Cov Lus Zais Cia Txog Kev Vuam Laser: Kho Cov Teeb Meem Feem Ntau Tam Sim No!

Kev Taw Qhia:

Ib Daim Ntawv Qhia Txog Kev daws teeb meem tiav

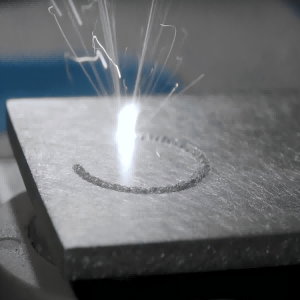

Cov Tshuab Vuam Laser Tes

Tshuab vuam laser fiber ntau tes tau txais kev nyiam heev hauv ntau yam lag luam vim nws qhov kev ua haujlwm raug thiab kev ua haujlwm zoo.

Txawm li cas los xij, zoo li lwm yam txheej txheem vuam, nws tsis zam kev cov nyom thiab teeb meem uas yuav tshwm sim thaum lub sijhawm vuam.

Qhov kev sib koom ua ke nokev daws teeb meem ntawm laser weldinglub hom phiaj yog los daws cov teeb meem uas feem ntau ntsib nrog cov tshuab vuam laser tes, cov teeb meem ntsig txog kev vuam, thiab cov teeb meem hais txog qhov zoo ntawm cov vuam.

Cov Ntsiab Lus:

Ua Ntej Pib Laser Welding Tshuab Faults & Solutions

1. Cov khoom siv tsis tuaj yeem pib (Lub zog)

Kev daws teeb meem: Xyuas seb lub qhov hluav taws xob puas muaj zog.

2. Teeb Tsis Tau Ci

Kev daws teeb meem: Tshawb xyuas lub rooj tsavxwm ua ntej hluav taws nrog lossis tsis muaj 220V voltage, tshawb xyuas lub teeb board; 3A fuse, xenon teeb.

3. Lub teeb tau ci lawm, tsis muaj Laser

Kev daws teeb meem: Saib seb lub tshuab laser vuam tes ntawm lub vijtsam puas tawm ntawm lub teeb. Ua ntej tshaj plaws, xyuas seb lub pob laser ntawm lub CNC puas kaw, yog tias kaw, ces qhib lub pob laser. Yog tias lub pob laser zoo li qub, qhib lub vijtsam tswj tus lej kom pom seb qhov chaw teeb tsa rau lub teeb tas mus li, yog tias tsis yog, ces hloov mus rau lub teeb tas mus li.

Cov Teeb Meem thiab Kev Kho ntawm Lub Tshuab Welding Theem Laser

Lub Weld Seam yog Dub

Cov roj tiv thaiv tsis qhib, tsuav yog cov roj nitrogen qhib, nws tuaj yeem daws tau.

Qhov kev taw qhia ntawm cov pa roj tiv thaiv tsis yog lawm, qhov kev taw qhia ntawm cov pa roj tiv thaiv yuav tsum ua qhov sib txawv ntawm qhov kev taw qhia ntawm qhov chaw ua haujlwm.

Tsis Muaj Kev Nkag Mus Rau Hauv Kev Vuam

Qhov tsis muaj zog laser tuaj yeem txhim kho qhov dav thiab tam sim no.

Lub lens focusing tsis yog qhov ntau npaum li cas, los kho qhov ntau npaum li cas focusing ze rau qhov chaw focusing.

Kev qaug zog ntawm lub teeb laser

Yog tias cov dej txias muaj kuab paug lossis tsis tau hloov pauv ntev, nws tuaj yeem daws tau los ntawm kev hloov cov dej txias thiab ntxuav lub raj iav UV thiab lub teeb xenon.

Lub lens tsom lossis lub diaphragm resonant cavity ntawm lub laser puas lawm lossis muaj kuab paug, nws yuav tsum tau hloov lossis ntxuav raws sijhawm.

Tsiv lub laser mus rau hauv txoj kev pom kev tseem ceeb, kho qhov kev cuam tshuam tag nrho thiab lub diaphragm semi-reflection hauv txoj kev pom kev tseem ceeb, xyuas thiab puag ncig qhov chaw nrog daim ntawv duab.

Lub laser tsis tso tawm los ntawm lub nozzle tooj liab hauv qab lub taub hau tsom. Kho lub diaphragm reflective 45-degree kom lub laser tso tawm los ntawm qhov chaw nruab nrab ntawm lub nozzle roj.

Kev daws teeb meem zoo ntawm Laser Vuam

1. Cov dej tawg

Tom qab laser vuam tiav lawm, ntau cov hlau me me tshwm sim rau ntawm qhov chaw ntawm cov khoom siv lossis daim haujlwm, txuas rau ntawm qhov chaw ntawm cov khoom siv lossis daim haujlwm.

