Ịsacha ihe nhicha laser

Ịsacha ihe nhicha laser bụ usoro eji ewepụ ihe ruru unyi, oxides, na ihe ndị ọzọ a na-achọghị n'elu ihe mkpuchi ahụ.Tupu na MgbeUsoro ịgbado ọkụ agwụla. Nhicha a bụ nzọụkwụ dị mkpa n'ọtụtụ ngwa ụlọ ọrụ mmepụta ihe na mmepụta ihe ijiHụ na Iguzosi Ike n'Ezi Ihe na Ọdịdịnke Njikọ A Gbara Ọkụ.

Ịsacha Laser maka Metal

N'oge usoro ịgbado ọkụ, ihe ndị na-adịghị ọcha na ihe ndị sitere na ya nwere ike ịdaba n'elu ebe a na-agbado ọkụ, dịka ọmụmaatụslag, splatter, na mgbanwe agba.

A hapụ ha ka ha ghara ịdị ọcha, ihe ndị a nwere ike imena-emetụta ike nke weld ahụ, iguzogide nchara, na ịma mma anya n'ụzọ na-adịghị mma.

Nhicha njikọta laser na-eji ọkụ laser dị elu eme ka ọ gbazee ma wepụ ihe ndị a na-anaghị achọ ka e tinye n'elu ya.na-emebighị iheígwè dị n'okpuru ya.

Uru nke nhicha Laser Weld

1. Nkọcha ziri ezi- Enwere ike iji laser ahụ hichaa naanị ebe a na-agbakọta ihe na-enweghị mmetụta na ihe gbara ya gburugburu.

2. Ọsọ- Ihicha laser bụ usoro ngwa ngwa, akpaaka nke nwere ike ihicha ihe mkpuchi ọkụ ngwa ngwa karịa usoro aka.

3. Ịdị n'otu- Nhicha laser na-emepụta otu ihe ahụ, nke a pụrụ imegharị ugboro ugboro, na-eme ka a na-ehicha ihe niile n'otu ọkwa dị elu.

4. Enweghị ihe oriri ọ bụla- Ihicha laser anaghị achọ ihe mkpofu ma ọ bụ kemịkalụ, nke na-ebelata ọnụ ahịa ọrụ na ihe mkpofu.

Ngwa: Ịsacha Laser Weld

Efere ígwè dị elu nke nwere ike dị ala (HSLA) nke na-ehicha laser weld

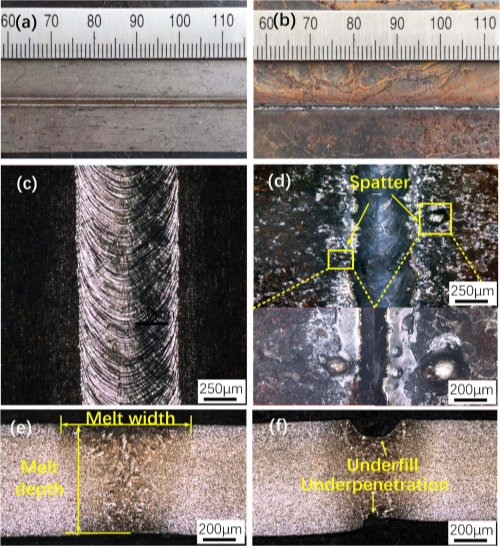

Ọdịdị nke nhicha laser agwọ ọrịa (a, c, e) na enweghị ọgwụgwọ site na nhicha laser (b, d, f)

Usoro nhicha laser kwesịrị ekwesị nwere ike imewepụnchara na mmanụ sitere n'elu ihe eji arụ ọrụ.

Ntinye aka dị elua hụrụ ihe nlele ndị e sachara ma e jiri ya tụnyere ndị a na-asachaghị.

Ọgwụgwọ nhicha laser tupu ọgwụgwọ na-enyere aka nke ọmazeremmebi na pores na weld nana-aka mmaàgwà nhazi nke weld ahụ.

Ọgwụgwọ maka nhicha laser Weld na-ebelata ọtụtụ ntụpọ dịka oghere na mgbawa dị n'ime weld ahụ, si otú a na-ebelata mmebi ndị dị na ya.na-akawanye mmaNjirimara nrụgide nke weld ahụ.

Ike nrụgide nke ihe nlele ahụ site na iji laser hichaa tupu ọgwụgwọ bụ 510 MPa, nke bụ30% karịakarịa nke ahụ na-enweghị nhicha laser tupu ọgwụgwọ.

Ogologo nke njikọ weld e ji laser hichaa bụ 36% nke bụugboro 3nke njikọ njikọta weld a na-adịghị ọcha (12%).

