Kedu otu esi ahọrọ ngwakọta gas kacha mma maka ịgbado ọkụ laser gị?

Ụdị, Uru, na Ngwa

Okwu Mmalite:

Ihe Ndị Dị Mkpa Ị Ga-ama Tupu Ịbanye n'Ime Mmiri

Ịgbado ọkụ laser bụ ụzọ ịgbado ọkụ nke na-eji ogwe laser agbaze ihe e ji arụ ọrụ wee mepụta njikọta ọkụ mgbe ọ jụrụ oyi. Na ịgbado ọkụ laser, gas na-arụ ọrụ dị mkpa.

Ọ bụghị naanị na gas nchebe ahụ na-emetụta nhazi nke njikọta ịgbado ọkụ, ịdị mma nke njikọta ịgbado ọkụ, ntinye nke njikọta ịgbado ọkụ, na obosara nke njikọta, kamakwa ọ na-emetụta kpọmkwem ịdị mma na arụmọrụ nke njikọta laser.

Kedu gas dị mkpa maka ịgbado ọkụ laser?Isiokwu a ga-eleba anya nke ọma namkpa nke gas ịgbado ọkụ laser, gas ndị e ji mee ihe, na ihe ha na-eme.

Anyị ga-akwadokwaigwe ịgbado ọkụ laser kacha mmamaka mkpa gị.

Gịnị mere e ji chọọ gas maka ịgbado ọkụ laser?

Ịkwado Laser Beam

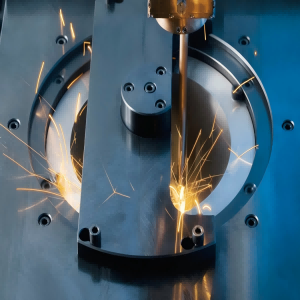

N'oge usoro ịgbado ọkụ laser, a na-elekwasị anya na ogwe laser dị elu nke nwere ike ịgbado ọkụ n'ebe ọrụ ahụ dị.

Na-eme ka ihe e ji rụọ ọrụ gbazee ozugbo.

A chọrọ gas n'oge ịgbado ọkụ laser iji chebe ebe ịgbado ọkụ.

Na-achịkwa okpomọkụ, na-eme ka mma nke ihe e ji alụ ọlụ ahụ ka mma, ma na-echebe sistemụ anya.

Ịhọrọ ụdị gas kwesịrị ekwesị na paramita ọkọnọ bụ ihe dị mkpa iji hụ na ọ dị irè.

Na usoro ịgbado ọkụ laser kwụsiri ike ma nweta nsonaazụ ịgbado ọkụ dị elu.

1. Nchedo Ebe Ịgbado Ọkụ

N'oge usoro ịgbado ọkụ laser, a na-ekpughe mpaghara ịgbado ọkụ ahụ na gburugburu ebe obibi dị n'èzí ma ikuku oxygen na gas ndị ọzọ dị n'ikuku na-emetụta ya ngwa ngwa.

Oxygen na-akpali mmeghachi omume oxidation nke nwere ike ibute mbelata mma nke ịgbado ọkụ, yana imepụta oghere na ihe ndị dị n'ime ya. Enwere ike ichebe ịgbado ọkụ ahụ nke ọma pụọ na mmetọ oxygen site n'inye gas kwesịrị ekwesị, nke na-abụkarị gas na-adịghị arụ ọrụ dị ka argon, n'ebe a na-agbado ọkụ.

2. Njikwa Okpomọkụ

Nhọrọ na ọkọnọ gas nwere ike inye aka ijikwa okpomọkụ nke ebe ịgbado ọkụ. Site n'ịgbanwe ọsọ na ụdị gas, a pụrụ imetụta ọsọ oyi nke ebe ịgbado ọkụ. Nke a dị mkpa iji chịkwaa mpaghara ọkụ metụtara (HAZ) n'oge ịgbado ọkụ ma belata mgbagọ okpomọkụ.

3. Mma mma nke ịgbado ọkụ

Ụfọdụ gas ndị ọzọ, dị ka oxygen ma ọ bụ nitrogen, nwere ike ime ka mma na arụmọrụ nke welds ka mma. Dịka ọmụmaatụ, itinye oxygen nwere ike ime ka mbepụ nke weld dịkwuo mma ma mee ka ọsọ weld dịkwuo elu, ebe ọ na-emetụtakwa ọdịdị na omimi nke weld ahụ.

