Yuav Ua Li Cas Xaiv Cov Roj Sib Xyaws Zoo Tshaj Plaws Rau Koj Lub Laser Vuam?

Cov Hom, Cov Txiaj Ntsig, thiab Cov Kev Siv

Kev Taw Qhia:

Tej Yam Tseem Ceeb Yuav Tsum Paub Ua Ntej Dhia Mus Rau Hauv Dej

Kev vuam laser yog ib txoj kev vuam uas siv lub teeb laser los yaj cov khoom siv ntawm qhov chaw ua haujlwm thiab tom qab ntawd tsim cov vuam tom qab txias. Hauv kev vuam laser, roj ua lub luag haujlwm tseem ceeb.

Cov roj tiv thaiv tsis yog tsuas yog cuam tshuam rau qhov tsim ntawm cov kab vuam, qhov zoo ntawm cov kab vuam, qhov nkag mus ntawm cov kab vuam, thiab qhov dav ntawm qhov nkag mus xwb tab sis kuj cuam tshuam ncaj qha rau qhov zoo thiab kev ua haujlwm ntawm laser vuam.

Cov roj twg xav tau rau kev vuam laser?Tsab xov xwm no yuav saib tob txogqhov tseem ceeb ntawm cov pa roj laser vuam, cov pa roj siv, thiab lawv ua dab tsi.

Peb kuj yuav pom zoolub tshuab laser vuam zoo tshaj plawsrau koj cov kev xav tau.

Vim li cas thiaj xav tau roj rau Laser Welding?

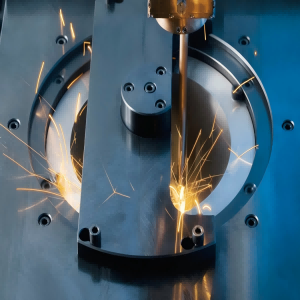

Laser Beam Vuam

Thaum lub sijhawm vuam laser, lub teeb laser muaj zog heev yog tsom mus rau thaj chaw vuam ntawm qhov workpiece.

Ua rau yaj sai sai ntawm cov khoom siv saum npoo ntawm qhov workpiece.

Cov roj yuav tsum tau siv thaum lub sijhawm vuam laser los tiv thaiv thaj chaw vuam.

Tswj qhov kub thiab txias, txhim kho qhov zoo ntawm qhov vuam, thiab tiv thaiv lub kaw lus kho qhov muag.

Kev xaiv hom roj thiab cov yam ntxwv ntawm kev muab roj yog cov yam tseem ceeb uas ua kom muaj kev ua haujlwm zoo.

Thiab cov txheej txheem vuam laser ruaj khov thiab tau txais cov txiaj ntsig vuam zoo.

1. Kev Tiv Thaiv Cov Chaw Vuam

Thaum lub sijhawm vuam laser, thaj chaw vuam raug rau sab nraud thiab yooj yim cuam tshuam los ntawm cov pa oxygen thiab lwm yam roj hauv huab cua.

Cov pa oxygen ua rau muaj cov tshuaj oxidation uas yuav ua rau qhov zoo ntawm qhov vuam txo qis, thiab ua rau muaj cov qhov thiab cov khoom sib xyaw. Qhov vuam tuaj yeem tiv thaiv tau zoo los ntawm kev ua pa oxygen los ntawm kev muab cov roj tsim nyog, feem ntau yog cov roj inert xws li argon, rau thaj chaw vuam.

2. Kev Tswj Kub

Kev xaiv roj thiab kev muab roj tuaj yeem pab tswj qhov kub ntawm thaj chaw vuam. Los ntawm kev kho qhov nrawm thiab hom roj, qhov nrawm txias ntawm thaj chaw vuam tuaj yeem raug cuam tshuam. Qhov no yog qhov tseem ceeb los tswj thaj chaw kub-cuam tshuam (HAZ) thaum lub sijhawm vuam thiab txo qhov thermal distortion.

3. Kev Txhim Kho Zoo ntawm Weld

Qee cov pa roj pab, xws li oxygen lossis nitrogen, tuaj yeem txhim kho qhov zoo thiab kev ua haujlwm ntawm cov vuam. Piv txwv li, kev ntxiv oxygen tuaj yeem txhim kho qhov nkag mus ntawm qhov vuam thiab ua kom qhov vuam ceev dua, thaum tseem cuam tshuam rau cov duab thiab qhov tob ntawm qhov vuam.

