Kuwotcherera kwa laserluso lamakono lasintha mafakitale opangira zinthu ndi kupanga, kupereka kulondola kosayerekezeka, kuthamanga, ndi kusinthasintha. Njira yowotcherera yapamwambayi imagwiritsa ntchito matabwa a laser okhazikika kuti asungunuke ndikulumikiza zida, zomwe zimapangitsa kuti zikhale zoyenera kugwiritsa ntchito zosiyanasiyana.

Chimodzi mwazabwino zazikulu za kuwotcherera kwa laser ndikutha kugwira ntchito ndi zida zosiyanasiyana, zomwe zimapangitsa opanga kupanga zolumikizira zolimba, zolimba pazinthu zosiyanasiyana.

M'nkhaniyi, tiwona zida zofunika zomwe zimatha kuwotcherera pogwiritsa ntchito makina opangira laser, ndikuwunikira zomwe zili ndi ntchito zawo zapadera.

1. Laser Machine kuwotcherera Zitsulo

a. Chitsulo chosapanga dzimbiri

Chitsulo chosapanga dzimbiri ndi chimodzi mwa zitsulo zomwe zimagwiritsidwa ntchito kwambiri pogwiritsa ntchito ukadaulo wa laser. Chitsulo chosapanga dzimbiri chimagwiritsidwa ntchito kwambiri m'mafakitale monga kukonza zakudya, mankhwala, kupanga magalimoto, kupanga, kupanga ndi kulimba kwake, komwe kumadziwika kuti kukana dzimbiri komanso mphamvu zake.

Kuwotcherera kwa laser kumapereka ma weld apamwamba kwambiri, oyera okhala ndi madera ochepa omwe amakhudzidwa ndi kutentha (HAZ), kuwonetsetsa kuti zinthu zakuthupi zimakhalabe. Kutha kuwongolera bwino mphamvu ya laseramalola kuwotcherera zigawo zoonda ndi zokhuthala mofanana, kuzipanga kukhala zoyenera zojambulajambula ndi misonkhano yovuta.

b. Chitsulo cha Carbon

Mpweya wa carbon ndi chitsulo china chomwe chimabwereketsa bwino ku kuwotcherera kwa laser. Izi ndizofala kwambiri pakumanga ndi kupanga, komwe zimagwiritsidwa ntchito pazinthu zamakina ndi makina.Kuwotcherera kwa laser kumawonjezera mphamvu komanso kulimba kwa ma welds a zitsulo za kaboni ndikusunga kumaliza kwapamwamba.

Njirayi ndi yothandiza, kuchepetsa chiopsezo cha kumenyana ndi kupotoza komwe nthawi zambiri kumagwirizanitsidwa ndi njira zowotcherera zachikhalidwe. Kuphatikiza apo, kuthamanga kwa kuwotcherera kwa laser kumalola opanga kuonjezera zokolola popanda kusokoneza khalidwe.

c. Aluminiyamu ndi Aluminiyamu Aloyi

Aluminiyamu ndi yamtengo wapatali chifukwa cha zinthu zake zopepuka komanso zolimbana ndi dzimbiri, zomwe zimapangitsa kuti ikhale chinthu choyamikirika m'mafakitale am'mlengalenga ndi magalimoto. Komabe, kuwotcherera aluminiyamu kumatha kukhala kovuta chifukwa cha kuchuluka kwake kwamafuta komanso kukhudzidwa ndi zovuta zokhudzana ndi kutentha.

Kuwotcherera kwa laser kumathana ndi zovutazi popereka gwero la kutentha lomwe limachepetsa kuyika kwa kutentha ndikuchepetsa kupotoza.Njirayi imalola kulumikiza molondola kwa zigawo za aluminiyamu, zomwe zimathandizira kupanga zinthu zopepuka zokhala ndi makina abwino kwambiri.

d. Copper ndi Copper Alloys

Copper imadziwika chifukwa cha mphamvu zake zamagetsi, zomwe zimapangitsa kuti zikhale zofunikira pamagetsi monga mawaya ndi ma boardboard.

Ngakhale kuwotcherera mkuwa kungakhale kovuta chifukwa cha matenthedwe ake apamwamba komanso kuwunikira, makina owotcherera a laser okhala ndi zoikamo zapamwamba amatha kupeza zotsatira zabwino.

