Dab tsi yog laser vuam? Laser Vuam piav qhia! Txhua yam koj yuav tsum paub txog laser vuam, suav nrog cov hauv paus ntsiab lus tseem ceeb thiab cov txheej txheem tseem ceeb!

Coob tus neeg muas zaub tsis to taub cov ntsiab cai ua haujlwm ntawm txoj cai laser vuam vuam tshuab, txawm li cas los pab txoj cai txoj cai Laser Vuam vuam.

Dab tsi yog laser vuam?

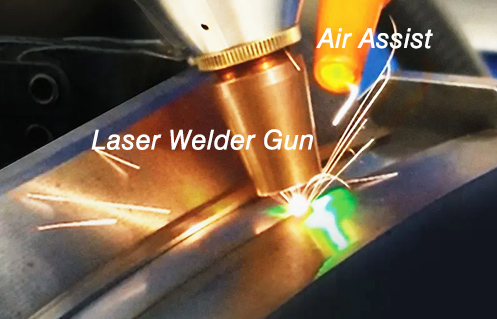

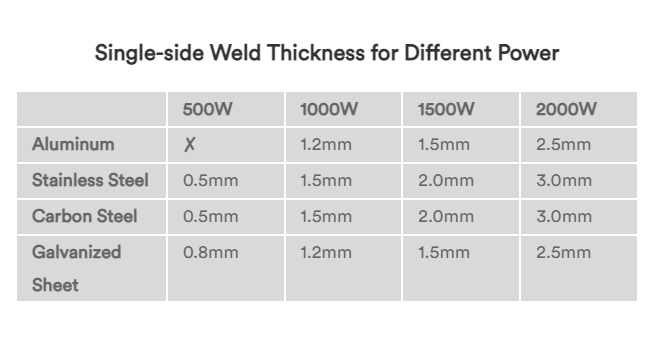

Laser Vuam yog ib hom ntawm cov nqaj laser yog los ntawm kev siv hluav taws xob tshwj xeeb, thiab tom qab ntawd hloov pauv hluav taws xob hnyav, thaum lub nqaj Thiab cov ua haujlwm daig sib chwv, lub zog yuav nqus tau los ntawm daim ntawv ua haujlwm, thaum qhov kub txog qhov tseeb melting taw tes ntawm cov khoom tuaj yeem welded.

Raws li tus thawj tswj hwm tsev kawm ntawv ntawm vuam pas, laser vuam muaj ob qhov kev sib tw vuam (cov kub taub hau vuam thiab tob nkag) vuam. Cov cua sov tsim los ntawm tshav kub conduction vuam yog diffused rau cov haujlwm los ntawm kev hloov pauv tshav kub, uas feem ntau siv nyob rau hauv vuam ntawm tsawg-ish Cheebtsam. Kaus ntxaij Kusion vuam vacing vaporizes cov khoom thiab ua ntau cov ntshav ntshav loj. Vim yog lub siab kom sov, yuav muaj qhov nyob sab xub ntiag ntawm lub pas dej molten. Kev sib sib zog nqus vuam yog qhov feem ntau siv cov roj Laser Vuam vuam, nws tuaj yeem Weld cov haujlwm ua kom huv si, thiab lub zog tawm hluav taws xob yog loj heev, ua rau nrawm vuam.

Cov txheej txheem tsis nyob hauv Laser Vuam

Muaj ntau cov txheej txheem tsis cuam tshuam uas cuam tshuam rau kev ua kom zoo nkauj, laser mem tes WaveForm, defraniving, vuam ceev thiab xaiv ntawm cov roj av roj.

Laser Hluav Taws Xob Hluav Taws Xob

Fais fab ceev yog ib qho tseem ceeb tshaj plaws hauv kev ua laser. Nrog lub zog hluav taws xob siab dua, txheej saum npoo av tuaj yeem ua kom sov kom npau npau rau lub microsecond, ua rau muaj ntau yam kev vaporization loj. Yog li ntawd, lub siab-zog ntom yog qhov zoo dua rau cov txheej txheem tshem tawm xws li drilling, txiav thiab engraving. Rau cov hluav taws xob tsis tshua muaj zog, nws siv ntau lab tus kiv cua kom ncav cuag lub boiling taw tes, thiab ua ntej kom yooj yim los ua ib qho zoo melting weld. Yog li ntawd, nyob rau hauv daim ntawv ntawm tshav kub conduction laser vuam, muaj hwj chim siv hluav taws xob ntau yog 104-106W / cm2.

Laser mem tes WaveForm

Laser mem tes WaveForm tsis tsuas yog ib qho tseem ceeb rau kev paub qhov txawv ntawm cov khoom siv, tab sis kuj tseem ceeb ntsuas los txiav txim cov khoom ntim thiab tus nqi ua cov khoom siv. Thaum lub siab siv nqaj yog tua pov tseg rau saum npoo ntawm cov khoom siv yuav muaj 60 ~ 90% ntawm cov khoom siv laser, nyiaj, tooj liab, titanium thiab lwm cov ntaub ntawv uas muaj Muaj zog xav txog thiab nrawm nrawm hloov. Qhov kev sib cuam tshuam ntawm cov hlau sib txawv nrog lub sijhawm nyob rau lub sijhawm laser. Thaum lub qhov cub saum npoo ntawm cov khoom nce mus rau qhov pom melting, cov kev xav txo sai, thiab thaum lub xeev melting, cov kev sib tw muaj txiaj ntsig ntawm tus nqi.