4. Roj Txias

Hauv kev siv laser vuam, thaj chaw vuam feem ntau raug cuam tshuam los ntawm qhov kub siab. Kev siv lub tshuab cua txias roj tuaj yeem pab tswj qhov kub ntawm thaj chaw vuam thiab tiv thaiv kom tsis txhob kub dhau. Qhov no yog qhov tseem ceeb los txo qhov kev ntxhov siab thermal hauv thaj chaw vuam thiab txhim kho qhov zoo ntawm kev vuam.

Kev Siv Tshuab Laser Beam Vuam

5. Kev Tiv Thaiv Roj Ntawm Cov Tshuab Kho Qhov Muag

Lub teeb laser yog tsom mus rau thaj chaw vuam los ntawm lub kaw lus kho qhov muag.

Thaum lub sijhawm soldering, cov khoom siv molten thiab aerosols tsim tawm yuav ua rau cov khoom siv kho qhov muag puas tsuaj.

Los ntawm kev qhia cov pa roj rau hauv thaj chaw vuam, qhov kev pheej hmoo ntawm kev ua qias tuaj yeem txo qis thiab lub neej ntawm lub kaw lus kho qhov muag tau ntev dua.

Cov Gases Twg Siv Hauv Laser Welding?

Hauv kev vuam laser, cov roj tuaj yeem cais cov huab cua ntawm lub phaj vuam thiab tiv thaiv nws kom tsis txhob cuam tshuam nrog huab cua. Ua li no, qhov chaw vuam ntawm lub phaj hlau yuav dawb dua thiab zoo nkauj dua. Kev siv roj kuj tiv thaiv cov lens ntawm cov hmoov av vuam. Feem ntau, cov roj hauv qab no yog siv:

1. Cov roj tiv thaiv:

Cov pa roj tiv thaiv, qee zaum hu ua "cov pa roj inert," ua lub luag haujlwm tseem ceeb hauv cov txheej txheem laser vuam. Cov txheej txheem laser vuam feem ntau siv cov pa roj inert los tiv thaiv lub pas dej vuam. Cov pa roj tiv thaiv feem ntau siv hauv laser vuam feem ntau suav nrog argon thiab neon. Lawv cov khoom siv lub cev thiab tshuaj lom neeg sib txawv, yog li lawv cov teebmeem ntawm qhov vuam kuj sib txawv.

Cov Roj Tiv Thaiv:Argon

Argon yog ib qho ntawm cov pa roj inert uas siv ntau tshaj plaws.

Nws muaj qib siab ntawm ionization nyob rau hauv qhov kev ua ntawm lub laser, uas tsis zoo rau kev tswj hwm kev tsim cov plasma huab, uas yuav muaj qee qhov cuam tshuam rau kev siv lasers zoo.

Qhov xwm txheej inert ntawm argon ua rau nws tawm ntawm cov txheej txheem soldering, thaum nws kuj tso cua sov tawm zoo, pab tswj qhov kub hauv thaj chaw soldering.

Cov Roj Tiv Thaiv:Neon

Neon feem ntau siv ua roj inert, zoo ib yam li argon, thiab feem ntau yog siv los tiv thaiv thaj chaw vuam los ntawm cov pa oxygen thiab lwm yam kuab paug hauv ib puag ncig sab nraud.

Nws yog ib qho tseem ceeb uas yuav tsum nco ntsoov tias neon tsis haum rau txhua daim ntawv thov laser welding.

Nws feem ntau yog siv rau qee qhov haujlwm vuam tshwj xeeb, xws li vuam cov ntaub ntawv tuab dua lossis thaum xav tau cov seams vuam tob dua.

2. Cov Roj Pab Txhawb:

Thaum lub sijhawm vuam laser, ntxiv rau cov roj tiv thaiv tseem ceeb, cov roj pabcuam kuj tseem siv tau los txhim kho kev ua haujlwm vuam thiab zoo. Cov hauv qab no yog qee cov roj pabcuam siv hauv kev vuam laser.

Cov Roj Pab:Cov pa oxygen

Cov pa oxygen feem ntau siv ua roj pab thiab siv tau los ua kom sov thiab vuam tob dua thaum vuam.

Kev ntxiv cov pa oxygen tuaj yeem ua rau kom vuam ceev thiab nkag mus tau zoo dua, tab sis yuav tsum tau tswj kom zoo kom tsis txhob muaj cov pa oxygen ntau dhau ua rau muaj teeb meem oxidation.

