Mene ne walding na laser? Laser Welding bayyana! Abin da kawai za a sani game da walsing waldi, gami da maɓallin ƙa'idar mahimmin da sigogin tsari!

Yawancin abokan ciniki ba su fahimci ka'idodin aiki na Laser Welding na Laser ba, duk da haka Mimowrk Laser na dama yana nan don taimaka muku wajen yin tallafi na laser don taimaka muku wajen fahimtar da hankali Laser.

Mene ne walding na laser?

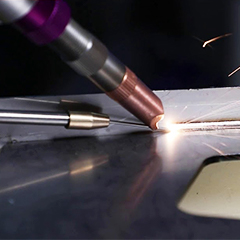

Laser Welding wani nau'in walding ne na narkewar walding, wanda ake amfani da shi a wani takamaiman hanyar da ke motsa jiki, lokacin da katako Kuma aikin aiki ya sadu da juna, kuzari yana tunawa da kayan aikin, lokacin da zazzabi ya kai ga narkewar kayan da za a iya welded.

Dangane da babban aikin Pool, Welding Laser yana da ka'idodi guda biyu na walda: walwala mai zafi da shigar azzakari ciki. Zafin da aka kirkira ta hanyar zafi wanda aka ba da izini ga yanki na aiki ta hanyar canja wurin zafi, wanda sau da yawa ya narke, wanda ake yawan amfani da shi a cikin walda na bakin ciki-Ishun. Deep fushin walda vaporikes kayan kuma siffofin da yawa na plasma. Saboda tsananin zafi, za a sami ramuka a gaban tafkin tafkin. Deep shigar da farkawa shine mafi yawan amfani Laseright Welding Laser, zai iya web da makamashi sosai, yana haifar da saurin shigar da sauri.

Aiwatar da sigogi a cikin Laser Welding

Akwai wasu sigogi da yawa da ke shafar ingancin walƙiyar laser, kamar ƙimar wutar lantarki, ƙididdigar bugun wuta da zaɓin iskar gas.

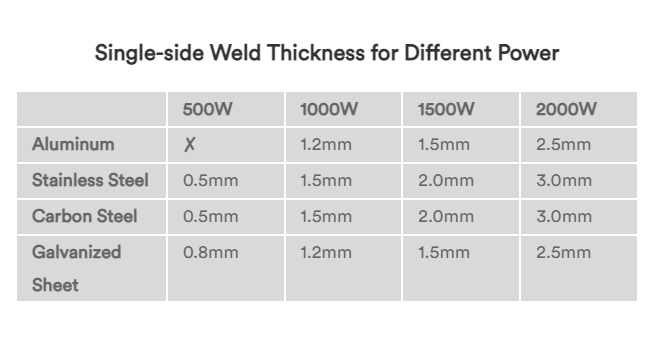

Laserarfin Laser

Yawan wutar lantarki yana ɗaya daga cikin mahimman sigogi cikin aiki mai lasis. Tare da girman iko na iko, farfajiyar farfajiya za a iya mai zafi zuwa tafasa a cikin microsecond, wanda ya haifar da adadin vaporization. Sabili da haka, ƙimar babban iko yana da fa'ida ga ayyukan cire kayan da ake cirewa kamar hakowa, yankan da kuma zanen. Don yawan wutar lantarki, yana ɗaukar millisiyoyin da yawa don zafin jiki don isa ga tafasasshen maya, wanda yake da sauki a samar da walwala mai kyau. Sabili da haka, a cikin nau'i na zafi laserent waldi, ƙimar ƙarfi na iko shine 104-106W / cm2.

Laser bugun fansho

Kamfanin Laser bugun fan Shaida ne don bambance cire abu daga kayan abu, amma kuma mabuɗin mabuɗi don ƙayyade ƙarar kayan aiki. Lokacin da aka harbe nauyin da aka harbe zuwa saman kayan, farfajiya na kayan zai sami 60 ~ 90% na Lissafin Laserum, Aluminum, Titanium da sauran kayan da suke da mai karfi da canja wuri mai zafi. Tunani na karfe ya bambanta da lokaci yayin murhun Laser. A lokacin da sararin samaniya ya hau zuwa m munthy, rashawa yana raguwa cikin hanzari, kuma lokacin da farfajiya yake cikin melting jihar, tunani ya karu a wani darajar.

