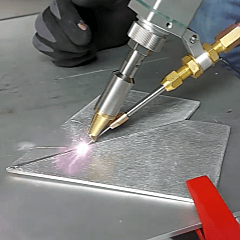

Yadda ake Laser Weld Aluminum Alloys

Aluminum Welding na iya zama da wahala

Aluminum alloys an kasaftasu cikin jeri bisa ga na farko alloying abubuwan.

Kowane jeri yana da keɓaɓɓen kaddarorin da ke shafar walƙiyar sa, musamman lokacin amfani da walda ta hannu.

Da ke ƙasa akwai bayyani na jerin gwanon allo na gama gari, halayensu, iskar garkuwa da ta dace, wayoyi masu fidda da suka dace, da shawarwari don cimma manyan welds.

Teburin Abun Ciki:

1. Na kowa Aluminum Alloys for Laser Welding

Mataki na Farko don Samun Kyakkyawan Weld: Fahimta

1000 Series Aluminum Alloys

Abun ciki:Ya ƙunshi 99.00% aluminum ko fiye.

Kaddarori:Mai nauyi da ductile sosai, yana sauƙaƙa aiki da shi.

Gas ɗin Garkuwa:100% Argon an bada shawarar don hana hadawan abu da iskar shaka.

Waya Filler:Yi amfani da 4047 ko 4045 filler waya don ingantacciyar dacewa.

Tukwici na walda:Tabbatar cewa saman yana da tsabta kuma ba shi da oxides. Gabaɗaya preheating ba lallai ba ne saboda babban ductility.

2000 Series Aluminum Alloys

Abun ciki:An haɗa da farko tare da jan karfe (2-10%).

Kaddarori:Babban ƙarfi amma ƙananan ductility; mai saurin fashewa yayin walda.

Gas ɗin Garkuwa:Argon tare da ƙaramin kaso na Helium na iya taimakawa inganta shigar ciki.

Waya Filler:Yi amfani da 4047 ko 2319 filler waya, wanda aka ƙera don gami mai wadatar tagulla.

Tukwici na walda:Preheat kayan don rage haɗarin fashewa. Sarrafa shigarwar zafi a hankali don guje wa matsanancin zafin zafi.

3000 Series Aluminum Alloys

Abun ciki:Alloyed tare da manganese.

Kaddarori:Kyakkyawan juriya da ƙarfin lalata; yana riƙe ƙarfi a yanayin zafi mai tsayi.

Gas ɗin Garkuwa:100% Argon yana da tasiri.

Waya Filler:4045 ko 4047 filler waya ya dace.

Tukwici na walda:Tsaftace saman da kyau don cire duk wani gurɓataccen abu. Kula da tsayayyen saurin tafiya don tabbatar da ko da rarraba zafi.

4000 Series Aluminum Alloys

Abun ciki:Ya ƙunshi siliki, wanda ke rage wurin narkewa.

Kaddarori:Ƙarfafa ductility kuma mafi kyau ga mutuwar-simintin gyare-gyare; mara zafi magani.

Gas ɗin Garkuwa:An fi son Argon.

Waya Filler:Yi amfani da waya filler 4047 don kyakkyawan sakamako.

Tukwici na walda:Preheating na iya taimakawa tare da shiga ciki. Saka idanu da shigar da zafi sosai don guje wa faɗa.

5000 Series Aluminum Alloys

Abun ciki:Alloyed tare da magnesium.

Kaddarori:Babban ƙarfi da kyakkyawan juriya na lalata; dace da zanen gado da faranti.

Gas ɗin Garkuwa:100% Argon an bada shawarar.

Waya Filler:Yi amfani da 5356 filler waya don ingantacciyar dacewa.

Tukwici na walda:Preheating yana da amfani ga sassa masu kauri. Yi amfani da dabarar turawa don inganta aikin tsaftacewa da rage gurɓatawa.

6000 Series Aluminum Alloys

Abun ciki:Ya ƙunshi duka magnesium da silicon.

