Hiki iā ʻoe ke ʻoki laser i ka ʻūhā EVA?

Papa maʻiʻo:

He aha ka EVA Foam?

ʻO ka EVA foam, i kapa ʻia ʻo Ethylene-Vinyl Acetate foam, he ʻano mea synthetic i hoʻohana nui ʻia no ka nui o nā noi. Hana ʻia ia ma ka hoʻohui ʻana i ka ethylene a me ka vinyl acetate ma lalo o ka wela a me ke kaomi, e loaʻa ana i kahi mea paʻa paʻa, māmā, a maʻalahi hoʻi. ʻIke ʻia ʻo EVA foam no kāna mau mea cushioning a me ka haʻalulu, e lilo ia i mea koho kaulana no nā mea haʻuki, kāmaʻa, a me nā mea hana.

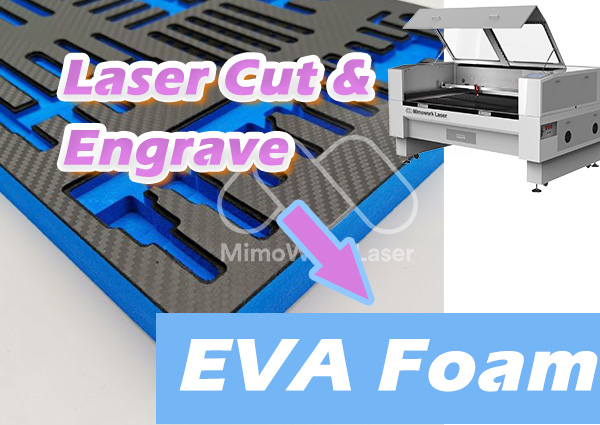

Hoʻonohonoho ʻia ʻo Laser Cut Eva Foam

ʻO ka ʻoki ʻoki ʻana he ala kaulana no ka hana ʻana a me ka ʻoki ʻana i ka pahu EVA ma muli o kona pololei a me ka versatility. Hiki ke ʻokoʻa nā hoʻonohonoho ʻoki ʻoki laser maikaʻi loa no ka pua EVA ma muli o ka mea ʻoki laser kikoʻī, kona mana, ka mānoanoa a me ka nui o ka pua, a me nā hopena ʻoki i makemake ʻia. He mea nui e hana i nā ʻoki hoʻāʻo a hoʻoponopono i nā hoʻonohonoho e like me ia. Eia naʻe, eia kekahi mau alakaʻi maʻamau e hoʻomaka ai ʻoe:

▶ Mana

E hoʻomaka me kahi hoʻonohonoho mana haʻahaʻa, ma kahi o 30-50%, a hoʻonui mālie inā pono. Pono paha ka ʻōhū EVA mānoanoa a ʻoi aku ka ʻoi aku o ka mana, ʻoiai ʻo ka huʻa lahilahi e koi aku i ka mana haʻahaʻa e pale aku ai i ka hoʻoheheʻe nui ʻana a i ʻole ka hū.

▶ Māmā

E hoʻomaka me ka wikiwiki o ka ʻoki ʻana, ma kahi o 10-30 mm/s. Eia hou, pono ʻoe e hoʻoponopono i kēia ma muli o ka mānoanoa a me ka paʻa o ka ʻūhā. Hiki i nā māmā māmā ke hopena i nā ʻoki maʻemaʻe, ʻoiai ʻoi aku ka wikiwiki o ka wikiwiki e kūpono i ka huʻa lahilahi.

▶ Nānā

E hōʻoia i ka nānā pono ʻana o ka laser ma ka ʻili o ka pahu EVA. E kōkua kēia i ka loaʻa ʻana o nā hopena ʻoki maikaʻi. E hahai i nā ʻōlelo aʻoaʻo i hāʻawi ʻia e ka mea hana ʻoki laser e pili ana i ka hoʻoponopono ʻana i ka lōʻihi o ke kiko.

▶ Oki hoao

Ma mua o ka ʻoki ʻana i kāu hoʻolālā hope, e hana i nā ʻoki hoʻāʻo ma kahi ʻāpana liʻiliʻi o ka pahu EVA. E hoʻohana i nā mana like ʻole a me nā hoʻonohonoho wikiwiki e ʻimi i ka hui maikaʻi loa e hāʻawi ai i nā ʻoki maʻemaʻe a pololei me ka ʻole o ka wela a me ka heheʻe.

Video | Pehea e ʻoki ʻia ai ʻo Laser Cut Foam

ʻO Laser Cut Foam Cushion no ka noho kaʻa!

Pehea ka mānoanoa e hiki ai i ka Laser Cut Foam?

