Menene tsabtatawa na laser

Ta hanyar fallasa Laser da mai da hankali zuwa saman gurbataccen aikin da aka gurbata, Laser Tsabtace na iya cire datti nan da nan ba tare da lalata tsarin substrate ba. Zabi ne ga sabon tsararraki na fasahar tsabtace masana'antu.

Fasaha ta Laser kuma ta zama fasahar tsaftataccen yanayin tsabtace na zamani a masana'antar, jigilar jigilar kaya, wanda aka cire siliki na taya, wanda ya cire silicon ƙwararrun mai a farfajiya na zinariya Fim, da babban tsarin tsabtace masana'antar microecronics.

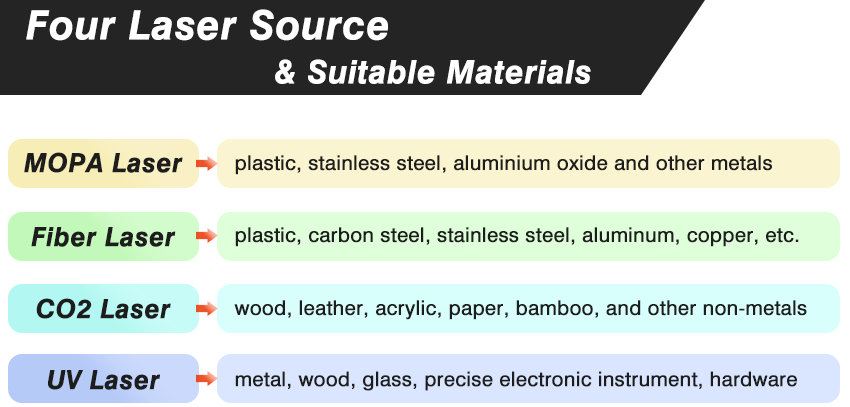

Don fasahar Laser kamar ƙwararren Laser, Laser zanen, Laser Tsabtarwa, Walding Laser, zaku iya sanin waɗannan amma tushen Laser mai alaƙa. Akwai wani tsari don bayanin ku wanda yake game da kayan Laser hudu da dacewa da kayan da ya dace da aikace-aikace.

Hudu masoya tushen game da Laser tsabtatawa

Saboda bambance-bambance a cikin mahimman sigogi kamar su raƙuman ruwa mai ban sha'awa, abubuwan ban sha'awa na Laser na tsabtace Laser a bisa ga takamaiman abubuwan cirewa.

▶ Mopa Pulse Laser Tsaftacewa

(Aiki akan kowane irin abu)

Mopa Laser shine irin nau'in tsabtace layin laser. Mo ya tsaya ga Jagora Oscilloror. Tun da tsarin mopa na fiber Laser a cikin tsananin daidai da asalin iri tare da tsarin, abubuwan da suka dace na lasernorth, bugun jini ba za a canza shi ba. Saboda haka, girman daidaitawa ya fi girma kuma kewayon ya fi girma. Don yanayin aikace-aikace daban-daban na kayan daban-daban, daidaitawa yana da ƙarfi da tsarin taga taga ya fi girma, wanda zai iya haɗuwa da tsaftacewa daban-daban kayan.

▶ Kwamitan Karatun Fiber Laser

(mafi kyawun zabi don cire fenti)

Tsaftataccen Laser yana amfani da Laseronductor ci gaba ɗaya don samar da fitarwa na ciki, da kuma mulkokin faduwa da ya haifar da sha da gurbataccen ƙarfe. Lokacin da Laser ya haifar Laser mai ƙarfi Laser, girgije girgije zai kwaso haɗe-haɗe tare da rauni mai ƙarfi Laser.

Tsabtace Laser Halitta ya haɗu da Laser kuma ja layi na Laser a lokaci guda. Babban saurin, babban aiki, da kuma ƙarin tsabtatawa daban-daban, na iya amfani da igiyar ruwa daban-daban na tsabtatawa na Laser a lokaci guda don cimma manufar cire stain.

Misali, a cikin mai tsabtace laser na lokacin farin ciki kayan aiki, fitarwa na Laser Multi mai ƙarfin lantarki yana da girma kuma farashin yana da girma. Lasali na tsabtace Laser da Semiconductors Laseral na iya hanzarta inganta ingancin tsabtace, kuma baya haifar da lalacewar substrate. A cikin mai tsabtace kayan kwalliya na kayan kwalliya kamar su aluminum ado, ƙasin guda ɗaya yana da wasu matsaloli kamar su babban aiki. Yin amfani da bugun jini Laser da Semiconductor Laser-tsafta Lasicaukar Tsabtace Lasiconductor Reportics, ƙara yawan ƙwaƙwalwar ƙwaƙwalwar ƙwayar cuta na iya kwasfa iriska da sauri, inganta ingancin cirewa Toofi sosai, musamman ingancin cirewar fenti yana ƙaruwa sama da sau 2.

▶ Laser Laser

(mafi kyawun zaɓi don tsabtace kayan ƙarfe marasa ƙarfe)

Laser dioxide Laser Laser ne mai gas tare da kayan co2 kamar kayan aiki, heliumi da nitrogen har ma da karamin adadin hydrogen ko xenon). Dangane da yanayinta na musamman, Co2 Laser shine mafi kyawun zaɓi don tsabtace saman kayan ƙarfe kamar conating manne, shafi da tawada. Misali, yin amfani da CO2 Laser don cire compite fenti fenti a kan aluminum alloy ba ya lalata farjin fim ɗin uwan.

▶ Laser Laser tsabtatawa

(mafi kyawun zabi don na'urar lantarki ta zamani)

Lasers lasters da aka yi amfani da shi a Laser Micromachining galibi sun hada da Lacers extrimer da duk masu karfi-jihar Laya. Ulontravolet Lacleth ne, kowane hoto guda ɗaya na iya isar da ƙarfin kuzari, zai iya karya shaidun sunadarai kai tsaye tsakanin kayan. Ta wannan hanyar, kayan da aka rufe suna da tushe a farfajiya a cikin hanyar gas ko barbashi, da kuma tsarin tsabtatawa, da kuma tsarin tsabtatawa, da kuma tsarin tsabtatawa yana samar da karamin yanki akan aikin aiki. A sakamakon haka, tsabtace UV Laser yana da fa'idodi na musamman a cikin masana'antu, kamar tsabtatawa stremiconals, ma'adanan lu'ulu'u, da polycarbonate (PC) da sauran kayan polymer, na iya yin amfani da shi haɓaka ingancin masana'antu.

UV Laser anyi la'akari da shi shine mafi kyawun tsarin aiwatar da laser a fagen lantarki, mafi yawan halayyarsa mai sarrafa "sanyi" ba ya canza kayan aikin sarrafa abu a lokaci guda, farfajiya na micro inji da sarrafawa, iya A yi amfani da shi sosai a cikin sadarwa, Optics, sojoji, bincike, likita da sauran masana'antu da filayen. Misali, ERA 5g ta kirkiro wata kasuwa don sarrafa FPC. Aikace-aikacen UV Laser Mashin injin ya ba zai yiwu a iya yin daidai da injin din na FPC da sauran kayan.

Lokaci: Oct-10-2022