Laser Welding vs TIG Welding: Abin da Ya Canza a 2024

Menene Walƙiyar Laser Na Hannu?

Hannun Laser Welding Bakin Karfe

Laser waldi na hannuyana amfani da na'urar Laser šaukuwa don haɗa kayan, yawanci karafa.

Hannun Laser waldi damar donmafi girmamaneuverability da daidaito,

Kuma yana samar da ingantaccen weld mai tsabta tare dakadanshigar zafi,

Ragewamurdiya da buqatar aiki mai yawa bayan walda.

Masu aiki za su iya daidaita ƙarfi da saurin laser cikin sauƙi,

Yin kunnawadaidaita saitunadon abubuwa daban-daban da kauri.

Teburin Abun Ciki:

Mene ne Laser Weld Cleaning?

Muhimmancin Tsafta a Welding

Pre-Weld Cleaning don TIG Welding

Idan ana maganar walda.

Tsafta tana taka muhimmiyar rawa wajen samun nasarahigh quality-sakamako.

Wannan ka'ida ta shafi duka TIG waldi da waldawar laser na hannu,

Amma hanyoyin shirya kayan sun bambanta sosai.

Ga kowane tsarin walda,

Kasancewar gurɓatattun abubuwa kamar tsatsa, fenti, da mai

Canyin sulhu mai tsananimutuncin weld.

Wadannan ƙazanta na iya haifar da raunin haɗin gwiwa, porosity, da sauran lahani

Wannan yana lalata ƙarfin samfurin ƙarshe.

Wannan shine Yadda kukeYA KAMATAMagance waɗannan gurɓatattun abubuwa:Laser Weld Cleaning.

Laser Welding vs TIG Welding: Laser Weld Cleaning

Tsaftace Filaye Yana Samar da Welds masu inganci

Laser Weld Cleaning for Handheld Laser Cleaning

Yayin da TIG waldi ya dogaramanualhanyoyin tsaftacewa kamar niƙa kusurwa da gogewar acetone,

Waldawar Laser na hannu yana ba da ƙarindacemadadin tare da hadedde tsaftacewa damar.

Wannan bidi'a ba kawai yana haɓaka inganci ba

Amma kuma yana tabbatar da cewa tsarin walda yana da tasiri sosai kamar yadda zai yiwu.

Ƙarshe yana haifar da kyakkyawan sakamako.

TIG Shirye-shiryen Welding:

A TIG (Tungsten Inert Gas) walda, shiri sosai yana da mahimmanci.

Kafin fara aikin walda,

Yana da na kowa don amfanikwana grindersdon cire tsatsa ko sutura daga saman kayan.

Wannan tsaftacewa na inji yana taimakawa wajen tabbatar da cewa saman ba shi da ƙazanta.

Bayan haka, goge sosai tare daacetoneyawanci ana yi.

Acetone ne mai ƙarfi ƙarfi wandayadda ya kamata cireduk sauran maiko ko gurɓatawa,

Barin wuri mai tsabta don walda.

Wannan tsarin tsaftacewa na matakai biyu na iya ɗaukar lokaci,

Amma yana da mahimmanci don samun ƙarfi kuma mai dorewa.

Hannun Laser Welding Shiri

Sabanin haka, na hannu Laser walda yayi tayi

A ƙaristreamlined mto surface shiri.

Da a3-in-1Laser waldi, da tsari zama muhimmanci sauki.

Waɗannan injunan ci-gaba yawanci suna zuwa da sanye take da sunozzles masu canzawa

Wannan yana ba da izinin tsaftace ƙasa dama kafin walda.

Ba kamar hanyoyin al'ada ba, inda ake buƙatar kayan aiki daban da abubuwan tsaftacewa,

Laser welders na iya ƙoƙarin tsaftace farfajiyar tare da katako na Laser mai da hankali.

Wannan ba kawai yana adana lokaci ba amma har ma yana ragewaadadin kayan aikida ake bukata a kan-site.

