ʻO ke kaʻina hana hoʻoheheʻe laser maʻamau e pili ana i ka nānā ʻana i kahi kukuna laser ma ka ʻāpana hui ma waena o nā mea ʻelua me ka hoʻohana ʻana i kahi ʻōnaehana hoʻopuka optical. Ke hoʻopili ka lāʻau i nā mea, hoʻololi i kona ikehu, hoʻomehana wikiwiki a hoʻoheheʻe i kahi wahi liʻiliʻi.

Papa Maʻiʻo

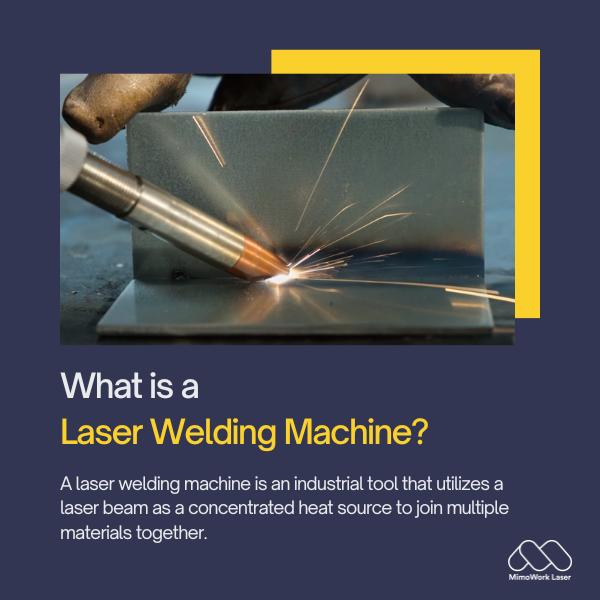

1. He aha ka mīkini welding laser?

ʻO ka mīkini welding laser kahi mea hana ʻenehana e hoʻohana ana i kahi kukuna laser ma ke ʻano he kumu wela e hui pū ai i nā mea he nui.

ʻO kekahi mau hiʻohiʻona nui o nā mīkini welding laser penei:

1. Kumu Laser:ʻO ka hapa nui o nā mea welder laser hou e hoʻohana i nā diodes laser solid-state e hana i kahi kukuna laser mana kiʻekiʻe i ka spectrum infrared. ʻO nā kumu laser maʻamau ka CO2, fiber, a me nā laser diode.

2. Optik:Ke hele nei ka kukuna laser ma o nā ʻāpana opipika e like me nā aniani, nā lens, a me nā nozzles e kālele ana a kuhikuhi i ke kukui i kahi weld me ka pololei. Hoʻonoho nā lima ʻelescoping a i ʻole nā gantries i ke kukui.

3. ʻOmomi:Nui nā welders laser e hōʻike ana i ka hoʻohui ʻana o ka computer numerical control (CNC) a me nā robotics e hoʻomaʻamaʻa i nā ʻano hoʻohālike paʻakikī a me nā kaʻina hana. ʻO nā ala hiki ke hoʻolālā ʻia a me nā mea ʻike manaʻo e hōʻoia i ka pololei.

4. Nānā Kaʻina Hana:ʻO nā kāmela i hoʻohui ʻia, nā spectrometers, a me nā mea ʻike ʻē aʻe e nānā i ke kaʻina hana wili i ka manawa maoli. Hiki ke ʻike koke ʻia a hoʻoponopono ʻia nā pilikia me ka alignment beam, ke komo ʻana, a i ʻole ka maikaʻi.

5. Palekana Interlocks:ʻO nā hale pale, nā puka, a me nā pihi e-stop e mālama i nā mea hoʻohana mai ka kukuna laser mana kiʻekiʻe. Hoʻopaʻa nā Interlocks i ka laser inā e uhaki ʻia nā protocol palekana.

No laila, i ka hōʻuluʻulu manaʻo, ʻo ka mīkini wiliwī laser he mea hoʻokele kamepiula, mea hana pono hana ʻenehana e hoʻohana ana i kahi kukuna laser i hoʻopaʻa ʻia no nā noi wiliwili ʻokiʻoki.

