Laser welding inonyanya kuitirwa kuvandudza kugona kwewelding uye kunaka kwezvinhu zvakatetepa madziro uye nemazvo zvikamu. Nhasi hatisi kuzotaura nezve zvakanakira laser welding asi tarisa mashandisiro ekudzivirira magasi ekuisa laser welding nemazvo.

Sei uchishandisa shield gasi kune laser welding?

Mune laser welding, nhovo gasi inokanganisa weld kuumba, weld mhando, weld kudzika, uye weld hupamhi. Muzviitiko zvakawanda, kuridza gasi rinobatsirwa kuchava nemigumisiro yakanaka pane weld, asi inogonawo kuunza migumisiro yakaipa.

Paunoridza nhovo gasi nemazvo, zvinokubatsira:

✦Kunyatso chengetedza dziva re weld kuderedza kana kudzivirira oxidation

✦Zvinonyatso dzikisa splash inogadzirwa muwelding process

✦Zvinobudirira kuderedza weld pores

✦Batsira dziva re weld kupararira zvakaenzana kana kusimba, kuitira kuti weld seam iuye nekwakachena uye kwakatsetseka.

✦Iyo yekudzivirira mhedzisiro yesimbi vapor plume kana plasma gore pane laser inodzikiswa zvinobudirira, uye inoshanda chiyero chekushandisa laser inowedzera.

As long as thenhovo gasi rudzi, gasi kuyerera mwero, uye kufuridza modhi sarudzondizvozvo, unogona kuwana yakanakira mhedzisiro yewelding. Nekudaro, kushandiswa zvisirizvo kwegasi rekudzivirira kunogona kukanganisawo welding. Kushandisa iyo isiriyo mhando yenhovo gasi kunogona kutungamira kune creaks mune weld kana kuderedza ma mechanic zvinhu zvewelding. Kunyanya kukwira kana kuderera zvakanyanya gasi rekuyerera kunogona kutungamirira kune yakakomba weld oxidation uye kukanganiswa kwakanyanya kwekunze kwesimbi mukati meweld pool, zvichikonzera kudonha kwe weld kana kusaenzana kuumbwa.

Mhando dzeshield gasi

Iwo anowanzo shandiswa ekudzivirira magasi e laser welding anonyanya kushandisa N2, Ar, uye Iye. Zvimiro zvavo zvemuviri nemakemikari zvakasiyana, saka mhedzisiro yavo pane welds zvakare yakasiyana.

Nitrogen (N2)

Iyo ionization simba reN2 ine mwero, yakakwirira kupfuura iyo yeAri, uye yakaderera pane iyo yaIye. Pasi pemwaranzi yelaser, iyo ionization degree yeN2 inogara pane imwe keel, iyo inogona kuderedza zvirinani kuumbwa kwegore replasma uye kuwedzera chiyero chekushandisa kwelaser. Nitrogen inogona kuita nealuminium alloy uye kabhoni simbi pane imwe tembiricha kugadzira nitrides, iyo inovandudza weld brittleness uye kuderedza kuomarara, uye kuve nemhedzisiro yakaipa pamichina yemagetsi majoini. Naizvozvo, hazvikurudzirwe kushandisa nitrogen kana welding aruminiyamu alloy uye kabhoni simbi.

Nekudaro, iyo kemikari inopindirana pakati penitrogen nesimbi isina tsvina inogadzirwa nenitrogen inogona kuvandudza kusimba kweiyo weld joint, izvo zvichave zvinobatsira kuvandudza ma mechanical properties ye weld, saka welding yesimbi isina tsvina inogona kushandisa nitrogen sechidziviriro gasi.

