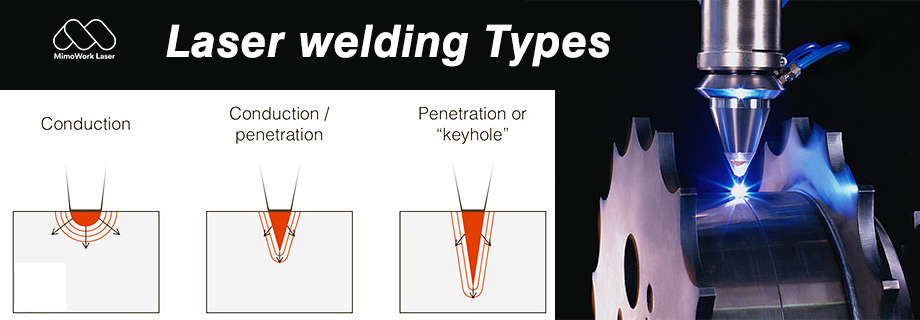

Kupinza kweLaser kunogona kuitwa nejenareta yelaser inoenderera mberi kana kuti inopusha. Nheyo yekupinza kweLaser inogona kukamurwa kuita welding yekupisa uye welding yeLaser yakadzika. Kuwanda kwesimba kusingasviki 104 ~ 105 W / cm2 ndiko kupinza kwekupisa, panguva ino, kudzika kwekunyunguduka, uye kumhanya kwewelding kunonoka; Kana simba rayo rakakura kupfuura 105 ~ 107 W / cm2, pamusoro pesimbi panopinda mu "maburi ekiyi" pasi pekupisa, zvichiita welding yakadzika, ine hunhu hwekumhanya kwewelding nekukurumidza uye chiyero chikuru chekudzika-upamhi.

Nhasi, tichanyanya kutaura nezvezvinhu zvikuru zvinokanganisa kunaka kwe laser deep fusion welding.

1. Simba reLaser

Mukusanganisa laser deep fusion, simba relaser rinodzora kudzika kwekupinda uye kumhanya kwewelding. Kudzika kweweld kwakabatana zvakananga nehuremu hwesimba remuti uye ibasa resimba remuti wechiitiko uye nzvimbo inotarisa danda. Kazhinji, kune rimwe dhayamita remuti welaser, kudzika kwekupinda kunowedzera nekuwedzera kwesimba remuti.

2. Nzvimbo Yekutarisa

Saizi yedanda remuti ndeimwe yezvinhu zvinonyanya kukosha mukubatanidza nelaser nekuti ndiyo inosarudza huwandu hwesimba. Asi kuiyera idambudziko kune malaser ane simba guru, kunyangwe paine nzira dzakawanda dzekuyera dzisina kunanga dziripo.

Saizi yenzvimbo ine muganho we diffraction ye beam focus inogona kuverengerwa zvichienderana nedzidziso ye diffraction, asi saizi chaiyo yenzvimbo yakakura kupfuura kukosha kwakaverengerwa nekuda kwekuvapo kwekusaratidza kwakashata kwe focal. Nzira iri nyore yekuyera ndiyo nzira ye iso-temperature profile, iyo inoyera dhayamita yenzvimbo ine muganho uye kubooka mushure mekunge bepa gobvu rapiswa uye rapinda nepakati pe polypropylene plate. Nzira iyi kuburikidza nekudzidzira kwekuyera, inonyatsoongorora saizi yesimba re laser uye nguva yekushanda kwe beam.

