Aluminum Laser Welding

Don walda aluminum a cikin aminci da inganci, yana da mahimmanci a bi hanyoyin da suka dace da matakan tsaro.

Wannan ya haɗa da tsaftacewa sosai a saman aluminum,

ta amfani da madaidaicin raƙuman laser da ƙarfi,

da samar da isassun iskar gas na garkuwa.

Tare da dabarun da suka dace, walƙiya Laser na hannu na aluminum na iya zama hanya mai dacewa kuma mai fa'ida ta haɗin gwiwa.

Menene walƙiya Laser Handheld?

Hannun Laser Welding Aluminum

Waldawar Laser na hannu wata sabuwar dabara ce wacce ta sami gagarumin tasiri a masana'antar karfe a cikin 'yan shekarun nan.

Sabanin hanyoyin walda na al'ada kamar MIG ko TIG,

wannan tsari yana amfani da katako mai ƙarfi na Laser don narke da haɗa abubuwan haɗin ƙarfe tare da daidaito na musamman.

Babban fa'idodin walda na Laser na hannu sun haɗa da saurin gaske, ingantaccen daidaito, da aiki mai sauƙin amfani.

A zahiri, waldawar laser na iya samun saurin gudu har sau huɗu cikin sauri fiye da walƙiyan MIG ko TIG na gargajiya,

yayin da sosai mayar da hankali Laser tabbatar m, high quality welds.

Godiya ga ci gaban fasahar Laser fiber,

waɗannan tsare-tsaren sun zama masu fa'ida kuma masu ɗorewa, suna haɓaka karɓuwarsu da yawa a fannin aikin ƙarfe.

Za a iya aluminium Laser Welded?

Aluminum Laser Welding tare da Aluminum Laser Welder

Eh, aluminum za a iya samun nasarar walda Laser, ciki har da na hannu Laser walda tsarin.

Waldawar Laser yana ba da fa'idodi da yawa don walda aluminum idan aka kwatanta da sauran hanyoyin walda.

Abũbuwan amfãni ga Laser Welding Aluminum

Ƙunƙarar Haɗaɗɗen Weld & Ƙananan Yankunan da Zafi Ya Shafi:

Wannan yana rage girman murdiya mai mahimmanci yayin da yake kiyaye daidaiton tsarin sassan aluminum.

Madaidaicin Sarrafa:

Waldawar Laser yana ba da damar keɓancewa ta atomatik, yana ba da damar daidaitaccen shirye-shiryen don yunifom, walƙiya masu inganci.

Ikon Weld Bakin Aluminum Sassan:

Waldawar Laser na iya haɗawa da aluminum kamar bakin ciki kamar 0.5 mm ba tare da ƙonewa ta cikin kayan ba.

Kalubale na Musamman na Laser Welding Aluminum

Babban Nuni

Filayen aluminium mai kyalli yana haifar da hasara mai yawa na makamashin Laser, yana haifar da ƙalubale don haɗakar katako da kayan aiki mai inganci. Hanyoyin sarrafawa na ci gaba suna da mahimmanci don haɓaka ƙarfin ƙarfin laser.

Hali ga Porosity da Zafafan Cracking

Saurin ɓarkewar zafi na Aluminum da halaye narkar da ruwa yakan haifar da lahani na walda kamar ramukan iskar gas da fashewar zafi. Madaidaicin tsari na masu canjin tsari da kariyar iskar gas yana da mahimmanci.

Laser Welding Aluminum na iya zama kalubale

Zamu iya Samar da Saitunan da suka dace a gare ku

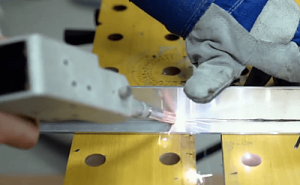

Yadda ake Laser Weld Aluminum lafiya?

Laser Welding Highly Reflective Aluminum

Aluminum Laser walda yana ba da ƙalubale da yawa na musamman waɗanda dole ne a magance su don tabbatar da aminci da nasarar walda.

Ta fuskar abin duniya,

Aluminum high thermal conductivity,

Ƙananan narkewa,

Halin samar da yadudduka na oxide

Duk iya taimaka wa matsalolin walda.

Ta yaya za a shawo kan waɗannan kalubale? (Don Aluminum Laser Weld)

Sarrafa shigar da zafi:

Aluminum high thermal conductivity yana nufin cewa zafi zai iya bazuwa cikin sauri a ko'ina cikin aikin, wanda zai haifar da narkewa mai yawa ko nakasawa.

Yi amfani da na'urar waldawa ta Laser tare da isasshen iko don kutsawa cikin kayan, amma a hankali sarrafa shigar da zafi ta hanyar daidaita sigogi kamar saurin walda da ikon Laser.

Cire Layer Oxide

Layin oxide wanda ke samuwa a saman aluminum yana da ma'anar narkewa fiye da karfen tushe, wanda zai iya haifar da porosity da sauran lahani.

Tsaftace saman da kyau kafin waldawa, ko dai ta hanyar injiniya ko sinadarai, don tabbatar da ingancin walda.

Hana Gubawar Hydrocarbon

Duk wani mai mai ko gurɓataccen abu akan saman aluminum shima na iya haifar da al'amura yayin walda.

Tabbatar da workpiece ne gaba daya tsabta da bushe kafin fara walda tsari.

La'akari na Musamman Tsaro (Don Laser Welding Aluminum)

Tsaron Laser

Ƙwararren haske na Aluminum yana nufin cewa katako na Laser zai iya billa kewaye da wurin aiki, yana ƙara haɗarin ido da bayyanar fata.