Kaddarori:Kyakkyawan ductility da zafi-magani; manufa domin extrusions.

Gas ɗin Garkuwa:Argon ko cakuda Argon da Helium.

Waya Filler:4045 ko 5356 filler waya ya dace.

Tukwici na walda:Tabbatar da tsaftacewa mai kyau na saman. Yi amfani da mafi girman saurin tafiya don hana zafi fiye da kima.

7000 Series Aluminum Alloys

Abun ciki:Da farko gami da zinc.

Kaddarori:Ƙarfin ƙarfi amma gabaɗaya baya dace da haɗakar walda saboda al'amurra masu fashewa.

Gas ɗin Garkuwa:Argon tare da Helium na iya zama da amfani.

Waya Filler:Yi amfani da 7072 ko 7005 filler waya.

Tukwici na walda:Preheating yana da mahimmanci don rage haɗarin fashewa. Yi amfani da shigarwar zafi mai sarrafawa kuma kauce wa wuce kima gudun tafiya.

Tare da Ci gaban Fasahar Zamani

Farashin Injin Welding Laser bai taɓa kasancewa mai araha ba!

2. Nasihu na yau da kullun don Laser Welding Aluminum

Don Cimma Sakamakon Walda Mai Kyau, Ga wasu Mahimman Abubuwan:

Shirye-shiryen Sama

Koyaushe tsaftace saman aluminum don cire oxides da gurɓataccen abu.

Kula da zafi

Kula da shigar da zafi a hankali don guje wa wargajewa da hargitsi, musamman a kan ƙananan kayan.

Gudun tafiya

Daidaita saurin tafiya gwargwadon kaurin kayan don daidaita shigar da shigar zafi.

Daidaita Wurin Wuta

Mayar da hankali da Laser dan kadan kasa da surface domin mafi kyau shigar azzakari cikin farji da kuma rage reflectivity.

Zabi Tsakanin Nau'in Nau'in Laser Welding Machine?

Zamu Iya Taimakawa Yin Hukuncin Da Ya Kamata Akan Aikace-aikace

3. Yadda ake Cimma Weld mai kyau tare da Aluminum Alloys

Fahimtar Kayan ku Rabin Hanya ne a can

Fahimtar jerin gwanon allo na al'ada na gama gari yana da mahimmanci don cimma kyakkyawan walƙiya tare da walƙiyar laser na hannu saboda dalilai da yawa:

Kayayyakin Kayayyaki

Kowane jerin gami na aluminum yana da kaddarorin musamman, gami da ƙarfi, ductility, da wurin narkewa.

Sanin waɗannan kaddarorin yana taimakawa wajen zaɓar sigogin walda masu dacewa, kamar saitunan wutar lantarki da saurin tafiya, don tabbatar da ingantaccen walda mai ƙarfi.

Kalubalen walda

Daban-daban jerin gami suna gabatar da takamaiman ƙalubale yayin walda.

Misali, 2000 jerin allurai suna da saurin fashewa, yayin da jerin gami 4000 na iya gudana cikin sauƙi.

Fahimtar waɗannan ƙalubalen yana baiwa masu walda damar yin amfani da dabaru don rage al'amura, kamar preheating ko daidaita kayan filler.

Daidaituwar Kayan Filler

Allunan aluminum daban-daban suna buƙatar kayan filaye masu dacewa don tabbatar da haɗin gwiwa mai ƙarfi.

Misali, yin amfani da waya mai cika daidai zai iya hana al'amura kamar porosity ko rashin isashen fuska.

Ilimin jerin gami yana taimakawa wajen zaɓar madaidaicin waya mai filler don haɓaka ingancin walda.

Zaɓin Garkuwar Gas

Zaɓin garkuwar gas na iya tasiri sosai ga ingancin walda.

Kowane jerin gami na iya buƙatar takamaiman iskar gas don hana iskar shaka da haɓaka shigar ciki.

