Kuwotcherera kwa Laser vs TIG Welding: Zomwe Zinasintha mu 2024

Kodi kuwotcherera m'manja Laser ndi chiyani?

Handheld Laser Welding Stainless Steel

Kuwotcherera kwa laser m'manjaamagwiritsa ntchito chipangizo chonyamula cha laser kuti agwirizane ndi zinthu, makamaka zitsulo.

Kuwotcherera m'manja laser kumalolachachikulumaneuverability ndi kulondola,

Ndipo amapanga weld wapamwamba kwambiri, woyera ndizochepakulowetsa kutentha,

Kuchepetsakupotoza ndi kufunikira kochulukira pambuyo pa kuwotcherera.

Othandizira amatha kusintha mphamvu ndi liwiro la laser mosavuta,

Kuthandizirazokonda zokondakwa zipangizo zosiyanasiyana ndi makulidwe.

Zamkatimu:

Kodi Laser Weld Cleaning ndi chiyani?

Kufunika Kwa Ukhondo Pakuwotcherera

Pre-Weld Cleaning for TIG Welding

Pankhani yowotcherera,

Ukhondo umakhala ndi gawo lalikulu pakukwaniritsamapangidwe apamwambazotsatira.

Mfundo imeneyi imagwira ntchito pa kuwotcherera kwa TIG ndi kuwotcherera kwa laser m'manja,

Koma njira zokonzera nkhanizo zimasiyana kwambiri.

Panjira iliyonse yowotcherera,

Kukhalapo kwa zowononga monga dzimbiri, utoto, ndi mafuta

Muthakunyengerera kwambirikukhulupirika kwa weld.

Zonyansazi zimatha kuyambitsa mafupa ofooka, porosity, ndi zolakwika zina

Izi zimawononga mphamvu ya chinthu chomaliza.

Umu ndi Momwe inuAYENERAYang'anani ndi Zoyipa izi:Laser Weld Kuyeretsa.

Kuwotcherera kwa Laser vs TIG Welding: Laser Weld Cleaning

Malo Oyeretsedwa Amapanga Mawotchi Apamwamba

Laser Weld Kuyeretsa Kwa Handheld Laser Kuyeretsa

Pomwe kuwotcherera kwa TIG kumadalirabukunjira zoyeretsera monga kugaya ngodya ndi kupukuta acetone,

Kuwotcherera kwa laser m'manja kumapereka zambiriyabwinonjira ina ndi integrated kuyeretsa mphamvu.

Izi zatsopano sikuti zimangowonjezera luso

Koma zimatsimikiziranso kuti kuwotcherera ndi kothandiza momwe ndingathere,

Pamapeto pake zimabweretsa zotsatira zabwino.

Kukonzekera kwa TIG Welding:

Mu TIG (Mafuta a Tungsten Inert) kuwotcherera, kukonzekera mosamala ndikofunikira.

Asanayambe ntchito yowotcherera,

Ndizofala kugwiritsa ntchitoangle grinderskuchotsa dzimbiri kapena zokutira pamwamba pa zinthu.

Kuyeretsa makinawa kumathandiza kuti pamwamba pakhale opanda zonyansa.

Potsatira izi, bwinobwino pukuta ndiacetonezimachitika kawirikawiri.

Acetone ndi chosungunulira champhamvu chomwebwino amachotsamafuta otsala kapena zonyansa,

Kusiya malo oyera kwa weld.

Njira yotsuka ziwirizi imatha kutenga nthawi,

Koma ndikofunikira kuti mukhale ndi weld wamphamvu komanso wokhazikika.

M'manja Laser kuwotcherera Kukonzekera

Mosiyana, m'manja laser kuwotcherera amapereka

A zambirinjira yowongokakukonzekera pamwamba.

Ndi a3-mu-1laser welder, ndondomekoyi imakhala yosavuta kwambiri.

Makina apamwamba awa nthawi zambiri amakhala ndi zidama nozzles osinthika

Izi zimalola kuyeretsa pamwamba musanawotchere.

Mosiyana ndi njira zachikhalidwe, pomwe zida zapadera ndi zoyeretsera zimafunikira,

Mawotchera a laser amatha kuyeretsa pansi mosavuta ndi mtengo wolunjika wa laser.

Izi sizimangopulumutsa nthawi komanso zimachepetsakuchuluka kwa zidazofunikira pa tsamba.

