Yadda za a Zaɓi Mafi kyawun Gas ɗin Gas don Welding Laser ɗinku?

Nau'i, Fa'idodi, da Aikace-aikace

Gabatarwa:

Muhimman Abubuwan Da Ya Kamata Ku Sani Kafin Nutsewa

Laser waldi hanya ce mai madaidaicin walƙiya wacce ke amfani da katako na Laser don narkar da kayan aikin aikin sannan kuma samar da walda bayan sanyaya. A cikin waldawar laser, iskar gas tana taka muhimmiyar rawa.

Gas mai karewa ba wai kawai yana shafar samuwar kabu na walda ba, ingancin kabu na walda, shigar da kabu na walda, da fadin shigar ciki amma kuma kai tsaye yana shafar inganci da ingancin waldawar Laser.

Wadanne iskar gas ake bukata don waldawar laser?Wannan labarin zai yi nazari mai zurfiMuhimmancin gas ɗin walda na Laser, iskar gas da ake amfani da su, da abin da suke yi.

Za mu kuma ba da shawaramafi kyau Laser waldi injidon bukatunku.

Me yasa Ana Bukatar Gas Don Welding Laser?

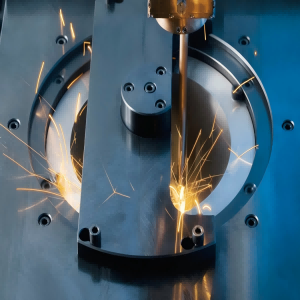

Laser Beam Welding

A lokacin aikin waldawar Laser, katako mai ƙarfi mai ƙarfi-yawan laser yana mai da hankali kan yankin walda na kayan aikin.

Yana haifar da narkewa nan take na kayan aikin kayan aiki.

Ana buƙatar iskar gas yayin waldawar laser don kare yankin walda.

Sarrafa zafin jiki, haɓaka ingancin walda, da kare tsarin gani.

Zaɓin nau'in gas ɗin da ya dace da sigogin samar da kayayyaki sune mahimman abubuwan da ke tabbatar da ingantaccen aiki.

Kuma barga Laser waldi tsari da kuma samun high quality waldi sakamakon.

1. Kare Wuraren Walda

A lokacin aikin waldawar Laser, yankin walda yana nunawa ga yanayin waje kuma ana iya samun sauƙin iskar oxygen da sauran iskar gas a cikin iska.

Oxygen yana haifar da halayen iskar shaka wanda zai iya haifar da raguwar ingancin walda, da ƙirƙirar pores da haɗawa. Ana iya kiyaye walda yadda ya kamata daga gurɓataccen iskar oxygen ta hanyar samar da iskar gas mai dacewa, yawanci iskar da ba ta da ƙarfi kamar argon, zuwa wurin walda.

2. Kula da zafi

Zaɓin zaɓin iskar gas da wadata na iya taimakawa wajen sarrafa zafin wurin waldawa. Ta hanyar daidaita magudanar ruwa da nau'in iskar gas, ana iya shafar yanayin sanyi na yankin walda. Wannan yana da mahimmanci don sarrafa yankin da ke fama da zafi (HAZ) a lokacin walda da rage gurɓataccen yanayi.

3. Ingantattun Weld Quality

Wasu iskar gas, kamar oxygen ko nitrogen, na iya inganta inganci da aikin walda. Alal misali, ƙara oxygen zai iya inganta shigar da walda da kuma ƙara saurin walda, yayin da kuma yana shafar siffar da zurfin walda.

4. Gas Sanyi

A cikin walda na Laser, yawancin yanayin zafi yana shafar yankin walda. Yin amfani da tsarin sanyaya gas zai iya taimakawa wajen sarrafa zafin wurin walda da kuma hana zafi. Wannan yana da mahimmanci don rage damuwa na thermal a cikin yankin walda da inganta ingancin walda.

Laser Beam Welding mai sarrafa kansa

5. Kariyar Gas Na Na'urorin gani

Laser katako yana mayar da hankali kan yankin walda ta hanyar tsarin gani.

Yayin aikin saida kayan, narkakkar kayan da iska da aka samar na iya gurɓata abubuwan gani.

Ta hanyar shigar da iskar gas a cikin yankin waldawa, haɗarin kamuwa da cuta yana raguwa kuma an tsawaita rayuwar tsarin gani.

Wadanne Gas Ne Ake Amfani da su A Wajen walda na Laser?