Cov Roj Pab:Hydrogen / Hydrogen Sib Xyaws

Hydrogen txhim kho qhov zoo ntawm cov welds thiab txo qhov tsim ntawm porosity.

Cov khoom sib xyaw ntawm argon thiab hydrogen yog siv rau hauv qee qhov kev siv tshwj xeeb, xws li vuam cov hlau tsis xeb. Cov hydrogen hauv cov khoom sib xyaw feem ntau yog li ntawm 2% txog 15%.

Cov Roj Tiv Thaiv:Nitrogen

Nitrogen kuj tseem siv tau ua roj pabcuam hauv laser vuam.

Lub zog ionization ntawm nitrogen yog nruab nrab, siab dua li argon thiab qis dua li hydrogen.

Feem ntau, qib ionization yog nyob rau hauv qhov kev ua ntawm lub laser. Nws tuaj yeem txo qhov kev tsim ntawm cov huab plasma, muab cov vuam zoo dua thiab cov tsos, thiab txo qhov cuam tshuam ntawm cov pa oxygen rau ntawm cov vuam.

Nitrogen kuj tseem siv tau los tswj qhov kub ntawm thaj chaw vuam thiab txo qhov tsim ntawm cov npuas thiab cov qhov hws.

Cov Roj Tiv Thaiv:Helium

Helium feem ntau yog siv rau kev vuam laser muaj zog heev vim nws muaj cov thermal conductivity tsawg thiab tsis yooj yim ionized, uas ua rau lub laser hla mus zoo thiab lub zog ntawm lub teeb mus txog qhov chaw ua haujlwm yam tsis muaj kev cuam tshuam.

Ua rau muaj zog vuam ntau dua. Helium kuj tseem siv tau los txhim kho qhov zoo ntawm vuam thiab tswj qhov kub ntawm vuam. Qhov no yog cov roj tiv thaiv zoo tshaj plaws uas siv hauv kev vuam laser, tab sis nws kim heev.

3. Roj Txias:

Cov roj txias feem ntau siv thaum lub sijhawm vuam laser los tswj qhov kub ntawm thaj chaw vuam, tiv thaiv kom tsis txhob kub dhau, thiab tswj qhov zoo ntawm kev vuam. Cov hauv qab no yog qee cov roj txias uas siv ntau:

Roj Txias / Nruab Nrab:Dej

Dej yog ib qho khoom siv txias uas feem ntau siv los txias cov tshuab hluav taws xob laser thiab cov tshuab vuam laser optical.

Cov tshuab ua kom txias dej tuaj yeem pab tswj kom qhov kub thiab txias ntawm lub tshuab hluav taws xob laser thiab cov khoom siv kho qhov muag kom ntseeg tau tias lub teeb laser ruaj khov thiab ua tau zoo.

Roj Txias / Nruab Nrab:Cov Pa Roj Hauv Huab Cua

Hauv qee cov txheej txheem laser welding, cov pa roj ambient atmospheric tuaj yeem siv rau kev txias.

Piv txwv li, nyob rau hauv lub tshuab hluav taws xob kho qhov muag ntawm lub tshuab hluav taws xob laser, cov pa roj ib puag ncig tuaj yeem muab cov nyhuv txias.

Roj Txias / Nruab Nrab:Cov Pa roj Inert

Cov pa roj inert xws li argon thiab nitrogen kuj tseem siv tau ua cov pa roj txias.

Lawv muaj cov thermal conductivity qis dua thiab siv tau los tswj qhov kub ntawm thaj chaw vuam thiab txo qhov chaw cuam tshuam los ntawm cua sov (HAZ).

Roj Txias / Nruab Nrab:Cov Pa Nitrogen Ua Kua

Cov kua nitrogen yog ib qho khoom siv txias uas tsis kub heev uas siv tau rau kev vuam laser muaj zog heev.

Nws muab cov txiaj ntsig txias zoo heev thiab ua kom muaj kev tswj kub hauv thaj chaw vuam.

4. Cov roj sib xyaw:

Cov roj sib xyaw feem ntau siv rau hauv kev vuam kom zoo dua ntau yam ntawm cov txheej txheem, xws li kev vuam ceev, qhov tob nkag mus, thiab kev ruaj khov ntawm arc. Muaj ob hom roj sib xyaw tseem ceeb: binary thiab ternary sib xyaw.

