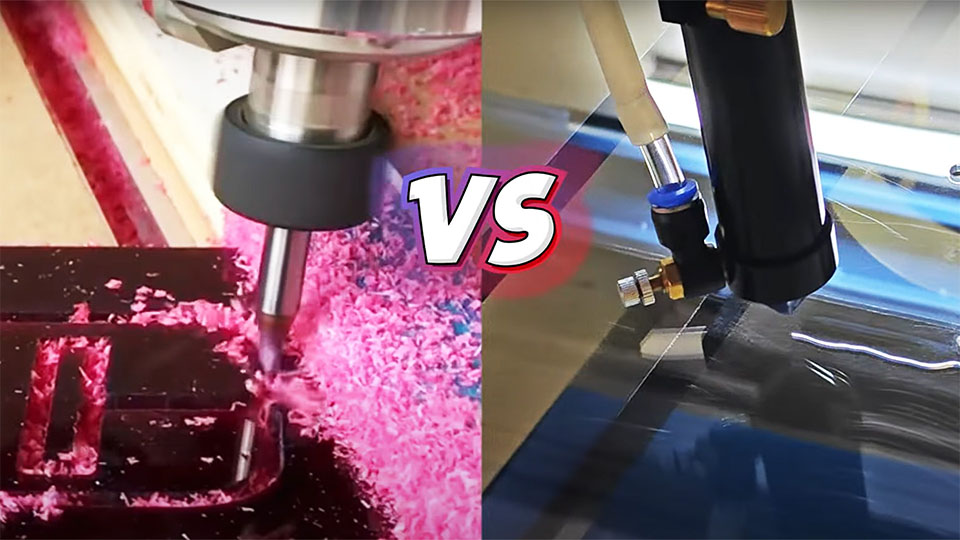

Idan ya zo ga yankan acrylic da zane-zane, ana kwatanta hanyoyin CNC da lasers sau da yawa. Wanne ya fi kyau? Gaskiyar ita ce, sun bambanta amma suna haɗa juna ta hanyar taka rawa na musamman a fagage daban-daban. Menene waɗannan bambance-bambance? Kuma ta yaya ya kamata ku zaba? Ku shiga cikin labarin kuma ku gaya mana amsar ku.

Yaya Aiki? CNC Acrylic Yankan

CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa kayan aiki ne na gargajiya da ake amfani da shi sosai. Ragowa iri-iri na iya ɗaukar yankan da zana acrylic a zurfin zurfi da madaidaici daban-daban. Masu amfani da hanyar CNC na iya yanke zanen gadon acrylic har zuwa kauri 50mm, wanda yake da kyau don haruffan talla da siginar 3D. Koyaya, CNC-yanke acrylic yana buƙatar gogewa daga baya. Kamar yadda wani masanin CNC ya ce, 'Minti daya don yanke, mintuna shida don gogewa.' Wannan yana cin lokaci. Bugu da ƙari, maye gurbin ragowa da saita sigogi daban-daban kamar RPM, IPM, da ƙimar ciyarwa yana ƙara ƙimar koyo da aiki. Mafi muni shine ƙura da tarkace a ko'ina, wanda zai iya zama haɗari idan an sha shi.

Sabanin haka, Laser yankan acrylic shine mafi tsabta kuma mafi aminci.

Yaya Aiki? Laser Yankan Acrylic

Bayan yankan mai tsabta da yanayin aiki mai aminci, masu yankan Laser suna ba da mafi girman yankewa da daidaitaccen zane tare da katako mai bakin ciki kamar 0.3mm, wanda CNC ba zai iya daidaitawa ba. Babu polishing ko bit canji da ake bukata, kuma tare da kasa tsaftacewa, Laser yankan kawai daukan 1/3 na lokacin CNC milling. Duk da haka, Laser yankan yana da kauri gazawar. Gabaɗaya, muna ba da shawarar yanke acrylic a cikin 20mm don cimma mafi kyawun inganci.

Don haka, wanene ya kamata ya zaɓi abin yanka na Laser? Kuma wa ya kamata ya zaɓi CNC?

Wanene Ya Kamata Zaba CNC Router?

• Makanikai Geek

Idan kuna da gogewa a cikin injiniyan injiniya kuma kuna iya ɗaukar ma'auni masu rikitarwa kamar RPM, ƙimar ciyarwa, sarewa, da sifofi (cue animation na na'ura mai ba da hanya tsakanin hanyoyin sadarwa na CNC kewaye da sharuddan fasaha tare da kallon 'kwakwalwa-soyayyen'), na'ura mai ba da hanya tsakanin hanyoyin sadarwa na CNC babban zaɓi ne.

