Iyo yakakosha laser welding process inosanganisira kutarisa laser beam panzvimbo yakabatana pakati pezvinhu zviviri uchishandisa optical delivery system. Kana danda richibata zvinhu, rinotamisa simba raro, nekukurumidza kupisa uye kunyungudutsa nzvimbo diki.

Tafura yeZviri mukati

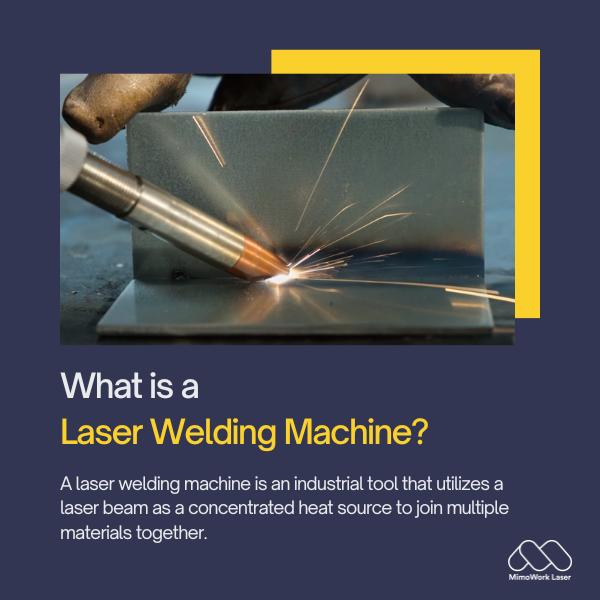

1. Chii chinonzi Laser Welding Machine?

Laser welding muchina chishandiso cheindasitiri chinoshandisa laser danda seyakaomeswa kupisa sosi kubatanidza akawanda zvinhu pamwechete.

Mamwe akakosha maitiro e laser welding michina anosanganisira:

1. Laser Source:Mazhinji emazuva ano laser welders anoshandisa solid-state laser diodes iyo inoburitsa yakakwirira-simba laser danda mune infrared spectrum. Yakajairika laser masosi anosanganisira CO2, faibha, uye diode lasers.

2. Optics:Iyo laser beam inofamba nemunhevedzano yezvinhu zvemaziso semagirazi, lenzi, uye nozzles zvinotarisa uye kutungamira danda kunzvimbo yeweld nemazvo. Telescoping maoko kana gantries inoisa danda.

3. Automation:Mazhinji laser welder anoratidza komputa nhamba yekudzora (CNC) yekubatanidza uye marobhoti otomatiki akaomarara welding mapatani uye maitiro. Nzira dzinorongwa uye masensa emhinduro anovimbisa huchokwadi.

4. Maitiro ekutarisa:Akasanganiswa makamera, spectrometers, uye mamwe ma sensors anotarisisa maitiro ekushongedza munguva chaiyo-nguva. Chero nyaya dzine kurongeka kwedanda, kupinda, kana mhando inogona kukurumidza kuonekwa nekugadziriswa.

5. Safety Interlocks:Dziviriro dzimba, magonhi, uye e-stop mabhatani anochengetedza vashandisi kubva kune yakakwirira-powered laser beam. Interlocks inovhara laser kana maprotocol ekuchengetedza akatyorwa.

Saka muchidimbu, laser welding muchina inodzorwa nekombuta, maindasitiri chaiwo chishandiso chinoshandisa yakatarisana nelaser danda kune otomatiki, inodzokororwa welding application.

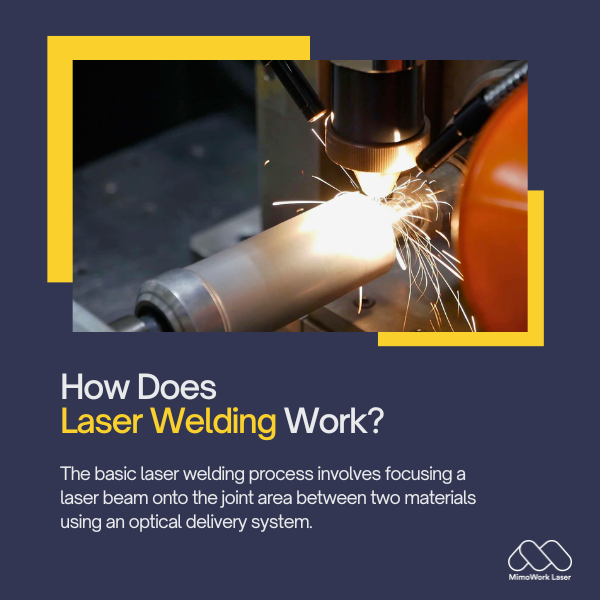

2. Ko Laser Welding Inoshanda Sei?

Mamwe matanho akakosha muiyo laser welding process anosanganisira:

