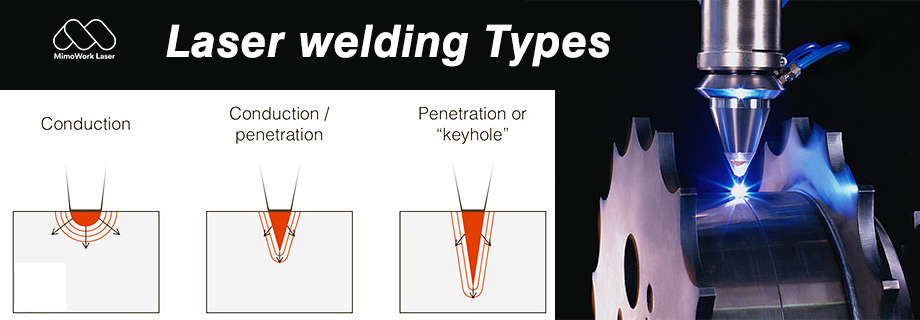

Laser walda za a iya gane ta ci gaba ko pulsed Laser janareta. Za a iya raba ka'idar waldawar Laser zuwa walƙiyar wutar lantarki da walƙiya mai zurfi na Laser. Ƙarfin wutar lantarki ƙasa da 104 ~ 105 W / cm2 shine walƙiyar wutar lantarki, a wannan lokacin, zurfin narkewa, da saurin waldawa yana jinkirin; Lokacin da yawan ƙarfin wutar lantarki ya fi 105 ~ 107 W / cm2, saman ƙarfe yana ɓoye cikin "maɓallin maɓalli" a ƙarƙashin aikin zafi, yana samar da walƙiya mai zurfi, wanda ke da halaye na saurin waldawa da sauri da kuma girman zurfin-nisa rabo.

A yau, za mu yafi rufe ilimin manyan abubuwan da ke shafar ingancin walƙiya mai zurfi na Laser

1. Ƙarfin Laser

A cikin walƙiya mai zurfi na Laser, ikon Laser yana sarrafa zurfin shigar ciki da saurin walda. Zurfin walda yana da alaƙa kai tsaye da ƙarfin ƙarfin katako kuma aiki ne na ƙarfin katakon abin da ya faru da wurin mai da hankali kan katako. Gabaɗaya magana, don takamaiman diamita na katako na Laser, zurfin shigar ciki yana ƙaruwa tare da haɓaka ƙarfin katako.

2. Focal Spot

Girman tabo na katako yana ɗaya daga cikin mafi mahimmancin masu canji a cikin waldawar laser saboda yana ƙayyade yawan ƙarfin. Amma auna shi ƙalubale ne ga Laser masu ƙarfi, kodayake akwai dabarun auna kai tsaye da yawa.

Za'a iya ƙididdige ƙimar iyakacin girman tabo na katakon katako bisa ga ka'idar diffraction, amma ainihin girman tabo ya fi kimar da aka ƙididdigewa saboda kasancewar rashin hangen nesa mara kyau. Hanyar ma'auni mafi sauƙi ita ce hanyar bayanin martabar iso-zazzabi, wanda ke auna diamita na wurin mai da hankali da raɗaɗi bayan takarda mai kauri ya ƙone kuma ya shiga cikin farantin polypropylene. Wannan hanyar ta hanyar aikin aunawa, ƙware girman ƙarfin Laser da lokacin aikin katako.

3. Gas mai kariya

Laser walda tsari sau da yawa yana amfani da m gas (helium, argon, nitrogen) don kare narkakkar pool, hana workpiece daga hadawan abu da iskar shaka a cikin walda tsari. Dalili na biyu na yin amfani da iskar gas mai karewa shine don kare ruwan tabarau mai mai da hankali daga kamuwa da tururin ƙarfe da kuma zubar da ɗigon ruwa. Musamman a cikin waldi na laser mai ƙarfi, ejecta ya zama mai ƙarfi sosai, yana da mahimmanci don kare ruwan tabarau. Tasiri na uku na iskar gas mai karewa shine cewa yana da matukar tasiri wajen tarwatsa garkuwar plasma da aka samar ta hanyar walda mai karfin gaske. Turin ƙarfe yana ɗaukar katakon Laser kuma yana yin ionizes zuwa gajimaren plasma. Gas mai kariya da ke kewaye da tururin ƙarfe shima yana yin ionizes saboda zafi. Idan plasma ya yi yawa, ana amfani da katako na laser ko ta yaya plasma. A matsayin makamashi na biyu, plasma yana wanzuwa akan farfajiyar aiki, wanda ke sa zurfin walda yayi zurfi da kuma shimfidar tafkin walƙiya mai faɗi.

Yadda za a zabi iskar kariya mai kyau?

4. Yawan sha

Ƙunƙarar Laser na kayan ya dogara da wasu mahimman kaddarorin kayan, kamar ƙimar sha, haɓakawa, haɓakar zafi, zafin jiki na narkewa, da zafin jiki na evaporation. Daga cikin dukkanin abubuwan, mafi mahimmanci shine yawan sha.

Abubuwa guda biyu suna shafar ƙimar ɗaukar kayan zuwa katako na Laser. Na farko shine juriya coefficient na kayan. An gano cewa yawan shayar da kayan ya yi daidai da tushen murabba'in ma'aunin juriya, kuma ƙarfin juriya ya bambanta da zafin jiki. Abu na biyu, yanayin yanayin (ko ƙare) na kayan yana da tasiri mai mahimmanci akan ƙimar ɗaukar katako, wanda ke da tasiri mai mahimmanci akan tasirin walda.

5. Gudun walda

Gudun waldawa yana da babban tasiri akan zurfin shiga. Ƙara gudun zai sa zurfin shigar shiga shallower, amma kuma low zai kai ga wuce kima narkewar kayan da workpiece waldi ta. Don haka, akwai kewayon saurin walda da ya dace don wani abu na musamman tare da takamaiman ikon Laser da wani kauri, kuma ana iya samun matsakaicin zurfin shigar a cikin ƙimar saurin daidai.

6. Tsawon Hankali na Lens mai da hankali

Ana shigar da ruwan tabarau na mayar da hankali a kan gunkin walda, gabaɗaya, ana zaɓi tsayin tsayin 63 ~ 254mm (diamita 2.5 "~ 10"). Girman tabo mai mai da hankali ya yi daidai da tsayin mai da hankali, guntu tsayin mai da hankali, ƙaramin tabo. Duk da haka, da tsawon mai da hankali tsawon kuma rinjayar zurfin mayar da hankali, wato, zurfin mayar da hankali yana ƙaruwa synchronously tare da mai da hankali tsawon, don haka da takaice mai da hankali tsawon zai iya inganta ikon yawa, amma saboda zurfin mayar da hankali ne kananan, da nisa tsakanin ruwan tabarau da workpiece dole ne a daidai kiyaye, da kuma zurfin shigar azzakari cikin farji ba babba. Saboda tasirin fantsama da yanayin Laser yayin waldawa, mafi guntu zurfin zurfin da ake amfani da shi a ainihin walda shine mafi yawa 126mm (diamita 5 ") Ana iya zaɓar ruwan tabarau mai tsayi mai tsayi na 254mm (diamita 10 ") lokacin da kabu yana da girma ko kuma ana buƙatar ƙara walda ta ƙara girman tabo. A wannan yanayin, ana buƙatar ƙarfin fitarwa na laser mafi girma (yawan iko) don cimma tasirin rami mai zurfi.

Ƙarin tambayoyi game da farashin injin walda na Laser na hannu

Lokacin aikawa: Satumba-27-2022