Argon (Ar)

Iyo ionization simba reArgon yakadzikira, uye dhigirii rayo reionization richave rakakwirira pasi pechiito chelaser. Zvadaro, Argon, segasi rinodzivirira, haigoni kudzora zvinobudirira kuumbwa kwemakore eplasma, izvo zvinoderedza kushandiswa kunoshanda kwelaser welding. Mubvunzo unomuka: ko argon mumiriri wakashata wekushandisa welding segasi rinodzivirira? Mhinduro ndeyokuti Kwete. Kuva gasi inert, Argon yakaoma kuita nehuwandu hwesimbi, uye Ar yakachipa kushandisa. Mukuwedzera, kuwanda kweAr kwakakura, kuchaita kuti kunyura pamusoro pechidziva che weld yakanyungudutswa uye inogona kudzivirira zviri nani dziva re weld, saka Argon inogona kushandiswa seyakajairwa inodzivirira gasi.

Helium (Iye)

Kusiyana neArgon, Helium ine simba rakanyanya ionization rinogona kudzora kuumbwa kwe plasma makore nyore. Panguva imwecheteyo, Helium haina kuita chero nesimbi. Ichokwadi sarudzo yakanaka ye laser welding. Dambudziko chete nderekuti Helium inodhura. Kune vanogadzira zvigadzirwa vanopa zvigadzirwa zvesimbi zvekugadzira misa, helium inowedzera mari yakawanda kumutengo wekugadzira. Saka helium inowanzoshandiswa mukutsvagisa kwesainzi kana zvigadzirwa zvine kukosha kwakanyanya kwakawedzerwa.

Nzira yekuputira sei nhovo gasi?

Chokutanga pane zvose, zvinofanira kunge zvakajeka kuti iyo inonzi "oxidation" ye weld inongova zita rinowanzozivikanwa, iro rinongotaura rinoreva maitiro emakemikari pakati pe weld uye zvinhu zvinokuvadza mumhepo, zvichiita kuti kuparara kwe weld. Kazhinji, weld metal inopindirana neokisijeni, nitrogen, uye hydrogen mumhepo pane imwe tembiricha.

Kudzivirira weld kubva "oxidized" kunoda kuderedza kana kudzivisa kusangana pakati pezvinhu zvinokuvadza zvakadaro uye weld simbi pasi pekushisa kwepamusoro, iyo isiri chete musimbi yakanyungudutswa yedziva asi nguva yose kubva panguva iyo weld simbi inonyungudutswa kusvikira simbi yakanyungudutswa yedhamu yasimbiswa uye tembiricha yaro iri kutonhora kusvika kune imwe tembiricha.

Nzira mbiri huru dzekufuridza nhovo gasi

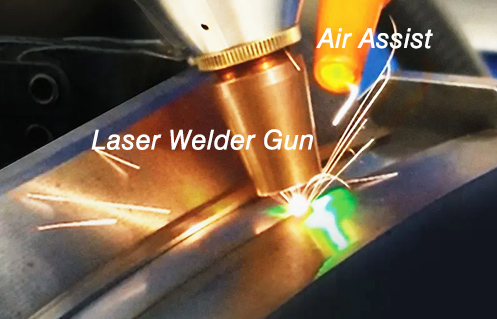

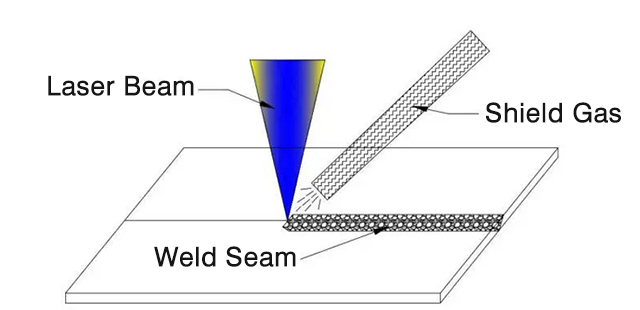

▶Imwe iri kufuridza nhovo gasi padivi peaxis, sezvinoratidzwa mumufananidzo 1.

