Chii chinonzi laser Laser Welding akatsanangura! Zvese iwe zvaunoda kuziva nezve laser weldering, kusanganisira nheyo huru uye maipareji makuru emakarati!

Vatengi vazhinji havanzwisisi nzira dzekushanda dzeLaser Weler

Chii chinonzi laser

Laser Welding rudzi rwekunyungudika, uchishandisa laser bears seyakaisa kupisa sosi yekukwira sosi inoshanda, uye wobva washandura mumahombekombe ekurira, kana danda uye chidimbu chebasa kuonana, simba rinobatwa nechinhu chebasa, kana tembiricha ichisvika padanho rekunyungudika yezvinyorwa zvinogona kuve Welded.

Sekureva kweiyo huru mechenism yeWalding Pool, Laser Welding ine maviri ekutanga mashini ekutenderera: kupisa kuunganidzwa nelting uye penetirmation yakadzika (keyhole) welding. Kupisa kunogadzirwa nekupisa kwehutachiona kune icho chidimbu chebasa kuburikidza nekushambadzira kwekushisa, hapana mupfusi unofanirwa kuve unoitika, unowanzoshandiswa muzvikamu zvekudzikira-zvakadzika zvidimbu zvidiki-ish zvikamu. Yakadzika fusion inobuda inovhara zvinhu uye inoumba huwandu hukuru hweplasma. Nekuda kwekumisa kukwidziridzwa, pachave nemakomba kumberi kwedziva rakanyungudutswa. Yakadzika penetiration yelching ndiyo inonyanya kushandiswa laser welder

Maitiro paramita mu laser weldering

Kune akawanda maitiro emahara anokanganisa mhando yeLaser Welating, yakadai sekusimba kwesimba, laser pulse waveform, inokanganisa kumhanya uye sarudzo yezvinhu zvebetsero.

Laser simba density

Power Density ndeimwe yeakanyanya kukosha parameter mune laser kugadzirisa. Ine simba rakakwirira density, iyo nzvimbo yepasi inogona kupiswa kune inovhara point mukati me micosecond, zvichikonzera huwandu hukuru hwemaporization. Naizvozvo, iyo yakakwirira-simba density inobatsira kuendeswa kwekubvisa maitiro akadai sekukweva, kucheka uye kunyora. Kuti uwane simba rakaderera remagetsi, zvinotora milliseciseconds yemusoro kuti usvike pese poindi, uye pamberi pechiso chinoputika, pasi rinosvika pakunyungudika, iro riri nyore kuumba yakanaka yekunyungudika. Naizvozvo, muchimiro chekupisa cheki laser welasing, iyo Simba Density renji ndeye 104-10W / cm2.

Laser pulse waveform

Laser pulse waveform haisi chete paramende yakakosha kusiyanisa kubviswa kwezvinhu kubva mukunyungudika, asi zvakare kiyi paramende kuti uone huwandu uye mutengo wekugadzirisa michina. Kana iyo yakakwira simba laser ichipfurwa pamusoro pezvinyorwa, pamusoro pezvinyorwa zvichave nemakumi matanhatu neshanu chesimba, sirivheri, sirivheri, aluminium, titanium uye zvimwe zvinhu zvine kuraswa kwakasimba uye nekukurumidza kupisa kuendesa. Kurudziro yesimbi inoshanduka nenguva panguva yekudzora pulse. Kana tembiricha yemukati yakati yabuda munzvimbo yekunyungudika, kuratidzwa kunoderera nekukurumidza, uye kana pamusoro pazvo muchinyungudika, kuratidzwa kunoita kuti uzive pane imwe kukosha.

Laser pulse upamhi

Pulse upamhi ihure rakakosha paramende rakanangidzirwa laser welder. Iyo pulse uplat yakatemerwa nekudzika kwekupinza uye kupisa kwakakanganiswa nzvimbo. Iyo yakareba iyo pulse upfulation yaive, iyo yakakura kupisa kwakakanganiswa nzvimbo yaive, uye kudzika kwekupaza kwakawedzera neiyo 1/2 simba rePulse upfu hwakakura. Nekudaro, kuwedzera kwe pulse upfu hwakakura kuchaderedza simba repamusoro, saka kuwedzera kwehupamhi kwacho kunowanzoitwa pakupisa kwehutachiona, kwakakwanira saizi yerudzi, kunyanya yakakodzera yemapuranga ematehwe akaonda uye akareba. Nekudaro, yakaderera peak Simba inoguma nekuwedzera kupisa kupisa, uye chimwe nechimwe chinhu chine yakakwana pulse upamhi iyo inowedzera kudzika kwekupinza.

