Ịdọkọta Laser na TIG: Ihe Gbanwere na 2024

Gịnị bụ aka Laser ịgbado ọkụ?

Igwe anaghị agba nchara nke Laser aka

Ịgbado ọkụ laser akana-eji ngwaọrụ laser ebugharị ebugharị iji jikọta ihe, nke na-abụkarị ọla.

Ịgbado ọkụ laser aka na-enye ohere makaka ukwuuike ịnyagharị na nkenke,

Ma na-emepụta weld dị elu, dị ọcha napere mpentinye okpomọkụ,

Mbelatamgbagwoju anya na mkpa maka nhazi sara mbara mgbe a gbasịrị ya.

Ndị ọrụ nwere ike ịgbanwe ike na ọsọ nke laser ngwa ngwa,

Na-enyere akantọala ahaziri ahazimaka ihe dị iche iche na ọkpụrụkpụ.

Isiokwu Ọdịnaya:

Gịnị bụ nhicha laser weld?

Mkpa Ọcha Dị na Ịgbado Ọkụ

Nhicha Tupu Ịgbado ọkụ maka Ịkwado ọkụ TIG

Mgbe a bịara n'ihe gbasara ịgbado ọkụ,

Ịdị ọcha na-arụ ọrụ dị oke mkpa n'imezu ihe mgbaru ọsọịdị mma Dị elunsonaazụ.

Ụkpụrụ a metụtara ma ịgbado ọkụ TIG na ịgbado ọkụ laser aka,

Mana ụzọ e si akwadebe ihe dị iche iche.

Maka usoro ịgbado ọkụ ọ bụla,

Ọnụnọ nke ihe ndị na-emerụ emerụ dịka nchara, agba, na mmanụ

Nwere ikenkwekọrịta siri ikeiguzosi ike n'ezi ihe nke weld ahụ.

Ihe ndị a na-adịghị ọcha nwere ike ibute nkwonkwo na-adịghị ike, oghere, na ntụpọ ndị ọzọ

Nke ahụ na-emebi ike nke ngwaahịa ikpeazụ.

Nke a bụ otú ị siKWESỊRỊJikọta ihe ndị a na-emerụ ahụ:Ịsacha ihe nhicha laser.

Ịgbado ọkụ Laser vs ịgbado ọkụ TIG: Ịsacha ịgbado ọkụ Laser

Ebe ndị a na-ehicha nke ọma na-emepụta ihe ndị a na-akpọ Weld dị elu

Ịsacha Laser Weld maka Nhicha Laser aka

Ọ bụ ezie na ịgbado ọkụ TIG na-adabere naakwụkwọ ntuziakaụzọ nhicha dị ka ịpị akụkụ na ihicha acetone,

Njikọta laser aka na-enye ihe kachasị mmadị mfenhọrọ ya na ikike nhicha ya agbakwunyere.

Ihe ọhụrụ a abụghị naanị na ọ na-eme ka arụmọrụ ka mma

Ma na-emekwa ka usoro ịgbado ọkụ ahụ dị irè dịka o kwere mee,

N'ikpeazụ, ọ na-eduga n'ihe ka mma.

Nkwadebe maka ịgbado ọkụ TIG:

Na TIG (Gas Tungsten Inert) ịgbado ọkụ, nkwadebe nke ọma dị mkpa.

Tupu ịmalite usoro ịgbado ọkụ,

A na-ejikarị ya eme ihendị na-egweri nkukuiji wepụ nchara ma ọ bụ ihe mkpuchi n'elu ihe ahụ.

Nhicha igwe a na-enyere aka hụ na elu ya enweghị ihe ruru unyi.

Mgbe nke a gasịrị, hichaa nke ọma naacetonea na-emekarị ya.

Acetone bụ ihe mgbaze dị ike nke na-eme ka ahụ dị nrona-ewepụ nke ọmammanụ ma ọ bụ ihe ndị na-emerụ emerụ ọ bụla fọdụrụ,

Ịhapụ ebe dị ọcha maka ịgbado ọkụ ahụ.

