Laser Weld Kuchenesa

Laser Weld Kuchenesa iTekinoroji inoshandiswa Kubvisa Zvakasvibiswa, Oxides, uye Zvimwe Zvisizvo Zvisingadikanwi kubva paPamusoro peWeld.Pamberi & Mushureiyo Welding Process Yakwana. Iyi Yekuchenesa Inhanho Yakakosha MuMazhinji Maindasitiri neKugadzira Zvikumbiro kuneIva nechokwadi cheKutendeseka uye ChitarisikoyeWelded Joint.

Laser Kuchenesa Kwesimbi

Munguva yewelding process, kusvibiswa kwakasiyana-siyana uye byproducts zvinogona kuiswa pane weld pamusoro, sengeslag, spatter, uye discoloration.

Akasiyiwa asina kuchena, aya anogonazvinokanganisa simba re weld, corrosion resistance, uye aesthetics yekuona.

Laser weld yekuchenesa inoshandisa yakakwira-simba laser danda kusarudza vaporize uye kubvisa izvi zvisingadiwe pamusoro pedhipoziti.pasina kukuvadzasimbi yepasi.

Zvakanakira Laser Weld Kuchenesa

1. Kururama-Iyo laser inogona kunyatsonangwa kuchenesa chete nzvimbo yeweld pasina kukanganisa zvinhu zvakatenderedza.

2. Kumhanya- Laser kuchenesa inokurumidza, otomatiki maitiro anogona kuchenesa welds nekukurumidza kupfuura manyorero maitiro.

3. Kuwirirana-Laser yekuchenesa inoburitsa yunifomu, inodzokororwa mhedzisiro, kuve nechokwadi chekuti mawelds ese akacheneswa kune imwechete yakakwirira mwero.

4. No Consumables- Laser kuchenesa hakudi abrasives kana makemikari, kuderedza kushanda mutengo uye tsvina.

Zvishandiso: Laser Weld Kuchenesa

Yakakwirira-Simba Yakaderera-Alloy (HSLA) Steel Plates Laser Weld Kuchenesa

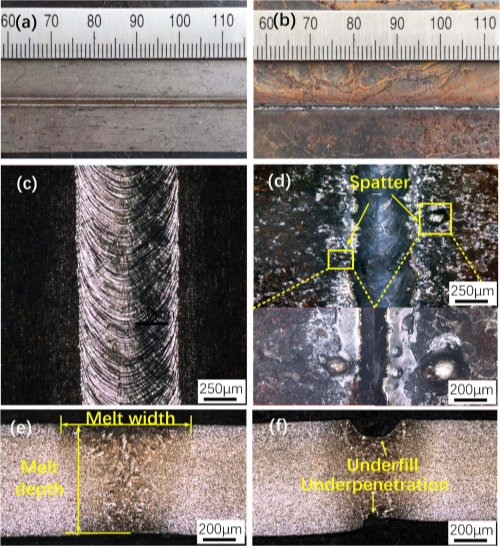

Weld Kuonekwa Kwekubatwa neLaser Kuchenesa (a, c, e) uye Kusagadziriswa neLaser Kuchenesa (b, d, f)

Iyo yakakodzera laser yekuchenesa process paramita inogonaBvisaiyo ngura uye girizi kubva pane workpiece pamusoro.

Kupinda kwepamusoroakaonekwa mune zvienzaniso zvakacheneswa zvichienzaniswa neasina kucheneswa.

Iyo laser yekuchenesa pre-kurapa inobatsiraavoidkuitika kwe pores uye kuputika mu weld uyeinovandudzakuumba mhando ye weld.

Laser Weld Kuchenesa pre-kurapwa kunoderedza kuremara kwakawanda senge pores uye makatsemuka mukati meweld, nekudaro.kunatsakusimba kweiyo weld.

Avhareji yekusimba kwesimba remuenzaniso nelaser yekuchenesa pre-kurapa ndeye 510 MPa, inova30% yakakwirirakupfuura izvozvo pasina laser kuchenesa pre-kurapwa.

Kurebesa kwelaser-yakacheneswa weld joint i36% inova3 nguvaiyo yejoint yeweld isina kuchena (12%).

