Kedu ihe nhicha laser

Site na ikpughe ike laser na elu nke workpiriise workpied, nhicha laser nwere ike wepu akwa unyi ozugbo n'enweghi imebi usoro. Ọ bụ nhọrọ kachasị mma maka ọgbọ ọhụrụ nke teknụzụ nhicha ụlọ ọrụ.

Teknụzụ nhicha dị ọcha na-abụkwa teknụzụ dị ọcha na ụlọ ọrụ, ụgbọ mmiri, na mpaghara ndị ọzọ na-emepụta elu, na mwepụ nke silicon mmanụ na-eme ihe mkpuchi Ihe nkiri, na nhicha nhicha nke ụlọ ọrụ microlelecry.

Maka teknụzụ laser dị ka laser na-egbugharị, ịsa ahụ laser, nhicha laser, ị nwere ike ịmara ndị a ma ọ bụrụ na isi iyi nke ndị metụtara laser. Enwere mpempe akwụkwọ maka ntụle gị nke bụ ihe dị ka ebe obibi anọ na akwụkwọ dabara adaba na ngwa.

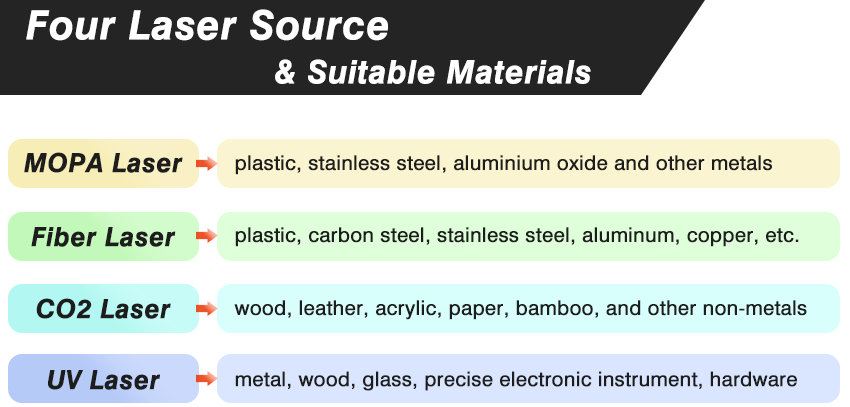

Isi mmalite nke Laser banyere nhicha laser

N'ihi ọdịiche dị na usoro dị mkpa dị ka ebili mmiri na ike nke ihe dị iche iche na ike dị iche iche, yabụ ịkwesịrị ịhọrọ igwe nhicha nke laser maka ihe ndị a ga-eme.

Nzọụkwụ MOPA Puller nhicha

(na-arụ ọrụ n'ụdị ihe niile)

MOPA Laser bụ ụdị nhicha nke laser. Mosed guzoro maka Master Oscillator. Ebe ọ bụ na enwere ike idozi usoro moda fiber na-emetụta usoro mkpụrụ nke mkpụrụ dabeere, njirimara dị mkpa nke laser dị ka etiti ebili mmiri na oke obosara a na-agaghị agbanwe. Ya mere, usoro mmezi ahụ dị elu dị elu na oke dị ka wider. Maka ọnọdụ dị iche iche nke ihe dị iche iche, mmeghari ahụ siri ike na usoro window na-agafe agafe, nke nwere ike iru elu nhicha nke ihe dị iche iche.

▶ mejupụtara fiber fiber

(nhọrọ kachasị mma maka iwepụ agba)

Nhicha nke na-esi na ya na-eme ka ọ dị laser na-aga n'ihu na-ewepụta mmepụta okpomọkụ na-eme ka ikuku na-efe efe na akwa igwe na mmejọ ahụ, na-ebelata ike nke internallayer. Mgbe isi iyi nke laser na-emepụta ike na-eme ka ikuku dị elu na-awụ akpata oyi ga-awụpụ mgbakwunye na ike adhesion na-adịghị ike, ka iji nweta nhicha ngwa ngwa.

Nhicha nke LASEr Compalite na-ejikọ laser na-aga n'ihu na-arụ ọrụ laser laser n'otu oge. Oke ọsọ, arụmọrụ dị elu, na ụdị ihe dị iche iche, maka ihe dị iche iche, nwekwara ike iji ụgbọ elu dị iche iche nke laser dị iche iche n'otu oge iji mezuo ebumnuche nke iwepu ntụpọ.

Iji maa atụ, na nhicha nke ihe mkpuchi dị elu, otu laser nwere ike ibute ya bụ nnukwu ma ọnụ ahịa dị elu. Nhicha nke na-asacha nke na-acha uhie uhie na semiconductor laser nwere ike ime ka ịdị ọcha dị ọcha na-eme ka ọ dị ọcha. Na nhicha nke ihe ndị dị elu dị ka aluminom alloy, otu laser nwere nsogbu dị ka iche echiche. Iji ihe na-eme ihe na-acha uhie uhie na igwe na-acha ọcha na semicder memiconductor laser laser laser laser na-ebupute ya, na-abawanye ụdị mmachi ahụ, na-eme ka arụmọrụ dị mma N'ezie, ọkachasị arụmọrụ nke mwepụ agba na-abawanye site na ihe karịrị ugboro abụọ.

▶ nhicha nhicha

(nhọrọ kachasị mma maka ihicha ihe na-abụghị ọla)

Carbon dioxide bụ gas laser na gas gas dị ka ihe na-arụ ọrụ, nke jupụtara na gas na gas (helium na nitrogen ma ọ bụ ynon). Dabere na ite mmiri pụrụ iche ya, CO2 laser bụ nhọrọ kachasị mma maka ihicha elu nke ihe ndị na-abụghị mitalsic dị ka ihe dị ka iwepụ ya na ink. Iji maa atụ, ojiji nke Co2 laser iji wepu ihe na-eme ihe na-eme ihe na-adịghị mma n'elu aluminom anaghị emebi elu nke ihe nkiri Atodic Oxigi mara mma, ma ọ bụ belata ọkpụrụkpụ ya.

▶ UV laser nhicha

(nhọrọ kachasị mma maka ngwaọrụ elektrọnik)

Ultraviolet las ndị ejiri na micromachining karị na-agụnye lasers na lasers niile siri ike. Ultraviolet laser na-efegharị na-adị mkpụmkpụ, otu photon ọ bụla nwere ike inyekọ ikike dị elu, nwere ike imebi nkekọ kemịkalụ n'etiti ihe. N'ụzọ dị otu a, a na-ewepụ ihe ndị a na-eyikwasị elu na ụdị gas ma ọ bụ ihe nhicha ahụ dum na-emepụta ume ikpo ọkụ nke ga-emetụta obere mpaghara na workpirisime. N'ihi nke a, nhicha UV laser nwere uru pụrụ iche na nzụlite Micro, dị ka nhicha nke ihe, na political (pI), polycarbonate (pc) na ihe ndị ọzọ polymer melite ogo nke imeputa.

A na-ewere laser laser dị ka usoro nhicha nke laser kachasị mma na teknụzụ na-enweghị isi nke ihe ahụ n'otu oge, elu igwe micro na nhazi, nwere ike Na-eme ihe n'ọtụtụ ebe na nkwukọrịta, optics, ndị agha, mpụ, ahụike na ụlọ ọrụ na ubi ndị ọzọ. Dịka ọmụmaatụ, oge 5g emepụtara ahịa chọrọ maka nhazi FPC. Ngwa nke igwe nke UV laser na-eme ka o kwe omume ịkpụcha oyi nke FPC na ihe ndị ọzọ.

Oge Post: Ọkt-10-2022