Laser Pulse Dav

Mem tes dav yog qhov tseem ceeb parameter ntawm pulsed laser vuam. Cov mem tes dav tau txiav txim siab los ntawm qhov tob ntawm kev nkag mus thiab qhov chaw kub cuam tshuam. Ntev cov mem tes dav yog, qhov loj dua lub tshav kub tuaj yeem yog, thiab qhov tob ntawm kev nkag mus nce nrog 1/2 lub zog ntawm cov mem tes dav. Txawm li cas los xij, qhov nce ntawm mem tes dav yuav txo cov peel lub zog, yog li qhov nce ntawm cov vuam hlau loj, tshwj xeeb yog tsim nyog rau lap vuam ntawm nyias thiab tuab daim hlau. Txawm li cas los xij, qis dua lub zog hluav taws xob tau tshwm sim ntau tshaj tshav kub tawm, thiab txhua cov khoom muaj cov ntsuas kev pom zoo ntawm qhov tob ntawm qhov nkag mus.

Defocus kom muaj nuj nqis

Laser vuam feem ntau yuav tsum muaj qee qhov kev tiv thaiv, vim tias lub zog ceev ntawm lub qhov chaw laser yog qhov siab dhau heev, uas yog qhov yooj yim los kev cov khoom siv vuam rau hauv qhov. Kev faib tawm ntawm lub zog ceev yog cov uniform nyob rau hauv txhua lub dav hlau pov tseg los ntawm lub laser tsom.

Muaj ob lub defocus hom:

Zoo thiab tsis zoo defocus. Yog tias lub dav hlau dav dav nyob saum cov workpiece, nws yog qhov zoo defocus; Txwv tsis pub, nws yog qhov tsis zoo ntshai. Raws li cov dav hlau opticStory, thaum qhov kev ncua deb ntawm qhov kev tiv thaiv zoo thiab tsis zoo rau lub dav hlau sib npaug, tab sis qhov tseeb, cov tau txais Molten pas dej zoo txawv. Nyob rau hauv cov ntaub ntawv ntawm qhov tsis zoo defocus, ntau dua kev nkag mus tau, uas cuam tshuam nrog cov txheej txheem tsim ntawm Molten pas dej.

Vuam ceev

Welding Welding Kev txiav txim siab vuam nto zoo, nkag siab tob, thaj chaw kub thiab lwm yam. Lub vuam ceev yuav cuam tshuam rau cov kev tawm tswv yim cua sov rau ib teev sijhawm. Yog hais tias lub vuam ceev yog qeeb heev, cov lus tawm thaum tshav kub kub dhau lawm, ua rau hauv workpiece hlawv los ntawm. Yog hais tias lub vuam ceev nrawm heev, cov lus tawm tshiab yog tsawg heev, ua rau lub workpiece vuam ib nrab thiab tsis tiav. Txo Vuam ceev feem ntau yog siv los txhim kho kev nkag mus.

Ntu Kev Tiv Thaiv Cov Roj

Ntu kev tiv thaiv roj yog ib txoj kev ua haujlwm tseem ceeb hauv siab lub zog laser vuam. Ntawm ib sab tes, los tiv thaiv cov khoom hlau los ntawm kev tawm hws thiab paug cov iav tsom; Ntawm qhov tod tes, nws yog los tiv thaiv cov ntshav tawm hauv cov txheej txheem vuam los ntawm kev ua kom pom kev ntau dhau thiab tiv thaiv lub laser los ntawm mus txog saum npoo ntawm cov khoom. Nyob rau hauv cov txheej txheem ntawm laser vuam, helon, nitrogen thiab lwm cov roj av siv los tiv thaiv cov pas dej Molteniece los ntawm oxidation hauv vuam engineering. Yam khoom xws li hom kev tiv thaiv roj, qhov loj ntawm lub tshuab cua ntws thiab lub tshuab ua kom muaj qhov cuam tshuam zoo rau kev xav tau ntawm vuam zoo.

Peb pom zoo tuav tes laser laser:

Laser Welder - Chaw Ua Haujlwm

Hnov Kub Ntau Ib puag ncig ua haujlwm: 15 ~ 35 ℃

◾ Cov av noo ntawm cov chaw ua haujlwm: <70% tsis muaj hws

◾ Muab dej txias: Dej Chiller yog qhov tsim nyog vim muaj kev tshem tawm cov cua sov

(Cov kev siv cov ncauj lus kom ntxaws thiab qhia txog cov dej chiller, koj tuaj yeem tshawb xyuas:ME NYUAM-FEFEING NTSEEG RAU CO2 Laser System)

Xav paub ntau ntxiv txog Laser Whders?

Lub Sijhawm Post: Dec-22-2022