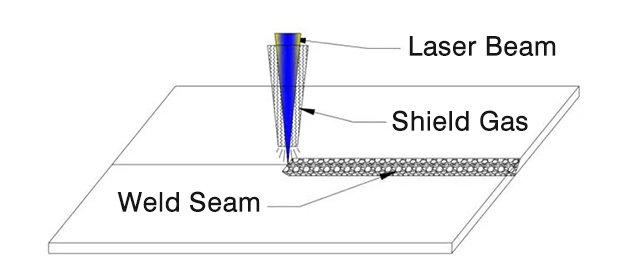

▶Imwe yacho ndeye coaxial kuvhuvhuta nzira, sezvakaratidzwa mumufananidzo 2.

Mufananidzo 1.

Mufananidzo 2.

Sarudzo chaiyo yenzira mbiri dzekufuridza ndeyekutarisisa kwakadzama kwezvinhu zvakawanda. Kazhinji, zvinokurudzirwa kutora nzira yedivi-inoputika gasi rinodzivirira.

Mimwe mienzaniso yelaser welding

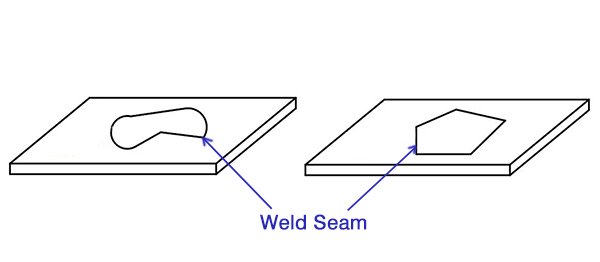

1. Sight bead/line welding

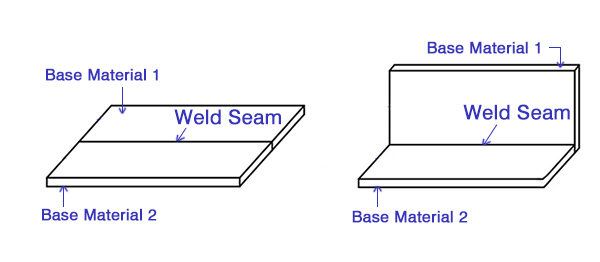

Sezvinoratidzwa muMufananidzo 3, chimiro cheweld chechigadzirwa chine mutsara, uye fomu rejoint rinogona kunge riri rebutt joint, lap joint, negative corner joint, kana over overlaped welding joint. Kune rudzi urwu rwechigadzirwa, zviri nani kutora padivi-axis inofuridza inodzivirira gasi sezvakaratidzwa muFigure 1.

2. Vhara nhamba kana nzvimbo welding

Sezvinoratidzwa muMufananidzo 4, iyo weld shape yechigadzirwa inzira yakavharwa yakadai sedenderedzwa rendege, ndege yakasiyana-siyana chimiro, ndege yakawanda-segment linear shape, etc. Iyo yakabatana fomu inogona kuva butt joint, lap joint, overlapping welding, etc. Zviri nani kutora nzira ye coaxial inodzivirira gasi sezvinoratidzwa mumufananidzo 2 wemhando iyi yechigadzirwa.

Kusarudzwa kwegasi rinodzivirira kunokanganisa zvakananga kunaka kwewelding, kushanda zvakanaka, uye mutengo wekugadzira, asi nekuda kwekusiyana kwezvinhu zvewelding, mune chaiyo welding process, kusarudzwa kwegasi rewelding kunonyanya kuoma uye kunoda kutariswa kwakadzama kwewelding zvinhu, welding nzira, welding chinzvimbo, pamwe nezvinodiwa zvewelding. Kuburikidza nemiyedzo yewelding, unogona kusarudza iyo yakanyatsokodzera welding gasi kuti uwane mhedzisiro iri nani.

Kufarira laser welding uye kuda kudzidza nzira yekusarudza shield gasi

Related Links:

Nguva yekutumira: Oct-10-2022