1. Laser Beam Generation:Iyo yakasimba-state laser diode kana imwe sosi inoburitsa infrared danda.

2. Beam Delivery: Magirazi, lenzi, uye nozzle zvinonyatso tarisa danda kunzvimbo yakasimba pane yebasa.

3. Material Heating:Iyo danda inokurumidza kupisa zvinhu, ine density inosvika 106 W / cm2.

4. Kunyunguduka nekubatanidza:Dziva duku rakanyunguduka rinoumba panosanganiswa zvinhu. Sezvo dziva rinosimba, mubatanidzwa we weld unogadzirwa.

5. Kutonhodza uye Kubatanidzazve: Iyo weld nzvimbo inotonhorera pamazinga akakwirira pamusoro pe104 ° C / yechipiri, ichigadzira yakanaka-grained, yakaoma microstructure.

6. Kufambira mberi:Danda rinofamba kana zvikamu zvinoiswazve uye maitiro anodzokorora kupedzisa weld seam. Inert inodzivirira gasi inogona kushandiswa zvakare.

Saka muchidimbu, laser welding inoshandisa yakanyanya kutariswa laser beam uye inodzorwa inopisa bhasikoro kuburitsa emhando yepamusoro, yakaderera-inokanganisa nzvimbo welds.

Isu Takapa Ruzivo Runobatsira paLaser Welding Machines

Pamwe neCustomized Solutions dzeBhizinesi rako

3. Ko Laser Welding nani pane MIG?

Kana ichienzaniswa neyechinyakare simbi inert gasi (MIG) welding maitiro...

Laser welding inopa akawanda mabhenefiti:

1. Kururamisa: Laser matanda anogona kutariswa kune diki 0.1-1mm nzvimbo, ichigonesa yakanyatsojeka, inodzokororwa welds. Izvi zvakanakira zvikamu zviduku, zvepamusoro-kushivirira.

2. Kumhanya:Welding mitengo yelaser inokurumidza kupfuura MIG, kunyanya pamageji matete. Izvi zvinovandudza kubereka uye kuderedza nguva dzekutenderera.

3. Hunhu:Iyo yakanyanya kupisa sosi inoburitsa kushoma kukanganisa uye yakamanikana kupisa-inokanganiswa nzvimbo. Izvi zvinoguma nemawelds akasimba, emhando yepamusoro.

4. Automation:Laser welding inongoitwa otomatiki uchishandisa marobhoti uye CNC. Izvi zvinogonesa mapatani akaoma uye yakagadziridzwa kuenderana vs manual MIG welding.

5. Zvishandiso:Lasers inogona kujoinha akawanda musanganiswa wezvinhu, kusanganisira akawanda-zvinhu uye akasiyana simbi welds.

Nekudaro, MIG welding inezvimwe zvakanakirapamusoro pe laser mune mamwe maapplication:

1. Mutengo:MIG midziyo ine yakaderera yekutanga mari yekudyara pane laser masisitimu.

2. Zvishandiso zvakakora:MIG inokodzera zvirinani kukwenenzvera zvikamu zvesimbi zvakakora pamusoro pe3mm, uko kunyura kwelaser kunogona kunetsa.

3. Kudzivirira gasi:MIG inoshandisa inert gasi nhovo kuchengetedza iyo weld nzvimbo, nepo laser inowanzoshandisa yakavharwa danda nzira.

Saka muchidimbu, laser welding inowanzofarirwakurongeka, otomatiki, uye mhando yewelding.

Asi MIG inoramba ichikwikwidza kugadzirwa kwezviyero zvakakora pane bhajeti.

Maitiro akakodzera anoenderana neiyo chaiyo welding application uye chikamu chinodiwa.