Ịsacha Aluminom Alloy 5A06 Laser Weld

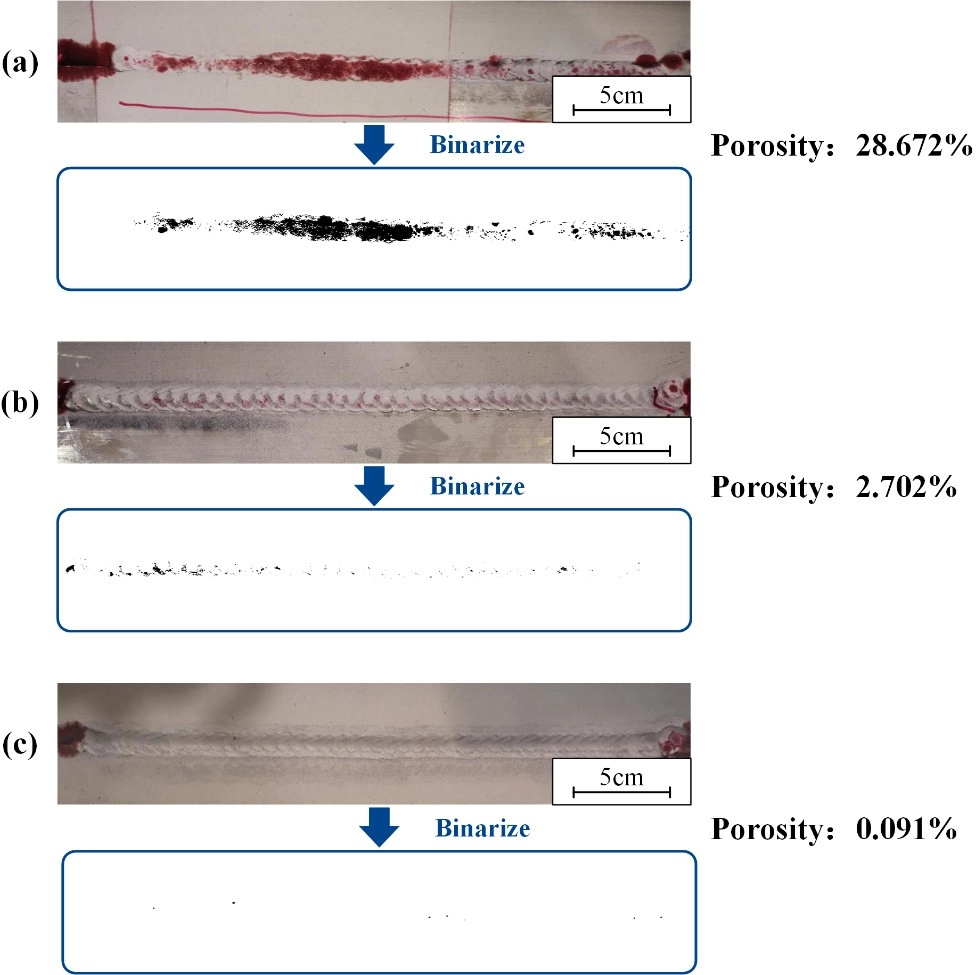

Nsonaazụ nke Nnwale Permeation na Porosity na Sample nwere: (a) Mmanụ; (b) Mmiri; (c) Nhicha Laser.

Ọkpụrụkpụ nke oyi akwa oxide nke Aluminom alloy 5A06 bụ 1-2 lm, nhicha laser na-egosikwammetụta dị mmana mwepụ nke oxide maka ịgbado ọkụ TIG.

A chọtara porosityna mpaghara njikọta nke njikọta TIGmgbe ala nkịtị gasịrị, a lekwara anya n'ihe ndị nwere ọdịdị dị nkọ.

Mgbe nhicha laser gasịrị,ọ dịghị porosity dịna mpaghara njikọta ahụ.

Ọzọkwa, ọnụnọ nke oxygenbelatara nke ukwuu, nke kwekọrọ na nsonaazụ ndị gara aga.

Tụkwasị na nke ahụ, obere oyi akwa nke agbaze okpomọkụ mere n'oge nhicha laser, nke butereusoro ihe owuwu a nụchara anụchana mpaghara njikọta ahụ.

Lee akwụkwọ nyocha mbụ gbasara ọnụ ụzọ nyocha ebe a.

Ma ọ bụ Lelee Isiokwu a Anyị Bipụtara na:Ịsacha Aluminom nke Laser (Otu Ndị Nchọpụta Si Mee Ya)

Ị chọrọ ịma maka nhicha laser weld?

Anyị nwere ike inye aka!

Kedu ihe m nwere ike iji hichaa ihe m ji ehicha ákwà m?