Welding Laser vs TIG Welding ya canza a cikin 2024

Tuntuɓe mu don ƙarin game da Tsarin walda Laser na Hannu

Me yasa ake amfani da Gas ɗin Garkuwa a Welding?

Zaɓin Gas ɗin Garkuwa yana Taka Mahimman Matsayi

Garkuwar Gas don Tig Welding: Argon

Idan ana maganar walda.

Zaɓin garkuwar gas yana da mahimmanci don tabbatar da sakamako mai inganci.

Musamman, walƙiya TIG da walƙiyar laser na hannu suna da buƙatu da zaɓuɓɓuka daban-daban

Lokacin da yazo ga garkuwar gas, yana tasiri duka aiki da farashi.

Garkuwar Gas inTIG Welding

A cikin TIG (Tungsten Inert Gas) waldi,

Gas ɗin kariya na farko da ake amfani da shi shinehigh-tsarkiargon.

An zaɓi wannan iskar gas mai daraja don kyakkyawan ƙarfinsakare tafkin walda

Daga gurɓatar yanayi, musamman oxidation.

Oxidation na iya haifar dalahania cikin weld, kamar porosity da rauni gidajen abinci,

Wanneyin sulhugaba ɗaya amincin karfe.

Saboda ingancinsa.

walda TIG sau da yawa yana buƙatar aci gabasamar da argon a ko'ina cikin tsarin walda.

Duk da haka, argon na iya zama mai tsada sosai, wanda zai haifar da farashin aiki mafi girma,

Musamman a cikin ayyukan da ke buƙatar walƙiya mai yawa.

Garkuwar Gas inLaser Walda na Hannu

Madadin Garkuwar Gas don Welding Laser: Nitrogen

A daya hannun, walda Laser na hannu yakan yi amfani da nitrogen a matsayin iskar kariya.

Nitrogen ba kawai ba netasiria hana oxidation

Amma kuma yana da mahimmanci fiye da hakamfiye da argon.

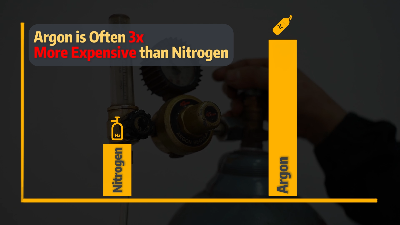

Bambancin farashin na iya zama babba;

Nitrogen na iya zama kusansau ukumai rahusa fiye da high-tsarki argon.

Wannan ya sa nitrogen ya zama zaɓi mai ban sha'awa ga kasuwancin da ke neman rage farashiba tare da sadaukarwa bainganci.

TIG vs Laser Welding: Garkuwar Gas Zaɓuɓɓuka

Cimma Tattaunawa Yayin Kula da Inganci

Kwatanta Farashin Tsakanin Argon da Nitrogen

Canjawa zuwa nitrogen a cikin tayin walda na laser na hannuda yawaabũbuwan amfãni

Tattalin Kuɗi:

Tare damuhimmancibambanci tsakanin argon da nitrogen,

Yin amfani da nitrogen na iya haifar da tanadi mai yawa a cikin lokaci.

Wannan shinemusamman amfanidon manyan ayyuka ko kasuwanci

Wannan yana yin ayyukan walda akai-akai.

Kariya mai inganci:

Nitrogen yana bayarwaisasshen garkuwada oxidation,

Tabbatar da cewa walda ya kasancemai tsabta da ƙarfi.

Duk da yake an san argon don kariya mafi girma,

Nitrogen yana nan har yanzuzaɓi mai yiwuwawanda ya dace daidai da bukatun aikace-aikacen walda da yawa.

Kwatanta Tsarin Welding: Laser vs TIG Welding

Hankali na Hankali ga Fasaha Yana Samun Mafi kyawun Sakamako

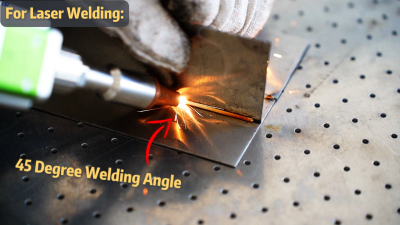

Madaidaicin kusurwa don waldawar Laser: 45 Degree

Da zarar garkuwar gas ɗin yana gudana yadda ya kamata.

