1. Kucheka Speed

Vatengi vazhinji mukubvunzana kwelaser yekucheka muchina vanobvunza kuti inokurumidza sei laser muchina unogona kucheka. Chokwadi, muchina wekucheka laser unoshanda zvakanyanya midziyo, uye kucheka kumhanya ndiko kwakaringana kutarisa kwevatengi. Asi iyo inokurumidza kucheka kumhanya haitsanangure mhando yekucheka laser.

Kukurumidza tiye achicheka speed

a. Haikwanise kucheka nepakati

b. Nzvimbo yekucheka inopa oblique zviyo, uye hafu yepasi ye workpiece inobudisa tsvina inonyunguduka

c. rough cutting edge

Kunyanya kunonoka kucheka kukurumidza

a. Pamusoro pekunyunguduka neiyo rough cutting surface

b. Yakakura yekucheka gapu uye kona yakapinza inonyungudutswa kuita makona akatenderedzwa

Kuita kuti laser yekucheka muchina midziyo itambe basa rayo rekucheka, usangobvunza kuti kukurumidza sei muchina welaser unogona kucheka, mhinduro inowanzove isiriyo. Zvakapesana, ipa MimoWork nekutsanangurwa kwezvinyorwa zvako, uye isu tichakupa mhinduro ine mutoro.

2. Focus Point

Nekuti iyo laser simba density ine pesvedzero huru pakumhanya kwekucheka, kusarudzwa kwelens yekutarisa kureba ipfungwa yakakosha. Iyo laser spot size mushure melaser beam inotarisisa inoenderana nehurefu hwakatarisana nelens. Mushure mekunge danda relaser ratariswa nelenzi ine ipfupi yekutarisa kureba, saizi yelaser nzvimbo idiki kwazvo uye simba remagetsi panzvimbo yakatarisana rakakwira zvakanyanya, izvo zvinobatsira kucheka zvinhu. Asi chakashata chayo ndechekuti nekudzika kupfupi kwekutarisa, kungoita diki gadziriso mvumo yehukobvu hwezvinhu. Kazhinji, iyo lens yekutarisa ine pfupi yakatarisa kureba inonyanya kukodzera kune yakakwirira-kumhanya yekucheka zvinhu zvitete. Uye iyo lenzi yekutarisa ine kureba kwekutarisa kune yakafara kudzika kwakadzika, chero iine simba rakakwana density, inonyanya kukodzera kucheka makobvu ekushanda senge furo, acrylic, uye huni.

Mushure mekuona kuti ndeipi yakatarisa kureba lens yekushandisa, iyo yakatarisana nzvimbo yekutarisa kune iyo workpiece yepamusoro yakakosha kuve nechokwadi chekucheka mhando. Nekuda kweiyo yakanyanya simba density panzvimbo yekutarisa, kazhinji, nzvimbo yekutarisa ingori kana zvishoma pazasi pepamusoro peiyo workpiece paunenge uchicheka. Mukuita kwese kwekucheka, chinhu chakakosha kuve nechokwadi chekuti chinzvimbo chekutarisa uye workpiece chinogara chiripo kuti uwane yakagadzikana yekucheka mhando.

3. Air Blowing System & Auxiliary Gas

Kazhinji, zvinhu laser kucheka kunoda kushandiswa kwegasi rinobatsira, rinonyanya kuenderana nerudzi uye kudzvanywa kwegasi rinobatsira. Kazhinji, iyo yekubatsira gasi inodzingwa coaxially nelaser beam kuchengetedza lens kubva pakusvibiswa uye kuputira slag pazasi penzvimbo yekucheka. Kune zvisiri zvesimbi uye zvimwe zvinhu zvesimbi, mhepo yakamanikidzwa kana inert gasi inoshandiswa kubvisa zvakanyungudutswa uye evaporated zvinhu, uku ichidzivirira kupisa kwakanyanya munzvimbo yekucheka.

Pasi pemamiriro ekuvimbisa ebetsero gasi, gasi kudzvanywa chinhu chakakosha zvakanyanya. Paunenge uchicheka zvinhu zvitete pakumhanya zvakanyanya, gasi rakakwirira rinodiwa kudzivirira slag kuti isanamatira kumashure kwekucheka (inopisa slag ichakuvadza kumucheto kwekucheka kana ichirova workpiece). Kana ukobvu hwezvinhu huchiwedzera kana kumhanya kwekucheka kuchinonoka, gasi rinomanikidza rinofanira kuderedzwa zvakakodzera.