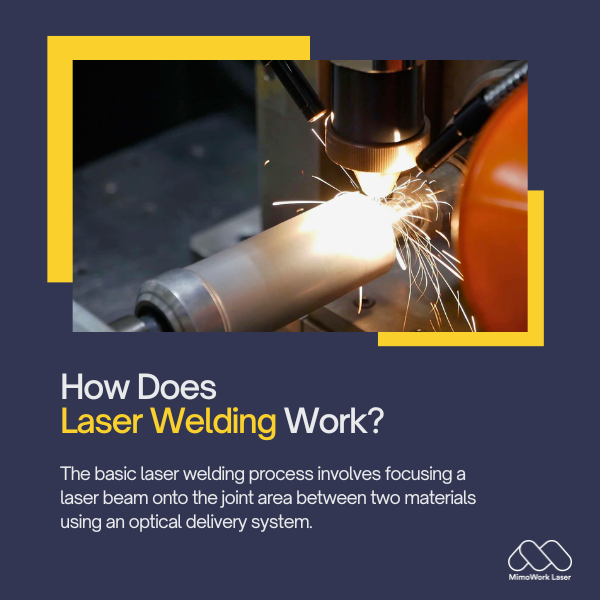

2. Pehea e hana ai ka welding laser?

ʻO kekahi mau ʻanuʻu koʻikoʻi i ke kaʻina hana welding laser penei:

1. Hoʻokumu ʻia ʻo Laser Beam:ʻO kahi diode laser solid-state a i ʻole nā kumu ʻē aʻe e hoʻopuka i kahi kukuna infrared.

2. Hāʻawi ʻia ke kukui: ʻO nā aniani, nā lens, a me ka nozzle e hoʻopaʻa pololei i ke kukui i kahi paʻa ma ka mea hana.

3. Mea hoʻomehana:Hoʻomaʻamaʻa wikiwiki ka lāʻau i ka mea, me ka mānoanoa kokoke i 106 W/cm2.

4. Heohe a hui:Hoʻokumu ʻia kahi wai hoʻoheheʻe liʻiliʻi kahi e hui ai nā mea. I ka paʻa ʻana o ka loko, hana ʻia kahi hui weld.

5. Hooluu a hooikaika hou: Hoʻomaʻalili ka wahi weld i nā kumukūʻai kiʻekiʻe ma luna o 104 ° C / kekona, e hana ana i kahi microstructure paʻakikī.

6. Holomua:Ke neʻe nei ke kukui a i ʻole nā ʻāpana i hoʻonohonoho hou ʻia a hana hou ke kaʻina hana no ka hoʻopau ʻana i ka weld seam. Hiki ke hoʻohana ʻia ke kinoea pale ʻole.

No laila, i ka hōʻuluʻulu manaʻo, hoʻohana ka welding laser i kahi kukuna laser i hoʻopaʻa ʻia a hoʻomalu ʻia i ka paikikala wela no ka hana ʻana i nā weld wahi wela haʻahaʻa.

Hāʻawi mākou i ka ʻike kōkua no nā mīkini welding laser

E like me nā hoʻonā i hoʻopilikino ʻia no kāu ʻoihana

3. Ua ʻoi aku ka maikaʻi o ka welding laser ma mua o MIG?

Ke hoʻohālikelike ʻia me nā kaʻina hana kuʻuna metala inert gas (MIG) ...

Hāʻawi ka welding laser i nā pono he nui:

1. pololei: Hiki ke hoʻopaʻa ʻia nā kukuna laser i kahi wahi liʻiliʻi 0.1-1mm, e hiki ai i nā welds pololei loa. He kūpono kēia no nā ʻāpana liʻiliʻi, kiʻekiʻe.

2. Ka māmā holo:ʻOi aku ka wikiwiki o ka welding rate no ka laser ma mua o MIG, ʻoi aku hoʻi ma nā anana lahilahi. Hoʻonui kēia i ka huahana a hoʻemi i nā manawa pōʻai.