Cov Khoom Sib Xyaws Binary Gas:Argon + Pa

Ntxiv me ntsis oxygen rau hauv argon yuav ua rau arc ruaj khov dua, ua kom lub weld pool zoo dua, thiab ua kom vuam ceev dua. Cov khoom sib xyaw no feem ntau siv rau kev vuam cov hlau carbon, cov hlau uas tsis muaj alloy ntau, thiab cov hlau tsis xeb.

Cov Khoom Sib Xyaws Binary Gas:Argon + Cov Pa roj carbon dioxide

Qhov ntxiv CO₂ rau hauv argon ua rau lub zog vuam thiab tiv taus xeb ntau dua thaum txo cov spatter. Cov khoom sib xyaw no feem ntau siv rau kev vuam cov hlau carbon thiab cov hlau tsis xeb.

Cov Khoom Sib Xyaws Binary Gas:Argon + Hydrogen

Hydrogen ua rau qhov kub ntawm arc nce ntxiv, ua kom qhov ceev ntawm kev vuam zoo dua, thiab txo qhov tsis zoo ntawm kev vuam. Nws yog qhov tshwj xeeb tshaj yog rau kev vuam cov hlau nickel thiab cov hlau tsis xeb.

Cov Khoom Sib Xyaws Roj Ternary:Argon + Pa + Carbon Dioxide

Cov khoom sib xyaw no muab cov txiaj ntsig ntawm ob qho tib si argon-oxygen thiab argon-CO₂ sib xyaw ua ke. Nws txo cov spatter, txhim kho qhov weld fluidity, thiab txhim kho qhov zoo ntawm weld. Nws yog siv dav rau kev vuam ntau yam tuab ntawm carbon steel, low-alloy steel, thiab stainless steel.

Cov Khoom Sib Xyaws Roj Ternary:Argon + Helium + Carbon Dioxide

Cov khoom sib xyaw no pab txhim kho qhov ruaj khov ntawm arc, ua rau qhov kub ntawm lub pas dej vuam nce ntxiv, thiab ua rau qhov ceev ntawm kev vuam nce ntxiv. Nws yog siv rau hauv kev vuam luv luv thiab kev siv vuam hnyav, muab kev tswj hwm zoo dua ntawm kev oxidation.

Kev Xaiv Roj Hauv Cov Ntawv Thov Sib Txawv

Kev Siv Tes Ua Laser Vuam

Hauv kev siv laser vuam sib txawv, kev xaiv cov roj tsim nyog yog qhov tseem ceeb heev, vim tias kev sib xyaw ua ke ntawm cov roj sib txawv tuaj yeem tsim cov vuam zoo, ceev, thiab ua haujlwm tau zoo sib txawv. Nov yog qee cov lus qhia los pab koj xaiv cov roj zoo rau koj daim ntawv thov tshwj xeeb:

Hom Khoom Siv Vuam:

Hlau tsis xebfeem ntau sivArgon los yog Argon/Hydrogen Sib Tov.

Aluminium thiab Aluminium Alloysfeem ntau sivArgon ntshiab.

Cov Khoom Siv Titaniumfeem ntau sivNitrogen.

Cov Hlau Uas Muaj Carbon Siabfeem ntau sivOxygen ua ib qho roj pabcuam.

Vuam Ceev Thiab Pentration:

Yog tias xav tau kev vuam ceev dua lossis kev vuam tob dua, kev sib xyaw ua ke ntawm cov pa roj tuaj yeem hloov kho tau. Kev ntxiv cov pa oxygen feem ntau txhim kho kev nrawm thiab kev nkag mus, tab sis yuav tsum tau tswj hwm kom zoo kom tsis txhob muaj teeb meem oxidation.

Kev Tswj Xyuas Thaj Chaw Kub Cuam Tshuam (HAZ):

Nyob ntawm seb cov khoom siv yuav tsum tau ntxuav li cas, tej zaum yuav muaj cov khib nyiab txaus ntshai uas yuav tsum tau ua cov txheej txheem tshwj xeeb thaum lub sijhawm ntxuav. Qhov no tuaj yeem ntxiv rau tus nqi tag nrho ntawm cov txheej txheem ntxuav laser.

Kev Zoo ntawm Weld:

Qee cov roj sib xyaw ua ke tuaj yeem txhim kho qhov zoo thiab qhov tsos ntawm cov vuam. Piv txwv li, nitrogen tuaj yeem ua rau qhov tsos zoo dua thiab qhov zoo ntawm qhov chaw.