Tekinoloje iyi imathandizira kulumikizana bwino kwa mkuwa ndi ma aloyi ake, kuonetsetsa kulumikizana kwamphamvu komanso kodalirika komwe kuli kofunikira pakugwiritsa ntchito magetsi.

e. Nickel ndi Nickel Aloyi

Nickel ndi ma alloys ake amagwiritsidwa ntchito kwambiri m'malo otentha kwambiri komanso owononga, monga m'mafakitale amafuta ndi mafuta.

Kuwotcherera kwa laser kumapereka njira yabwino komanso yothandiza yolumikizira zidazi, kuwonetsetsa kuti ma welds amasunga umphumphu wawo pansi pazovuta kwambiri.

Kulondola kwa kuwotcherera kwa laser kumakhala kopindulitsa makamaka pakugwiritsa ntchito komwe kulumikizidwa kowotcherera ndikofunikira.

2. Kugwiritsa Ntchito Laser Welding Pulasitiki

Kuwonjezera pa zitsulo,kuwotcherera kwa laser kumathandizanso pamapulasitiki osiyanasiyana, kukulitsa kugwiritsidwa ntchito kwake m'mafakitale osiyanasiyana.

Chitsulo Laser Welding Machine Aluminium

a. Polypropylene (PP)

Polypropylene imagwiritsidwa ntchito kwambiri pakuyika, zida zamagalimoto, ndi zinthu za ogula. Kuwotcherera kwa laser kumalola kulumikizana kolimba, kopanda msoko komwe kumatha kupititsa patsogolo magwiridwe antchito azinthu za polypropylene.

Njirayi ndi yoyera komanso yothandiza, kuchepetsa kufunikira kwa zomatira zowonjezera kapena zomangira zamakina, zomwe zimatha kusunga nthawi ndikuchepetsa ndalama.

b. Polyethylene (PE)

Polyethylene ndi pulasitiki ina wamba yomwe imatha kuwotcherera pogwiritsa ntchito ukadaulo wa laser. Amagwiritsidwa ntchito popanga zinthu kuyambira m'mitsuko kupita ku makina opopera.Laser kuwotcherera kwa polyethylene kumapereka njira yolumikizira yolimba yomwe imatha kupirira mikhalidwe yosiyanasiyana ya chilengedwe.Kulondola kwa ndondomekoyi kumatsimikizira kuti ma welds ndi amphamvu komanso odalirika, kukwaniritsa zofunikira za ntchito zovuta.

c. Polycarbonate (PC)

Polycarbonate ndi yamtengo wapatali chifukwa cha kukana kwake komanso kumveka bwino kwa kuwala, zomwe zimapangitsa kukhala chisankho chabwino pakugwiritsa ntchito monga magalasi otetezera chitetezo ndi zowonetsera zamagetsi. Kuwotcherera kwa laser kumapereka njira yolumikizira zida za polycarbonate popanda kusokoneza kukhulupirika kwawo.Kutha kumeneku kumakhala kopindulitsa makamaka m'mafakitale omwe kuwonekera komanso kukhazikika ndikofunikira.

d. Polyamide (nayiloni)

Nayiloni, yomwe imadziwika ndi mphamvu zake komanso kusinthasintha kwake, imagwiritsidwa ntchito kwambiri pamagalimoto, nsalu, komanso zinthu za ogula. Kuwotcherera kwa laser kungagwiritsidwe ntchito kuti agwirizane ndi zida za nayiloni bwino, kupereka zomangira zolimba zomwe zimatha kupirira kupsinjika kwamakina.Kutha kuwotcherera nayiloni pogwiritsa ntchito ma lasers kumatsegula mwayi watsopano pakupanga zinthu ndi uinjiniya.

Mukufuna Kugula Chowotcherera cha Laser?

3. Laser kuwotcherera kompositi Zida

Pamene mafakitale akutembenukira kuzinthu zophatikizika pazinthu zawo zapadera,ukadaulo wowotcherera wa laser ukusintha kuti ukwaniritse zosowa izi.

a. Zida za Metal-Pulasitiki

Zophatikizira zachitsulo-pulasitiki zimaphatikiza zabwino za zida zonse ziwiri, zomwe zimapereka mayankho opepuka koma amphamvu pazogwiritsa ntchito zosiyanasiyana.