Usoro nhicha a nke nwere nzọụkwụ abụọ nwere ike were oge,

Ma ọ dị mkpa iji nweta njikọ siri ike ma sie ike.

Nkwadebe maka ịgbado ọkụ laser aka

N'aka nke ọzọ, a na-enye ọrụ njikọta laser aka.

Ihe ọzọusoro dị mfeiji kwadebe elu.

Na3-n'ime-1igwe na-arụzi laser, usoro ahụ na-adị mfe nke ukwuu.

Igwe ndị a dị elu na-abịakarị nanozzles ndị a na-agbanwe agbanwe

Nke ahụ na-enye ohere maka ihicha elu ozugbo tupu ịgbado ọkụ.

N'adịghị ka usoro ọdịnala, ebe achọrọ ngwaọrụ na ihe nhicha dị iche iche,

Ndị na-agbado ọkụ laser nwere ike ihicha elu ahụ n'enweghị nsogbu site na iji ọkụ laser lekwasịrị anya.

Nke a anaghị echekwa naanị oge kamakwa ọ na-ebelatakwa ogeọnụọgụ akụrụngwaachọrọ n'ebe ahụ.

Ịkwado ọkụ laser vs TIG agbanweela na 2024

Kpọtụrụ Anyị Maka Ihe Ndị Ọzọ Banyere Sistemụ Ịgbado Ọkụ Laser Aka

Gịnị mere e ji eji Gas Nchebe na Ịgbado ọkụ?

Nhọrọ nke Gas Nchebe Na-arụ Ọrụ Dị Mkpa

Mmanụ Nchekwa Maka Ịgbado Ọkụ TIG: Argon

Mgbe a bịara n'ihe gbasara ịgbado ọkụ,

Nhọrọ nke gas nchebe dị oke mkpa iji hụ na nsonaazụ dị elu.

Karịsịa, ịgbado ọkụ TIG na ịgbado ọkụ laser aka nwere ihe dị iche iche achọrọ na nhọrọ dị iche iche

Mgbe ọ na-abịa n'ihe gbasara nchekwa gas, ọ na-emetụta ma arụmọrụ ma ọnụ ahịa.

Gas nchekwa n'imeỊkwado TIG

N'ime TIG (Tungsten Inert Gas) ịgbado ọkụ,

Isi ihe eji ekpuchi ihe bụ gas nchekwa nke e jiịdị ọcha dị eluargọn.

A na-ahọrọ gas a dị mma maka ikike ya dị mmachebe ọdọ mmiri ịgbado ọkụ

Site na mmetọ ikuku, ọkachasị oxidation.

Oxidation nwere ike ibutentụpọn'ime ihe mgbochi ahụ, dịka porosity na nkwonkwo adịghị ike,

Kedu nkenkwekọrịtaiguzosi ike n'ezi ihe nke ígwè ahụ.

N'ihi na ọ dị irè,

Ịgbado ọkụ TIG na-achọkarịna-aga n'ihuọkọnọ nke argon n'oge usoro ịgbado ọkụ.

Agbanyeghị, argon nwere ike ịdị oke ọnụ, na-ebute ọnụ ahịa ọrụ dị elu.

Karịsịa n'ọrụ ndị chọrọ nnukwu ịgbado ọkụ.

Gas nchekwa n'imeỊgbado ọkụ Laser aka

Gas Nchekwa Ọzọ maka Ịkwado Laser: Nitrogen

N'aka nke ọzọ, ịgbado ọkụ laser ejiri aka na-ejikarị nitrogen eme ihe dị ka gas nchebe.

Nitrogen abụghị naanị ihedị irèna igbochi oxidation

Ma ọ dịkwa oke mkpadị irèkarịa argọn.