Vim li cas ho tawg: qhov chaw ntawm cov khoom siv ua tiav lossis cov khoom ua haujlwm tsis huv, muaj roj lossis cov pa phem, nws kuj tseem yuav tshwm sim los ntawm kev ua kom cov txheej galvanized volatilization.

1) Ua tib zoo saib xyuas kev ntxuav cov khoom siv lossis cov khoom ua haujlwm ua ntej laser vuam;

2) Qhov tawg yog muaj feem cuam tshuam ncaj qha rau lub zog ceev. Kev txo qis lub zog vuam kom zoo tuaj yeem txo qhov tawg.

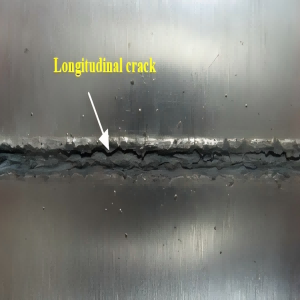

2. Cov kab nrib pleb

Yog tias qhov ceev ntawm qhov workpiece txias dhau lawm, qhov kub ntawm cov dej txias yuav tsum tau kho rau ntawm lub fixture kom nce qhov kub ntawm dej.

Thaum qhov sib txawv ntawm qhov workpiece loj dhau los yog muaj burr, qhov kev ua haujlwm raug ntawm qhov workpiece yuav tsum tau txhim kho.

Cov khoom ua haujlwm tsis tau raug ntxuav. Hauv qhov no, cov khoom ua haujlwm yuav tsum tau ntxuav dua.

Tus nqi ntws ntawm cov roj tiv thaiv loj dhau, uas tuaj yeem daws tau los ntawm kev txo tus nqi ntws ntawm cov roj tiv thaiv.

3. Qhov Ntswg Ntawm Qhov Chaw Weld

Cov laj thawj rau kev tsim cov porosity:

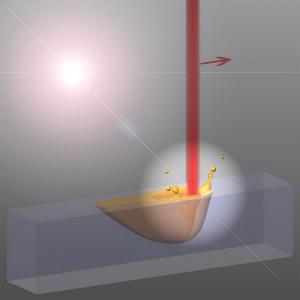

1) Lub laser vuam molten pas dej tob thiab nqaim, thiab qhov txias txias sai heev. Cov roj tsim tawm hauv lub pas dej molten lig dhau lawm kom dhau mus, uas tuaj yeem ua rau muaj porosity.

2) Qhov chaw ntawm qhov vuam tsis tau ntxuav, lossis cov pa zinc ntawm daim ntawv galvanized tau volatilized.

Ua ntej vuam, ntxuav qhov chaw ua haujlwm thiab qhov chaw vuam kom zoo dua thaum cua sov.

4. Kev Sib Hloov ntawm Kev Vuam

Cov hlau vuam yuav tsis khov kho hauv nruab nrab ntawm cov qauv sib koom ua ke.

Vim li cas ho tsis ua haujlwm: Qhov chaw tsis raug thaum vuam, lossis lub sijhawm sau thiab kev sib dhos hlau tsis raug.

Kev daws teeb meem: Kho qhov chaw vuam, lossis lub sijhawm sau thiab qhov chaw xaim, nrog rau qhov chaw ntawm lub teeb, xaim thiab vuam.

5. Kev Ntws Slag Ntawm Qhov Chaw, Uas Feem Ntau Tshwm Sim Ntawm Cov Txheej

Kev ntes ntawm cov slag saum npoo av ua rau:

1) Thaum vuam ntau txheej, txheej txheej ntawm cov khaubncaws sab nraud povtseg tsis huv; lossis qhov chaw ntawm qhov vuam dhau los tsis tiaj tus lossis qhov chaw ntawm qhov vuam tsis ua raws li qhov yuav tsum tau ua.

2) Cov txheej txheem vuam tsis raug, xws li lub zog vuam qis, vuam ceev dhau.

Kev daws teeb meem: Xaiv qhov tam sim no vuam thiab qhov ceev vuam tsim nyog, thiab cov txheej txheej interlayer yuav tsum tau ntxuav thaum vuam ntau txheej. Zom thiab tshem tawm cov vuam nrog slag ntawm qhov chaw, thiab ua kom cov vuam yog tias tsim nyog.

Lwm Cov Khoom Siv - Cov Teeb Meem thiab Kev Dais Teeb Meem Feem Ntau ntawm Lub Tshuab Welder Laser

1. Kev Ua Tsis Tau Zoo ntawm Cov Khoom Siv Tiv Thaiv Kev Nyab Xeeb

Cov khoom siv tiv thaiv kev nyab xeeb ntawm lub tshuab laser vuam, xws li lub qhov rooj vuam chamber, lub ntsuas roj ntws, thiab lub ntsuas kub, yog qhov tseem ceeb rau nws txoj haujlwm kom zoo. Kev ua tsis tiav ntawm cov khoom siv no tsis tsuas yog cuam tshuam kev ua haujlwm ib txwm ntawm cov khoom siv tab sis kuj ua rau muaj kev pheej hmoo ntawm kev raug mob rau tus neeg teb xov tooj.

