Gịnị bụ ịgbado ọkụ? A na-eme ka ndị laser na-eme ka a kọwara! Naanị ihe ị ga - achọ ịma gbasara laser ịgbado ọkụ, gụnyere ụkpụrụ dị mkpa na usoro isi usoro!

Ọtụtụ ndị ahịa aghọtaghị ụkpụrụ ọrụ na-agba aja nke Laser na-agba ọsọ igwe, agbanyeghị na Memowork Laser dị mma iji nyere gị aka ime mkpebi ọzọ iji nyere gị aka ịghọta ịgbado ọkụ.

Gịnị bụ ịgbado ọkụ?

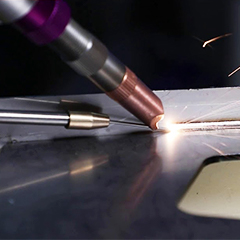

Na-agbado ọkụ bụ ụdị na-agbaze, na-eji akwa laser dị ka ihe eji eme ka ọ bụrụ usoro iji kpalie ya nke ọma, na-agbanwe n'ime mmiri radiesh na-akpali akpali, mgbe okirikiri Na ibe ya na-akpọtụrụ ibe anyị, ibe ọrụ ahụ, mgbe ọnọdụ ọrụ na-erute na-emegharị ihe na-emesi ike.

Dabere na usoro iwu ịgbado ọkụ na-ewu ewu, nwere usoro ịgbado ọkụ isi abụọ: okpomoku na-agba ọkụ na mmiri miri emi (Keyhole). Ọkụ na-emepụta site na ịgbado ọkụ na-agbasa site na ntinye ọrụ site na mbugharị ọkụ, ọ nweghị ihe na-agbazekwa, nke a na-ejikarị na-agba aja ọkụ na-agbado ọkụ. Feed Find na-agbado vaporizes ihe ma mepụta oke nke plasma. N'ihi okpomọkụ dị elu, a ga-enwe oghere dị n'ihu ọdọ mmiri a wụrụ. Mgbakwunye mmiri nke ọma bụ ebe ịgbado na-agbado, ọ nwere ike wepụta ọrụ ahụ nke ọma, yana ikike ntinye buru ibu, na-eduga n'ịgba iwe ngwa ngwa.

Oke usoro usoro na-ewu ewu

Enwere ọtụtụ usoro usoro na-emetụta ogo ịgbado ọkụ, dị ka ike njupụta, ebili mmiri na-efe efe, na-egbochi, ịgba iwe ngwa na nhọrọ nke gas na-echekwa gas.

Laser ike njupụta

Ọnọdụ njupụta ike bụ otu n'ime ọtụtụ ihe dị mkpa na nhazi laser. Enwere ike iwe iwe dị elu, elu oyi akwa ka esi esi n'ime microsion, na-ebute nnukwu vaporization. Ya mere, njupụta dị elu bara uru maka usoro iwepụ ihe dịka igwu egwu, ịkpụ na ihe osise. Maka njupụta dị ala, ọ na-ewe ọtụtụ milliseconds maka elu mmiri iji ruo ebe ị na-esi, na ala na-erulata ihe na-agbaze, nke dị mfe iji weld dị mma. Ya mere, n'ụdị nke ịgbado ọkụ na-agbado, oke dị egwu bụ 104-106w / cm2.

Laser Palloform

Laser Pormuna Tarform abụghị naanị oke oke iji mata ọdịiche dị n'etiti iwepụ ihe ọghọm site na ịkọ ahịhịa iji chọpụta olu na ụgwọ ọrụ nhazi. Mgbe agbagburu akwa dị elu na-agbago elu nke ihe ahụ, elu nke ihe ahụ ga-enwe 60 ~ 90 nke laser, ọla ọcha, ọla kọpa na ihe ndị ọzọ nwere ntụgharị siri ike na mbufe ngwa ngwa. Ntughari nke igwe di iche na oge n'oge nsogbu laser. Mgbe ọnọdụ dị elu nke ihe onwunwe nke ihe na-eme ka ọ na-agbaze isi, echiche na-ebelata ngwa ngwa, na mgbe elu dị na ala na-agbaze n'otu uru.

Laser obosara obosara

Oghere okirikiri bụ nnukwu oke nke ịgbado ọkụ. Omitu nke penetration kpebiri kpebie mpaghara na mpaghara okpomọkụ okpomọkụ. Ogologo oge nke okpomọkụ bụ, ka ukwuu na mpaghara okpomọkụ ahụ na-emetụta, omimi nke nganga mụbara na ike nke 1/2 nke obosara 1/2 nke okirikiri. Agbanyeghị, mmụba nke oke okirikiri ga-ebelata ike dị elu, yabụ mmụba nke oke ọkụ maka ịgbado ọkụ, nke na-ebute ihe na-emighị emi, karịsịa ọfụma maka ịgbado ọkụ na akwa. Agbanyeghị, ike dị elu dị ala na-ebute oke ntinye ọkụ, yana ihe ọ bụla nwere obosara kachasị mma nke na-eme ka omimi nke ọrịa.