Commercial Aluminium Alloy 5A06 Laser Weld Kuchenesa

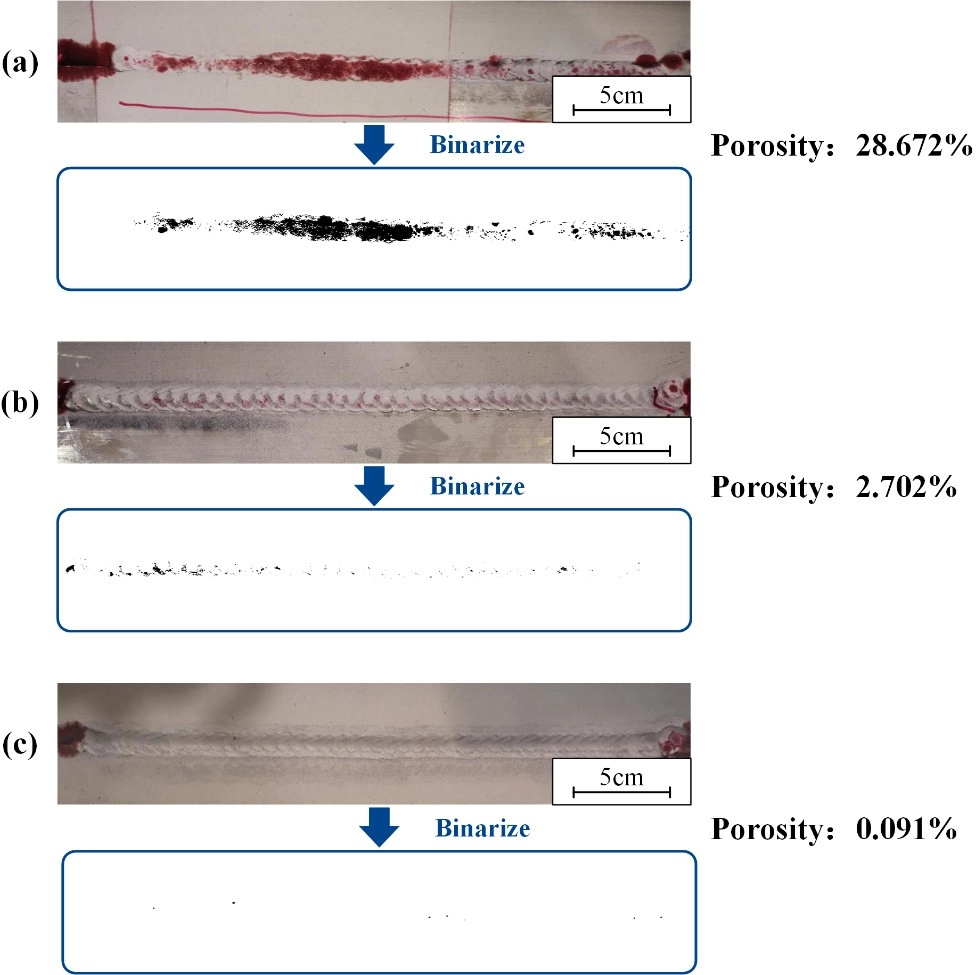

Mhedzisiro yePermeation Testing uye The Porosity paSample ne: (a) Mafuta; (b) Mvura; (c) Laser Kuchenesa.

Ukobvu hweAluminium alloy 5A06 oxide layer ndeye 1-2 lm, uye kuchenesa laser kunoratidzazvinovimbisapakubviswa kweoxide yeTIG welding.

Porosity yakawanikwamunzvimbo yefusion yeTIG weldsafter normal ground, uye inclusions ine yakapinza morphology yakaongororwa zvakare.

Mushure mekuchenesa laser,hapana porosity yaivepomunzvimbo yefusion.

Uyezve, iyo oksijeni yemukatiyakaderera zvakanyanya, iyo inobvumirana nemigumisiro yapfuura.

Mukuwedzera, iyo yakatetepa yekunyungudika yekupisa yakaitika panguva yekuchenesa laser, zvichikonzerayakanatswa microstructuremunzvimbo yefusion.

Wona Pepa Rokutsvagisa Pepa paGedhi Rekutsvaga Pano.