4. Iju Mmiri Gas

N'ịgbado ọkụ laser, ebe ịgbado ọkụ na-enwekarị okpomọkụ dị elu. Iji sistemu oyi gas nwere ike inyere aka ijikwa okpomọkụ nke ebe ịgbado ọkụ ma gbochie oke okpomọkụ. Nke a dị mkpa iji belata nrụgide okpomọkụ na mpaghara ịgbado ọkụ ma melite mma ịgbado ọkụ.

Ịkwado Laser akpaghị aka

5. Nchedo Gas nke Sistemụ Anya

A na-elekwasị anya na oghere laser ahụ na mpaghara ịgbado ọkụ site na sistemụ anya.

N'oge usoro ịgbado ọkụ, ihe gbazere agbaze na aerosols ndị e mepụtara nwere ike imerụ ihe ndị dị n'anya.

Site n'itinye gas n'ime ebe a na-agbakọta ihe, ihe ize ndụ nke mmetọ na-ebelata ma na-agbatịkwu ndụ nke sistemụ anya.

Kedu gas ndị a na-eji na ịgbado ọkụ laser?

N'ịgbado ọkụ laser, gas ahụ nwere ike kewapụ ikuku na efere ịgbado ọkụ ma gbochie ya imeghachi omume na ikuku. N'ụzọ dị otu a, elu ịgbado ọkụ nke efere ígwè ahụ ga-adị ọcha ma mara mma karịa. Iji gas na-echebekwa anya ahụ pụọ na uzuzu ịgbado ọkụ. Ọtụtụ mgbe, a na-eji gas ndị a:

1. Gas Nchedo:

Gas ndị na-echebe onwe ha, nke a na-akpọkarị "gas ndị na-adịghị agbanwe agbanwe," na-arụ ọrụ dị mkpa na usoro ịgbado ọkụ laser. Usoro ịgbado ọkụ laser na-ejikarị gas ndị na-adịghị agbanwe agbanwe echebe ọdọ mmiri ịgbado ọkụ. Gas ndị a na-ejikarị eme ihe na ịgbado ọkụ laser gụnyere argon na neon. Njirimara anụ ahụ na kemịkalụ ha dị iche iche, yabụ mmetụta ha na ịgbado ọkụ ahụ dịkwa iche.

Gas Nchedo:Argọn

Argon bụ otu n'ime gas ndị a na-ejikarị eme ihe.

O nwere oke ionization dị elu n'okpuru ọrụ nke laser, nke na-adịghị mma ịchịkwa nhazi nke ígwé ojii plasma, nke ga-enwe mmetụta ụfọdụ na ojiji nke lasers dị irè.

Ọdịdị nke argon na-adịghị arụ ọrụ na-egbochi ya ịbanye n'ime usoro ịgbado ọkụ, ebe ọ na-ewepụkwa okpomọkụ nke ọma, na-enyere aka ijikwa okpomọkụ dị n'ebe a na-agbado ọkụ.

Gas Nchedo:Neon

A na-ejikarị neon eme ihe dị ka gas na-adịghị arụ ọrụ, nke yiri argon, a na-ejikwa ya echebe ebe a na-agbakọta ihe site na ikuku oxygen na ihe ndị ọzọ na-emerụ emerụ n'èzí.

Ọ dị mkpa ịmara na neon adabaghị maka ngwa ịgbado ọkụ laser niile.

A na-ejikarị ya eme ihe maka ụfọdụ ọrụ ịgbado ọkụ pụrụ iche, dịka ihe ndị siri ike ma ọ bụ mgbe achọrọ njikọ ịgbado ọkụ miri emi.

2. Gas enyemaka:

N'oge usoro ịgbado ọkụ laser, tinyere gas nchebe bụ isi, enwere ike iji gas enyemaka mee ka arụmọrụ na ịdị mma nke ịgbado ọkụ dịkwuo mma. Ndị a bụ ụfọdụ gas enyemaka a na-ejikarị eme ihe na ịgbado ọkụ laser.

Gas Inyeaka:Oxygen

A na-ejikarị oxygen eme ihe dị ka gas enyemaka, a pụkwara iji ya mee ka okpomọkụ na omimi nke ịgbado ọkụ dịkwuo elu n'oge ịgbado ọkụ.

Ịtinye oxygen nwere ike ime ka ọsọ ịgbado ọkụ na ịbanye n'ime ahụ dịkwuo elu, mana ọ dị mkpa ka a na-achịkwa ya nke ọma iji zere oke oxygen na-akpata nsogbu oxidation.