Tabbatar da ingantattun ka'idojin aminci na Laser suna cikin wurin, gami da amfani da rigar ido da kariya.

Cire Fume

Welding aluminum na iya haifar da hayaki mai haɗari, gami da waɗanda ke fitowa daga turɓayar abubuwa masu haɗawa kamar magnesium da zinc.

Ingantacciyar iskar iska da tsarin fitar da hayaki suna da mahimmanci don kare walda da kewaye.

Rigakafin Wuta

Babban shigarwar zafi da narkakkar ƙarfe da ke da alaƙa da aluminium walda na laser na iya haifar da haɗarin wuta.

Yi taka tsantsan don hana ƙonewa na kayan konawa kusa da samun kayan aikin kashe gobara da suka dace a hannu.

Laser Welding Aluminum Saituna

Laser walda Aluminum Frame na hannu

Lokacin da ya zo ga Laser walda aluminum, da hakkin saituna iya yin duk bambanci.

Gabaɗaya Saituna don Aluminum Welding Laser (Don Magana kawai)

Ƙarfin Laser

Aluminum high reflectivity yana nufin cewa mafi girma Laser ikon ne yawanci ake bukata, jere daga 1.5 kW zuwa 3 kW ko fiye, dangane da kayan kauri.

Mahimmin Bayani

Mai da hankali kan katakon laser dan kadan a ƙasa da saman aluminium (kusan 0.5 mm) na iya taimakawa haɓaka shigar azzakari cikin farji da rage tunani.

Garkuwar Gas

Argon shine mafi yawan amfani da iskar garkuwa don walda aluminum, saboda yana taimakawa hana oxidation da porosity a cikin walda.

Diamita na katako

Haɓaka diamita na katako na Laser, yawanci tsakanin 0.2 da 0.5 mm, na iya daidaita shigar ciki da shigarwar zafi don takamaiman kauri.

Gudun walda

Dole ne a daidaita saurin walda don hana duka rashin shiga ciki (da sauri da sauri) da shigar da zafi mai yawa (jinkirin da yawa).

Gudun da aka ba da shawarar yawanci suna kewayo daga inci 20 zuwa 60 a cikin minti ɗaya.

Aikace-aikace don Laser Welding Aluminum

Aluminum Laser Welding tare da Laser Welder na Hannu

walda Laser ya zama sanannen dabara don haɗa abubuwan aluminum a cikin masana'antu daban-daban saboda fa'idodinsa na musamman.

Masana'antar Motoci

Aluminum Laser welders ana amfani da su sosai a cikin masana'antar kera motoci don haɗa bangarorin aluminum, kofofin, da sauran sassan tsarin.

Wannan yana taimakawa rage nauyin abin hawa, inganta ingantaccen mai, da haɓaka ƙarfin gabaɗaya da tsaurin jikin abin hawa.

Masana'antar Aerospace

A cikin sashin sararin samaniya, ana amfani da walda na Laser don haɗa ruwan injin injin, fayafai na injin turbine, bangon gida, da kofofin da aka yi da allo na aluminum.

Madaidaicin iko da ƙaramin yankin da zafi ya shafa na waldawar Laser yana tabbatar da daidaiton tsari da dorewar waɗannan mahimman abubuwan haɗin jirgin.

Lantarki da Sadarwa

Ana amfani da waldar Laser don walda abubuwan aluminum a cikin na'urorin lantarki, kamar allunan kewayawa, firikwensin, da nuni.

Babban madaidaici da aiki da kai na walƙiya ta Laser yana ba da damar ingantaccen haɗin kai da daidaito, mai mahimmanci don aiki da kwanciyar hankali na samfuran lantarki.

Na'urorin likitanci

Ana amfani da walda ta Aluminum wajen kera na'urorin likitanci, gami da kayan aikin tiyata, allura, stent, da na'urorin hakori.

Halin bakararre da rashin lalacewa na waldawar Laser yana da mahimmanci don tabbatar da aminci da tsaftar waɗannan samfuran likitanci.

Sarrafa Mold

Ana amfani da waldi na Laser a cikin masana'antar sarrafa ƙera don gyarawa da gyara ƙirar aluminum,

Irin su stamping molds, allura gyare-gyare, da ƙirƙira gyare-gyare.

Madaidaicin ƙari na kayan abu da saurin gyare-gyaren ƙarfin walƙiya na Laser

Taimakawa tsawaita rayuwa da aikin waɗannan mahimman kayan aikin masana'antu.

Tare da ƙaƙƙarfan bayyanar na'ura da ƙananan na'ura, na'urar walda laser mai ɗaukuwa tana sanye take da bindigar walda na hannu mai motsi, wanda ba shi da nauyi kuma ya dace da aikace-aikacen walda na laser da yawa a kowane kusurwa da saman.

Ƙarfin Laser:1000-1500W

Girman Kunshin (mm):500*980*720

Hanyar sanyaya:Sanyaya Ruwa

Tasirin Kuɗi & Mai ɗaukar nauyi

Na'urar waldawa ta fiber Laser mai lamba 3000W tana da ƙarfin fitarwa mai ƙarfi, yana ba shi damar yin walƙiya mai kauri na ƙarfe a cikin sauri.

An sanye shi da babban abin sanyaya ruwa mai ƙarfi don kwantar da zafin jiki na Laser, mai ƙarfin fiber Laser walda zai iya aiki da kyau kuma yana samar da ingancin walda mai inganci akai-akai.

Babban Fitar Wutadon Saitin Masana'antu

Babban inganciDon Kauri Material

Chilling Ruwan Masana'antudon Ƙwararren Ƙwaƙwalwa