, ana iya yin canje-canjen ƙira na ƙarshesauƙi ta hanyar gyara fayil ɗin dijital. Wannan yana ba da damar haɓaka ƙirar ƙira da sauri da gajerun samarwa da ake buƙata.

5. Daidaituwar kayan aiki

CO2 Laser na iya fitar da nau'ikan nau'ikan acrylic bayyanannu iri-iri da kauri. Wannanyana buɗe damar ƙirƙiraidan aka kwatanta da sauran matakai tare da ƙuntataccen abu.

6. Gudu

Tsarin Laser na zamani na iya ƙulla ƙira mai ƙima a cikin sauri har zuwa 1000 mm / s, yin alamar acrylic.inganci sosaidon samar da taro da manyan aikace-aikace.

Don Laser Etching Acrylic (Yanke & Zane)

Bayan jagororin haske da sigina, Laser etching yana ba da damar sabbin aikace-aikacen acrylic da yawa:

1. Nuni na Na'urar Lantarki

2. Abubuwan Gine-gine

3. Motoci/Tafi

4. Likita/Kiwon Lafiya

5. Hasken Ado

6. Kayayyakin Masana'antu

Laser Processing Acrylic Yana Bukatar Wasu Hankali Karɓa

Ciki har da Saitin gyare-gyare don Tabbatar da Ingantacciyar inganci, Sakamako marar Burr.

5. Mafi kyawun Ayyuka don Laser Etching Acrylic

1. Shirye-shiryen Kayan aiki

Koyaushe farawa da acrylic mai tsabta, mara ƙura.Ko da ƙananan barbashi na iya haifar da tarwatsa katako kuma su bar tarkace a cikin wuraren da aka ƙera.

2. Cire Fume

Samun iska mai kyau yana da mahimmancilokacin Laser etching. Acrylic yana samar da hayaki mai guba wanda ke buƙatar ingantaccen shayewa kai tsaye a yankin aiki.

3. Mai da hankali kan Haske

Ɗauki lokaci don daidai mayar da hankali kan katako na Laser akan saman acrylic.Ko da ƙananan ɓata lokaci yana haifar da ƙarancin ƙarancin ƙima ko rashin cikar cire kayan.

4. Gwaji Samfurin Kayayyakin

Gwada etch samfurin yanki da farkota amfani da saitunan da aka tsara don bincika sakamako kafin sarrafa manyan gudu ko ayyuka masu tsada. Yi gyare-gyare kamar yadda ake bukata.

5. Matsawa da kyau & Gyarawa

Acrylicdole ne a manne ko amintaccesaka don hana motsi ko zamewa yayin sarrafawa. Tef bai isa ba.

6. Inganta Ƙarfi & Gudu

Daidaita wutar lantarki, mita, da saitunan sauri don cire kayan acrylic cikakke ba tare dayawan narkewa, caja ko fashewa.

7. Bayan-Processing

Yashi mai sauƙi tare da babban grit takardabayan etching yana kawar da tarkace ko rashin lahani don ƙarewa mai laushi.

Riko da waɗannan mafi kyawun ayyuka na laser etching yana haifar da ƙwararru, alamun acrylic marasa burr kowane lokaci.

Ingantaccen saitin da ya dace shine mabuɗin don sakamako mai inganci.

6. FAQs akan Laser Acrylic Etching

1. Yaya tsawon lokacin da laser etching yake ɗauka?

Lokacin etching ya dogara da rikitaccen ƙira, kaurin abu, da saitunan wutar lantarki/gudu. Sauƙaƙan rubutu yawanci yana ɗaukar mintuna 1-3 yayin da hadaddun zane-zane na iya ɗaukar mintuna 15-30 don takardar 12x12”.Ana buƙatar gwajin da ya dace.

2. Za a iya Laser etch launuka a cikin acrylic?

A'a, Laser etching kawai yana cire kayan acrylic don bayyana madaidaicin filasta a ƙasa. Don ƙara launi, acrylic dole ne a fara fenti ko rina kafin sarrafa Laser.Etching ba zai canza launi ba.

3. Wani nau'i na zane zai iya zama laser etched?

Kusan kowane tsarin fayil ɗin hoto na vector ko rasterya dace don etching laser akan acrylic. Wannan ya haɗa da hadaddun tambura, zane-zane, tsarin lamba/alharu na jeri, lambobin QR, da cikakkun hotuna ko zane-zane.

4. Etching na dindindin ne?

Ee, daidai Laser etched acrylic marks samar da m engraving cewa zaibaya dushewa, karce, ko buƙatar sake aikace-aikace.Etching yana jure wa yanayin muhalli da kyau don ganowa mai dorewa.

5. Zan iya yin laser etching na kaina?

Duk da yake Laser etching na bukatar na musamman kayan aiki, wasu tebur Laser cutters da engravers yanzu araha isa ga sha'awar sha'awa da kuma kananan kasuwanci yi na asali acrylic alama ayyukan a-gida.Koyaushe bi matakan tsaro.

6. Ta yaya zan tsaftace etched acrylic?

Don tsaftacewa na yau da kullun, yi amfani da mai tsabtace gilashi mai laushi ko sabulu da ruwa.Kada ku yi amfani da magunguna masu tsauriwanda zai iya lalata filastik na tsawon lokaci. Ka guji yin zafi sosai lokacin tsaftacewa. Tufafi mai laushi yana taimakawa cire zane-zanen yatsa da smudges.

7. Menene matsakaicin girman acrylic don etching laser?

Yawancin tsarin Laser CO2 na kasuwanci na iya ɗaukar girman takardar acrylic har zuwa ƙafa 4x8, kodayake ƙananan girman tebur kuma na kowa. Madaidaicin yanki na aiki ya dogara da ƙirar laser mutum ɗaya - bincika koyausheƙayyadaddun ƙira don iyakokin girman girman.