Ee, za ku iya cikakken Laser yanke fiberglass ta amfani da ƙwararren CO2 Laser sabon na'ura!

Duk da yake fiberglass yana da tauri kuma mai ɗorewa, Laser yana ɗaukar naushi tare da ƙarfinsa mai ƙarfi, yana yanke kayan cikin wahala.

Sirarriyar katako mai ƙarfi amma tana yin zips ta hanyar zanen fiberglass, zanen gado, ko bangarori, yana barin ku da tsaftataccen yankewa kowane lokaci.

Laser yankan fiberglass ba kawai inganci ba ne amma kuma hanya ce mai ban sha'awa don kawo ƙirar ƙirar ku da hadaddun sifofi zuwa rayuwa tare da wannan kayan masarufi. Za ku yi mamakin abin da za ku iya ƙirƙira!

Faɗa game da Fiberglas

Fiberglass, sau da yawa ana kiranta filastik-ƙarfafa gilashi (GRP), wani abu ne mai ban sha'awa wanda aka yi da filaye masu kyau na gilashi waɗanda aka saka a cikin matrix resin.

Wannan haɗe-haɗe na wayo yana ba ku kayan da ba nauyi ba ne kawai amma har ma da ƙarfi da yawa.

Za ku sami fiberglass a cikin kowane nau'in masana'antu - ana amfani da shi don komai daga kayan aikin tsari da rufi zuwa kayan kariya a fagage kamar sararin samaniya, mota, gini, da ruwa.

Lokacin da ya zo ga yanke da sarrafa fiberglass, yin amfani da kayan aiki masu dacewa da kiyaye kariya shine mabuɗin don samun aikin cikin aminci da daidai.

Yanke Laser da gaske yana haskakawa a nan, yana ba ku damar cimma waɗancan tsaftataccen yanke, yankewa waɗanda ke yin kowane bambanci!

Laser Yankan Fiberglas

Laser yankan fiberglass duk game da yin amfani da katako mai ƙarfi na Laser don narke, ƙonewa, ko vaporation kayan tare da takamaiman hanya.

Abin da ya sa wannan tsari ya kasance daidai shi ne software na taimakon kwamfuta (CAD) wanda ke sarrafa na'urar laser, yana tabbatar da kowane yanke daidai da daidaito.

Ɗaya daga cikin mafi kyawun abubuwa game da yankan Laser shine cewa yana aiki ba tare da wani hulɗar jiki tare da kayan ba, wanda ke nufin za ku iya cimma waɗancan ƙira, ƙira dalla-dalla ba tare da wahala ba.

Tare da saurin yankan saurin sa da ingancin inganci, ba abin mamaki ba ne cewa yankan Laser ya zama hanyar tafi-da-gidanka don yin aiki tare da zanen fiberglass, mats, da kayan rufi!

Bidiyo: Laser Yanke Fiberglas Mai Rufe Silikon

Fiberglass mai rufin siliki babban shingen kariya ne daga tartsatsin wuta, spatter, da zafi, yana mai da shi kima a cikin masana'antu daban-daban.

Duk da yake yankan shi da wuka ko jaws na iya zama da wahala sosai, yankan Laser yana sa tsarin ba kawai zai yiwu ba har ma da sauƙi, yana ba da ingantaccen inganci tare da kowane yanke!

Ba kamar na gargajiya yankan kayan aikin kamar jigsaws ko Dremels, Laser yankan inji amfani da wadanda ba lamba hanyar magance fiberglass.

Wannan yana nufin babu kayan aiki da lalacewa ga kayan - yin yankan Laser kyakkyawan zaɓi!

Amma wane nau'in Laser ya kamata ku yi amfani da shi: Fiber ko CO₂?

Zaɓin madaidaicin laser shine mabuɗin don samun sakamako mafi kyau lokacin yanke fiberglass.

Yayin da ake ba da shawarar laser CO₂ sau da yawa, bari mu bincika duka CO₂ da Laser fiber don ganin fa'idodinsu da gazawarsu don wannan aikin.

CO2 Laser Yankan Fiberglass

Tsawon tsayi:

CO₂ Laser yawanci suna aiki a tsawon mita 10.6, wanda ke da tasiri sosai don yanke kayan da ba na ƙarfe ba, gami da fiberglass.

Tasiri:

Tsawon tsayin laser CO₂ yana da kyau ta hanyar kayan fiberglass, yana ba da damar yankan inganci.

CO₂ Laser yana ba da tsabta, daidaitaccen yanke kuma yana iya ɗaukar kauri daban-daban na fiberglass.