4. Ko Laser Welding Zviri Nani pane TIG Welding?

Tungsten inert gasi (TIG) welding ibhuku, hunyanzvi hwekuita hunyanzvi hunogona kuburitsa mhedzisiro yakanaka pazvinhu zvitete.

Nekudaro, laser welding ine zvimwe zvakanakira pamusoro peTIG:

1. Kumhanya:Laser welding inokurumidza zvakanyanya kupfuura TIG yekugadzira maapplication nekuda kweiyo otomatiki chaiyo. Izvi zvinovandudza throughput.

2. Kururama:Iyo yakatarisana nelaser beam inobvumira kumira kwechokwadi kusvika mukati memazana emamirimita. Izvi hazvigone kuenzaniswa neruoko rwemunhu neTIG.

3. Kudzora:Maitiro akasiyana-siyana senge kupinza kwekupisa uye weld geometry inodzorwa zvakasimba nelaser, ichiva nechokwadi chekuenderana mhedzisiro batch pamusoro pebatch.

4. Zvishandiso:TIG yakanakira kutetepa conductive zvinhu, nepo laser welding ichivhura yakafaranuka akasiyana-siyana emhando yekubatanidza zvinhu.

5. Automation: Robotic laser masisitimu inogonesa yakazara otomatiki welding pasina kuneta, nepo TIG ichiwanzoda kutarisisa kwakazara kwemushandisi uye hunyanzvi.

Nekudaro, TIG welding inochengetedza mukana wemutete-gauge kunyatsoita basa kana alloy weldinguko kupisa kunopinza kunofanira kunyatsogadziriswa. Pazvikumbiro izvi kubata kwenyanzvi ine hunyanzvi kunokosha.

5. Chii chakaipira Laser Welding?

Sezvinei nechero maindasitiri maitiro, laser welding ine zvimwe zvinogona kudzika zvekufunga nezvazvo:

1. Mutengo: Ichiri kudhura zvakanyanya, yakakwirira-simba laser masisitimu inoda yakakosha capital investment kana ichienzaniswa nedzimwe nzira dzewelding.

2. Consumables:Manozzles egasi uye optics anoshatisa nekufamba kwenguva uye anofanirwa kutsiviwa, zvichiwedzera kumutengo wevaridzi.

3. Kuchengetedza:Maprotocol akasimba uye akavharirwa ekuchengetedza dzimba anodiwa kudzivirira kuratidzwa kune yakakwirira-yakasimba laser beam.

4. Kudzidzisa:Vashandi vanoda kudzidziswa kushanda zvakachengeteka uye nemazvo kuchengetedza laser welding michina.

5. Mutsara wekuona:Iyo laser beam inofamba mumitsara yakatwasuka, saka yakaoma geometries inogona kuda akawanda matanda kana workpiece reposition.

6. Absorptivity:Zvimwe zvinhu zvakaita sesimbi gobvu kana aluminium zvinogona kunetsa kupinza kana dzikasatora laser's chaiyo wavelength zvinobudirira.

Nekungwarira kwakaringana, kudzidziswa, uye kugadzirisa maitiro, zvisinei, laser welding inopa kugadzirwa, kunyatsojeka, uye kunaka kwakanakira kune akawanda maindasitiri maapplication.

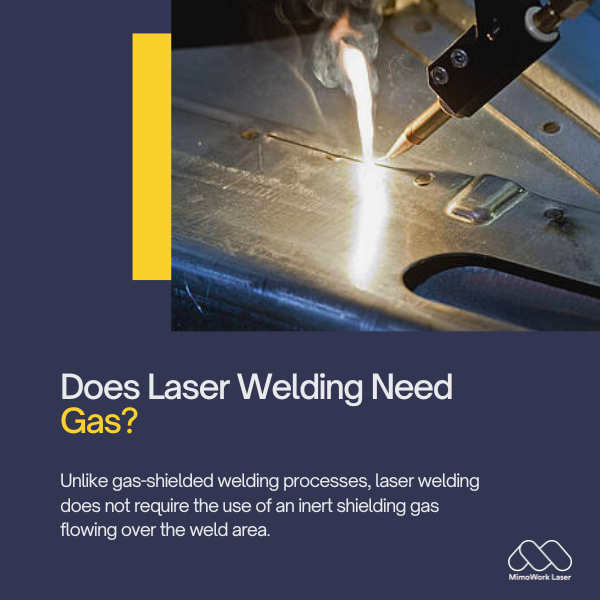

6. Ko Laser Welding Inoda Gasi?

Kusiyana negasi-yakadzivirirwa welding maitiro, laser welding haidi kushandiswa kweinert shielding gasi inoyerera pamusoro penzvimbo yeweld. Izvi zvinodaro nekuti:

1. Iyo yakanangwa laser beam inofamba nemumhepo kugadzira diki, repamusoro-simba weld dziva rinonyunguduka uye rinobatanidza zvinhu.