3. Gasi Rinodzivirira

Maitiro ekugadzira laser anowanzo shandisa magasi anodzivirira (helium, argon, nitrogen) kudzivirira dziva rakanyungudutswa, zvichidzivirira workpiece kubva mukuoxidation mukuita kwewelding. Chikonzero chechipiri chekushandisa gasi rinodzivirira ndechekudzivirira lenzi yekutarisa kubva mukusvibiswa nehutsi hwesimbi uye kudonha nemadonhwe emvura. Kunyanya mukushongedza laser ine simba guru, ejecta inova nesimba guru, zvakakosha kuchengetedza lenzi. Mhedzisiro yechitatu yegasi rinodzivirira ndeyekuti rinoshanda zvikuru mukupararira kweplasma shielding inogadzirwa nekugadzira laser ine simba guru. Utsi hwesimbi hunotora laser beam uye hunoiswa muplasma cloud. Gasi rinodzivirira rakatenderedza utsi hwesimbi rinoiswawo ioni nekuda kwekupisa. Kana paine plasma yakawandisa, laser beam inodyiwawo neplasma. Sesimba rechipiri, plasma iripo pamusoro pebasa, izvo zvinoita kuti kudzika kweweld kuve kushoma uye pamusoro pedziva reweld kuve kwakafara.

Ungasarudza sei gasi rekudzivirira rakakodzera?

4. Mwero weKunyudzwa

Kutorwa kwezvinhu nelaser kunoenderana nezvimwe zvinhu zvakakosha zvechinhu ichi, zvakaita sehuwandu hwekunyungudika, kupenya kwechiedza, kutenderera kwekupisa, kupisa kunopisa, uye kupisa kwemvura. Pakati pezvinhu zvese, chinonyanya kukosha chiyero chekunyungudika.

Zvinhu zviviri zvinokanganisa mwero wekunyudzwa kwezvinhu kusvika kuchiedza chelaser. Chekutanga i resistance coefficient yezvinhu. Zvinowanikwa kuti mwero wekunyudzwa kwezvinhu unoenderana ne square root ye resistance coefficient, uye resistance coefficient inosiyana nekupisa. Chechipiri, mamiriro epamusoro (kana kupera) kwezvinhu zvine pesvedzero yakakosha pa mwero wekunyudzwa kwechiedza, izvo zvine pesvedzero yakakosha pa welding effect.

5. Kumhanya Kwekushongedza

Kumhanya kwewelding kune simba guru pakadzika kwekupinda. Kuwedzera kumhanya kuchaita kuti kudzika kwekupinda kudzika, asi kuderera zvakanyanya kuchaita kuti zvinhu zvinyungudike zvakanyanya uye workpiece welding ipfuure. Saka, kune mwero wakakodzera wekumhanya wewelding wechinhu chakati chine simba relaser uye ukobvu hwakati, uye kudzika kwekupinda kwakanyanya kunogona kuwanikwa pamutengo wekumhanya unoenderana.

6. Kureba kweLenzi yeFocus

Lenzi yekutarisa inowanzoiswa mumusoro wepfuti yekubatanidza, kazhinji, urefu hwe63 ~ 254mm (dhayamita 2.5 "~ 10") hunosarudzwa. Saizi yenzvimbo yekutarisa inoenderana nehurefu hwenzvimbo, kureba kwenzvimbo kupfupi, nzvimbo yacho idiki. Zvisinei, kureba kwenzvimbo yekutarisa kunokanganisawo kudzika kwekutarisa, ndiko kuti, kudzika kwekutarisa kunowedzera pamwe chete nehurefu hwenzvimbo yekutarisa, saka kureba kupfupi kunogona kuvandudza huwandu hwesimba, asi nekuti kudzika kwekutarisa kudiki, daro riri pakati pelenzi nechishandiso chebasa rinofanira kuchengetedzwa nemazvo, uye kudzika kwekupinda hakuna kukura. Nekuda kwesimba re splashes uye laser mode panguva yekubatanidza, kudzika kupfupi kwenzvimbo yekutarisa kunoshandiswa mukushongedza chaiko kunonyanya kuva 126mm (dhayamita 5 "). Lenzi ine urefu hwe254mm (dhayamita 10 ") inogona kusarudzwa kana musono wakakura kana weld ichida kuwedzerwa nekuwedzera saizi yenzvimbo. Muchiitiko ichi, simba repamusoro rekubudisa laser (simba resimba) rinodiwa kuti uwane mhedzisiro yegomba rekupinda rakadzika.

Mimwe mibvunzo nezve mutengo wemuchina we laser welding weruoko uye magadzirirwo awo

Nguva yekutumira: Gunyana-27-2022