Kuwotcherera kwa laser kumatha kujowina zophatikizika izi, ndikupangitsa kuti ikhale njira yofunikira pakupanga magalimoto ndi zamagetsi.

Kukhoza kupanga zilumikizano zolimba popanda kuwonjezera kulemera kwakukulu ndizopindulitsa kwambiri m'mafakitalewa.

b. Fiber-Reinforced Composites

Zidazi, zomwe zimaphatikizira ulusi mu utomoni wa utomoni, zimadziwika chifukwa cha mphamvu zawo zolemera kwambiri.

Ukadaulo wowotcherera wa laser utha kugwiritsidwa ntchito pamitundu ina yamagulu olimbikitsira ulusi, kulola kujowina kolondola komwe kumasunga kukhulupirika kwa ulusi.

Kuthekera kumeneku kumakhala kothandiza kwambiri pazamlengalenga komanso pamagalimoto, pomwe zida zopepuka ndizofunikira kwambiri kuti zigwire ntchito.

4. Laser Welding Machine Weld Emerging Application

Kusinthasintha kwaukadaulo wa kuwotcherera kwa laser kumabweretsa kukhazikitsidwa kwatsopano komanso kwatsopano.

Mafakitale monga mphamvu zongowonjezwdwa akuwunika kugwiritsa ntchito kuwotcherera kwa laser popanga solar panel, komwe kutha kujowina zida zofananira ndikofunikira.

Kuonjezera apo,Kupita patsogolo kwaukadaulo wa laser kukupangitsa kuwotcherera kwa zida zovuta kwambiri, kukulitsa kukula kwa kuwotcherera kwa laser.

5. Mapeto

Makina owotcherera a laser amatha kujowinamitundu yosiyanasiyana ya zida, kuphatikizapo zitsulo, mapulasitiki, ndi ma composites.

Kulondola komanso kuchita bwino kwa kuwotcherera kwa laser kumapangitsa kukhala chisankho choyenerazamafakitale osiyanasiyana, kuphatikiza zamagalimoto, zakuthambo, zamagetsi, ndi ntchito zamankhwala.

Pomwe ukadaulo ukupitilirabe patsogolo, zida zingapo zomwe zitha kuwotcherera bwino pogwiritsa ntchito ma lasers zitha kukulirakulira, kupititsa patsogolo kusinthasintha kwake komanso kugwiritsidwa ntchito pakupanga kwamakono.

Kusinthasintha kumeneku kumayika kuwotcherera kwa laser ngati njira yofunika kwambiri pakukwaniritsa zinthu zapamwamba, zokhazikika pamsika womwe ukupikisana nawo kwambiri.

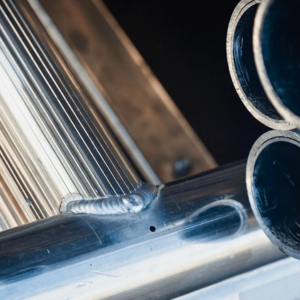

Laser Welder Welding Metal

Ndikufuna Kudziwa Zambiri ZaLaser Welder?

Makina Ofananira: Ma laser Welders

Chowotcherera cham'manja cha fiber laser chapangidwa ndi magawo asanu: nduna, gwero la fiber laser, makina ozungulira ozizirira madzi, makina owongolera a laser, ndi mfuti yowotcherera pamanja.

Makina osavuta koma okhazikika amathandizira kuti wogwiritsa ntchito azisuntha makina otsekemera a laser mozungulira ndikuwotcherera zitsulo momasuka.

Chowotcherera cha laser chonyamula chimagwiritsidwa ntchito powotcherera zitsulo zamabillboard, kuwotcherera zitsulo zosapanga dzimbiri, kuwotcherera kabati yachitsulo, ndi kuwotcherera kwazitsulo zazikulu zamapepala.

Makina a fiber laser welder ali ndi mfuti yowotcherera ya laser yomwe imakuthandizani kuti mugwire ntchito yogwira dzanja.

Kutengera chingwe CHIKWANGWANI cha utali winawake, khola ndi apamwamba laser mtengo imafalitsidwa kuchokera gwero CHIKWANGWANI laser kuti laser kuwotcherera nozzle.

Izi zimathandizira index ya chitetezo ndipo ndizochezeka kwa woyambitsa kugwiritsa ntchito chowotcherera cham'manja cha laser.

Nthawi yotumiza: Jan-06-2025