3. Pono:ʻO ke kumu wela koʻikoʻi e hoʻopuka i ka distortion liʻiliʻi a me nā ʻāpana pili i ka wela. ʻO kēia ka hopena i nā welds ikaika a kiʻekiʻe.

4. 'Okomi:Hoʻohana maʻalahi ka welding laser me ka hoʻohana ʻana i nā robotics a me CNC. Hiki i kēia ke hana i nā ʻano paʻakikī a me ka hoʻomaikaʻi ʻana i ke kūpaʻa ʻana me ka wili lima MIG manual.

5. Mea Hana:Hiki i nā lasers ke hui pū me nā hui waiwai he nui, me nā welds metala like ʻole.

Eia nō naʻe, loaʻa ka MIG weldingkekahi mau ponoma luna o ka laser ma nā noi ʻē aʻe:

1. Koina:He haʻahaʻa haʻahaʻa ke kumu kūʻai hoʻopukapuka mua ma mua o nā ʻōnaehana laser.

2. Mea mānoanoa:ʻOi aku ka maikaʻi o ka MIG no ka hoʻopaʻa ʻana i nā ʻāpana kila mānoanoa ma luna o 3mm, kahi e pilikia ai ka absorption laser.

3. Ke kinoea pale:Hoʻohana ʻo MIG i kahi pale kinoea inert no ka pale ʻana i ka wahi weld, ʻoiai hoʻohana pinepine ʻo laser i kahi ala kaola i hoʻopaʻa ʻia.

No laila, i ka hōʻuluʻulu ʻana, makemake ʻia ka welding laser nopololei, automation, a me ka maikaʻi wili.

Akā hoʻomau ka MIG i ka hoʻokūkū no ka hana ʻana onā ana mānoanoa ma kahi kālā.

ʻO ke kaʻina hana kūpono e pili ana i ka noi welding kikoʻī a me nā koi ʻāpana.

4. ʻOi aku ka maikaʻi o ka welding laser ma mua o ka welding TIG?

ʻO ka hoʻoheheʻe ʻana o Tungsten inert gas (TIG) he manual, kaʻina hana akamai i hiki ke hana i nā hopena maikaʻi loa ma nā mea lahilahi.

Eia nō naʻe, ʻoi aku ka maikaʻi o ka welding laser ma mua o TIG:

1. Ka māmā holo:ʻOi aku ka wikiwiki o ka welding laser ma mua o TIG no nā noi hana ma muli o kāna kikoʻī automated. Hoʻonui kēia i ka throughput.

2. pololei:Hiki i ka kukuna laser kālele i ka pololei o ka hoʻonohonoho ʻana i loko o nā haneli o ka millimeter. ʻAʻole hiki ke hoʻohālikelike ʻia me ka lima kanaka me TIG.

3. Mana:Hoʻopaʻa paʻa ʻia nā ʻano hoʻololi e like me ka hoʻokomo wela a me ka weld geometry me ka laser, e hōʻoiaʻiʻo ana i nā hopena like ʻole ma luna o ka pūʻulu.

4. Mea Hana:ʻOi aku ka maikaʻi o TIG no nā mea conductive thinner, ʻoiai ʻo ka welding laser e wehe i kahi ʻano nui o nā hui like ʻole.

5. 'Okomi: Hiki i nā ʻōnaehana laser robotic ke hoʻopili piha ʻia me ka luhi ʻole, ʻoiai ʻo TIG maʻamau e koi i ka nānā piha a me ke akamai o ka mea hoʻohana.

Eia naʻe, mālama ʻo TIG welding i kahi pono noka hana pololei a i ʻole ka wiliwili ʻanakahi e pono e hoʻololi pono ʻia ka hoʻokomo wela. No kēia mau noi he mea waiwai ka hoʻopā ʻana o ka ʻenehana akamai.

