Me Yasa Ka Zaba Laser Welder Na Hannu?

Injin walda Laser Mai Hannu - Jagorar Sabuwar Iskar Masana'antar

Laser mai riƙe da hannu - yana kama da kayan aiki mai sanyi, ko ba haka ba? A cikin yanayin masana'antu mai sauri da sauri. Bukatar ingantacciyar mafita ta walda mai inganci ba ta taɓa zama mafi mahimmanci ba.

Saboda haka, idan aka kwatanta da na gargajiya Laser waldi inji. Menene ke sa na'urar waldawa ta Laser ta hannu ta fice?

Bari in gabatar mukuda abũbuwan amfãni daga na hannu Laser welder idan aka kwatanta da gargajiya waldi hanyoyin.

Kumayadda masu walda laser na hannu a zahiri ke kawo wayewa.

Teburin Abun Ciki:

Menene Injin Laser Na Hannu?

Yana da hanyar walda tare da babban inganci, kyakkyawan inganci da ƙarancin farashi.

Na'urar Laser na hannu wani nau'in aiki ne mai dacewa da hannu.

Babban abin da ke cikin shi shine yin amfani da katako na Laser don yin tambari na dindindin a saman abin.

Wannan hanya ce ta ingantaccen inganci, inganci da ƙarancin farashi.

Abin mamaki, hanyoyin walda na gargajiya (kamar MIG ko TIG) suna da wuyar aiwatarwa.

Yayin da katakon Laser na hannu yana da ƙananan diamita mai mayar da hankali.

Ƙaddamar da daidaiton alamar ƙananan matakan don tabbatar da cewa abun cikin alamar ya fi haske.

Ba da dadewa ba, ina taimaka wa masana'anta da ke yin sassa na walda na al'ada.

Ɗaya daga cikin mafi ƙalubale ayyuka da muka ci karo da shi shi ne yadda za a haɗa sirararan aluminum tare da matsanancin zafi.

Lokacin da muka canza zuwa waldar laser mai hannu.

Mun gano cewa ya samar da high quality welds tare da kadan thermal girgiza.

Rage haɗarin warping sosai da tabbatar da tsabtar walda ba tare da buƙatar gamawa mai yawa bayan walda ba.

Abu ne mai dadi, ko ba haka ba?

Kwatanta Da Na'urar Welding Laser Na Gargajiya

Injin walda da hannu sun fi kyau

A cikin 'yan shekarun nan, ƙasashe a duniya suna da buƙatu masu girma da girma don kare muhalli.

Argon baka walda zai samar da babban adadin walda kura da slag.

Yana da matukar illa ga muhalli.

Kamfanonin da suka kasa cika ka'idojin kare muhalli za su fuskanci kulawar tsari.

Kuma waldawar hannu ta Laser ba ta da illa ga muhalli.

Ana iya amfani dashi ko'ina a wasu masana'antu marasa tsari da rikitarwa.

Gabatarwar Argon Arc Welding

Amfani

1. Al'ada argon baka walda kuma yana da kwatanci fa'ida. Farashin yana da ƙasa, gabaɗaya daga ƴan dubbai zuwa 20,000 zuwa 30,000.

2. Ko da yake sarrafawa yana da ɗan ƙanƙara, ƙarfin yana da ƙarfi fiye da sauran. Ya dace da sifofin ƙarfe masu ɗaukar nauyi tare da saurin walƙiya a hankali.

Rashin amfani

1. Kaurin walda yana da ɗanɗano lokacin farin ciki, ya dace da faranti mai kauri sama da 4mm.

2. Argon baka waldi na bukatar balagagge welders. Kuma albashin manyan masu walda a kowane wata yana farawa akalla 8K.

Gabatarwa Laser waldi na hannu

Amfani

1. Cikakken saitin kayan walda na laser na hannu yana da ƙarfi. Ergonomically ƙera kuma dace da wurare daban-daban na aiki. Yana da aikin kariya na aminci na Laser na musamman. Kuma yana iya tabbatar da amincin ma'aikaci lokacin aiki.

2. Aiki yana da sauƙin koya da sauri don amfani. Kuma ƙofar fasaha na mai aiki ba shi da yawa, wanda ke adana farashin aiki.

3. Waldawar hannu yana da sauƙin koya. Masu aiki na yau da kullun na iya farawa a cikin rabin yini. Albashin kowane wata na talakawa walda na hannu yana kusan 4k.

4. Gudun na'urar waldawa ta Laser shine sau 10-20. Ma'aikatan Laser na yau da kullun na iya sarrafa shi cikin sauƙi, kuma yanayin aiki yana annashuwa. Albashi na daya argon baka welder na iya daukar ma'aikatan Laser guda uku.

Zabi nau'in nau'in na'ura mai waldawa ta hannu?

Zamu Iya Taimakawa Yin Hukuncin Da Ya Kamata Akan Aikace-aikace

Fa'idodin Welder Laser Hannu

Akwai wasu Fa'idodi na Haƙiƙa don Amfani da walƙar Laser na hannu

Samfurin ƙarshe na walda Laser na hannu ba shi da tabo kuma baya buƙatar yashi ko sake yin aiki.

Walda na hannu ba kawai ya dace da wannan ma'auni ba, har ma ya wuce shi.

Ingantattun Kyawun Kyau

Hannun rikodi na Laser walda suna samar da samfurori tare da ingantaccen ingancin gani.

Ingancin katako mai tsayi yana tabbatar da ƙarfi, santsi, da kyawu mai ɗorewa, yana rage lalacewa da tabon walda.