A cikin waldawar laser, iskar gas na iya ware iska daga farantin walda kuma ya hana shi amsawa da iska. Ta wannan hanyar, farfajiyar walda na farantin karfe zai zama fari kuma mafi kyau. Amfani da iskar gas kuma yana kare ruwan tabarau daga ƙurar walda. Yawanci, ana amfani da iskar gas masu zuwa:

1. Gas mai kariya:

Garkuwar iskar gas, wani lokaci ana kiranta "gas ɗin da ba a taɓa gani ba," suna taka muhimmiyar rawa a cikin tsarin waldawar laser. Hanyoyin waldawar Laser sukan yi amfani da iskar gas marasa amfani don kare tafkin walda. Abubuwan da aka saba amfani da su na kariya a waldawar Laser sun haɗa da argon da neon. Halin su na zahiri da na sinadarai sun bambanta, don haka tasirinsu akan walda shima ya bambanta.

Gas mai kariya:Argon

Argon yana daya daga cikin iskar da ba a iya amfani da ita ba.

Yana da babban matakin ionization a ƙarƙashin aikin laser, wanda ba shi da amfani don sarrafa samuwar gizagizai na plasma, wanda zai haifar da wani tasiri akan ingantaccen amfani da laser.

Halin rashin aiki na argon yana kiyaye shi daga tsarin siyar da shi, yayin da kuma ya watsar da zafi da kyau, yana taimakawa wajen sarrafa zafin jiki a cikin yanki.

Gas mai kariya:Neon

Ana amfani da Neon sau da yawa azaman iskar gas mara amfani, kama da argon, kuma ana amfani dashi galibi don kare yankin waldawa daga iskar oxygen da sauran gurɓataccen yanayi a waje.

Yana da mahimmanci a lura cewa neon bai dace da duk aikace-aikacen walda na laser ba.

Ana amfani da shi musamman don wasu ayyuka na walda na musamman, kamar kayan walda masu kauri ko lokacin da ake buƙatar ƙwanƙwasa mai zurfi.

2. Gas Na Agaji:

A lokacin aikin waldawar laser, baya ga babban iskar kariya, ana iya amfani da iskar gas ɗin taimako don haɓaka aikin walda da inganci. Wadannan su ne wasu iskar gas ɗin da aka saba amfani da su wajen waldawar Laser.

Gas Na Agaji:Oxygen

Ana amfani da iskar oxygen a matsayin iskar gas mai taimako kuma ana iya amfani dashi don ƙara zafi da zurfin walda yayin walda.

Ƙara iskar oxygen na iya ƙara saurin waldawa da shiga, amma yana buƙatar kulawa da hankali don guje wa wuce haddi na iskar oxygen da ke haifar da matsalolin iskar shaka.

Gas Na Agaji:Haɗin Hydrogen / Hydrogen

Hydrogen yana inganta ingancin walda kuma yana rage samuwar porosity.

Ana amfani da cakuda argon da hydrogen a wasu aikace-aikace na musamman, kamar walda bakin karfe. Abubuwan hydrogen na cakuda yawanci jeri daga 2% zuwa 15%.

Gas mai kariya:Nitrogen

Nitrogen kuma galibi ana amfani da shi azaman iskar gas ɗin taimako wajen waldawar Laser.

Ƙarfin ionization na nitrogen yana da matsakaici, sama da argon kuma ƙasa da hydrogen.

Matsayin ionization gabaɗaya yana ƙarƙashin aikin laser. Zai fi kyau rage samuwar gizagizai na plasma, samar da mafi kyawun walda da bayyanar, da rage tasirin iskar oxygen akan walda.

Hakanan ana iya amfani da Nitrogen don sarrafa yanayin yanayin walda da rage samuwar kumfa da pores.

Gas mai kariya:Helium

Helium yawanci ana amfani dashi don walƙiya mai ƙarfi mai ƙarfi saboda yana da ƙarancin ƙarancin zafin jiki kuma ba a sauƙaƙe ion, yana barin Laser ɗin ya wuce lafiyayye kuma ƙarfin katako ya isa wurin aikin ba tare da wani cikas ba.

Conducive zuwa mafi girma iko waldi. Hakanan ana iya amfani da helium don haɓaka ingancin walda da sarrafa yanayin walda. Wannan shine iskar garkuwa mafi inganci da ake amfani da ita wajen waldawar Laser, amma yana da tsada.

3. Gas mai sanyaya:

Ana amfani da iskar gas mai sanyaya sau da yawa yayin waldawar Laser don sarrafa zafin wurin waldawa, hana zafi fiye da kima, da kiyaye ingancin walda. Gas ɗin sanyaya da aka saba amfani dasu:

Iskar Gas/Matsakaici:Ruwa

Ruwa ne na kowa sanyaya matsakaici sau da yawa amfani da su kwantar da Laser janareta da Laser na gani tsarin walda.

