• Gudanar da inganci a cikin layin laser?

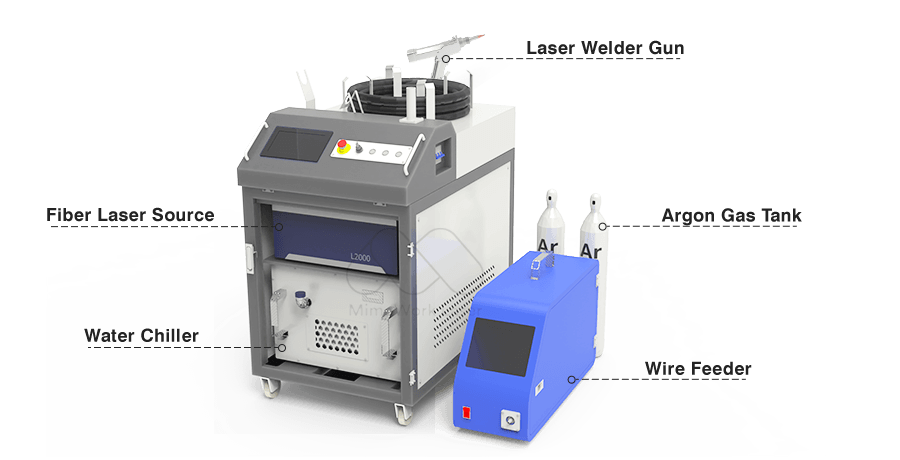

Tare da babban aiki, babban aiki, haɓaka atomatik, da kuma sauran fa'idodi, da masana'antu, gami da sojoji wajen samar da ƙarfe, likita, Aerospace, 3C Kashi na mota, ƙarfe na mota, ƙarfe na injin, sabon makamashi, tsinkayen kayan masarufi, da sauran masana'antu.

Koyaya, kowane irin walda idan ba ya rusa ka'idar ta da fasaha, zai haifar da wasu lahani ko samfurori masu lalacewa, waldive Laser ba ta daɗe ba.

• Me zan iya magance waɗancan lamuran?

Abinda kawai kyakkyawar fahimta game da waɗannan lahani, da kuma koyon yadda za a guji waɗannan lahani, don mafi kyawun wasa darajar walsing, da kuma sarrafa kyakkyawan yanayi.

Injiniya ta hanyar tattara ƙwarewa na dogon lokaci, ta taƙaice wasu lahani na yau da kullun na mafita, don maganganun masana'antu!

Menene lahani biyar na yau da kullun?

Fara >> Fashewa

Fara >> Pores a Weld

>> Spash

>> Tsanantawa

>> Azuan tafkin teku

Idan kana son ƙarin sani game da siyarwar lasadan lasereld, zaku iya duba shafinmu don ƙarin bayanita hanyar mahaɗin ƙasa ƙasa!

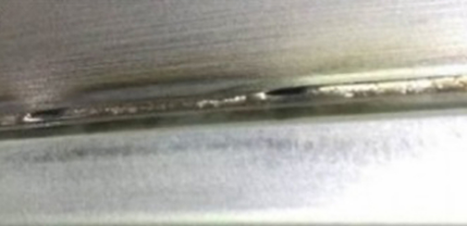

Furrura lokacin da layin laser

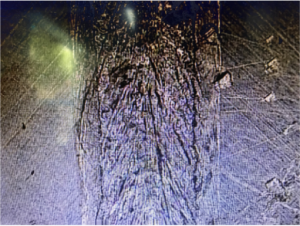

Biran da aka samar a cikin Laser ci gaba waldiges galibi wasu fasa ne, kamar fasa crystallization, circuied fasa, da sauransu.

Babban dalilin shi ne cewa Weld yana samar da babban karfi mai tsoka kafin cikakken tabbatar da ta'addanci.

Yin amfani da mai ciyar da waya don cika wires ko preheataying ƙarfe na ƙarfe na iya raguwa ko kawar da fasahar da aka nuna a lokacin waldient walda.