5. He aha ka hemahema o Laser Welding?

E like me ke kaʻina hana ʻoihana, loaʻa i ka welding laser kekahi mau mea pono e noʻonoʻo ai:

1. Koina: ʻOiai e lilo ana i mea kūʻai aku, pono nā ʻōnaehana laser kiʻekiʻe i kahi hoʻopukapuka waiwai nui i hoʻohālikelike ʻia me nā ʻano hana welding ʻē aʻe.

2. Mea hoopau:ʻO nā nozzles kinoea a me nā optics e hoʻohaʻahaʻa i ka manawa a pono e pani ʻia, e hoʻohui i ke kumukūʻai o ka ʻona.

3. Palekana:Pono nā protocols koʻikoʻi a me nā hale palekana i hoʻopaʻa ʻia e pale i ka ʻike ʻana i ka kukuna laser kiʻekiʻe.

4. Aʻo:Pono nā mea hana i ka hoʻomaʻamaʻa ʻana e hana me ka palekana a mālama pono i nā lako welding laser.

5. Laina ʻike:Hele ka kukuna laser ma nā laina pololei, no laila e koi ana nā geometries paʻakikī i nā kaola he nui a i ʻole ka hoʻonohonoho hou ʻana o ka mea hana.

6. Ka hoʻopili ʻana:Hiki ke paʻakikī ke wili i kekahi mau mea e like me ke kila mānoanoa a i ʻole ka aluminika inā ʻaʻole lākou e komo pono i ka lōʻihi hawewe kikoʻī o ka laser.

Me ka mālama pono ʻana, ka hoʻomaʻamaʻa ʻana, a me ka loiloi kaʻina hana, akā, hāʻawi ka welding laser i ka huahana, pololei, a me nā pono maikaʻi no nā noi ʻoihana he nui.

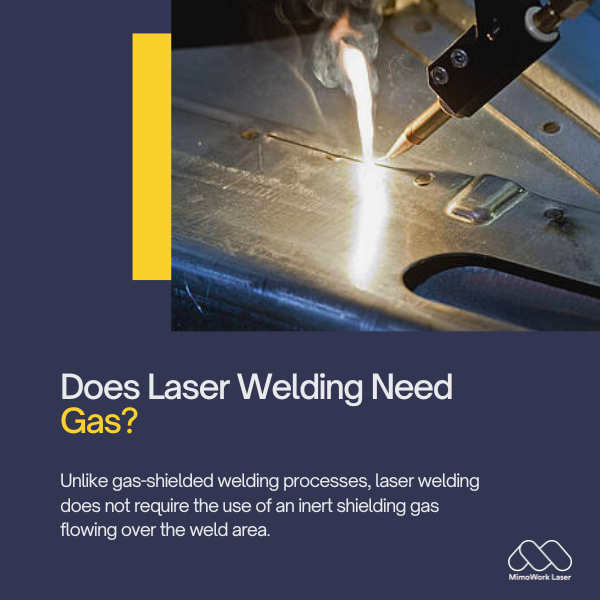

6. Pono anei ka welding laser i ke kinoea?

ʻAʻole like me nā kaʻina hana hoʻoheheʻe i pale ʻia i ke kinoea, ʻaʻole pono ka welding laser i ka hoʻohana ʻana i kahi kinoea pale inert e kahe ana ma luna o ka wahi weld. ʻO kēia no ka mea:

1. Ke hele nei ka kukuna laser i hoʻopaʻa ʻia ma ka lewa e hana i kahi wai wai weld ikaika kiʻekiʻe e hoʻoheheʻe a hui pū me nā mea.

2. ʻAʻole i hoʻokuʻu ʻia ka ea a puni e like me ke kinoea plasma arc a ʻaʻole ia e hoʻopilikia i ka hoʻokumu ʻana o ke kukui a weld.