ʻO nā nīnau e pili ana i ka ʻoki ʻana i ka pahu eva

Manaʻo ʻia ka mīkini ʻoki ʻoki ʻoki no ka EVA foam

He palekana paha i ka ʻoki ʻana i ka EVA Foam?

Ke hoʻopili ka kukuna laser me ka EVA foam, hoʻomaʻamaʻa a hoʻoheheʻe ia i ka mea, hoʻokuʻu i nā kinoea a me nā mea ʻala. ʻO ka uahi i hana ʻia mai ka ʻoki ʻoki ʻana i ka pahu EVA maʻamau i loko o nā mea hoʻohuihui kūlohelohe (VOC) a me nā ʻāpana liʻiliʻi a i ʻole nā palapala. Hiki i kēia mau mahu ke ʻala a loaʻa paha nā mea e like me ka acetic acid, formaldehyde, a me nā huahana hoʻopau ʻē aʻe.

He mea nui ka loaʻa ʻana o ka ventila kūpono i ka wā e ʻoki ai i ka pahu EVA e hoʻoneʻe i ka uahi mai ka wahi hana. ʻO ka hoʻoheheʻe ʻana kūpono e kōkua i ka mālama ʻana i kahi wahi hana palekana ma o ka pale ʻana i ka hōʻiliʻili ʻana o nā kinoea hiki ke hoʻopōʻino a hōʻemi i ka ʻala e pili ana i ke kaʻina hana.

Aia kekahi noi mea waiwai?

ʻO ke ʻano maʻamau o ka pua i hoʻohana ʻia no ka ʻoki ʻana i ka laserʻūhā polyurethane (puʻa PU). Palekana ʻo PU foam i ka ʻoki ʻia ʻana i ka laser no ka mea he liʻiliʻi ka uahi a ʻaʻole hoʻokuʻu i nā mea ʻawaʻawa ke ʻike ʻia i ka kukuna laser. Ma waho aʻe o ka puʻupuʻu PU, nā huʻa i hana ʻia maipolyester (PES) a me ka polyethylene (PE)He kūpono hoʻi no ka ʻoki ʻana i ka laser, ke kahakaha ʻana, a me ka hōʻailona ʻana.

Eia nō naʻe, hiki ke hoʻohua i nā kinoea ʻawaʻawa i ka wā e hoʻohana ʻia ai ka pahu PVC. Hiki ke koho maikaʻi ʻia kahi mea hoʻoheheʻe fume e noʻonoʻo inā pono ʻoe e ʻoki i ka laser-ʻoki ʻana i kēlā mau huʻa.

ʻOkiʻoki i ka pua: Laser VS. CNC VS. Mea ʻoki Make

ʻO ke koho o ka mea hana maikaʻi loa e hilinaʻi nui ʻia i ka mānoanoa o ka EVA foam, ka paʻakikī o nā ʻoki, a me ke kiʻekiʻe o ka pololei e pono ai. ʻO nā pahi hoʻohana, ʻokiʻoki, nā ʻoki ʻoki uea wela, nā mea ʻoki laser CO2, a i ʻole nā mea ala CNC hiki ke lilo i mau koho maikaʻi i ka wā e ʻoki ai i ka pahu EVA.

Hiki ke koho maikaʻi ʻia ka pahi ʻoi a me ka ʻokiʻoki inā pono ʻoe e hana i nā kihi curved pololei a maʻalahi paha, ʻoi aku ka maikaʻi o ke kumu kūʻai. Eia nō naʻe, hiki ke ʻoki ʻia a ʻokiʻoki ʻia paha nā lau ʻeleʻele EVA foam wale nō.

Inā ʻoe i ka ʻoihana, Automation, a me ka pololei ʻo ia kāu mea nui e noʻonoʻo ai.

Ina pela,he mea ʻokiʻoki laser CO2, CNC router, a me Die Cutting Machinee noonooia.

▶ Alaula CNC

Inā loaʻa iā ʻoe kahi mea hoʻokele CNC (Computer Numerical Control) me kahi mea ʻoki kūpono (e like me ka mea hana rotary a i ʻole ka pahi), hiki ke hoʻohana ʻia no ka ʻoki ʻana i ka pahu EVA. Hāʻawi nā mea hoʻokele CNC i ka pololei a hiki ke mālamanā lau ʻeleʻele mānoanoa.

▶ Mīkini ʻoki Make

ʻO kahi mea ʻoki laser, e like me ka laser CO2 desktop a i ʻole ka laser fiber, he koho pololei a maikaʻi hoʻi no ka ʻoki ʻana i ka pahu EVA, ʻoi aku no kapaʻakikī a paʻakikī paha. Hāʻawi nā mea ʻoki lasermaʻemaʻe, hoʻopaʻa ʻiaa hoʻohana pinepine ʻia nonui-nuinā papahana.

