Typical Applications yelaser welding

Laser welding michina inogona kuwedzera huwandu hwekugadzira uye kugadzirisa mhando yechigadzirwa kana zvasvika pakugadzirwa kwesimbi zvikamu. Inoshandiswa zvakanyanya mumatanho ese ehupenyu:

▶ Sanitary Ware Indasitiri: Welding yepombi fittings, reducer fittings, tees, valves, and shower.

▶ Indasitiri yekupfeka maziso: Kurukwa chaiko kwesimbi isina simbi, titanium alloy, uye zvimwe zvinhu zvekupfeka maziso uye furemu yekunze.

▶ Indasitiri ye Hardware: impeller, kettle, mubato welding, zvakaoma kutsika zvikamu, uye zvikamu zvekukanda.

▶ Indasitiri yemotokari: injini silinda pad, hydraulic tappet seal welding, spark plug welding, sefa welding, nezvimwe.

▶ Indasitiri yezvokurapa: welding yezviridzwa zvekurapa, masimbi esimbi isina tsvina, uye maumbirwo ezviridzwa zvekurapa.

▶ Indasitiri yezvemagetsi: Kuvharisa nekupwanya welding ye solid state relays, welding yezvinokonesa uye zvinobatanidza, welding yemashembu esimbi uye maumbirwo akaita senharembozha nemaMP3 player. Motokari dzakavharirwa uye zvibatanidza, fiber optic connector joints welding.

▶ Zvishandiso zvemumba, midziyo yekubikira, yekugezera, zvibato zvemadhoo zvesimbi isina tsvina, zvemagetsi, masensa, wachi, muchina wakanyatsojeka, kufambiswa kwemashoko, mabasa emaoko nemamwe maindasitiri, tapeti dzemotokari dzehydraulic, uye mamwe maindasitiri ane zvinhu zvinogadzirwa zvakasimba.

Zvimiro zvelaser welding

1. High simba concentration

2. Hapana kusvibiswa

3. Small welding spot

4. Yakasiyana-siyana yewelding zvinhu

5. Kushanda kwakasimba

6. Kushanda kwepamusoro uye kukwirira kwepamusoro-soro

Chii chinonzi laser welding muchina?

Iyo laser welding muchina inowanzozivikanwa seyakaipa mhinduro laser welding muchina, laser inotonhora welding muchina, laser argon welding muchina, laser welding michina, nezvimwe.

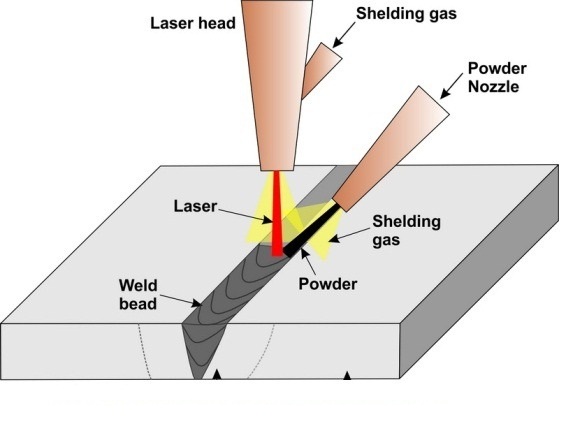

Laser welding inoshandisa high-energy laser pulses kudziya munzvimbo ino chinhu pamusoro penzvimbo diki. Simba remalaser mwaranzi rinoparadzirwa mukati mechinhu kuburikidza nekupisa conduction, uye zvinhu zvinonyunguduka kuita dziva rakanyungudutswa. Iyo inzira nyowani yewelding, inonyanya kushandiswa kune dzakatetepa madziro zvinhu uye chaiyo zvikamu welding. Inogona kuwana yakakwira chikamu chiyero, diki weld hupamhi, kudiki kupisa kwakakanganisa zone nzvimbo welding, butt welding, seam welding, seal welding, zvichingodaro. Diki deformation, inokurumidza welding kumhanya, yakatsetseka uye yakanaka weld, hapana kugadzirisa kana nyore kugadzirisa mushure mekugadzira, yemhando yepamusoro weld, isina pores, chaiyo kudzora, kutarisisa kudiki, yakakwirira chinzvimbo kurongeka, nyore kuona otomatiki.

Ndezvipi zvigadzirwa zvakakodzera kushandiswa kwelaser welding muchina

Zvigadzirwa zvine welding zvinodiwa:

Zvigadzirwa zvinoda welds zvakasungwa nelaser welding midziyo, iyo isina kungoita madiki welds upamhi asiwo haidi solder.

Zvigadzirwa zveotomatiki zvakanyanya:

Mune ino kesi, iyo laser welding midziyo inogona kurongwa nemaoko kuti weld uye nzira yacho inongoitika.

Zvigadzirwa pakupisa kwekamuri kana pasi pemamiriro akakosha:

Inogona kumisa welding pakamuri tembiricha kana pasi pemamiriro akakosha, uye laser welding michina iri nyore kuisa. Semuenzaniso, kana laser ichipfuura nepamunda wemagetsi, danda haritsvedzeri. Iyo laser inogona weld mune vacuum, mhepo, uye dzimwe nzvimbo dzine gasi, uye inogona kupfuura nepagirazi kana zvinhu zviri pachena kune danda kumisa welding.

Zvimwe zvakaoma-ku-kuwana-zvikamu zvinoda laser welding michina:

Inogona weld yakaoma-kusvika-kusvika zvikamu, uye kuwana isingabatanidzi kure welding, nekunzwa kwakanyanya. Kunyanya mumakore achangopfuura, pasi pemamiriro eYAG laser uye fiber laser tekinoroji yakakura kwazvo, laser welding tekinoroji yakasimudzirwa zvakanyanya uye kuiswa.

Dzidza zvakawanda nezve laser welding application uye mhando dzemuchina

Nguva yekutumira: Aug-16-2022