Nisa

Fide Falada shine muhimmin sigogi na jan layin Laser. Yankin bugun jini ya ƙaddara ta zurfin shigar azzakari cikin sauri da kuma zafi ya shafa. Ya ninka faɗuwar bugun jini shine, yankin da ya shafa mai zafi ya kasance, kuma zurfin shigar kundji ya ƙaru tare da ƙarfin 1/2 na faɗuwar faɗin. Koyaya, karuwar bugun bugun jini zai rage ƙarfin ƙamshi, don haka ana amfani da karuwar faɗar welding na zafi, wanda ya dace da walda na bakin ciki da kauri. Koyaya, ƙananan ƙarancin ƙarfin ƙarfin ƙwayar ƙwayar cuta, kuma kowane abu yana da kyakkyawan ƙa'idar bugun jini wanda ke ƙara zurfin shigar azzakari cikin farji.

Defocus

Welding Laser yawanci yana buƙatar wani adadin na nuna rashin ƙarfi, saboda yawan ikon cibiyar a cikin lase yana da girma, wanda yake mai sauƙin shafe kayan wales cikin ramuka. Rarraba ikon ikon iko yana da uniform a kowane jirgin sama daga laser.

Akwai hanyoyi biyu na defrocus:

Tabbatacce da mara kyau. Idan jirgin sama mai kyau yana sama da kayan aikin, yana da tabbatacce mai kyau; In ba haka ba, rashin adalci ne mara kyau. A cewar ka'idar Geometric na Geometric, lokacin da nisan da ke tsakaninta da kuma jirgin sama mai kyau daidai yake, amma a zahiri, pool siffar pool sigari ya bambanta. Game da batun rashin damuwa mai ban tsoro, za'a iya samun saurin shiga ciki, wanda ke da alaƙa da tsarin kirkirar hanyar tafkin tafkin.

Welding Speed

Welding Speedin yana tantance walding mai inganci, zurfin shigar shiga ciki, yankin da ya shafi zafi da sauransu. Saurin walda zai shafi shigarwar zafin a lokaci. Idan saurin walding ya yi jinkiri sosai, shigarwar zafi ya yi yawa, wanda ya haifar da ƙona aikin. Idan saurin walding ya yi sauri, shigarwar zafin ya yi kadan kadan, yana haifar da aikin kayan aiki da ba a kare shi ba wanda bai ƙare ba. Rage saurin walding yawanci ana amfani dashi don inganta shigar azzakari cikin shigar azzakari cikin shigar.

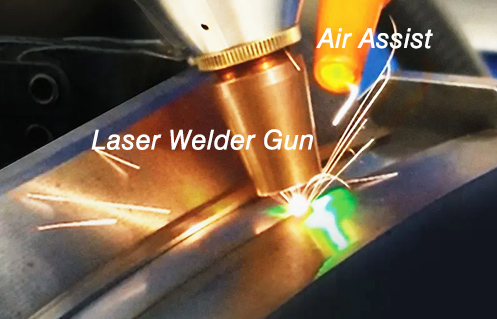

Isasshen gas mai kariya

Isar da gas mai kariya ta hanyar taimako muhimmiyar hanya ce a cikin Weld Laser Welding. A gefe guda, don hana kayan ƙarfe daga lalacewa da gurbataccen madubi; A gefe guda, shi ne hana plasma da aka samar da shi a cikin walding tsari daga mai da hankali sosai kuma hana Laser ya isa saman kayan. A kan aiwatar da walsing, helium, Argon, nitrogen da sauran gas na gas da ake amfani dasu don kare wurin yin shaye-shaye, don hana aikin hadada daga injina mai walwala. Abubuwan da ke da irin nau'in gas na kariya, girman iska mai gudana da kuma hurarrakin kusurwa suna da babban tasiri ga walda, da hanyoyin daban-daban kuma zasu sami wani tasiri ga ingancin waldi.

An yaba mana da shawarar Laser Welder:

Laser Welder - Matsakaicin Matsayi

Of kewayuwar yanayin aiki: 15 ~ 35 ℃

Yanayin zafi na aikin aiki: <70% Babu Condensation

Cooling: ruwan sha yana da mahimmanci saboda aikin zafi yana cire don amfani da kayan aikin laser-diseld da kyau.

(Cikakken amfani da jagora game da chiller na ruwa, zaka iya bincika:Dogewar matakan ingantawa don tsarin Laser)

Wanna wanna masoya game da allolin Laser?

Lokacin Post: Rage-22-2022