Nhicha Welds Na-enyeNjikọ siri ikenaIgbochi ire ere

Lee ụfọdụỤzọ Omenalamaka nhicha Welds:

Nkọwa:Jiri ahịhịa waya ma ọ bụ wiil wepụ ihe ndị na-emebi emebi, ihe ndị na-agbawa agbawa, na ihe ndị na-adịghị mma.

Uru:Ọ dị oke ọnụ ma dị irè maka ihicha elu.

Ọghọm:Ọ nwere ike ịdị oke ibu ma ọ gaghị eru ebe ndị siri ike.

Nkọwa:Jiri igwe e ji gweri ihe mee ka ihe ndị e ji gweri ihe dị nro ma wepụ ihe ndị na-adịghị mma.

Uru:Ọ dị irè maka nhicha na ịkpụzi ihe dị arọ.

Ọghọm:Nwere ike ịgbanwe profaịlụ weld ma nwee ike ibute okpomọkụ.

Nkọwa:Jiri ihe ngwọta ma ọ bụ ihe mgbaze sitere na acid gbazee ihe ndị na-emerụ ahụ.

Uru:Ọ dị irè maka ihe fọdụrụ siri ike ma enwere ike iji ya mee ihe n'ọtụtụ ngwa.

Ọghọm:Ọ chọrọ nchekwa na mkpofu kwesịrị ekwesị.

Nkọwa:Debe ihe na-emebi ihe n'ọsọ dị elu iji wepụ ihe ndị na-emerụ ahụ.

Uru:Ngwa ngwa ma dị irè maka nnukwu ebe.

Ọghọm:Ọ nwere ike ibute mbuze elu ma ọ bụrụ na achịkwaghị ya.

Nkọwa:Jiri ụda olu dị elu mee ihe nhicha iji wepụ ihe ndị mebiri emebi.

Uru:Ọ na-eru ọdịdị dị mgbagwoju anya ma na-ewepụ ihe ndị na-emerụ ahụ nke ọma.

Ọghọm:Ngwa nwere ike ịdị oke ọnụ, a pụkwara inwe oke nha nhicha.

MakaMbelata Laser & Nkwadebe Elu Laser:

Mbelata Laser

Nkọwa:Jiri ụzarị laser dị ike nke ukwuu mee ka ihe ndị na-emerụ ahụ ghara ịfụ mmiri n'enweghị ihe ndị dị n'ime ya.

Uru:Kpọmkwem, ọ dị mma maka gburugburu ebe obibi, ma dịkwa irè maka ojiji dị nro.

Ọghọm:Ngwaọrụ nwere ike ịdị oke ọnụ, ma chọọ ọrụ ọkachamara.

Nkwadebe Elu Laser

Nkọwa:Jiri laser kwadebe elu site na iwepụ ihe ndị na-emerụ emerụ na ihe ndị na-anaghị emerụ ahụ tupu ịgbado ọkụ.

Uru:Na-eme ka mma ịgbado ọkụ dịkwuo mma ma na-ebelata ntụpọ.

Ọghọm:Ngwaọrụ nwekwara ike ịdị oke ọnụ, ọ chọkwara ọrụ ọkachamara.

Kedu otu esi ehicha ígwè site na laser?

Nhicha Laser bụ ụzọ dị irè isi wepụ ihe ruru unyi

Yiri PPE kwesịrị ekwesị, gụnyere ugogbe anya nchekwa, uwe aka, na uwe nchebe.

Debe ihe ígwè ahụ n'ebe kwụsiri ike iji gbochie mmegharị mgbe a na-ehicha ya. Gbanwee isi laser ahụ ka ọ dị anya a tụrụ aro site na elu ahụ, nke na-abụkarị n'etiti etiti na etiti.10-30 mm.

Na-enyocha usoro nhicha ahụ mgbe niileChọọ mgbanwe n'elu ya, dịka iwepụ ihe ndị na-emerụ ahụ ma ọ bụ mmebi ọ bụla metụtara ígwè ahụ.

Mgbe ị sachara, lelee ebe a na-agbakọta ihe iji hụ na ọ dị ọcha na ihe ọ bụla ọzọ na-emerụ ahụ. Dabere na ojiji, tụlee ya.itinye ihe mkpuchi nchebeiji gbochie ire ere n'ọdịnihu.

Kedu ihe bụ ngwaọrụ kacha mma maka nhicha Welds?

Ịsacha Laser pụtara dịka otu n'ime ngwaọrụ kachasị mma dị

Maka onye ọ bụla metụtara imepụta ígwè ma ọ bụ mmezi, nhicha laser bụngwa ọrụ bara uru maka ihicha ihe ndị e ji asa ákwà.

Izi ezi ya, arụmọrụ ya, na uru gburugburu ebe obibi ya na-eme ka ọ bụrụ nhọrọ kacha mma makainweta nsonaazụ dị eluebe a na-ebelata ihe egwu na oge ezumike.