Depocus

Laser na-agbagharị oge na-achọkarị ihe na-egbochi ya, n'ihi na ike njupụta nke etiti ebe a na-elekwasị anya na-elekwasị anya dị oke elu, nke dị mfe ịpụpụ akwụkwọ na-agba agba. Nkesa nke ike dị na ụgbọelu nke ọ bụla na-agbagha.

E nwere ụdị ntụpọ abụọ:

Devecus dị mma na nke na-adịghị mma. Ọ bụrụ na ụgbọelu na-elekwasị anya dị n'elu ọrụ ọrụ, ọ bụ ezigbo ntụpọ; Ma ọ bụghị ya, ọ bụ ntụpọ ọjọọ. Dabere na usoro enyemaka nke Geometric, mgbe anya dị n'etiti ụgbọ elu dị mma na nke na-adịghị mma na ụgbọelu na-agbado, ma n'ezie, ọ dị otu a, mana n'eziokwu, enwetara ụdị ọdọ mmiri a mịrị amị dị iche. N'ihe banyere ihe na-adịghị mma Stoctus, enwere ike ịnweta mkpụrụ ole magburu onwe ya, nke metụtara usoro usoro ọdọ mmiri a ga-eme.

Gbanyụọ ọsọ

Gbanyụọ ọsọ na-ekpebi iweli elu elu elu, ọnya afọ, okpomọkụ emetụta na ndị ọzọ. Ntinye ọkụ ga-emetụta ntinye ọkụ kwa oge. Ọ bụrụ na ọsọ na-agba ọkụ na-adịkarị nwayọ, ntinye ọkụ dị oke elu, na-ebute na-ere ọkụ na-ere ọkụ. Ọ bụrụ na ịgba mgbakwunye na-adị oke ọsọ, ntinye ọkụ dị ntakịrị, na-ebute na-emeghe anya na-enye ohere ile anya. A na-ejikarị ngwa ngwa na-ebelata iji meziwanye ọnya.

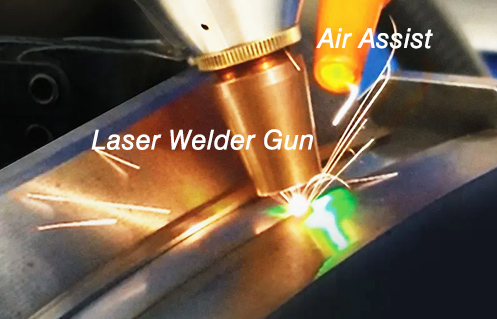

Gas na-eme ka mmiri na-efe efe

Gas na-eme ka ihe nchebe na-eme ka ihe dị mkpa dị mkpa na ịgbado ọkụ. N'otu aka, iji gbochie ihe eji eme ihe site na stutter na imetọ enyo na-elekwasị anya na enyo; N'aka nke ọzọ, ọ bụ igbochi plasma e mepụtara na usoro ịgbado ọkụ si na-elekwasị anya nke ukwuu ma gbochie laser site na iru n'elu ihe ahụ. Na usoro nke laser ịgbanyụ, na-elekọta Helium, a na-ejikarị Nitrogen na gas ichebe ọdọ mmiri a wụrụ, ka ọ gbochie onye na-enye ahụ ike na oxiding na-agba aja na-agba aja. Ihe ndị dị ka ụdị nke gas na-echebe, ogo nke ikuku na-efe efe na-efe efe na ndọtị na-arụ ọrụ, yana ụzọ na-efe efe ga-enwekwa mmetụta na-ewu ewu.

Akụ anyị na-atụ aro ya

Laser welder - gburugburu ebe obibi

◾ Okpomoku nke gburugburu ebe obibi: 15 ~ 35 ℃

Igwe iru mmiri nke gburugburu iru mmiri: <70% enweghị oghere

Jụụ: chiller mmiri dị mkpa n'ihi ọrụ nke ikpo ọkụ na-agbanye mmiri, na-enyere laser welder na-agba ọsọ nke ọma.

(Jiri ya na ya zuru ezu na ntuziaka banyere chiller mmiri, ị nwere ike ịlele onye ahụ:Ihe eji eme ihe na-ezighi ezi maka usoro co2 laser)

Chọrọ ịmatakwu banyere ebe a na-azụ ihe?

Oge post: Dec-22-2022