Wannan yana rage buƙatar polishing na biyu, adana lokaci da rage farashin aiki ga masana'antun.

Babban Gudu da Ƙarfafa Ƙarfafa Ƙirƙirar Ƙirƙira

Waldawar Laser yana da sauri fiye da hanyoyin gargajiya, tare da saurin da zai iya kaiwa sau 5 zuwa 10 cikin sauri.

Ikon kula da zurfin shigar ciki da ƙimar yawan amfanin ƙasa a cikin kayan daban-daban yana haɓaka yawan aiki.

Ci gaba da aiki yana goyan bayan tsarin sanyaya da aka keɓe, yana ba da izinin tafiyar aiki na awanni 24

Rashin Amfani da Zafi

Tsarin walƙiya na Laser yana haifar da ƙaramin yanki da zafi ya shafa, yana rage lalacewar thermal ga kayan da ke kewaye.

Wannan madaidaicin yana tabbatar da tsaftataccen walda kuma yana kiyaye mutuncin samfurin, yana rage haɗarin warping.

Welds mai tsabta

Welds yawanci suna fitowa mafi tsabta, suna buƙatar ƙarancin sarrafawa.

A cikin masana'antu inda bayyanar samfurin ƙarshe yana da mahimmanci kamar ƙarfinsa (tunanin motoci ko sararin samaniya), wannan babbar fa'ida ce.

Na'urar walda ta Laser mai hannu tana sauƙaƙa

tsarin samarwa!

Hannun Laser Welder Masu Aiwatar da Yanayin Aiki

Walda Laser Hannu Shine, Ba Ba Tare da La'akarin sa ba

Kodayake fa'idodin na'urorin walda na Laser na hannu suna da girma sosai.

Akwai kuma wasu matakan kiyayewa.

Na farko, kayan aiki suna da tsada kuma suna buƙatar takamaiman lokacin koyo don amfani da kiyayewa da kyau.

Har ila yau, yawancin abokan ciniki waɗanda suke da niyyar gabatar da na'urar walda ta laser na hannu.

Wanda ke da damuwa game da amfani da aikinsa.

Wasu abokan ciniki sun yi amfani da shi na ɗan lokaci kuma sun taƙaita abubuwan da ke gaba.

Injin walda Laser na Hannu

Na'urar Welding Laser Na Hannu Ya dace da Sharuɗɗan Aiki masu zuwa:

Babban yanki na walda yana buƙatar ingantaccen walda.

· Kaurin farantin yana sama da 0.5mm.

· Magance matsalar kyawon walda da nakasa.

· An yi shi da bakin karfe, farantin ƙarfe, da aluminum.

· Akwai takamaiman adadin sarari na kasafin kuɗi.

· Don magance matsalar aiki, mai walƙiya Laser na hannu zai iya fara aiki tare da tushen walda na sifili.

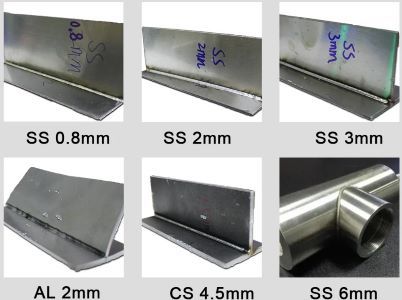

Yaya Kauri Can Laser Weld Machine Weld?

Mafi girma da kauri daga cikin welded workpiece, da girma da ikon da zaɓaɓɓen Laser waldi inji ya kamata.

1. 1000W Laser Welder Machine: tasirin walda yana da kyau ga faranti tare da kauri na ƙasa da 3mm.

2. 1500W Laser Welder Machine: tasirin walda yana da kyau ga faranti tare da kauri na ƙasa da 5mm.

3. 2000W Laser Welder Machine: tasirin walda yana da kyau ga faranti tare da kauri na ƙasa da 8mm.

Kuna buƙatar sanin: Yadda za a zaɓi na'urar Laser na hannu

Babban Ƙarfi & Wattage don Aikace-aikacen Welding Daban-daban

Na'urar waldawa ta hannu ta 2000W tana da ƙananan girman injin amma ingancin walda mai walƙiya.

Tsayayyen tushen Laser fiber fiber da kebul na fiber da aka haɗa suna ba da isar da katako mai aminci da tsayayye.

Tare da babban iko, Laser keyhole waldi ne cikakke kuma sa waldi hadin gwiwa firmer ko da lokacin farin ciki karfe.

Abun iya ɗauka don sassauƙa

Tare da ƙaƙƙarfan bayyanar na'ura da ƙarami, na'urar walda laser mai ɗaukar hoto tana sanye take da bindigar walda na hannu mai motsi wanda yake da nauyi kuma ya dace da aikace-aikacen walda mai-laser da yawa a kowane kusurwa da saman.

Zaɓuɓɓuka iri-iri na Laser walda nozzles da kuma atomatik waya ciyar tsarin sa Laser waldi aiki sauki da cewa shi ne sada zumunci ga sabon shiga.

High-gudun Laser waldi ƙwarai qara your samar yadda ya dace da kuma fitarwa yayin kunna wani kyakkyawan Laser waldi sakamako.

Abubuwan da kuke buƙatar sani game da: walda Laser na hannu

Idan kun ji daɗin wannan bidiyon, me zai hana ku yi la'akarikuyi subscribing na Youtube Channel namu?

Aikace-aikace masu alaƙa Wataƙila kuna sha'awar:

Yakamata Kowanne Saye Ya Kasance Da Sanin Bayani

Zamu iya Taimakawa da Cikakken Bayani da Shawarwari!

Lokacin aikawa: Janairu-13-2025