Ka Pono o ka Laser Cutting Foam

I ka wā e ʻoki ai i ka ʻūhā ʻoihana, nā pono omea ʻoki laserma luna o nā mea hana ʻoki ʻē aʻe ua maopopo. Hiki iā ia ke hana i nā contours maikaʻi loa ma muli oʻoki pololei a pili ʻole, me ka nui loa clihilihi a palahalaha.

I ka hoʻohana ʻana i ka ʻoki ʻana i ka wai, e omo ʻia ka wai i loko o ka huʻa i ka wā o ka hoʻokaʻawale ʻana. Ma mua o ka hana houʻana, pono e hoʻomaloʻoʻia ka mea, he hana manawa. Hoʻopau ka ʻoki laser i kēia kaʻina hana a hiki iā ʻoehoʻomau i ka hanaka mea koke. ʻO ka hoʻohālikelike ʻana, ʻike maopopo ka laser a ʻo ia ka mea hana helu hoʻokahi no ka hoʻoili ʻana i ka pua.

Ka hopena

ʻO nā mīkini ʻoki laser a MimoWork no ka EVA foam ua hoʻolako ʻia me nā ʻōnaehana hoʻoheheʻe fume i kūkulu ʻia e kōkua i ka hopu ʻana a hoʻoneʻe pololei i ka mahu mai kahi ʻoki. ʻO kahi ʻē aʻe, hiki ke hoʻohana ʻia nā ʻōnaehana ventila hou, e like me nā mea pā a i ʻole nā mea hoʻomaʻemaʻe ea, e hōʻoia i ka lawe ʻia ʻana o ka mahu i ka wā o ke kaʻina ʻoki.

Nā mea maʻamau o ka ʻoki ʻana i ka laser

FAQ

Hoʻokuʻu ʻia ka huʻa EVA ʻoki laser i nā VOC, ka waikawa acetic, a me ka formaldehyde, he mea pōʻino ke hoʻohu ʻia. E hoʻohana i kahi mea hoʻoheheʻe hū (e laʻa, Fume Extractor 2000) me kāu mea ʻoki laser e wehe i kēia mau mahu. E hōʻoia i ka hoʻoheheʻe maikaʻi ʻia o ka lumi hana me nā mea pā a i ʻole nā puka puka makani. E hōʻalo i ka hōʻike lōʻihi ma ke kau ʻana i ka respirator inā pono. E hoʻomaʻemaʻe mau i ka ʻōnaehana hoʻopau o ka mea ʻoki no ka mālama pono ʻana, no ka mea hiki i ke kūkulu ʻia ke hōʻemi i ka wehe ʻana o ka uahi a hoʻoweliweli i ke ahi.

ʻO ka mānoanoa kiʻekiʻe e pili ana i ka mana o ka laser. ʻO nā mea ʻoki laser CO2 papapihi (e laʻa, ka Mīkini ʻoki Laser Acrylic) e lawelawe maʻamau a hiki i ka 15-20mm mānoanoa EVA foam. Hiki i nā ʻano hana ʻenehana e like me ka Extended Flatbed Laser Cutter 160, me ka mana kiʻekiʻe, hiki ke ʻoki a hiki i ka 50mm mānoanoa o ka pahu i ka wā e hui pū ʻia me nā wikiwiki lohi (5-10 mm/s) e hōʻoia i ka hoʻopau piha ʻana. Pono paha ka ʻoki mānoanoa i nā kaʻa he nui, akā he mea koʻikoʻi ka ʻoki hoʻāʻo e pale aku i ka ʻoki piha ʻole a i ʻole ka nui o ka charring.

He mea koʻikoʻi nā ʻoki hoʻāʻo no ka hoʻomaʻemaʻe ʻana i nā hoʻonohonoho no kāu ʻōhū kikoʻī. ʻOkoʻa ka ʻōhua EVA i ka mānoanoa a me ka mānoanoa, no laila me nā alakaʻi maʻamau, ʻokoʻa ka mana a me ka wikiwiki. ʻO ka ʻoki hoʻāʻo ʻana i kahi ʻāpana huʻa liʻiliʻi e kōkua i ka ʻike ʻana i ke koena kūpono - ʻo ka nui o ka mana ke kumu o ka hū, a ʻo ka liʻiliʻi o nā lau liʻiliʻi i nā kihi. Mālama kēia i kāu papahana hope (e laʻa, nā ʻūlū noho kaʻa, nā hana hana) i pololei, i hoʻopaʻa ʻia nā ʻaoʻao, mālama i ka manawa a me nā mea ma ka pale ʻana i nā hewa me ka mea ʻoki laser.

Ka manawa hoʻouna: Mei-18-2023