Gas Inyeaka:Ngwakọta Haịdọn/Hịdọn

Haịdrojiin na-eme ka mma nke njikọta ihe dị iche iche ka mma ma na-ebelata mmepụta nke porosity.

A na-eji ngwakọta argon na hydrogen eme ihe n'ọtụtụ ụzọ pụrụ iche, dịka ịgbado ígwè anaghị agba nchara. Ọdịnaya hydrogen dị na ngwakọta ahụ na-adịkarị site na 2% ruo 15%.

Gas Nchedo:Nitrogen

A na-ejikarị Nitrogen eme ihe dị ka gas enyemaka na njikọta laser.

Ike ionization nke nitrogen dị n'etiti, dị elu karịa argon ma dị ala karịa hydrogen.

Ọ bụ laser na-arụ ọrụ nke ọma n'ọkwa ionization. Ọ nwere ike ibelata mmepụta nke ígwé ojii plasma nke ọma, nye njikọta na ọdịdị dị elu, ma belata mmetụta nke oxygen na welds.

A pụkwara iji Nitrogen chịkwaa okpomọkụ nke ebe a na-agbakọta ihe ma belata mmepụta nke afụ na oghere.

Gas Nchedo:Heliọm

A na-ejikarị helium eme ihe maka ịgbado ọkụ laser dị elu n'ihi na ọ nwere obere ike ikuku okpomọkụ ma ọ naghị adị mfe itinye ya na ion, nke na-eme ka laser ahụ na-agafe nke ọma ma na-enye ike ọkụ ahụ ohere iru n'elu ọrụ ahụ na-enweghị ihe mgbochi ọ bụla.

Ọ na-eme ka ịgbado ọkụ dị elu. Enwere ike iji helium mee ka mma ịgbado ọkụ dịkwuo mma ma chịkwaa okpomọkụ ịgbado ọkụ. Nke a bụ gas nchekwa kachasị mma eji eme ịgbado ọkụ laser, mana ọ dị oke ọnụ.

3. Gas na-ajụ oyi:

A na-ejikarị gas oyi eme ihe n'oge ịgbado ọkụ laser iji chịkwaa okpomọkụ nke ebe ịgbado ọkụ, gbochie oke okpomọkụ, ma nọgide na-enwe mma ịgbado ọkụ. Ndị a bụ ụfọdụ gas oyi a na-ejikarị eme ihe:

Gas/Ọkara nke na-ajụ oyi:Mmiri

Mmiri bụ ihe a na-ejikarị eme ka ihe na-eme ka ihe na-eme ka laser na sistemụ ọkụ laser dị jụụ.

Sistemụ mmiri oyi nwere ike inyere aka idobe okpomọkụ kwụsiri ike nke ihe na-emepụta laser na ihe ndị dị na ngwa anya iji hụ na oghere laser kwụsiri ike ma rụọ ọrụ nke ọma.

Gas/Ọkara nke na-ajụ oyi:Gas ikuku

N'ụfọdụ usoro ịgbado ọkụ laser, enwere ike iji gas ikuku gburugburu mee ka ọ jụọ oyi.

Dịka ọmụmaatụ, na sistemụ anya nke ihe na-emepụta laser, gas gburugburu ikuku nwere ike inye mmetụta oyi.

Gas/Ọkara nke na-ajụ oyi:Gas Ndị Na-adịghị Agbanwe

A pụkwara iji gas ndị na-adịghị arụ ọrụ dịka argon na nitrogen mee ihe dị ka gas jụrụ oyi.

Ha nwere obere ike okpomọkụ, a pụkwara iji ha chịkwaa okpomọkụ nke ebe a na-agbakọta ihe ma belata mpaghara okpomọkụ (HAZ).

Gas/Ọkara nke na-ajụ oyi:Nitrogen mmiri mmiri

Mmiri nitrogen bụ ihe na-eme ka oyi dị obere nke ukwuu nke enwere ike iji maka ịgbado ọkụ laser dị elu nke ukwuu.

Ọ na-enye mmetụta dị mma nke na-ajụ oyi ma na-ahụ na njikwa okpomọkụ dị na mpaghara ịgbado ọkụ.

4. Gas agwakọtara agwakọta:

A na-ejikarị ngwakọta gas eme ihe n'ịgbado ọkụ iji mee ka akụkụ dị iche iche nke usoro ahụ ka mma, dịka ọsọ ịgbado ọkụ, omimi ịbanye n'ime mmiri, na nkwụsi ike arc. E nwere ụdị ngwakọta gas abụọ bụ isi: ngwakọta binary na ngwakọta ternary.