Laser Welding vs TIG Welding yasintha mu 2024

Lumikizanani nafe kuti mudziwe zambiri za Handheld Laser Welding System

Chifukwa Chiyani Mumagwiritsire Ntchito Gasi Woteteza Pakuwotcherera?

Kusankha Kuteteza Gasi Kumakhala Ndi Udindo Wovuta

Gasi Woteteza kwa TIG Welding: Argon

Pankhani yowotcherera,

Kusankhidwa kwa gasi woteteza ndikofunikira kuti mutsimikizire zotsatira zapamwamba.

Makamaka, kuwotcherera kwa TIG ndi kuwotcherera kwa laser m'manja kumakhala ndi zofunikira ndi zosankha zosiyanasiyana

Pankhani yoteteza mpweya, zomwe zimakhudza magwiridwe antchito komanso mtengo.

Kuteteza Gasi mkatiKuwotchera kwa TIG

mu TIG (Tungsten Inert Gas) kuwotcherera,

Gawo loyamba la gasi lomwe limagwiritsidwa ntchitochiyero chapamwambaargon.

Mpweya wolemekezekawu umasankhidwa chifukwa cha luso lake labwino kwambirikuteteza dziwe weld

Kuchokera ku kuipitsidwa kwa mumlengalenga, makamaka makutidwe ndi okosijeni.

Oxidation imatha kuyambitsazolakwikamu weld, monga porosity ndi mafupa ofooka,

Zomwekunyengererakukhulupirika kwathunthu kwachitsulo.

Chifukwa cha mphamvu zake,

TIG kuwotcherera nthawi zambiri kumafuna amosalekezakupereka argon panthawi yonse yowotcherera.

Komabe, argon ikhoza kukhala yokwera mtengo, zomwe zimapangitsa kuti pakhale ndalama zambiri zogwirira ntchito,

Makamaka m'mapulojekiti omwe amafunikira kuwotcherera kwambiri.

Kuteteza Gasi mkatiKuwotcherera kwa Laser m'manja

Gasi Wotchinga Wina Wakuwotcherera Laser: Nayitrogeni

Kumbali ina, kuwotcherera m'manja kwa laser nthawi zambiri kumagwiritsa ntchito nayitrogeni ngati mpweya wotchingira.

Nayitrojeni si yekhaogwirapopewa oxidation

Koma ndizofunikanso kwambirizotsika mtengokuposa argon.

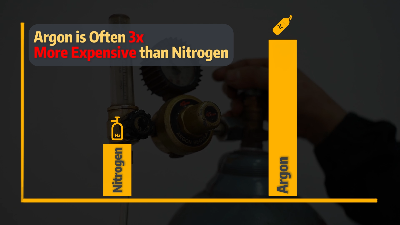

Kusiyana kwa mtengo kungakhale kwakukulu;

Nayitrogeni akhoza kukhala pafupifupikatatuzotsika mtengo kuposa argon oyeretsedwa kwambiri.

Izi zimapangitsa nayitrogeni kukhala njira yabwino kwa mabizinesi omwe akufuna kuchepetsa ndalamapopanda nsembekhalidwe.

TIG vs Laser kuwotcherera: Kuteteza Zosankha za Gasi

Pezani Ndalama Posunga Ubwino

Kuyerekeza Mtengo Pakati pa Argon ndi Nayitrogeni

Kusintha kwa nayitrogeni m'manja mwa laser kuwotchereraangapoubwino

Kupulumutsa Mtengo:

Ndikwambirikusiyana kwa mtengo pakati pa argon ndi nayitrogeni,

Kugwiritsa ntchito nayitrogeni kumatha kupulumutsa nthawi yayitali.

Izi ndizopindulitsa makamakakwa ma projekiti akuluakulu kapena mabizinesi

Izi zimagwira ntchito zowotcherera pafupipafupi.

Chitetezo Chogwira Ntchito:

Nayitrogeni amaperekachitetezo chokwaniramotsutsana ndi oxidation,

Kuonetsetsa kuti weld amakhalabewoyera ndi wamphamvu.

Ngakhale argon amadziwika chifukwa cha chitetezo chake chapamwamba,

Nayitrojeni akadalinjira yothekazomwe zimakwaniritsa zofunikira za ntchito zambiri zowotcherera.

Fananizani Njira Yowotcherera: Laser vs TIG Welding

Kusamala Kwambiri Njira Imapeza Zotsatira Zabwino Kwambiri

Mbali Yabwino Yowotcherera Laser: 45 Degree

Pamene mpweya woteteza ukuyenda bwino,

Ndi nthawi kuyang'ana pa ndondomeko kuwotcherera kwenikweni.