Tsarin sanyaya ruwa na iya taimakawa wajen kiyaye yanayin kwanciyar hankali na janareta na laser da kayan aikin gani don tabbatar da kwanciyar hankali da aiki na katako.

Iskar Gas/Matsakaici:Gases na yanayi

A wasu hanyoyin walda na Laser, ana iya amfani da iskar gas na yanayi don sanyaya.

Misali, a cikin tsarin gani na janareta na laser, iskar gas da ke kewaye na iya samar da sakamako mai sanyaya.

Iskar Gas/Matsakaici:Inert Gases

Haka kuma ana iya amfani da iskar gas maras amfani kamar argon da nitrogen azaman iskar gas mai sanyaya.

Suna da ƙananan ƙarancin wutar lantarki kuma ana iya amfani da su don sarrafa zafin jiki na yankin walda da rage yankin da zafi ya shafa (HAZ).

Iskar Gas/Matsakaici:Liquid Nitrogen

Liquid nitrogen shine matsakaicin sanyi mai ƙarancin zafin jiki wanda za'a iya amfani dashi don walƙiya mai ƙarfi mai ƙarfi.

Yana ba da tasiri mai tasiri sosai kuma yana tabbatar da kula da zafin jiki a cikin yankin walda.

4. Gas mai gauraya:

Ana amfani da gaurayawar iskar gas a walda don inganta fannoni daban-daban na tsari, kamar saurin walda, zurfin shiga, da kwanciyar hankali. Akwai manyan nau'ikan gaurayawan gas guda biyu: gaurayawan binary da ternary.

Haɗin Gas na Binary:Argon + Oxygen

Ƙara ƙaramin iskar oxygen zuwa argon yana inganta kwanciyar hankali, yana daidaita tafkin walda, kuma yana ƙara saurin walda. Ana amfani da wannan cakuda don walda karfen carbon, ƙananan ƙarfe, da bakin karfe.

Haɗin Gas na Binary:Argon + Carbon Dioxide

Ƙarin CO₂ zuwa argon yana ƙara ƙarfin walda da juriya na lalata yayin rage spatter. Ana amfani da wannan cakuda sau da yawa don walda carbon karfe da bakin karfe.

Haɗin Gas na Binary:Argon + hydrogen

Hydrogen yana ƙara yawan zafin jiki, yana inganta saurin walda, kuma yana rage lahani na walda. Yana da amfani musamman don walda abubuwan da suka shafi nickel da bakin karfe.

Haɗin Gas na Ternary:Argon + Oxygen + Carbon Dioxide

Wannan cakuda ya haɗu da fa'idodin duka argon-oxygen da argon-CO₂ gauraye. Yana rage spatter, inganta walda ruwa ruwa, da kuma inganta walda ingancin. An yadu amfani da waldi daban-daban kauri na carbon karfe, low-alloy karfe, da bakin karfe.

Haɗin Gas na Ternary:Argon + Helium + Carbon Dioxide

Wannan cakuda yana taimakawa inganta kwanciyar hankali, ƙara yawan zafin jiki na walda, da haɓaka saurin walda. Ana amfani dashi a cikin gajeriyar walda ta baka da aikace-aikacen walda mai nauyi, yana ba da mafi kyawun iko akan iskar shaka.

Zaɓin Gas A aikace-aikace daban-daban

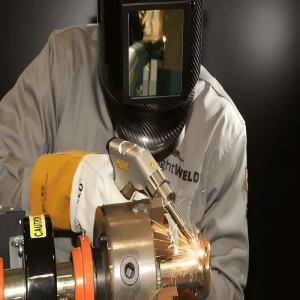

Laser Walda na Hannu

A daban-daban aikace-aikace na Laser waldi, zabar da dace gas yana da muhimmanci, saboda daban-daban gas haduwa iya samar daban-daban walda ingancin, gudun, da kuma yadda ya dace. Anan akwai wasu jagororin don taimaka muku zaɓin iskar gas mai dacewa don takamaiman aikace-aikacen ku:

Nau'in Kayan walda:

Bakin Karfeyawanci amfaniArgon ko Argon / Haɗin Hydrogen.

Aluminum da Aluminum Alloyssau da yawa amfaniPure Argon.

Titanium Alloyssau da yawa amfaniNitrogen

Karfe Masu Karfesau da yawa amfaniOxygen a matsayin Gas Na Gas.