Fahimtar abun da ke ciki na gami yana taimaka wa masu walda su zaɓi mafi kyawun iskar garkuwa don sakamako mafi kyau.

Gudanar da Zafi

Alloys daban-daban suna amsa daban-daban don zafi.

Wasu na iya buƙatar maganin zafin jiki ko bayan walda don rage damuwa.

Fahimtar jerin gwanon yana ba masu walda damar sarrafa shigar da zafi yadda ya kamata, rage haɗarin warping ko fashewa.

Dace da aikace-aikace

Wasu allunan aluminium sun fi dacewa da takamaiman aikace-aikace, kamar sararin samaniya ko mota.

Sanin halayen kowane jeri yana taimakawa wajen zaɓar madaidaicin gami don aikin, tabbatar da samfurin ƙarshe ya dace da aiki da ƙa'idodin aminci.

Ƙarfin Kuɗi

Yin amfani da ma'auni masu dacewa da walƙiya masu dacewa na iya haifar da ingantattun hanyoyin waldawa, rage sharar gida da sake yin aiki.

Fahimtar kaddarorin gami yana ba da gudummawa ga mafi kyawun tsari da aiwatarwa, a ƙarshe adana lokaci da farashi.

Tabbacin inganci

Sanin nau'in aluminum daban-daban yana taimakawa wajen kafa matakan kula da inganci.

Welders na iya ɗaukar takamaiman dabaru da ƙa'idodi dangane da nau'in gami, wanda ke haifar da daidaitattun walda masu inganci.

Aluminum walda yana da wahala da walda ta gargajiya

Welding Laser Sauƙaƙe wannan Tsarin

Kuna son ƙarin sani game da Laser Welding Aluminum?

Aluminum Welding ya fi walƙiya fiye da sauran kayan walda.

Don haka Mun Rubuta Labari game da Yadda ake Cimma Welds masu kyau tare da Aluminum.

Daga Saituna zuwa Yadda ake.

Tare da Bidi'o'i da Sauran Bayanai.

Kuna sha'awar Welding Laser Wasu Kayayyakin?

Kuna son farawa akan Laser Welding Fast?

Kuna son sabunta ilimin ku na Welding Laser?

Wannan Cikakken Jagoran Magana An Keɓance Maka kawai!

Babban Ƙarfi & Wattage don Aikace-aikacen Welding Daban-daban

Na'urar waldawa ta hannu ta 2000W tana da ƙananan girman injin amma ingancin walda mai walƙiya.

Tsayayyen tushen Laser fiber fiber da kebul na fiber da aka haɗa suna ba da isar da katako mai aminci da tsayayye.

Tare da babban iko, Laser keyhole waldi ne cikakke kuma sa waldi hadin gwiwa firmer ko da lokacin farin ciki karfe.

Abun iya ɗauka don sassauƙa

Tare da ƙaƙƙarfan bayyanar na'ura da ƙarami, na'urar walda laser mai ɗaukar hoto tana sanye take da bindigar walda na hannu mai motsi wanda yake da nauyi kuma ya dace da aikace-aikacen walda mai-laser da yawa a kowane kusurwa da saman.

Zaɓuɓɓuka iri-iri na Laser walda nozzles da kuma atomatik waya ciyar tsarin sa Laser waldi aiki sauki da cewa shi ne sada zumunci ga sabon shiga.

High-gudun Laser waldi ƙwarai qara your samar yadda ya dace da kuma fitarwa yayin kunna wani kyakkyawan Laser waldi sakamako.

Abubuwan da kuke buƙatar sani game da: walda Laser na hannu

Idan kun ji daɗin wannan bidiyon, me zai hana ku yi la'akarikuyi subscribing na Youtube Channel namu?

Aikace-aikace masu alaƙa Wataƙila kuna sha'awar:

Yakamata Kowanne Saye Ya Kasance Da Sanin Bayani

Zamu iya Taimakawa da Cikakken Bayani da Shawarwari!

Lokacin aikawa: Dec-20-2024