Onse TIG (Tungsten Inert Gasi) kuwotcherera ndi kuwotcherera m'manja laser

Amafunanjira zenizenikupeza zotsatira zabwino kwambiri,

Komabe, amasiyana malinga ndi zofunikira zawo ndi njira zawo.

Kuwotchera kwa TIGNjira

Yesetsani kusunga ma electrode pamtunda woyenera ndi liwirokupanga ndi kutsogolera dziwe la weld.

Mtunda uwu ukhoza kusiyana kutengera zakuthupi ndi makulidwe omwe amawotcherera.

Kusunga ngodya yolondola, nthawi zambiri mozungulira15 mpaka 20 madigiri,

Zimathandiza kuti mukhale ndi weld wokhazikika komanso woyera.

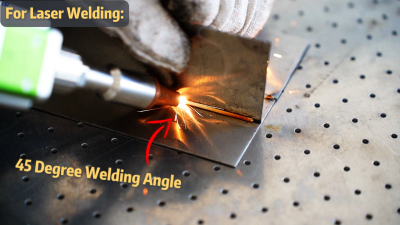

Kuwotcherera kwa Laser m'manjaNjira

Chimodzi mwazabwino za kuwotcherera kwa laser ndikutha kuyika ngodya yosasinthika

Kawirikawiri mozungulira45 digiri, kulola kuwongolera kosavuta kwa njira yowotcherera.

Pamene ngodya yakhazikitsidwa, kusungaliwiro lokhazikikandi key.

Kuwotcherera kwa laser m'manja kumapangakutentha pang'onopoyerekeza ndi kuwotcherera kwa TIG.

Izi zikutanthauza kuti alipochiwopsezo chochepa cha kukhumudwa kapena kusokonezeka,

Kupangitsa kuti ikhale yabwino kuti igwire bwino ntchito pazinthu zowonda kwambiri.

Laser Weld Strength vs TIG: Debunking Myths

Maganizo Olakwika Pankhani Yowotcherera Laser

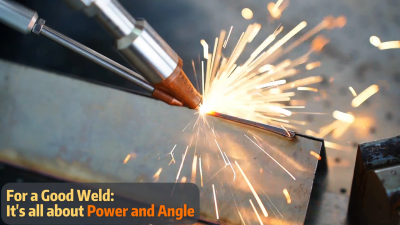

Kwa Good Handheld Laser Welding: Mphamvu & Angle

Ubwino umodzi wofunikira pakuwotcherera kwa laser m'manja ndikutha kwake kupereka mphamvu zokhazikikandendendekumene kuli kofunika.

Ndizokonda mphamvundi angodya yabwino

Kawirikawiri mozungulira45 digiri, kuwotcherera laser kumatha kulowa bwino komanso mphamvu.

Kutulutsa Kwamagetsi Koyenera

Kuyika mphamvu kwa welder laser ndikofunikira.

Mphamvu yotsika kwambiri imatha kubweretsakulowa kosakwanira, zomwe zimatsogolera ku ma welds ofooka.

Mosiyana ndi zimenezi, mlingo woyenera wa mphamvu umalola kuti laser isungunuke bwino zinthuzo, kupanga ziwalo zolimba.

Kugwiritsa ntchito zida zocheperako sikungabweretse zotsatira zomwe mukufuna.

Zonse za TIG ndi Handheld Laser Welding ndizothandiza

Mukufuna Kudziwa Zambiri Zokhudza Kuwotcherera Pamanja kwa Laser?

Kuwotcherera kwa Laser m'manja: Momwe Mungasungire Zida

Chisamaliro Choyenera ndi Kusamalira Tsatanetsatane Zidzatsimikizira Kuchita Zochita ndi Kudalirika

Kodi mumadziwa kuti kuwotcherera kwa TIG (Tungsten Inert Gas) ndi kuwotcherera kwa laser m'manja kumagawidwa ngati

Non-consumable njira kuwotcherera?

Izi zikutanthauza kuti, pansi pamikhalidwe yabwino komanso chisamaliro choyenera,

Zigawo zazikulu zomwe zimagwiritsidwa ntchito muzochitikazi zimatha nthawi yayitali

Popanda kufuna kusinthidwa pafupipafupi.