Lokaci ya yi da za a mai da hankali kan ainihin aikin walda.

Dukansu TIG (Tungsten Inert Gas) waldi da walƙiya na hannu

bukatadaidai dabarudon samun sakamako mai inganci,

Koyaya, sun bambanta a cikin takamaiman buƙatu da hanyoyin su.

TIG WeldingDabaru

Nufin kula da lantarki a wanimafi kyawun nisa da saurin gududon samar da jagorancin tafkin walda.

Wannan nisa na iya bambanta dangane da kayan da kauri da ake waldawa.

Tsayawa daidai kusurwa, yawanci a kusa15 zuwa 20 digiri,

Taimaka wajen samun daidaito da tsaftar walda.

Laser Walda na HannuDabaru

Ɗaya daga cikin fa'idodin walda na Laser shine ikon saita madaidaiciyar kusurwa

Yawanci a kusa45 digiri, kyale don sauƙin sarrafa tsarin walda.

Da zarar an saita kusurwa, kiyayewatsayayyen gudukey ne.

Waldawar Laser na hannu yawanci yana samarwarage zafiidan aka kwatanta da TIG waldi.

Wannan yana nufin akwaiƙasan haɗarin warping ko murdiya,

Yin shi manufa don daidaitaccen aiki akan kayan bakin ciki.

Ƙarfin Weld Laser vs TIG: Ƙarfafa Tatsuniyoyi

Ra'ayin gama gari Game da walda Laser

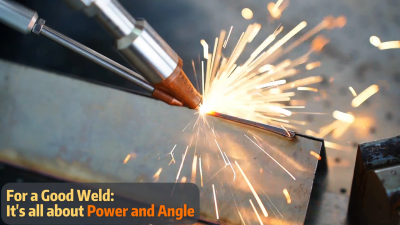

Don Kyakkyawan walƙiya Laser na Hannu: Ƙarfi & Angle

Ɗaya daga cikin mahimman fa'idodin walda na Laser na hannu shine ikon sa na isar da kuzari mai ƙarfidaidaiinda ake bukata.

Tare dadama ikon saitunakuma anmafi kyau duka kwana

Yawanci a kusa45 digiri, Laser waldi iya cimma kyau kwarai shigar azzakari cikin farji da kuma ƙarfi.

Fitar Wuta Mai Dama

Saitin wutar lantarki na walda laser yana da mahimmanci.

Rashin wutar lantarki da yawa na iya haifar da shirashin isashen shiga, haifar da rauni welds.

Sabanin haka, matakin ƙarfin da ya dace yana ba da damar laser don narke kayan da kyau, ƙirƙirar haɗin gwiwa mai ƙarfi.

Yin amfani da kayan aiki marasa ƙarfi ba zai haifar da sakamakon da ake so ba.

Dukansu TIG da Walƙar Laser Na Hannu suna da inganci

Kuna son ƙarin koyo Game da Walƙar Laser Na Hannu?

Welding Laser Hannu: Yadda ake Kula da Kayan aiki

Kulawar da ta dace da kuma Hankali ga Dalla-dalla za su Tabbatar da Aiki da Dogara

Shin kun san cewa duka TIG (Tungsten Inert Gas) walƙiya da walƙiyar Laser na hannu an rarraba su azaman

Hanyoyin walda marasa amfani?

Wannan yana nufin cewa, a ƙarƙashin kyakkyawan yanayi kuma tare da kulawa mai kyau.

Mabuɗin abubuwan da aka yi amfani da su a cikin waɗannan matakai na iya ɗaukar lokaci mai tsawo

Ba tare da buƙatar sauyawa akai-akai ba.