Gudun Welding Da Shiga:

Idan ana buƙatar ƙarin saurin walda ko zurfin shigar waldi, ana iya daidaita haɗin iskar gas. Ƙara iskar oxygen sau da yawa yana inganta saurin gudu da shiga, amma yana buƙatar kulawa da hankali don guje wa matsalolin iskar oxygen.

Sarrafa Yankin da zafi ya shafa (HAZ):

Dangane da kayan da ake tsaftacewa, ana iya haifar da sharar gida mai haɗari wanda ke buƙatar hanyoyin kulawa na musamman yayin aikin tsaftacewa. Wannan zai iya ƙara zuwa ga overall kudin na Laser tsaftacewa tsari.

Ingancin Weld:

Wasu haɗe-haɗen iskar gas na iya haɓaka inganci da bayyanar walda. Alal misali, nitrogen na iya samar da kyakkyawan bayyanar da ingancin saman.

Sarrafa Pore da Kumfa:

Don aikace-aikacen da ke buƙatar walda masu inganci sosai, ana buƙatar kulawa ta musamman ga samuwar pores da kumfa. Zaɓin gas ɗin da ya dace zai iya rage haɗarin waɗannan lahani.

Kayan Aiki Da La'akarin Kuɗi:

Hakanan zaɓin iskar gas yana tasiri ta nau'in kayan aiki da farashi. Wasu iskar gas na iya buƙatar tsarin samarwa na musamman ko ƙarin farashi.

Don takamaiman aikace-aikacen, ana ba da shawarar yin aiki tare da injiniyan walda ko ƙwararrun masana'antun kayan walda na laser don samun shawarwarin ƙwararru da haɓaka tsarin walda.

Ana buƙatar wasu gwaji da haɓakawa galibi kafin a zaɓi haɗin iskar gas na ƙarshe.

Dangane da takamaiman aikace-aikacen, ana iya gwada haɗakar gas daban-daban da sigogi don nemo mafi kyawun yanayin walda.

Abubuwan da Kuna Bukatar Sanin Game da: Walƙar Laser Na Hannu

Na'urar Welding Laser Nasiha

Don inganta aikin aikin ƙarfe da sarrafa kayanku, zaɓin kayan aiki masu dacewa yana da mahimmanci. MimoWork Laser yana ba da shawararNa'urar walda ta Laser ta Hannudon daidai kuma ingantaccen haɗin ƙarfe.

Babban Ƙarfi & Wattage don Aikace-aikacen Welding Daban-daban

Na'urar waldawa ta hannu ta 2000W tana da ƙananan girman injin amma ingancin walda mai walƙiya.

Tsayayyen tushen Laser fiber fiber da kebul na fiber da aka haɗa suna ba da isar da katako mai aminci da tsayayye.

Tare da babban iko, Laser keyhole waldi ne cikakke kuma sa waldi hadin gwiwa firmer ko da lokacin farin ciki karfe.

Tare da ƙaƙƙarfan bayyanar na'ura da ƙarami, na'urar walda laser mai ɗaukar hoto tana sanye take da bindigar walda na hannu mai motsi wanda yake da nauyi kuma ya dace da aikace-aikacen walda mai-laser da yawa a kowane kusurwa da saman.

Zaɓuɓɓuka iri-iri na Laser walda nozzles da kuma atomatik waya ciyar tsarin sa Laser waldi aiki sauki da cewa shi ne sada zumunci ga sabon shiga.

High-gudun Laser waldi ƙwarai qara your samar yadda ya dace da kuma fitarwa yayin kunna wani kyakkyawan Laser waldi sakamako.

Takaita

A takaice, waldawar Laser yana buƙatar amfani da iskar gas don kare wuraren waldawa, sarrafa zafin jiki, haɓaka ingancin walda, da kare tsarin gani. Zaɓin nau'ikan iskar gas da suka dace da sigogin samarwa shine muhimmin mahimmanci don tabbatar da ingantaccen tsarin waldawar laser mai inganci da kuma samun sakamako mai inganci. Daban-daban kayayyaki da aikace-aikace na iya buƙatar nau'ikan nau'ikan daban-daban da gaurayawan rabbai don saduwa da takamaiman buƙatun walda.

Ka iso gare mu a yaudon ƙarin koyo game da mu Laser cutters da kuma yadda za su iya inganta your yankan samar da tsari.

Hanyoyin haɗi

Wani Ra'ayi Game da Laser Welding Machines?

Lokacin aikawa: Janairu-13-2025