Ikon Madaidaici: Fahimtar Welding Laser da Aikace-aikacen sa

Duk abin da kuke so game da waldi na Laser

Welding tare da Laser tsari ne mai mahimmanci a masana'antun masana'antu da yawa, kuma akwai hanyoyi da yawa don haɗa abubuwan haɗin ƙarfe. Ɗayan ingantacciyar hanyar walda wacce ta fi ci gaba kuma ta dace ita ce walƙiya ta Laser, wadda ke amfani da Laser mai ƙarfi don narke da haɗa kayan aikin ƙarfe. A cikin wannan labarin, za mu bincika abin da Laser waldi ne, da aikace-aikace, da kuma amfanin yin amfani da Laser walda inji.

Menene Laser Welding?

Yin amfani da walda na Laser wani tsari ne da ke amfani da katako mai ƙarfi na Laser don zafi da narkar da gefuna na sassan ƙarfe, yana ba da damar haɗa su tare. Laser katako yana mayar da hankali kan saman karfe, yana haifar da kunkuntar tushen zafi mai zafi wanda zai iya narkewa da sauri da kuma haɗa karfe. Daidaitaccen walƙiya na laser yana ba da damar ƙirƙirar walƙiya mai ƙarfi, daidaici, da inganci a cikin nau'ikan ƙarfe da yawa.

Ana amfani da na'urar waldawa ta Laser a masana'antu kamar na motoci, sararin samaniya, da na'urorin lantarki, inda daidaito da inganci suke da mahimmanci. Babban saurin walƙiya da daidaiton walda na Laser ya sa ya dace don walda ƙananan abubuwa ko rikitattun abubuwan walda, inda hanyoyin walda na gargajiya bazai dace ba. Bugu da kari, ana iya amfani da walda tare da Laser don haɗa nau'ikan karafa iri-iri, wanda ke da wahala a cimma ta da hanyoyin walda na gargajiya.

Manyan nau'ikan Laser Welding guda biyu:

Akwai manyan nau'ikan walda na Laser guda biyu: walƙiya walƙiya da walƙiyar maɓalli. Welding ɗin wani tsari ne mai ƙarancin ƙarfi wanda ke haɗuwa da abubuwan ƙarfe ta hanyar narkar da shimfidar ƙasa, yayin da waldar maɓalli wani tsari ne mai ƙarfi wanda ke haifar da rami mai maɓalli a cikin ƙarfe, sannan a cika shi da narkakken ƙarfe don samar da walda.

Fa'idodin Amfani da Na'urar Welding Laser

• Babban Madaidaici da Daidaitawa

Za'a iya jagorantar katako na Laser zuwa wani yanki na musamman na karfe, wanda ke ba da izini ga madaidaicin walda mai sarrafawa. Babban saurin walƙar laser kuma yana nufin cewa ana iya haɗa abubuwan da aka gyara cikin sauri, wanda ke ƙara yawan aiki kuma yana rage farashin samarwa.

• Maɗaukaki masu inganci da ƙayatarwa

Ƙaƙƙarfan tushen zafi mai zafi na Laser yana haifar da ƙananan yanki mai zafi, wanda ke nufin cewa akwai ƙananan murdiya, kuma walda ba shi da splatter, wanda ke tabbatar da tsabta da tsabta.

• Tsari mara lamba

waldawar laser wani tsari ne wanda ba a tuntube shi ba wanda ke kawar da buƙatar haɗin jiki tare da saman ƙarfe, wanda ke rage haɗarin gurɓatawa da lalata abubuwan ƙarfe. Wannan ya sa walƙiya Laser manufa domin walda m aka gyara da kuma kayan da bukatar musamman handling.

A karshe

Welding da Laser Welder na hannu wata ci gaba ce kuma madaidaiciyar hanyar walda wacce ke ba da fa'idodi da yawa ga masana'antu da yawa. Madaidaicin daidaito, saurin gudu, da walƙiya masu inganci da yake bayarwa sun sa ya zama kyakkyawan zaɓi don aikace-aikacen da ke buƙatar babban matakin daidaito da inganci. Zuba jari a cikin na'urar waldawa ta Laser na iya zama yanke shawara mai hikima ga kasuwancin da ke buƙatar hanyar walƙiya mai sauri, daidai, kuma abin dogaro.

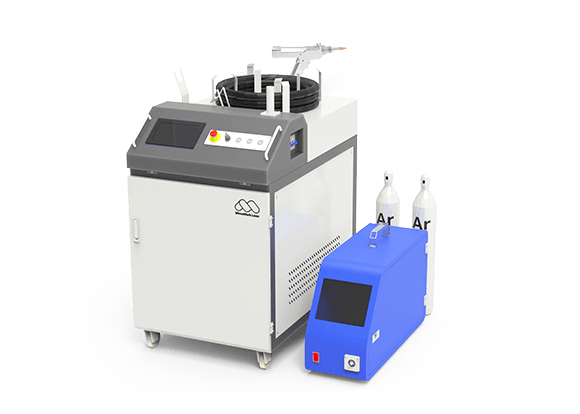

Na'urar walda Laser da aka ba da shawarar

Kuna son saka hannun jari a injin walda Laser?

Lokacin aikawa: Maris-02-2023