3. Hoʻopaʻa wikiwiki ka weld mai ka wela nui i hana ʻia ma mua o ka hiki ʻana o nā oxides ma ka ʻili.

Eia nō naʻe, e pōmaikaʻi paha kekahi mau noi wili laser kūikawā mai ka hoʻohana ʻana i ke kinoea kōkua:

1. No nā metala reactive e like me ka aluminika, pale ke kinoea i ka loko weld wela mai ka oxygen i ka lewa.

2. Ma nā hana laser kiʻekiʻe, hoʻopaʻa ke kinoea i ka plume plasma i hana ʻia i ka wā o nā welds komo hohonu.

3. Hoʻomaʻemaʻe nā pahu kinoea i nā uahi a me nā ʻōpala no ka hoʻouna ʻana i nā kukui ʻoi aku ka maikaʻi ma nā wahi lepo a pena ʻia paha.

No laila i ka hōʻuluʻulu ʻana, ʻoiai ʻaʻole pono, hiki i ke kinoea inert ke hāʻawi i nā pono no nā noi wili laser paʻakikī a i ʻole nā mea waiwai. Akā hiki i ke kaʻina hana ke hana maikaʻi me ka ʻole.

▶ He aha nā mea hiki ke hoʻopaʻa ʻia i ka Laser Welded?

Ma kahi kokoke i nā metala āpau hiki ke hoʻopili ʻia me ka laserkila, aluminika, titanium, nickel alloys, a me nā mea hou aku.

Hiki i nā hui metala like ʻole. ʻO lākou ke kīpono e komo pono i ka hawewe laser.

▶ Pehea ka mānoanoa o nā mea hiki ke wili?

ʻO nā lau e like me ka lahilahi0.1mm a me ka mānoanoa e like me 25mmHiki ke hoʻopili pinepine ʻia i ka laser, ma muli o ka noi kikoʻī a me ka mana laser.

Pono paha nā ʻāpana mānoanoa i ka welding multi-pass a i ʻole optics kūikawā.

▶ He kūpono anei ka welding laser no ka hana ʻana i ka leo kiʻekiʻe?

ʻOiaʻiʻo. Hoʻohana maʻamau ʻia nā cell welding laser robotic i nā kaiapuni hana kiʻekiʻe kiʻekiʻe no nā noi e like me ka hana automotive.

Hiki ke ho'okō 'ia ka nui o nā mika i kēlā me kēia minuke.

▶ He aha nā ʻoihana e hoʻohana ai i ka welding laser?

Hiki ke loaʻa nā noi hoʻoheheʻe laser maʻamau makaʻa kaʻa, uila, lāʻau lapaʻau, aerospace, mea paahana / make, a me ka hana liʻiliʻi liʻiliʻi.

ʻO ka ʻenehanae hoʻonui mau ana i nā ʻāpana hou.

▶ Pehea wau e koho ai i kahi ʻōnaehana welding laser?

ʻO nā mea e noʻonoʻo ai e pili ana i nā mea hana, ka nui/ka mānoanoa, ka pono o ka hoʻokomo ʻana, ka waihona kālā, a me ka maikaʻi o ka weld e pono ai.

Hiki i nā mea hoʻolako kaulana ke kōkua i ke kuhikuhi ʻana i ke ʻano laser kūpono, mana, optics, a me ka automation no kāu noi kikoʻī.

▶ He aha nā ʻano welds hiki ke hana ʻia?

ʻO nā ʻenehana hoʻoheheʻe laser maʻamau e pili ana i ka ʻūhā, ka ʻūhā, ka pū, ka ʻō ʻana, a me nā welds pale.

Ke puka mai nei kekahi mau ʻano hana hou e like me ka laser additive manufacturing no ka hoʻoponopono a me nā noi prototyping.

▶ He kūpono anei ka welding laser no ka hana hoʻoponopono?

ʻAe, kūpono maikaʻi ka welding laser no ka hoʻoponopono pololei ʻana i nā mea waiwai kiʻekiʻe.

ʻO ka hoʻokomo wela i hoʻemi ʻia e hōʻemi i ka pōʻino hou aku i nā mea kumu i ka wā e hoʻoponopono ai.

Makemake ʻoe e hoʻomaka me kahi mīkini welder laser?

No ke aha e noʻonoʻo ʻole ai iā mākou?

Ka manawa hoʻouna: Feb-12-2024