Zosagwiritsidwa Ntchito

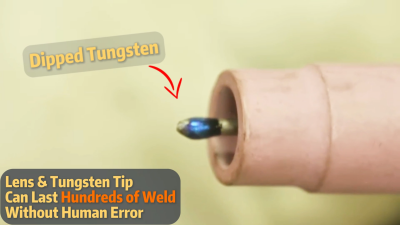

Cholakwika cha Tungsten Choviikidwa pa TIG Welding

Elekitirodi ya tungsten ndi gawo lofunikira pakuwotcherera kwa TIG.

Mosiyana ndi ma elekitirodi omwe amagwiritsidwa ntchito munjira zina zowotcherera,

monga kuwotcherera kwa MIG, electrode ya tungstensichisungunukapa kuwotcherera ndondomeko.

M'malo mwake, imasunga kukhulupirika kwake, kulola kugwiritsidwa ntchito kwa nthawi yayitali.

Komabe, electrode ikhoza kuipitsidwa kapena "kuviika" ngati ifikapafupi kwambiri ndi dziwe losungunuka.

Zikatero, iyenera kudulidwa ndikuyika pansi kuti ibwezeretsenso nsonga yake yakuthwa ndikugwira bwino ntchito.

Kusamalira nthawi zonsema elekitirodi a tungsten ndi ofunikira kuti akwaniritse ma welds oyera, apamwamba kwambiri.

M'manja Laser kuwotcherera Kukonzekera

Magalasi a Laser a Handheld Laser Welding Maintenance

Mu kuwotcherera m'manja kwa laser, lens ya laser imagwira ntchito ngati maziko a mtengo wa laser.

Lens yokhazikika bwino imatha kukhala nthawi yayitali, ikupereka magwiridwe antchito osasinthika.

Komabe, ngati mandala akusweka chifukwa cha malo osayenera kapena kukhudzana ndi kutentha kwambiri

Idzafunika kusinthidwa.

Kusunga magalasi abwino ndikofunikira,

Ngakhale kuwonongeka kwakung'ono kumatha kukhudza kulondola komanso mphamvu ya laser, zomwe zimatsogolera ku ma welds ocheperako.

Mukufuna Buku Lathunthu Lolozera Pamanja Pamanja Laser Welding?

Kuwotcherera kwa laser m'manja kumapereka zabwino zambiri,

Koma pamafunikanso chidwi kwambiri ndi ma protocol achitetezo.

Nkhaniyi iwunikanso zofunikira zachitetezo pakuwotcherera kwa laser m'manja.

Komanso perekani malingaliro oteteza kusankhidwa kwa gasi ndi zosankha zamawaya amitundu wamba zitsulo.

Kodi kuwotcherera kwa laser ndikolimba ngati kuwotcherera kwa TIG?

Kuwotcherera kwa laserndi kuwotcherera kwa TIG (Tungsten Inert Gas) onse amadziwika chifukwa cha kulondola kwawo komanso luso lawo pakujowina zitsulo.

Koma kodi amalimbana bwanji wina ndi mnzake pankhani yamphamvu?

Muvidiyoyi, tiwona kusiyana kwakukulu muweld ntchito,kuyanjana kwakuthupi,ndikukhazikika kwathunthupakati pa laser ndi TIG kuwotcherera.

Kuwotcherera M'manja Fiber Laser (M'manja Laser Weld)

Chowonjezera Chamtengo Wapatali ku Handheld Laser Weld Landscape

Laser Welder Wang'ono Amapangitsa Kuwotcherera Kukhale Kotchipa & Kutsika mtengo

Ndi mawonekedwe ang'onoang'ono komanso makina ang'onoang'ono.

The kunyamula laser kuwotcherera makina okonzeka ndi moveable m'manja laser welder mfuti amene aliopepuka.

Ndipo yabwino kwa multi-laser kuwotcherera ntchito pangodya iliyonsendipamwamba.

Zosankha zosiyanasiyana za laser welder nozzles.

Njira yopangira mawaya odzipangira okha imapangitsa kuti kuwotcherera kwa laser kukhale kosavuta komanso ndikosavuta kwa oyamba kumene.

Zinthu 5 Zokhudza Kuwotcherera kwa Laser (Zomwe Mudaphonya)

Ngati munakonda vidiyoyi, bwanji osaganizirakulembetsa ku Youtube Channel yathu?

Ntchito Zofananira Zomwe Mungakonde:

Handheld Laser Weld ndi Kusankha Kwabwino Kwambiri pa Ntchito Zowotcherera Pamanja

Ndipo Tsogolo Limayamba ndi Inu!

Nthawi yotumiza: Sep-14-2024