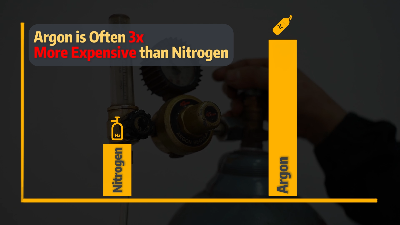

Ọdịiche ọnụahịa nwere ike ịdị oke mkpa;

Nitrogen nwere ike ime ihe fọrọ nke nta ka ọ bụrụugboro atọdị ọnụ ala karịa argon dị ọcha nke ukwuu.

Nke a na-eme ka nitrogen bụrụ nhọrọ mara mma maka azụmaahịa na-achọ ibelata ọnụ ahịan'achụghị àjààgwà.

Ịkwado TIG vs Laser: Nhọrọ Gas Na-echebe

Nweta ego echekwara ka ị na-echekwa ịdị mma

Ntụnyere Ọnụahịa n'etiti Argon na Nitrogen

Ịgbanwe gaa na nitrogen na nkwekọrịta ịgbado ọkụ laser akaọtụtụuru

Nchekwa ego:

Nanke dị mkpaihe dị iche n'etiti argon na nitrogen

Iji nitrogen eme ihe nwere ike ibute nnukwu nchekwa ka oge na-aga.

Nke a bụbara uru nke ukwuumaka nnukwu ọrụ ma ọ bụ azụmaahịa

Nke a na-arụ ọrụ ịgbado ọkụ ugboro ugboro.

Nchedo Dị Irè:

Nitrogen na-enyenchebe zuru okemegide oxidation,

Iji hụ na weld ahụ ka dịdị ọcha ma sie ike.

Ọ bụ ezie na a maara argon maka nchekwa ya dị elu,

Nitrogen ka dịnhọrọ dị irènke na-emezu mkpa nke ọtụtụ ngwa ịgbado ọkụ nke ọma.

Tụlee Usoro Ịgbado Ọkụ: Ịgbado Ọkụ Laser vs TIG

Nlebara anya nke ọma na usoro a na-enweta nsonaazụ kacha mma

Akụkụ Aka nri maka ịgbado ọkụ laser: ogo 45

Ozugbo gas nchekwa ahụ na-asọ nke ọma,

Oge eruola ka anyị lekwasị anya n'otú e si eji agbado ọkụ.

Ma ịgbado ọkụ TIG (Tungsten Inert Gas) na ịgbado ọkụ laser aka

Chọrọusoro ziri eziiji nweta nsonaazụ dị elu,

Agbanyeghị, ha dị iche na ihe achọrọ na ụzọ ha si eme ya.

Ịkwado TIGUsoro

Mee ka elektrọd ahụ dịgide naanya na ọsọ kacha mmaịmepụta ma duzie ọdọ mmiri ịgbado ọkụ.

Anya a nwere ike ịdị iche dabere na ihe na ọkpụrụkpụ nke a na-agbado.

Ịnọgide na-enwe akụkụ ziri ezi, na-abụkarị gburugburuokpomọkụ site na 15 ruo 20 degrees,

Na-enyere aka inweta njikọta na-adịgide adịgide ma dị ọcha.

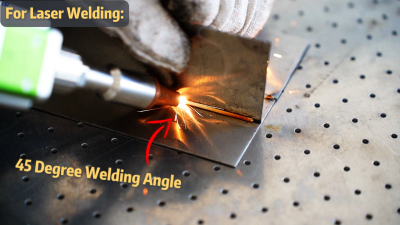

Ịgbado ọkụ Laser akaUsoro

Otu n'ime uru nke ịgbado ọkụ laser bụ ikike ịtọ akụkụ na-agbanwe agbanwe

Dịka ọ na-adịkarị, gburugburuOgo ogo 45, na-enye ohere maka njikwa dị mfe nke usoro ịgbado ọkụ.

Ozugbo e debere akụkụ ahụ, na-edobe yaọsọ kwụsiri ikebụ isi ihe.