• Don Yanke Kauri Material

Yana da manufa don yankan acrylic mai kauri, fiye da 20mm, yana mai da shi cikakke don haruffa 3D ko bangarorin akwatin kifaye masu kauri.

• Don Zane Mai zurfi

CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa ya yi fice a cikin ayyukan zane mai zurfi, kamar zanen tambari, godiya ga ƙarfin injinsa.

Wanene Ya Kamata Ya Zaba Laser Router?

• Don Madaidaicin Ayyuka

Manufa don ayyukan da ke buƙatar babban daidaito. Don allunan mutuwa na acrylic, sassan likitanci, dashboards na mota da na jirgin sama, da LGP, mai yankan Laser na iya cimma daidaiton 0.3mm.

• Ana Bukatar Babban Gaskiya

Don bayyanannun ayyukan acrylic kamar akwatunan hasken wuta, bangarorin nunin LED, da dashboards, lasers suna tabbatar da bayyananniyar haske da bayyananniyar gaskiya.

• Farawa

Don kasuwancin da ke mayar da hankali kan ƙananan abubuwa masu daraja kamar kayan ado, kayan fasaha, ko kofuna, mai yankan Laser yana ba da sauƙi da sassauci don gyare-gyare, ƙirƙirar cikakkun bayanai masu kyau da kyau.

Akwai biyu misali Laser sabon inji a gare ku: Small acrylic Laser engravers (don yankan da sassaka) da kuma manyan format acrylic takardar Laser sabon inji (wanda zai iya yanke kauri acrylic har zuwa 20mm).

1. Small Acrylic Laser Cutter & Engaraver

Wurin Aiki (W * L): 1300mm * 900mm (51.2" * 35.4")

• Ƙarfin Laser: 100W/150W/300W

Tushen Laser: CO2 Glass Laser Tube ko CO2 RF Metal Laser Tube

• Matsakaicin Gudun Yanke: 400mm/s

• Matsakaicin Gudun Zane: 2000mm/s

TheLaser abun yanka 130ya dace da kananan abubuwa yankan da sassaƙa, kamar keychain, kayan ado. Sauƙi don amfani kuma cikakke don ƙira mai rikitarwa.

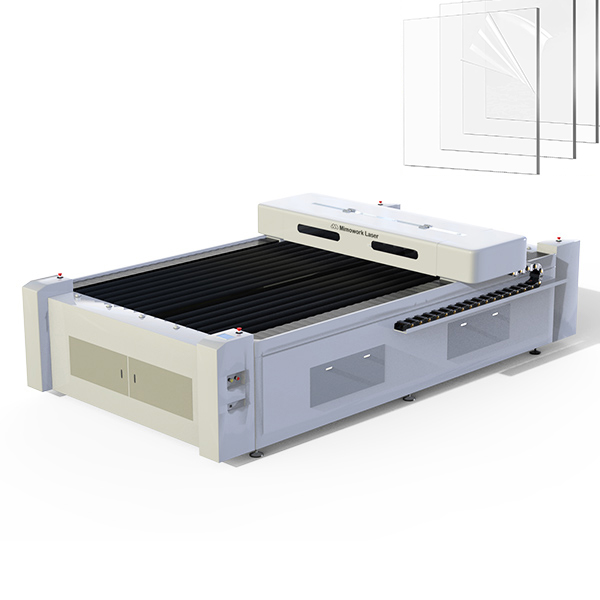

2. Babban Acrylic Sheet Laser Cutter

Wurin Aiki (W * L): 1300mm * 2500mm (51 "* 98.4")

• Ƙarfin Laser: 150W/300W/450W

Tushen Laser: CO2 Glass Laser Tube ko CO2 RF Metal Laser Tube

• Matsakaicin Gudun Yanke: 600mm/s

• Daidaiton Matsayi: ≤± 0.05mm

TheFlatbed Laser abun yanka 130Lya dace da babban tsari na acrylic takardar ko acrylic mai kauri. Yana da kyau a sarrafa alamar talla, nuni. Girman girman aiki, amma tsaftataccen yankewa.

Idan kuna da buƙatu na musamman kamar zane-zane akan abubuwa na silindi, yankan sprues, ko sassa na mota na musamman,tuntubar mudon ƙwararrun shawara na Laser. Muna nan don taimaka muku!