Abubuwan da Ba Masu Amfani ba

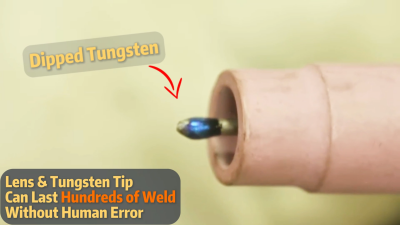

Kuskuren Tungsten Dipped don TIG Welding

Wutar lantarki ta tungsten wani abu ne mai mahimmanci a cikin walda na TIG.

Sabanin na'urorin lantarki da ake amfani da su a wasu hanyoyin walda,

irin su MIG waldi, tungsten electrodebaya narkea lokacin aikin walda.

Maimakon haka, yana kiyaye mutuncinsa, yana ba da damar yin amfani da shi na dogon lokaci.

Duk da haka, wutar lantarki na iya zama gurɓata ko "tsoma" idan ta samuma kusa da narkakken tafkin walda.

A irin waɗannan lokuta, dole ne a yanke shi baya da ƙasa don dawo da kaifinsa da ingantaccen aiki.

Kulawa na yau da kullunna tungsten electrode yana da mahimmanci don cimma tsaftataccen welds masu inganci.

Hannun Laser Welding Shiri

Lens na Laser don Kula da Welding Laser Hannu

A cikin waldawar Laser na hannu, ruwan tabarau na Laser yana aiki a matsayin wurin mai da hankali ga katako na Laser.

Madaidaicin ruwan tabarau na iya ɗaukar lokaci mai tsawo, yana samar da daidaiton aiki.

Duk da haka, idan ruwan tabarau ya fashe saboda rashin daidaiton matsayi ko bayyanar da zafi mai yawa

Za a buƙaci a maye gurbinsa.

Kula da ruwan tabarau a cikin yanayi mai kyau yana da mahimmanci,

Kamar yadda ko da ƙananan lalacewa na iya rinjayar daidaito da tasiri na laser, wanda zai haifar da ƙananan walda.

Kuna son Cikakken Jagoran Magana don Welding Laser Na Hannu?

walda Laser na hannu yana ba da fa'idodi da yawa,

Amma kuma yana buƙatar kulawa sosai ga ƙa'idodin aminci.

Wannan labarin zai bincika mahimman la'akari da aminci don waldawar laser na hannu.

Kazalika bayar da shawarwari akan zaɓin garkuwar gas da zaɓin waya mai filler don nau'ikan ƙarfe na gama gari.

Shin Laser Welding yana da ƙarfi kamar TIG Welding?

Laser waldada TIG (Tungsten Inert Gas) walda duk sun shahara saboda daidaitattun su da ingancin haɗin ƙarfe.

Amma ta yaya suke yin tari a kan juna ta fuskar ƙarfi?

A cikin wannan bidiyon, za mu nutse cikin mahimman bambance-bambance a cikiweld yi,dacewa kayan aiki, kumagaba ɗaya karkotsakanin Laser da TIG waldi.

Fiber Laser Welding na Hannu (Laser Weld na Hannu)

Ƙari mai ƙima zuwa Tsarin Laser Weld na Hannu

Smallaramin Laser Welder Yana Sa Welding Kudi mai inganci & Mai araha

Tare da ƙaƙƙarfan bayyanar na'ura.

Na'urar walda ta Laser mai ɗaukuwa tana sanye da bindiga mai walƙiya ta hannu wacce ita cemara nauyi.

Kuma dace da Multi-Laser waldi aikace-aikace akowane kusurwakumasaman.

Na zaɓi iri daban-daban na Laser walda nozzles.

Tsarin ciyarwar waya ta atomatik na zaɓi yana sa aikin waldawar Laser ya fi sauƙi kuma wannan shine abokantaka ga masu farawa.

Abubuwa 5 Game da Welding Laser (Waɗanda kuka Bace)

Idan kun ji daɗin wannan bidiyon, me zai hana ku yi la'akarikuyi subscribing na Youtube Channel namu?

Aikace-aikace masu alaƙa Wataƙila kuna sha'awar:

Laser Weld na Hannu shine Kyakkyawan Zaɓi don Ayyukan walda da hannu

Kuma gaba yana farawa da ku!

Lokacin aikawa: Satumba-14-2024