Fasa a cikin Laser Welding

◼ pores a Weld

Pores a Weld

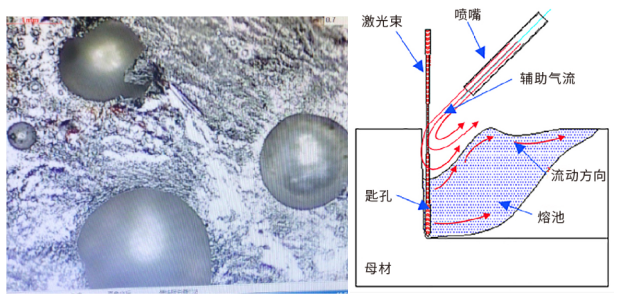

Yawancin lokaci, gidan yanar gizo na Laser yana da zurfi da kunkuntar, kuma kunshe shi koyaushe yana kyautata zafi sosai kuma super-sauri. Gas da aka samar a cikin ruwan tafkin Molten ba su da isasshen lokacin tserewa kafin ƙarfe masu wealing yana sanyaya ƙasa. Irin wannan yanayin yana da sauƙin haifar da samuwar pores.

Amma kuma saboda yankin da ake nuna yanayin Laser yayi karami, ƙarfe na iya sanyaya cikin sauri sosai, kuma sakamakon pacoot nuna a cikin walsing waldion na gargajiya.

Tsaftacewa farfajiya na kayan aiki kafin waldi zai iya rage halayen pores, kuma shugabanci na busa zai kuma tasiri samuwar pores.

◼ spash

Yã kãtã gudãna daga lold

Daukuwar Laser da Laser da gaske ke shafar ingancin walwala kuma zai iya gurbata da kuma lalata ruwan tabarau.

Spatter yana da alaƙa kai tsaye ga ƙarancin iko kuma ana iya rage shi ta hanyar rage ƙarfin waldi.

Idan shigar azanci ba shi da isasshen, ana iya rage saurin walding.

Da spanes a cikin waldi

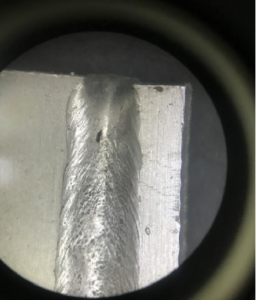

Idan saurin walding yayi jinkirin, zina yana da girma da fadi, da tashin hankali na moltse yana da wuya a kula da ƙarfe ruwa mai nauyi, cibiyar Weldpse zata nutsar da ƙarfe mai nauyi, cibiyar Weldpse zata nutsar da ƙarfe mai nauyi, Cibiyar Weld ta rushe da rami.

A wannan lokacin, wajibi ne don rage yawan ƙarfin makamashi yadda yakamata don kauce wa rushewar tafkin.

Rushewar tafkin

◼ ◼cut a cikin Laser Welding

Idan kun weld da kayan aikin ƙarfe yayi sauri, ƙarfe na ruwa a bayan rami ya nuna tsakiyar Weld ba shi da lokaci don rarraba.

Yarda da bangarorin biyu na Weld zai samar da cizo. Lokacin da rata tsakanin aiki biyu ya yi yawa sosai, za a sami isasshen ƙwayar ƙwayar ƙwayar ƙwayar ƙasa don cabbing, wanda yanayin walda zai ci gaba.

A ƙarshen mataki na Laser Welding, idan makamashi ya sauka da sauri, rami yana da sauƙin rushewa kuma ya haifar da lahani mai walwala. Mafi kyawun ƙarfin ma'auni da sauri don saitunan layin laser na iya magance ƙarni na cizo.

LATSA A CIKIN SAUKI

Hannun lasereld Laser ɗinku don ku zaɓi

Kuna son ƙarin sani game da waldi na Laser?

Duk wani rikice-rikice da tambayoyi don na'urar layin lashelding na layin?

Lokaci: Jan-30-2023