Ọ bụrụ na ịchọrọ imeziwanye usoro nhicha gị, tụlee itinye ego na teknụzụ nhicha laser.

Kedu ka esi eme ka Weld dị ọcha?

Ịsacha Laser Na-enyere Aka Inweta Weld Dị Ọcha na Ọkachamara

Nkwadebe nke Elu

Nhicha Mbụ:Tupu ịgbado ọkụ, hụ na ihe ndị na-emerụ emerụ dịka nchara, mmanụ, na unyi adịghị na ígwè ahụ.dị mkpa maka inweta weld dị ọcha.

Nhicha Laser:Jiri sistemụ nhicha laser wepụ ihe ruru unyi ọ bụla dị n'elu nke ọma. Usoro a na-eme ka ọ dị mkpa na a ga-ewepụ ihe ndị na-emerụ ahụ naanị.n'emebighị ígwè ahụ.

Nhicha Mgbe Ịkwadochara Mgbakwụnye

Nhicha Mgbe Agbachara Ọkụ:Mgbe ịgbado ọkụ gasịrị, jiri laser hichaa ebe ịgbado ọkụ ahụ ozugbo iji wepụ ihe mgbochi, nsị, na oxidation nke nwere ike imebi ọdịdị nke ịgbado ọkụ ahụ.

Ndakọrịta:Usoro nhicha laser na-enye nsonaazụ otu, na-eme ka njikọta niile nwee njedebe na-adịgide adịgide, dị ọcha.

Ngosipụta Vidiyo: Nhicha Laser maka ígwè

Gịnị bụ nhicha laser na otu o si arụ ọrụ?

Otu n'ime uru kachasị nke nhicha laser bụ na ọ na-eme ka o sie ikeusoro akọrọ.

Nke a pụtara na ọ dịghị mkpa ka e hichaa ihe ndị ahụ mgbe e hichara ha.

Naanị duzie oghere laser ahụ n'elu ebe ịchọrọ ihichana-emetụtaghị ihe dị n'okpuru ya.

Ndị na-ehicha laser bụkwa ndị a na-eji eme ihe nhicha laser.obere ma dị mfe ibugharị, na-ekwe kamaka nhicha dị irè n'ebe ahụ.

Ọ na-achọkarịnaanị ihe nchekwa onwe onye bụ isi, dị ka ugogbe anya nchekwa na ihe na-ekuru ume.

Ịsachapụ nchara Laser dị mma karịa

Ịsa ájá nwere ike ịmepụtaọtụtụ uzuzu ma chọọ nnukwu nhicha.

Ịsacha ice kpọrọ nkụ bụnwere ike ịdị oke ọnụ ma ghara ịdị mma maka nnukwu ọrụ.

Enwere ike iji nhicha kemịkalụ mee ihegụnyere ihe ndị dị ize ndụ na nsogbu mkpofu.

Na ntule ndịiche,Ịhịa aka n'ahụ laser pụtara dị ka ihe dị mkpa.

Ọ dị oke mma nke ukwuu, na-ejikwa ọtụtụ ihe ndị na-emerụ ahụ nke ọma

Usoro a na-efu ego n'oge dị anya n'ihinooriri ihe na obere ihe achọrọ maka mmezi.

Igwe nhicha Laser aka: Ịsacha Laser Weld

Ihe nhicha laser Pulsed(100W, 200W, 300W, 400W)

Ihe nhicha laser nke eriri pulsed dị mma nke ukwuu maka nhicha.dị nro,mmetụta dị nro, ma ọ bụadịghị ike na okpomọkụelu, ebe ọdịdị ziri ezi na nke a na-achịkwa nke laser pulsed dị mkpa maka nhicha dị irè na nke na-enweghị mmebi.

Ike Laser:100-500W

Mgbanwe Ogologo Obi:10-350ns

Ogologo eriri eriri:3-10m

Ogologo ebili mmiri:1064nm

Isi Iyi Laser:Eriri Laser Pulsed

Igwe mwepụ nchara laser(Nhicha ihe nhicha laser tupu na mgbe emechara)

A na-ejikarị laser welding arụ ọrụ n'ọtụtụ ụlọ ọrụ dịkaaerospace,ụgbọala,iwu ụgbọ mmiri, nammepụta eletrọnịkịebeewelds dị elu, enweghị ntụpọdị oke mkpa maka nchekwa, arụmọrụ, na ọdịdị.

Ike Laser:100-3000W

Ugboro Ugboro Ule Laser A Na-agbanwe agbanwe:Ruo 1000KHz

Ogologo eriri eriri:3-20m

Ogologo ebili mmiri:1064nm, 1070nm

NkwadoDị iche icheAsụsụ