Yog tias muaj teeb meem nrog cov khoom siv tiv thaiv kev nyab xeeb, nws yog qhov tseem ceeb heev uas yuav tsum nres qhov kev ua haujlwm tam sim ntawd thiab hu rau cov kws tshaj lij kom kho thiab hloov pauv.

2. Kev Txuas Hlau Feeder

Yog tias muaj lub xaim pub mis tsis ua haujlwm zoo li no, thawj qhov peb yuav tsum ua yog xyuas seb lub qhov taub phom puas txhaws, kauj ruam thib ob yog xyuas seb lub xaim pub mis puas txhaws thiab lub disk silk tig puas zoo li qub.

Sau luv luv

Nrog rau qhov tseeb tsis sib xws, ceev thiab versatility, laser welding yog ib qho thev naus laus zis muaj txiaj ntsig zoo hauv kev lag luam xws li automotive, aerospace thiab electronics.

Txawm li cas los xij, ntau yam tsis zoo yuav tshwm sim thaum lub sijhawm vuam, suav nrog porosity, tawg, splashing, irregular bead, hlawv tawm, deformation, thiab oxidation.

Txhua qhov tsis zoo muaj qhov ua rau tshwj xeeb, xws li qhov chaw teeb tsa laser tsis raug, cov khoom tsis huv, cov pa tiv thaiv tsis txaus, lossis cov pob qij txha tsis sib xws.

Los ntawm kev nkag siab txog cov teeb meem no thiab lawv cov hauv paus ua rau, cov tuam txhab tsim khoom tuaj yeem siv cov kev daws teeb meem tshwj xeeb, xws li kev ua kom zoo dua cov kev teeb tsa laser, xyuas kom meej tias qhov sib koom ua ke haum, siv cov roj tiv thaiv zoo, thiab siv cov kev kho ua ntej thiab tom qab vuam.

Kev cob qhia tus neeg teb xov tooj kom zoo, kev saib xyuas cov khoom siv txhua hnub thiab kev saib xyuas cov txheej txheem tiag tiag ua rau kev vuam zoo dua thiab txo qhov tsis zoo.

Nrog rau txoj hauv kev dav dav rau kev tiv thaiv qhov tsis zoo thiab kev ua kom zoo dua qub, laser welding yeej ib txwm xa cov welds ruaj khov, txhim khu kev qha thiab zoo uas ua tau raws li cov qauv kev lag luam nruj.

Tsis paub tias hom laser welding tshuab xaiv?

Koj yuav tsum paub: Yuav ua li cas xaiv lub tshuab laser tes

Muaj Peev Xwm Loj & Wattage rau Ntau Yam Kev Siv Vuam

Lub tshuab vuam laser tes 2000W yog tus cwj pwm los ntawm lub tshuab me me tab sis qhov zoo ntawm kev vuam.

Ib qho chaw ruaj khov fiber laser thiab cov cable fiber txuas nrog muab kev xa khoom laser beam nyab xeeb thiab ruaj khov.

Nrog lub zog siab, lub laser vuam qhov tseem ceeb yog qhov zoo tagnrho thiab ua rau lub vuam sib koom ua ke ruaj khov txawm tias rau cov hlau tuab.

Kev yooj yim nqa mus los

Nrog lub tshuab me me thiab me me, lub tshuab laser welder portable yog nruab nrog rab phom laser welder uas txav tau uas yog lub teeb thiab yooj yim rau ntau daim ntawv thov vuam laser ntawm txhua lub kaum sab xis thiab nto.

Cov xaiv tau ntau hom laser welder nozzles thiab cov tshuab pub hlau tsis siv neeg ua rau laser vuam ua haujlwm yooj yim dua thiab qhov ntawd yog tus phooj ywg rau cov pib tshiab.

Kev vuam laser ceev ceev ua rau koj cov khoom tsim tau zoo dua thiab cov zis ntau ntxiv thaum ua kom muaj txiaj ntsig zoo ntawm kev vuam laser.

Tej Yam Koj Yuav Tsum Paub Txog: Kev Siv Tes Ua Tes Laser Welding

Yog tias koj nyiam daim vis dis aus no, vim li cas ho tsis xav txogsubscribe rau peb Youtube Channel?

Cov Ntawv Thov Sib Xws Uas Tej Zaum Koj Yuav Txaus Siab:

Txhua qhov kev yuav khoom yuav tsum tau ua tib zoo saib xyuas

Peb tuaj yeem pab nrog cov ntaub ntawv ntxaws thiab kev sab laj!

Lub sijhawm tshaj tawm: Lub Ib Hlis-16-2025