Ngwakọta Gas Abụọ:Argon + Oxygen

Ịtinye obere oxygen na argon na-eme ka nkwụsi ike arc dịkwuo mma, na-eme ka ọdọ mmiri weld dị mma, ma na-eme ka ọsọ ịgbado ọkụ dịkwuo elu. A na-ejikarị ngwakọta a eme ihe maka ịgbado ígwè carbon, ígwè dị obere alloy, na ígwè anaghị agba nchara.

Ngwakọta Gas Abụọ:Argon + Carbon Dioxide

Mgbakwunye nke CO₂ na argon na-eme ka ike ịgbado ọkụ na iguzogide nchara dịkwuo elu ma na-ebelata mgbawa. A na-ejikarị ngwakọta a agbado ígwè carbon na ígwè anaghị agba nchara.

Ngwakọta Gas Abụọ:Argọn + Haịdọn

Haịdrojin na-eme ka okpomọkụ arc dịkwuo elu, na-eme ka ọsọ ịgbado ọkụ dịkwuo mma, ma na-ebelata ntụpọ ịgbado ọkụ. Ọ bara uru karịsịa maka alloys dabere na nickel na ígwè anaghị agba nchara.

Ngwakọta Gas Ternary:Argon + Oxygen + Carbon Dioxide

Ngwakọta a na-ejikọta uru nke ma argon-oxygen na argon-CO₂ ngwakọta. Ọ na-ebelata mgbasa, na-eme ka mmiri ịgbado ọkụ dịkwuo mma, ma na-eme ka mma ịgbado ọkụ dịkwuo mma. A na-ejikarị ya agbado ọtụtụ ọkpụrụkpụ nke ígwè carbon, ígwè dị ala, na ígwè anaghị agba nchara.

Ngwakọta Gas Ternary:Argon + Helium + Carbon Dioxide

Ngwakọta a na-enyere aka ime ka arc kwụsie ike, mee ka okpomọkụ ọdọ mmiri weld dịkwuo elu, ma mee ka ọsọ weld dịkwuo elu. A na-eji ya na obere sekit welding na ngwa welding dị arọ, na-enye njikwa ka mma na oxidation.

Nhọrọ Gas na Ngwa Dị Iche Iche

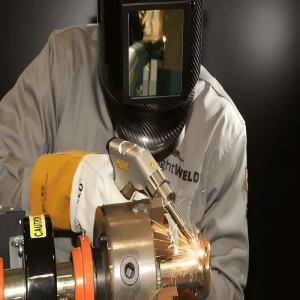

Ịgbado ọkụ Laser aka

N'ọtụtụ ụzọ dị iche iche e si eji laser welding eme ihe, ịhọrọ gas kwesịrị ekwesị dị oke mkpa, n'ihi na njikọta gas dị iche iche nwere ike imepụta ụdị mma ịgbado ọkụ dị iche iche, ọsọ, na arụmọrụ dị iche iche. Lee ụfọdụ ntuziaka ga-enyere gị aka ịhọrọ gas kwesịrị ekwesị maka ngwa gị kpọmkwem:

Ụdị ihe eji agbado ọkụ:

Igwe anaghị agba ncharana-ejikarị eme iheNgwakọta Argon ma ọ bụ Argon/Hydrogen.

Aluminom na Aluminom Alloysna-ejikarị eme iheArgọn dị ọcha.

Alloys Titaniumna-ejikarị eme iheNitrogen.

Ígwè Kabọn Dị Eluna-ejikarị eme iheOxygen dị ka Gas Inyeaka.

Ọsọ ịgbado ọkụ na ntinye aka:

Ọ bụrụ na ọ dị mkpa ka a gbakọta ọsọ ịgbado ọkụ ma ọ bụ itinye n'ime ala nke ọma, a pụrụ ịgbanwe njikọta gas. Ịtinye oxygen na-eme ka ọsọ na ntinye dịkwuo mma, mana ọ dị mkpa ka a chịkwaa ya nke ọma iji zere nsogbu oxidation.

Njikwa Mpaghara Mmetụ Okpomọkụ (HAZ):

Dabere na ihe a na-ehicha, ihe mkpofu dị ize ndụ nke chọrọ usoro njikwa pụrụ iche nwere ike ịpụta n'oge nhicha ahụ. Nke a nwere ike itinye ego na mkpokọta nke usoro nhicha laser.