Bayanin Bidiyo: CNC Router VS Laser Cutter

A taƙaice, masu amfani da hanyoyin sadarwa na CNC na iya ɗaukar acrylic mai kauri, har zuwa 50mm, kuma suna ba da juzu'i tare da ragowa daban-daban amma suna buƙatar goge bayan yankewa da samar da ƙura. Masu yankan Laser suna ba da mafi tsafta, mafi madaidaicin yanke, babu buƙatar maye gurbin kayan aiki, kuma babu kayan aiki. Amma, idan kuna buƙatar yanke acrylic thicker fiye da 25mm, lasers ba zai taimaka ba.

Don haka, CNC VS. Laser, wanne ya fi kyau don samar da acrylic ku? Raba bayanan ku tare da mu!

1. Menene bambanci tsakanin CNC acrylic da Laser sabon?

Masu amfani da hanyar CNC suna amfani da kayan aikin yankan jujjuya don cire kayan jiki, wanda ya dace da acrylic mai kauri (har zuwa 50mm) amma galibi yana buƙatar gogewa. Masu yankan Laser suna amfani da katako na Laser don narke ko vaporation kayan, suna ba da daidaito mafi girma da gefuna masu tsabta ba tare da buƙatar gogewa ba, mafi kyawun acrylic na bakin ciki (har zuwa 20-25mm).

2. Shin Laser yankan mafi alhẽri daga CNC?

Laser cutters da CNC hanyoyin sadarwa sun yi fice a yankuna daban-daban. Masu yankan Laser suna ba da daidaito mafi girma da yanke tsafta, manufa don ƙira masu rikitarwa da cikakkun bayanai. CNC na'ura mai ba da hanya tsakanin hanyoyin sadarwa na iya ɗaukar kayan kauri kuma sun fi kyau don zane mai zurfi da ayyukan 3D. Zaɓinku ya dogara da takamaiman bukatunku.

3. Menene CNC ke nufi a yankan Laser?

A cikin yankan Laser, CNC na nufin "Kwamfuta Lambobin Kula da Lambobi." Yana nufin sarrafa mai sarrafa Laser mai sarrafa kansa ta hanyar amfani da kwamfuta, wanda daidai yake jagorantar motsi da aiki na katako don yanke ko sassaƙa kayan.

4. Yaya sauri CNC idan aka kwatanta da laser?

Masu amfani da hanyar CNC galibi suna yanke kayan kauri da sauri fiye da masu yankan Laser. Koyaya, masu yankan Laser suna da sauri don cikakkun bayanai da ƙira masu ƙima akan kayan sirara, saboda ba sa buƙatar canje-canjen kayan aiki kuma suna ba da yanke tsafta tare da ƙarancin aiwatarwa.

5. Me yasa diode laser ba zai iya yanke acrylic ba?

Laser diode na iya yin gwagwarmaya tare da acrylic saboda batutuwa masu tsayi, musamman tare da abubuwa masu haske ko haske waɗanda ba sa ɗaukar hasken laser da kyau. Idan kuna ƙoƙarin yanke ko sassaƙa acrylic tare da laser diode, yana da kyau a fara gwadawa kuma ku kasance cikin shiri don yuwuwar gazawar, saboda gano saitunan da suka dace na iya zama ƙalubale. Don zane-zane, kuna iya gwada fentin fenti ko yin amfani da fim zuwa saman acrylic, amma gabaɗaya, Ina ba da shawarar yin amfani da laser CO2 don sakamako mafi kyau.

Menene ƙari, laser diode na iya yanke wasu duhu, acrylic opaque. Duk da haka, ba za su iya yanke ko sassaƙa acrylic bayyananne ba saboda kayan ba ya ɗaukar katako na Laser yadda ya kamata. Musamman, Laser diode mai haske mai shuɗi ba zai iya yanke ko zana acrylic shuɗi ba saboda wannan dalili: launi mai daidaitawa yana hana ɗaukar dacewa.

6. Wanne Laser ya fi kyau don yankan acrylic?

Mafi kyawun Laser don yankan acrylic shine Laser CO2. Yana ba da tsabta, madaidaicin yanke kuma yana da ikon yanke kauri daban-daban na acrylic yadda ya kamata. CO2 Laser suna da inganci sosai kuma sun dace da duka acrylic masu tsabta da masu launi, suna sanya su zaɓin da aka fi so don ƙwararrun ƙwararrun ƙwararrun ƙwararrun acrylic da sassaka.

Zaɓi injin da ya dace don samar da acrylic ku! Duk wata tambaya, tuntube mu!

Lokacin aikawa: Yuli-27-2024