Ịgbado ọkụ laser aka na-emepụtakarịobere okpomọkụma e jiri ya tụnyere ịgbado ọkụ TIG.

Nke a pụtara na e nwereobere ihe ize ndụ nke ịgbagọ ma ọ bụ ịgbagọ,

Ime ka ọ dị mma maka ịrụ ọrụ ziri ezi na ihe ndị dị gịrịgịrị.

Ike Ịdọkọta Laser vs TIG: Akụkọ Ifo Na-agbagha Echiche Ụgha

Echiche na-ezighi ezi gbasara ịgbado ọkụ laser

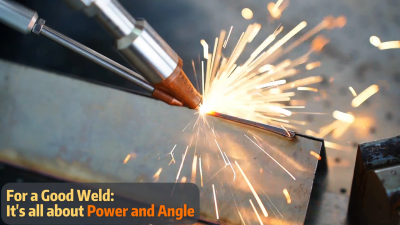

Maka Ezi Ngwunye Laser Aka: Ike & Angle

Otu n'ime uru dị na ịgbado ọkụ laser aka bụ ikike ya inye ike a na-etinye n'ime ihe niile.kpọmkwemebe a chọrọ ya.

Nantọala ike ziri ezinaakụkụ kacha mma

Dịka ọ na-adịkarị, gburugburuOgo ogo 45, ịgbado ọkụ laser nwere ike ime ka ọ banye n'ime na ike dị mma.

Mmepụta Ike Ziri Ezi

Ntọala ike nke ihe nkwado laser dị oke mkpa.

Oke mbelata nke mmepụta ike nwere ike ibutentinye aka na-ezughị oke, na-eduga na njikọta adịghị ike.

N'aka nke ọzọ, ọkwa ike kwesịrị ekwesị na-enye laser ohere ịgbaze ihe ahụ nke ọma, na-emepụta nkwonkwo siri ike.

Iji akụrụngwa ndị na-adịghị ike agaghị arụpụta ihe achọrọ.

Ma TIG na Handheld Laser Welding dị irè

Ị chọrọ ịmụtakwu gbasara ịgbado ọkụ laser aka?

Ịgbado Laser aka: Otu esi edozi akụrụngwa

Nlekọta kwesịrị ekwesị na nlebara anya zuru ezu ga-eme ka mmepụta na ntụkwasị obi dị

Ị maara na njikọta ọkụ TIG (Tungsten Inert Gas) na nke laser aka bụ nkewa dị ka nkewa

Ụzọ ịgbado ọkụ na-abụghị nke a na-ere ere?

Nke a pụtara na, n'okpuru ọnọdụ dị mma na nlekọta kwesịrị ekwesị,

Ihe ndị dị mkpa e ji mee ihe n'usoro ndị a nwere ike ịdịru ogologo oge

Na-enweghị mkpa nnọchi ugboro ugboro.

Ihe Ndị A Na-anaghị Eri

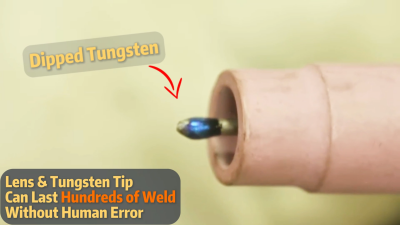

Njehie Tungsten e tinyere n'ime mmiri maka ịgbado ọkụ TIG

Elektrọd tungsten bụ ihe dị oke mkpa na njikọta TIG.

N'adịghị ka elektrọd ndị a na-eri eri nke e ji eme ihe n'ụzọ ndị ọzọ e si agbado ọkụ,

dịka ịgbado ọkụ MIG, elektrọd tungstenanaghị agbaze agbazen'oge usoro ịgbado ọkụ.

Kama nke ahụ, ọ na-anọgide na-eguzosi ike n'ihe, na-enye ohere maka ojiji ogologo oge.

Agbanyeghị, elektrọd ahụ nwere ike imerụ ahụ ma ọ bụ "mikpuo" ma ọ bụrụ na ọ banyedị nnọọ nso n'ọdọ mmiri ịgbado ọkụ ahụ.