Defocus kuwanda

Laser Welding kazhinji inoda imwe huwandu hwehunhu, nekuti density yenzvimbo nzvimbo panzvimbo yeiyo Laser inotarisa yakanyanya, iyo iri nyore kutapudza midziyo mumakomba. Kugoverwa kwesimba kwesimba kune yunifomu mune imwe ndege kure kure kubva kune laser inotarisa.

Kune maviri defices modes:

Yakanaka uye isina kunaka defocus. Kana iyo yeFocal ndege iri pamusoro pebasa rekushanda, yakanaka defipeni; Zvikasadaro, hazvina kunaka defocus. Sekureva kweGeometric Opolics Dzidziso, apo chinhambwe pakati pezvirongwa zvakanaka uye chisina kunaka uye chakashata ndege pane imwe ndege dzinenge dzakafanana, asi kutaura zvazviri, iyo yakawanikwa yakaumbwa chool chimiro chakasiyana. Panyaya yeiyo isina kunaka defocus, kupinza kwakakura kunogona kuwanikwa, iyo ine hukama nehunhu hwekuumbwa kwedziva rakanyungudutswa.

Welding kumhanya

Welding mhanyisa inomhanya inosarudza welding mamiriro ekunze, kupinza kwakadzika, kupisa kwakakanganiswa nzvimbo uye zvichingodaro. Iyo yekumhanyisa yekumhanyisa ichakanganisa kupisa kwekupisa pane yuniti nguva. Kana kumhanya kwekumhanya kunononoka kwazvo, iyo yekupisa yekuisa yakanyanya kukwirira, ichikonzerwa neyekubasa inopfuta kuburikidza. Kana iyo yekumhanyisa kumhanya zvakanyanya, iyo yekupisa yekuisa idiki, inokonzerwa neyekubatsira mulking zvishoma uye isina kupera. Kuderedza kumhanyisa kumhanya kunowanzo kuve kunovandudza kupinza.

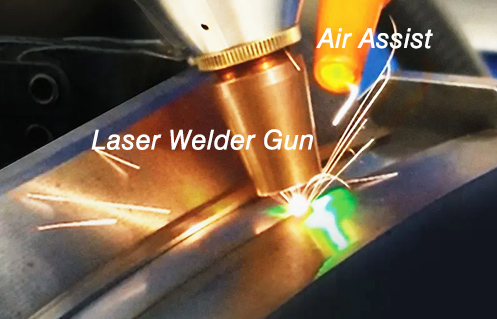

Auxiliary Blow Dziviriro Gasi

Auxiliary Blow Dziviriro Gasi inzira yakakosha mune yakakwirira Simba Laser Welding. Kune rimwe divi, kudzivirira zvinhu zvesimbi kubva pakupuruzira uye kusvibisa girazi rekutarisa; Kune rimwe divi, ndeyekudzivirira iyo plasma yakagadzirwa mumamiriro ezvinhu ekutarisa kubva pakutarisa zvakawandisa uye kudzivirira iyo laser kubva kune iyo nzvimbo yezvinyorwa. Mukuita kwaLaser Welding, Helgium, Argon, Nitrogen uye mamwe magasi anowanzoshandiswa kuchengetedza dziva rakanyungudutswa, kuti idzivise basa rekushanda muinjiniya. Zvinhu zvakadai sedzemhando yegesi yekudzivirira, kukura kwemhepo uye kuputika kwemhepo kwakanganisa zvikuru mhedzisiro, uye nzira dzekuputika dzakaputika dzicharwadzisa zvakare nemhando yemhando yepamusoro.

Yedu Yakakurudzirwa Halleld Laser Welder:

Laser Welder - Kushanda Nzvimbo

◾ Kupisa huwandu hwenzvimbo yekushanda: 15 ~ 35 ℃

◾ Humidity rima yekushanda nharaunda: <70% hapana concensionation

◾ Kutonhorera: Mvura Chiller inodikanwa nekuda kwebasa rekupisa kubvisa zvinhu zvekupfura zvimisikidzwa

Wanna kuziva zvakawanda nezve laser welders?

Kutumira Nguva: Dec-22-2022