Ogo ịgbado ọkụ:

Ụfọdụ ngwakọta gas nwere ike ime ka mma na ọdịdị nke welds ka mma. Dịka ọmụmaatụ, nitrogen nwere ike inye ọdịdị na ịdị mma elu ka mma.

Njikwa oghere na afụ:

Maka ngwa ndị chọrọ mmado dị elu, a ga-elebara anya nke ọma n'otú e si emepụta oghere na afụ. Nhọrọ gas kwesịrị ekwesị nwere ike ibelata ihe egwu nke ntụpọ ndị a.

Ihe gbasara akụrụngwa na ọnụ ahịa:

Ụdị akụrụngwa na ọnụ ahịa ya na-emetụtakwa nhọrọ gas. Ụfọdụ gas nwere ike ịchọ sistemụ ọkọnọ pụrụ iche ma ọ bụ ọnụ ahịa dị elu.

Maka ngwa ndị a kapịrị ọnụ, a na-atụ aro ka gị na onye injinia ịgbado ọkụ ma ọ bụ ọkachamara na-emepụta ngwa ịgbado ọkụ laser rụọ ọrụ iji nweta ndụmọdụ ọkachamara ma melite usoro ịgbado ọkụ.

A na-achọkarị nnwale na nhazi tupu ahọrọ ngwakọta gas ikpeazụ.

Dabere na ngwa a kapịrị ọnụ, enwere ike ịnwa njikọta gas na paramita dị iche iche iji chọta ọnọdụ ịgbado ọkụ kacha mma.

Ihe Ị Kwesịrị Ịma Banyere: Ịgbado ọkụ Laser aka

Igwe ịgbado ọkụ laser akwadoro

Iji mee ka ọrụ nhazi ígwè na ihe gị ka mma, ịhọrọ akụrụngwa kwesịrị ekwesị dị mkpa. MimoWork Laser na-akwado ya.Igwe ịgbado ọkụ Laser akamaka njikọ ígwè ziri ezi ma dị irè.

Ike dị elu na Wattage maka Ngwa Ịgbado Ọgba dị iche iche

Igwe ịgbado ọkụ laser nke nwere ike ịrụ ọrụ aka nke 2000W nwere obere nha igwe mana ọ na-egbuke egbuke.

Isi iyi laser eriri kwụsiri ike na eriri eriri ejikọtara na-enye nnyefe ọkụ laser dị nchebe ma kwụsie ike.

Site na ike dị elu, oghere igodo ịgbado ọkụ laser zuru oke ma na-eme ka nkwonkwo ịgbado ọkụ sie ike ọbụlagodi maka nnukwu ígwè.

N'ihi obere igwe dị obere, igwe ịgbado ọkụ laser a na-ebugharị ebugharị nwere egbe ịgbado ọkụ laser a na-ebugharị ebugharị nke dị mfe ma dịkwa mma maka ngwa ịgbado ọkụ laser dị iche iche n'akụkụ na elu ọ bụla.

Ụdị nhọrọ dị iche iche nke ihe mkpuchi laser na sistemụ nri waya akpaka na-eme ka ọrụ ịgbado ọkụ laser dịkwuo mfe, nke ahụ dịkwa mma maka ndị mbido.

Ịgbado ọkụ laser dị elu na-eme ka arụmọrụ mmepụta gị na mmepụta gị dịkwuo mma ma na-eme ka mmetụta ịgbado ọkụ laser dị mma.

chịkọta

Na nkenke, ịgbado ọkụ laser kwesịrị iji gas chebe ebe ịgbado ọkụ, ijikwa okpomọkụ, melite mma ịgbado ọkụ, na ichebe sistemụ anya. Ịhọrọ ụdị gas na paramita ọkọnọ kwesịrị ekwesị bụ ihe dị mkpa iji hụ na usoro ịgbado ọkụ laser dị irè ma kwụsie ike yana inweta nsonaazụ ịgbado ọkụ dị elu. Ihe na ngwa dị iche iche nwere ike ịchọ ụdị dị iche iche na nha agwakọtara iji mezuo ihe achọrọ ịgbado ọkụ.

Kpọtụrụ anyị taaiji mụtakwuo maka igwe eji egbutu laser anyị na otu ha ga-esi mee ka usoro mmepụta ịkpụ gị ka mma.

Njikọ ndị metụtara ya

Echiche ọ bụla gbasara igwe ịgbado ọkụ laser?

Oge ozi: Jenụwarị-13-2025