N'ọnọdụ ndị dị otú a, a ga-egbutu ya ma gwerie ya iji weghachi ike ya dị nkọ ma rụọ ọrụ nke ọma.

Mmezi mgbe niilenke tungsten electrode dị mkpa maka inweta njikọta dị ọcha ma dị elu.

Nkwadebe maka ịgbado ọkụ laser aka

Lens Laser maka Mmezi Ịdọkọta Laser n'aka

N'iji laser agbado aka, lenzi laser na-arụ ọrụ dị ka isi ihe maka ìhè laser.

Lensi e tinyere n'ọnọdụ kwesịrị ekwesị nwere ike ịdịru ogologo oge, na-enye arụmọrụ na-aga n'ihu.

Agbanyeghị, ọ bụrụ na lenzi ahụ agbawa agbawa n'ihi ọnọdụ na-ekwesịghị ekwesị ma ọ bụ ikpughe ya na oke okpomọkụ

A ga-achọ ka edochie ya.

Idobe lenzi ahụ n'ọnọdụ dị mma dị oke mkpa,

Ebe ọ bụ na obere mmebi nwere ike imetụta izi ezi na irè nke laser ahụ, na-eduga na welds na-adịghị mma.

Ị chọrọ ntuziaka zuru oke maka ịgbado ọkụ laser aka?

Njikọta laser aka nwere ọtụtụ uru,

Mana ọ chọkwara nlebara anya nke ọma na usoro nchekwa.

Isiokwu a ga-enyocha ihe ndị dị mkpa gbasara nchekwa maka ịgbado ọkụ laser aka.

Nakwa inye ndụmọdụ gbasara nhọrọ gas na nhọrọ waya njupụta maka ụdị ígwè nkịtị.

Ịkụnye ọkụ laser ọ̀ siri ike dịka ịgbado ọkụ TIG?

Ịgbado ọkụ laserna njikọta ígwè TIG (Tungsten Inert Gas) bụ ihe a ma ama maka nkenke na ịdị mma ha na njikọ ígwè.

Mana kedu ka ha si ejikọta onwe ha n'ihe gbasara ike?

Na vidiyo a, anyị ga-eleba anya n'ihe dị iche iche dị na ngwaahịa aarụmọrụ ịgbado ọkụ,ndakọrịta ihe, naogologo ndụ zuru oken'etiti ịgbado ọkụ laser na TIG.

Njikọta Laser Fiber Ejiri Aka (Ịdọta Laser Ejiri Aka)

Mgbakwunye bara uru na ala aka nke laser weld

Obere ihe na-agbakọta ígwè na-eme ka ịgbado ọkụ dị ọnụ ala ma dịkwa ọnụ ala

Na obere ọdịdị igwe.

Igwe igwe laser welder nke a na-ebugharị ebugharị nwere egbe laser welder nke a na-ebugharị agagharị nke bụdị fechaa.

Ọ dịkwa mma maka ngwa ịgbado ọkụ laser dị iche iche naakụkụ ọ bụlanaelu.

Ụdị dị iche iche nke laser welder nozzles nhọrọ.

Sistemụ nri waya akpaka nke nhọrọ na-eme ka ọrụ ịgbado ọkụ laser dịkwuo mfe, nke ahụ dịkwa mma maka ndị mbido.

Ihe Ise Banyere Ịgbado Ọkụ Laser (Nke Ị Na-efu)

Ọ bụrụ na vidiyo a masịrị gị, gịnị ma ị tụlee ya?ịdenye aha na ọwa Youtube anyị?

Ngwa Ndị Yiri Ya Ị Nwere Ike Ịmasị:

Njikọ Laser aka bụ ezigbo nhọrọ maka ọrụ ịgbado ọkụ aka

Ọdịnihu na-amalitekwa site n'aka gị!

Oge ozi: Sep-14-2024