4. Reflection Rate

Iyo yavelength yeCO2 laser ndeye 10.6 μm iyo yakanaka kune zvisiri-metallic zvinhu kutora. Asi iyo CO2 laser haina kukodzera kucheka simbi, kunyanya iyo simbi zvinhu zvine yakakwirira reflectivities segoridhe, sirivheri, mhangura uye aruminiyamu simbi, nezvimwe.

Kutorwa kwechinyorwa kudanda kunoita basa rakakosha padanho rekutanga rekudziya, asi kana gomba rekucheka richinge raumbwa mukati meiyo workpiece, dema-muviri mhedzisiro yegomba inoita kuti kunyura kwechinhu kune danda pedyo ne100%.

Mamiriro epamusoro echinyorwa anobata zvakananga kubatwa kwedanda, kunyanya kushata kwepamusoro, uye iyo yepamusoro oxide layer inokonzeresa shanduko dziri pachena mukutorwa kwepamusoro. Mukuita kwekucheka kwelaser, dzimwe nguva kuita kwekucheka kwezvinhu kunogona kuvandudzwa nekurudziro yemamiriro ezvinhu epamusoro pane danda rekunyudza.

5. Laser Head Nozzle

Kana iyo muromo yakasarudzwa zvisina kunaka kana kuchengetwa zvisina kunaka, zviri nyore kukonzera kusvibiswa kana kukuvadzwa, kana nekuda kweiyo yakashata kutenderera kwemuromo wemuromo kana kuvharika kwenzvimbo kunokonzerwa nekupisa kwesimbi inoputika, eddy currents inoumbwa mumhuno, zvichikonzera kucheka kwakanyanya kuita. Dzimwe nguva, muromo wemuromo hauenderane nedanda rakatariswa, richigadzira danda rekugera mupendero wemuromo, izvo zvinozokanganisa kunaka kwekucheka, kuwedzera hupamhi hwekutsemura uye kuita kuti saizi yekucheka iparare.

Kune ma nozzles, nyaya mbiri dzinofanirwa kutariswa zvakanyanya

a. Kufurira kwenozzle dhayamita.

b. Kufurira kwechinhambwe pakati penozzle uye workpiece pamusoro.

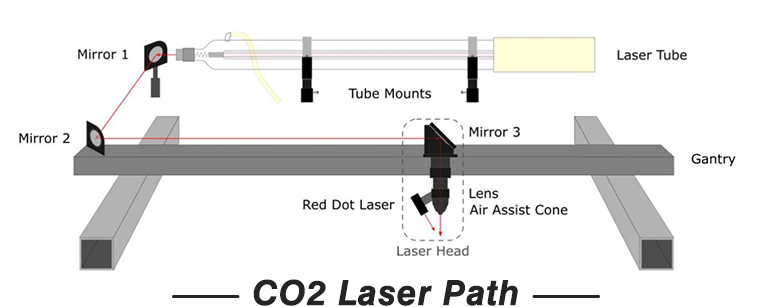

6. Optical Path

Danda rekutanga rinoburitswa nelaser rinofambiswa (kusanganisira kutarisisa uye kutapurirana) kuburikidza neyekunze optical nzira sisitimu, uye nekunyatso vhenekera pamusoro peiyo workpiece ine yakanyanya-yakanyanya simba density.

Zvinhu zvemaziso ekunze kwekunze optical path system zvinofanirwa kugara zvichitariswa uye kugadziridzwa nenguva kuti ive nechokwadi chekuti kana tochi yekucheka ichimhanya pamusoro pechishandiso, mwenje wemwenje unofambiswa nenzira kwayo pakati pe lens uye wakanangidzirwa munzvimbo diki kucheka workpiece nemhando yepamusoro. Kamwe chete chinzvimbo chechinhu chero chipi zvacho chemaziso chachinja kana kusvibiswa, kunaka kwekucheka kunokanganiswa, uye kunyangwe kucheka hakugone kuitwa.

Iyo yekunze yekuona nzira lens yakasvibiswa netsvina mumhepo inoyerera uye inosungirirwa nekuputika zvimedu munzvimbo yekucheka, kana lens haina kutonhodzwa zvakakwana, izvo zvinozoita kuti lenzi iwedzere kupisa uye kukanganisa kutapurirana kwesimba. Iyo inokonzeresa kudhumhana kweiyo nzira yekudonha uye inotungamira kune yakakomba mhedzisiro. Iyo lens overheating inoburitsawo kukanganiswa kwekutarisa uye kutoisa njodzi iyo lens pachayo.

Dzidza zvakawanda nezve co2 laser cutter mhando uye mitengo

Nguva yekutumira: Sep-20-2022