Laser Welding Machines Sigar Cikakkun Bayani

Waldawar Laser hanya ce mai inganci kuma mai inganci ta haɗa kayan, musamman karafa.

Fahimtar sigogin walda yana da mahimmanci don samun sakamako mafi kyau.

Wannan labarin ya zayyana mahimman ka'idoji da sigogi waɗanda ke tasiri tasirin waldawar laser, gami da kauri na kayan, diamita na waya, saitunan wuta, da ƙari.

Mabuɗin Ka'idodin Laser Welding

1. Kaurin Abu da Diamita na Waya:

o Lokacin walda kayan da suka fi kauri, yana da mahimmanci a yi amfani da waya mai kauri da kuma saitin wuta mafi girma.

Sabanin haka, don ƙananan kayan, mafi kyawun walda waya da ƙananan iko sun dace.

o Misali, idan kaurin kayan ya karu, diamita na waya shima ya kamata ya karu daidai gwargwado, kuma a daidaita wutar ya zama mafi girma yayin rage saurin ciyarwar waya.

Wannan yana tabbatar da cewa isassun makamashi yana shiga cikin kayan don ingantaccen walda.

2. Saitunan Wuta da Bayyanar Weld:

o Saitin wutar lantarki yana rinjayar bayyanar walda kai tsaye.

Ƙarfin ƙarfi yana ƙoƙarin samar da saman walda mai fari, yayin da mafi girman ƙarfin yana haifar da duhu, mafi launin weld ɗin.

Yayin da ƙarfin ke ƙaruwa, walda kuma na iya canzawa daga siffa mai launuka iri-iri zuwa launin baƙar fata galibi, wanda ke nuni da cewa walda tana buɗewa daga gefe ɗaya.

o Wannan sifa tana da mahimmanci don tantance ingancin walda da kuma tabbatar da ya cika ka'idojin da ake so.

3. Zaɓin Diamita na Waya:

o Zaɓin diamita mai dacewa na waya yana da mahimmanci.

Diamita na wayar walda bai kamata ya wuce kauri daga cikin kayan ba, kuma yakamata ya kasance mai son zuciya don zama mai kauri fiye da kayan tushe.

Wannan zaɓin yana tasiri sosai ga cikar ƙyallen walda.

o Waya mai kauri na iya ba da gudummawa wajen samar da walƙiya mai ƙarfi, yayin da waya mai sirara za ta iya haifar da rashin isashen haɗuwa da raunin haɗin gwiwa.

4. Diamita Waya Na Welding da Faɗin Bincike:

o Diamita na wayar walda shima yana shafar nisa na ledar katako.

Mafi kyawun waya zai buƙaci kunkuntar faɗin dubawa, wanda zai iya zama fa'ida ga ainihin aikace-aikacen walda inda ake buƙatar cikakkun bayanai.

o Wannan dangantakar tana ba da damar ingantaccen sarrafa shigarwar zafi kuma yana tabbatar da walda yana mai da hankali kan yankin da ake so, yana rage yuwuwar lalacewa ga kayan da ke kewaye.

Kuna son sanin ƙarin cikakkun bayanai

Game da Laser Welding?

Abubuwan Waje Da Suke Shafar Ma'aunin walda

Yana da mahimmanci a lura cewa abubuwa daban-daban na waje, kamar garkuwar gas da yanayin muhalli, na iya tasiri sosai kan tsarin walda.

Sabili da haka, yana da kyau a daidaita sigogin walda bisa ga yanayin lokaci na ainihi.

• Garkuwar Gas: Nau'in da yawan kwararar iskar gas ɗin garkuwa na iya shafar ingancin walda da kamanni.

Daidaitaccen ɗaukar iskar gas na iya hana iskar shaka kuma inganta haɓakar gabaɗaya.

• Yanayi na Muhalli: Abubuwa kamar zafin jiki, zafi, da kwararar iska na iya yin tasiri akan aikin na'urar walda ta Laser da kaddarorin walda.

Akwai wani Bayani Game da Laser Welder?

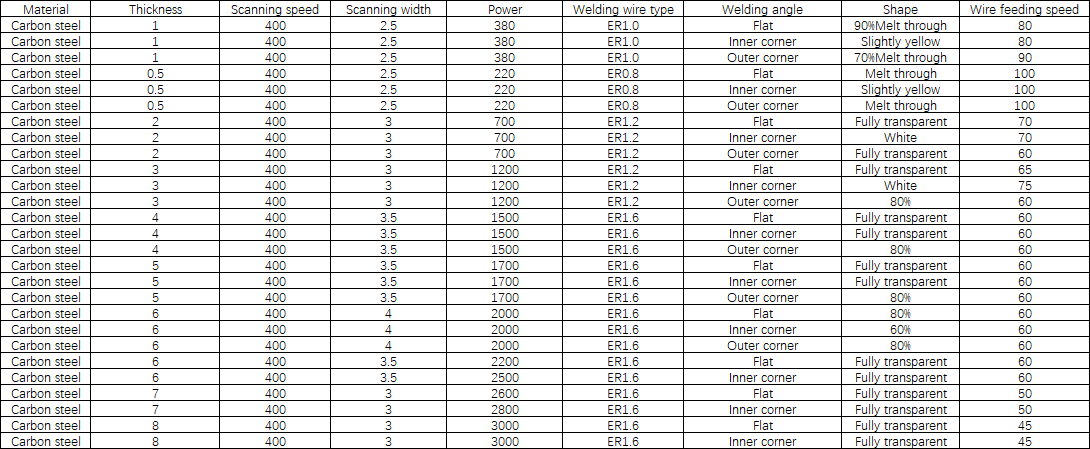

Laser Welding Carbon Karfe

Lura: Saboda tasirin zinc Layer na takardar galvanized, ana iya saukar da ikon takardar galvanized yadda ya kamata.

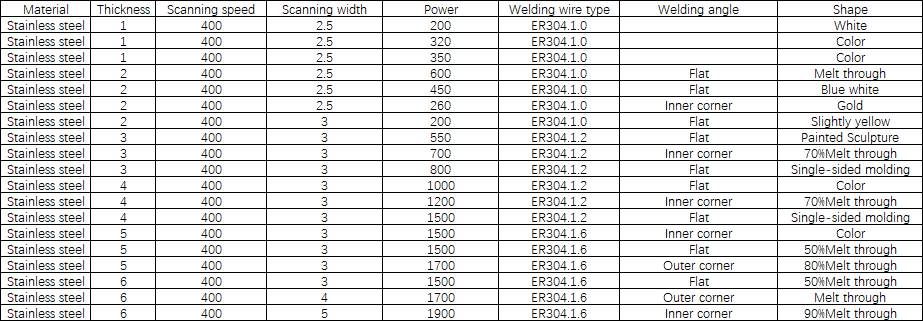

Hannun Laser Welding Bakin Karfe

Bayanan kula: 3000W bakin karfe ikon tunani carbon karfe

Baku san Yadda ake Zaɓan Injin Laser ba?

Zamu Iya Taimakawa!

Daga Shiga Bidiyo zuwa Labarun Labarai

Yadda Ake Amfani Da Hannun Laser Welder | Koyarwar Mafari

Lokacin aikawa: Janairu-06-2025