Amfani:

1. Babban madaidaici da gefuna masu tsabta.

2. Dace da yankan kauri zanen gado na fiberglass.

3. An kafa da kyau kuma ana amfani da shi sosai a aikace-aikacen masana'antu.

Iyakoki:

1. Yana buƙatar ƙarin kulawa idan aka kwatanta da lasers fiber.

2. Gabaɗaya ya fi girma kuma mafi tsada.

Fiber Laser Yankan Fiberglass

Tsawon tsayi:

Fiber Laser yana aiki a tsawon kusan 1.06 micrometers, wanda ya fi dacewa da yanke karafa kuma ba shi da tasiri ga waɗanda ba ƙarfe ba kamar fiberglass.

Yiwuwa:

Duk da yake fiber Laser na iya yanke wasu nau'ikan fiberglass, gabaɗaya ba su da tasiri fiye da laser CO₂.

Ƙunƙarar igiyar fiber Laser ta fiberglass yana da ƙasa, yana haifar da ƙarancin yankewa.

Tasirin Yanke:

Fiber Laser bazai samar da tsaftataccen yankewa akan fiberglass kamar CO₂ lasers.

Gefuna na iya zama mafi muni, kuma za a iya samun batutuwa tare da yankewar da ba ta cika ba, musamman tare da kayan kauri.

Amfani:

1. Babban ƙarfin ƙarfi da saurin yanke don karafa.

2. Ƙananan kulawa da farashin aiki.

3.Compact da inganci.

Iyakoki:

1. Rashin tasiri ga kayan da ba na ƙarfe ba kamar fiberglass.

2. Ba za a iya cimma burin yankan da ake so don aikace-aikacen fiberglass ba.

Yadda za a zabi Laser don Yanke Fiberglass?

Duk da yake fiber Laser ne sosai tasiri ga yankan karafa da kuma bayar da dama abũbuwan amfãni

Gabaɗaya ba su ne mafi kyawun zaɓi don yankan fiberglass ba saboda tsayinsu da halayen ɗaukar kayan.

CO₂ Laser, tare da tsayin tsayinsu, sun fi dacewa da yankan fiberglass, suna ba da mafi tsabta kuma mafi daidaitaccen yanke.

Idan kuna neman yanke fiberglass da kyau kuma tare da inganci mai kyau, CO₂ Laser shine zaɓin shawarar.

Za ku samu daga CO2 Laser Cutting Fiberglass:

✦Mafi Kyau:Tsawon tsayin laser CO₂ yana da kyau a sha ta fiberglass, yana haifar da mafi inganci kuma mafi tsafta.

✦ Dacewar Abu:CO₂ Laser an tsara su musamman don yanke kayan da ba na ƙarfe ba, wanda ya sa su dace da fiberglass.

✦ Yawanci: CO₂ Laser na iya ɗaukar nau'ikan kauri da nau'ikan fiberglass, suna ba da ƙarin sassauci a masana'antu da aikace-aikacen masana'antu. Kamar fiberglassrufi, ruwan teku.

| Wurin Aiki (W *L) | 1300mm * 900mm (51.2"* 35.4") |

| Software | Software na kan layi |

| Ƙarfin Laser | 100W/150W/300W |

| Tushen Laser | CO2 Gilashin Laser Tube ko CO2 RF Metal Laser Tube |

| Tsarin Kula da Injini | Sarrafa Belt Mataki na Mota |

| Teburin Aiki | Teburin Aiki na Ruwan Zuma ko Teburin Wuka Mai Aiki |

| Max Gudun | 1 ~ 400mm/s |

| Gudun Haɗawa | 1000 ~ 4000mm/s2 |

Zabuka: Haɓaka Laser Cut Fiberglass

Mayar da hankali ta atomatik

Kuna iya buƙatar saita takamaiman nisa mai da hankali a cikin software lokacin da kayan yankan ba su da faɗi ko tare da kauri daban-daban. Sa'an nan Laser shugaban zai ta atomatik hawa sama da ƙasa, ajiye mafi kyau duka mayar da hankali nisa zuwa abu surface.

Servo Motor

servomotor shine rufaffiyar madauki servomechanism wanda ke amfani da martanin matsayi don sarrafa motsinsa da matsayi na ƙarshe.