2. Mhepo yakakomberedza haina ionized segasi plasma arc uye haipindiri nedanda kana weld kugadzirwa.

3. Iyo weld inosimba nekukurumidza kubva mukupisa kwakanyanya zvekuti inoumba maokisidhi asati aita pamusoro.

Nekudaro, mamwe akasarudzika laser welding application anogona achiri kubatsirwa nekushandisa gasi rekubatsira:

1. Kune simbi dzinoshanda searuminiyamu, gasi rinodzivirira moto weld pool kubva kuokisijeni mumhepo.

2. Pamabasa ane simba guru relaser, gasi rinodzikamisa plasma plume inoumba panguva yakadzika yekupinda welds.

3. Majeti egasi anobvisa utsi nemarara kuitira kutapurirana danda zviri nani panzvimbo dzine tsvina kana dzakapendwa.

Saka muchidimbu, kunyangwe zvisiri kunyanyodikanwa, inert gasi inogona kupa zvakanakira kune chaiyo inonetsa laser welding application kana zvinhu. Asi maitiro anogona kazhinji kuita zvakanaka pasina iwo.

▶ Ndezvipi Zvishandiso zvinogona kuve Laser Welded?

Anenge ese masimbi anogona kuve laser welded kusanganisirasimbi, aluminium, titanium, nickel alloys, nezvimwe.

Kunyange kusanganiswa kwesimbi kwakasiyana kunogoneka. Chinokosha ndivoinofanira kutora laser wavelength zvakanaka.

▶ Zvishongo zvakakora zvinogona kusonwa sei?

Sheets dzakatetepa se0.1mm uye gobvu se25mminogona kazhinji kuve laser welded, zvichienderana neiyo chaiyo application uye laser simba.

Zvikamu zvakakora zvingada multi-pass welding kana special optics.

▶ Ko Laser Welding Inokodzera Kukwirisa Vhoriyamu Kugadzirwa?

Zvamazvirokwazvo. Robotic laser welding maseru anowanzo shandiswa munzvimbo dzekumhanya-mhanya, otomatiki dzekugadzira nharaunda dzekushandisa senge kugadzira mota.

Miyero yekupinda yemamita akati wandei paminiti inogoneka.

▶ Ndeapi maIndustries anoshandisa Laser Welding?

Yakajairika laser welding application inogona kuwanikwa mukatimota, zvemagetsi, zvekurapa, aerospace, turusi/kufa, uye diki diki diki kugadzira chikamu.

Iyo tekinoroji ndiyozvichiramba zvichiwedzera kuva zvikamu zvitsva.

▶ Ndinosarudza sei laser welding system?

Zvinhu zvekufunga nezvazvo zvinosanganisira workpiece zvinhu, saizi/hukobvu, zvinodikanwa zvekupfuura, bhajeti, uye inodiwa weld mhando.

Vane mukurumbira vatengesi vanogona kubatsira kutsanangura iyo chaiyo laser mhando, simba, optics, uye otomatiki kune yako chaiyo application.

▶ Ndeapi Mhando dzeWelds Inogona Kugadzirwa?

Yakajairika laser welding matekiniki anosanganisira butt, lap, fillet, kuboora, uye cladding welds.

Dzimwe nzira dzekuvandudza senge laser additive kugadzira dziri kubudawo kugadzirisa uye prototyping application.

▶ Ko Laser Welding Yakakodzera Basa Rokugadzirisa?

Ehe, laser welding yakanyatso kuenderana nekugadziriswa kwepamusoro-kukosha zvikamu.

Iyo yakadzika yekupisa yekuisa inoderedza kumwe kukuvadza kune base zvinhu panguva yekugadzirisa.

Unoda Kutanga neLaser Welder Machine?

Wadii Kufunga Isu?

Nguva yekutumira: Feb-12-2024