Kev Tswj Qhov Hnyuv Thiab Npuas:

Rau cov ntawv thov uas xav tau cov vuam zoo heev, yuav tsum tau ua tib zoo saib xyuas qhov tsim ntawm cov qhov thiab cov npuas dej. Kev xaiv cov roj kom raug tuaj yeem txo qhov kev pheej hmoo ntawm cov teeb meem no.

Cov Khoom Siv Thiab Cov Nqi Yuav Tsum Xav Txog:

Kev xaiv roj kuj tseem cuam tshuam los ntawm hom khoom siv thiab tus nqi. Qee cov roj yuav xav tau cov txheej txheem tshwj xeeb lossis tus nqi siab dua.

Rau cov ntawv thov tshwj xeeb, nws raug pom zoo kom ua haujlwm nrog tus kws ua vuam lossis tus kws tsim khoom siv laser vuam kom tau txais cov lus qhia tshaj lij thiab ua kom zoo dua cov txheej txheem vuam.

Feem ntau yuav tsum tau sim thiab ua kom zoo dua ua ntej xaiv cov roj sib xyaw ua ke kawg.

Nyob ntawm daim ntawv thov tshwj xeeb, ntau yam roj sib xyaw thiab cov txheej txheem tuaj yeem sim nrhiav qhov zoo tshaj plaws ntawm kev vuam.

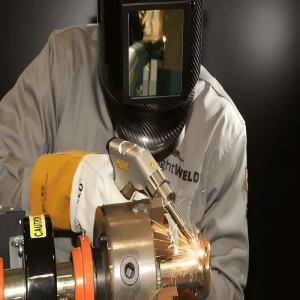

Tej Yam Koj Yuav Tsum Paub Txog: Kev Siv Tes Ua Tes Laser Vuam

Lub Tshuab Vuam Laser Pom Zoo

Yuav kom ua tau zoo tshaj plaws rau koj cov haujlwm ua hlau thiab cov khoom siv, kev xaiv cov khoom siv kom raug yog qhov tseem ceeb. MimoWork Laser pom zoo kom siv covTshuab Vuam Laser Tesrau kev sib txuas hlau kom meej thiab ua haujlwm tau zoo.

Muaj Peev Xwm Loj & Wattage rau Ntau Yam Kev Siv Vuam

Lub tshuab vuam laser tes 2000W yog tus cwj pwm los ntawm lub tshuab me me tab sis qhov zoo ntawm kev vuam.

Ib qho chaw ruaj khov fiber laser thiab cov cable fiber txuas nrog muab kev xa khoom laser beam nyab xeeb thiab ruaj khov.

Nrog lub zog siab, lub laser vuam qhov tseem ceeb yog qhov zoo tagnrho thiab ua rau lub vuam sib koom ua ke ruaj khov txawm tias rau cov hlau tuab.

Nrog lub tshuab me me thiab me me, lub tshuab laser welder portable yog nruab nrog rab phom laser welder uas txav tau uas yog lub teeb thiab yooj yim rau ntau daim ntawv thov vuam laser ntawm txhua lub kaum sab xis thiab nto.

Cov xaiv tau ntau hom laser welder nozzles thiab cov tshuab pub hlau tsis siv neeg ua rau laser vuam ua haujlwm yooj yim dua thiab qhov ntawd yog tus phooj ywg rau cov pib tshiab.

Kev vuam laser ceev ceev ua rau koj cov khoom tsim tau zoo dua thiab cov zis ntau ntxiv thaum ua kom muaj txiaj ntsig zoo ntawm kev vuam laser.

Sau luv luv

Hauv ntej, laser vuam yuav tsum siv roj los tiv thaiv thaj chaw vuam, tswj qhov kub thiab txias, txhim kho qhov zoo ntawm vuam, thiab tiv thaiv cov kab ke kho qhov muag. Kev xaiv cov hom roj thiab cov khoom siv tsim nyog yog qhov tseem ceeb hauv kev ua kom muaj kev vuam laser zoo thiab ruaj khov thiab tau txais cov txiaj ntsig vuam zoo. Cov ntaub ntawv sib txawv thiab cov ntawv thov yuav xav tau ntau hom thiab sib xyaw ua ke kom tau raws li qhov xav tau vuam tshwj xeeb.

Hu rau peb hnub nokom paub ntau ntxiv txog peb cov laser cutters thiab lawv tuaj yeem ua kom koj cov txheej txheem txiav ntau lawm zoo dua li cas.

Cov Kev Txuas Sib Xws

Muaj Lub Tswv Yim Txog Laser Welding Machines?

Lub sijhawm tshaj tawm: Lub Ib Hlis-13-2025