Kana Tarisai Chinyorwa ichi chatakaburitsa pa:Laser Yekuchenesa Aluminium (Maitirwo Akaitwa neVaongorori)

Unoda Kuziva nezve Laser Weld Kuchenesa?

Tinogona Kubatsira!

Chii Chandingashandisa Kuchenesa MaWelds angu?

Kuchenesa Welds IpaZvisungo ZvakasimbauyeKudzivirira Corrosion

Heano VamweNzira DzechivanhuYekuchenesa Welds:

Tsanangudzo:Shandisa waya bhurashi kana vhiri kubvisa slag, spatter, uye oxides.

Zvazvakanakira:Zvisingadhuri uye zvinobudirira pakuchenesa pamusoro.

ConsInogona kushanda nesimba uye inogona kusasvika panzvimbo dzakasimba.

Tsanangudzo:Shandisa grinder kupfavisa welds uye kubvisa kusakwana.

Zvazvakanakira:Inoshanda pakuchenesa kunorema uye kuumba.

ConsInogona kushandura weld profile uye inogona kuunza kupisa.

Tsanangudzo:Shandisa acid-based solutions kana zvinonyungudutsa kunyungudutsa zvinosvibisa.

Zvazvakanakira:Inoshanda kune yakaoma masara uye inogona kushandiswa mune dzakasiyana siyana maapplication.

ConsInoda kuchengetedzwa kwekuchengetedza uye kuraswa kwakakodzera.

Tsanangudzo:Propel abrasive material at high speed kubvisa zvinosvibisa.

Zvazvakanakira:Kurumidza uye kunoshanda kune nzvimbo huru.

ConsInogona kukonzera kukukurwa kwepasi kana ikasadzorwa.

Tsanangudzo:Shandisa mafungu e-high-frequency sound mugadziro yekuchenesa kubvisa tsvina.

Zvazvakanakira:Inosvika pazvimiro zvakaoma uye inobvisa zvinosvibisa zvakakwana.

ConsZvishandiso zvinogona kudhura & saizi yekuchenesa inogona kushomeka.

ForLaser Ablation & Laser Surface Kugadzirira:

Laser Ablation

Tsanangudzo:Shandisa high-energy laser matanda kunyungudutsa zvinosvibisa pasina kukanganisa base zvinhu.

Zvazvakanakira:Yakarurama, inoshamwaridzana nemamiriro ekunze, uye inoshanda kune dzakatetepa maapplication.

ConsZvishandiso zvinogona kudhura, uye zvinoda kushanda kwehunyanzvi.

Laser Surface Kugadzirira

Tsanangudzo:Shandisa ma lasers kugadzirira nzvimbo nekubvisa okisidhi uye zvinosvibisa usati wawelding.

Zvazvakanakira:Inosimudzira weld mhando uye inoderedza kuremara.

ConsMidziyo inogona zvakare kudhura, uye inoda kushanda kwehunyanzvi.

Sei Laser Kuchenesa Metal?

Laser Kucheneswa inzira Inoshanda Yekubvisa Zvinosvibisa

Pfeka PPE yakakodzera, kusanganisira magirovhosi, magirovhosi, uye zvipfeko zvinodzivirira.

Chengetedza chidimbu chesimbi munzvimbo yakagadzikana kudzivirira kufamba panguva yekuchenesa. Gadzirisa musoro welaser kune yakakurudzirwa chinhambwe kubva pamusoro, kazhinji pakati10-30 mm.

Ramba uchitarisa maitiro ekuchenesa. Tarisa kushanduka kwepamusoro, sekubviswa kwezvinosvibisa kana chero kukanganisa kwesimbi.

Mushure mekuchenesa, ongorora nzvimbo yeweld yehutsanana uye chero tsvina yasara. Zvichienderana nekushandiswa, fungakushandisa chivharo chekudzivirirakudzivirira ngura mune ramangwana.

Ndechipi Chakanakisa chishandiso chekuchenesa Welds?

Laser Yekuchenesa Inomira kunze seChimwe cheZvakanakisa Zvishandiso zviripo

Kune chero munhu anobatanidzwa mukugadzira simbi kana kugadzirisa, laser kuchenesa ndikochishandiso chakakosha chekuchenesa welds.