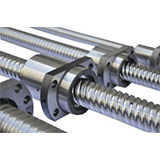

Kwallon Kaya

Ya bambanta da screws na gubar na al'ada, screws ƙwallo suna da yawa sosai, saboda buƙatar samun hanyar sake zagaya kwallaye. Ƙaƙwalwar ƙwallon ƙwallon yana tabbatar da babban sauri da kuma yankan Laser madaidaici.

| Wurin Aiki (W * L) | 1600mm * 1000mm (62.9"* 39.3") |

| Software | Software na kan layi |

| Ƙarfin Laser | 100W/150W/300W |

| Tushen Laser | CO2 Gilashin Laser Tube ko CO2 RF Metal Laser Tube |

| Tsarin Kula da Injini | Canja wurin bel & Matakin Mota |

| Teburin Aiki | Teburin Aiki na Ruwan Zuma / Teburin Wuƙa Mai Aiki / Teburin Mai ɗaukar Aiki |

| Max Gudun | 1 ~ 400mm/s |

| Gudun Haɗawa | 1000 ~ 4000mm/s2 |

Zabuka: Haɓaka Laser Yankan Fiberglass

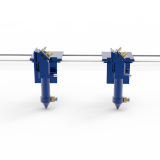

Dual Laser Heads

A cikin mafi sauƙi kuma mafi tattalin arziki hanya don hanzarta samar da yadda ya dace shi ne don hawa mahara Laser shugabannin a kan gantry iri daya da kuma yanke wannan tsari lokaci guda. Wannan baya ɗaukar ƙarin sarari ko aiki.

A lokacin da kake ƙoƙarin yanke dukan yawa daban-daban kayayyaki da kuma son ajiye abu zuwa mafi girma mataki, daNesting Softwarezai zama kyakkyawan zabi a gare ku.

TheFeeder ta atomatikhaɗe tare da Teburin Canjawa shine mafita mai kyau don jerin da samar da taro. Yana jigilar abubuwa masu sassauƙa (fabric mafi yawan lokaci) daga mirgina zuwa tsarin yankewa akan tsarin laser.

Yaya Kaurin Fiberglass Za a iya Yanke Laser?

Gabaɗaya, CO₂ Laser na iya yanke ta cikin fale-falen fiberglass masu kauri har zuwa 25mm zuwa 30mm.

Tare da kewayon ikon Laser daga 60W zuwa 600W, mafi girma wattage yana nufin mafi girman ikon yanke don kayan kauri.

Amma ba wai kawai game da kauri ba; nau'in fiberglass abu kuma yana taka muhimmiyar rawa. Daban-daban abun da ke ciki, halaye, da kuma gram nauyi iya muhimmanci rinjayar Laser sabon yi da inganci.

Wannan shine dalilin da ya sa yana da mahimmanci don gwada kayan ku tare da na'ura mai sana'a na Laser. Kwararrun laser ɗinmu za su bincika takamaiman fasalulluka na fiberglass ɗin ku kuma su taimaka muku nemo ingantacciyar injin injin da mafi kyawun sigogin yanke!

Za a iya Laser Yanke G10 Fiberglass?

G10 fiberglass wani laminate ne mai ƙarfi mai ƙarfi wanda aka yi ta hanyar tara yadudduka na gilashin gilashin da aka jiƙa a cikin resin epoxy da matsa su a ƙarƙashin matsanancin matsin lamba. Sakamakon abu ne mai yawa, ƙaƙƙarfan abu da aka sani don kyawawan kayan aikin injiniya da na lantarki.

Idan ya zo ga yanke G10 fiberglass, CO₂ Laser shine mafi kyawun fare ku, yana ba da tsabta, daidaitaccen yanke kowane lokaci.

Godiya ga halayensa masu ban sha'awa, G10 fiberglass ya zama cikakke don aikace-aikace iri-iri, kama daga rufin lantarki zuwa sassa masu girma na al'ada.

Muhimmiyar sanarwa: Laser yankan G10 fiberglass na iya sakin hayaki mai guba da ƙura mai kyau, don haka yana da mahimmanci a zaɓi ƙwararrun injin laser tare da ingantaccen tsarin iska da tsarin tacewa.

Koyaushe ba da fifikon matakan tsaro masu dacewa, gami da ingantaccen samun iska da sarrafa zafi, don tabbatar da sakamako mai inganci da yanayin aiki mai aminci lokacin yanke G10 fiberglass!

Duk wani Tambayoyi game da Laser Yanke Fiberglass

Yi magana da Masanin Laser ɗin mu!

Akwai Tambayoyi game da Laser Yanke Fiberglass Sheet?

Lokacin aikawa: Maris 25-2025