Kunyatsoita kwayo, kushanda nesimba, uye mabhenefiti ezvakatipoteredza zvinoita kuti ive sarudzo yakakwanakuwana mhedzisiro yemhando yepamusorouku uchideredza njodzi uye nguva yekuderera.

Kana iwe uchitsvaga kuwedzera maitiro ako ekuchenesa, funga kuisa mari mulaser yekuchenesa tekinoroji.

Iwe unoita sei kuti Welds itaridzike Yakachena?

Laser Kuchenesa Kunobatsira Kuwana Yakachena uye Nyanzvi-inotaridzika Welds

Kugadzirira kweSurface

Kutanga Kuchenesa:Usati welding, ita shuwa kuti base simbi haina tsvina senge ngura, mafuta, uye tsvina. Danho irizvakakosha kuti uwane weld yakachena.

Laser Kuchenesa:Shandisa laser yekuchenesa system kunyatso bvisa chero tsvina yepasi. Nzira yakanangwa inovimbisa kuti zvinosvibisa chete zvinobviswapasina kukuvadza simbi.

Post-Weld Kuchenesa

Post-Weld Cleaning:Mushure mekugadzira, kurumidza kuchenesa nzvimbo yeweld nelaser kubvisa slag, spatter, uye oxidation iyo inogona kukanganisa chitarisiko che weld.

Kuenderana:Iyo laser yekuchenesa maitiro inopa yunifomu mhedzisiro, kuve nechokwadi chekuti ese mawelds ane anowirirana, akachena kupera.

Vhidhiyo Kuratidzira: Laser Kucheneswa Kwesimbi

Chii chinonzi Laser Kuchenesa uye Inoshanda Sei?

Imwe yemabhenefiti makuru ekuchenesa laser ndeyekuti ndizvonzira yakaoma.

Zvinoreva kuti hapana chikonzero chekucheneswa kwemarara.

Ingo tungamira danda relaser kumusoro kwaunoda kuchenesapasina kukanganisa zvinhu zviri pasi.

Laser cleaners zvakarecompact uye inotakurika, kubvumirakuitira kuchenesa panzvimbo.

Zvinowanzodazvekutanga zvekuzvidzivirira nazvo chete, zvakadai semagirazi ekuchengetedza uye kufema.

Laser Ablation irinani paRust Cleaning

Sandblasting inogona kugadzirahuruva yakawanda uye inoda kucheneswa kukuru.

Dry ice cleaning ndiyoinogona kudhura uye isingakodzeri kuita mabasa makuru.

Kemikari kuchenesa inogonazvinosanganisira zvinhu zvine njodzi uye nyaya dzekurasa.

Mukupesana ne,laser kuchenesa inobuda seyakamira sarudzo.

Inoshandiswa zvakasiyana-siyana, inobata huwandu hwezvinosvibisa nemazvo

Iyo nzira inodhura-inoshanda munguva refu nekuda kwenokushandiswa kwezvinhu uye pasi pekugadzirisa zvinodiwa.

Handheld Laser Yekuchenesa Machine: Laser Weld Kuchenesa

Pulsed Laser Cleaner(100W, 200W, 300W, 400W)

Pulsed fiber laser cleaners inonyanya kukodzera kuchenesadelicate,sensitive, kanapanjodzi yekupisanzvimbo, uko iyo chaiyo uye inodzorwa hunhu hweiyo pulsed laser yakakosha pakuchenesa uye kukuvadza-isina kuchenesa.

Laser Simba:100-500W

Pulse Length Modulation:10-350ns

Fiber Cable Length:3-10m

Wavelength:1064nm

Laser Source:Pulsed Fiber Laser

Laser Rust Removal Machine(Pre & Post Laser Weld Kuchenesa)

Laser weld yekuchenesa inoshandiswa zvakanyanya mumaindasitiri akadaiaerospace,motokari,kuvaka ngarava,uyekugadzira zvemagetsikupiyepamusoro-soro, isina kukanganisa-isina weldszvakakosha pakuchengetedza, kuita, uye chitarisiko.

Laser Simba:100-3000W

Inogadziriswa Laser Pulse Frequency:Kusvika ku1000KHz

Fiber Cable Length:3-20m

Wavelength:1064nm, 1070nm

SupportVariousMitauro