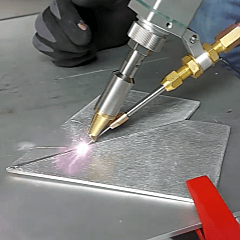

Maitiro eLaser Weld Aluminium Alloys

Welding Aluminium Inogona kunge Inonyengera

Aluminium alloys akakamurwa kuita akateedzana zvichienderana neyavo yekutanga alloying zvinhu.

Imwe neimwe yakatevedzana ine yakasarudzika zvimiro inokanganisa weldability yayo, kunyanya kana uchishandisa handheld laser welding.

Pazasi pane tarisiro yeakajairwa aluminium alloy akateedzana, maitiro avo, akakodzera ekudzivirira magasi, akakodzera waya dzekuzadza, uye matipi ekuwana emhando yepamusoro welds.

Table of Content:

1. Yakajairwa Aluminium Alloys yeLaser Welding

Nhanho Yekutanga Yekuwana Yakanaka Weld: Kunzwisisa

1000 Series Aluminium Alloys

Kuumbwa:Iine 99.00% aluminium kana kupfuura.

Properties:Huremu uye yakanyanya ductile, zvichiita kuti zvive nyore kushanda nayo.

Shielding Gasi:100% Argon inokurudzirwa kudzivirira oxidation.

Filler Wire:Shandisa 4047 kana 4045 filler waya kuti ienderane zvirinani.

Welding Tips:Ita shuwa kuti kumusoro kwakachena uye hakuna maokisi. Preheating kazhinji haina kudikanwa nekuda kweiyo yakakwira ductility.

2000 Series Aluminium Alloys

Kuumbwa:Alloyed kunyanya nemhangura (2-10%).

Properties:Simba guru asi ductility shoma; inokurumidza kutsemuka panguva yewelding.

Shielding Gasi:Argon ine chikamu chiduku cheHelium inogona kubatsira kuvandudza kupinda.

Filler Wire:Shandisa 4047 kana 2319 waya yekuzadza, iyo yakagadzirirwa mhangura-yakapfuma alloys.

Welding Tips:Preheat zvinhu kuti uderedze njodzi yekutsemuka. Chengetedza kupisa kwekuisa nekuchenjerera kudzivirira zvakanyanya kupisa kushushikana.

3000 Series Aluminium Alloys

Kuumbwa:Yakasanganiswa ne manganese.

Properties:Kuramba kwakanaka kwekuora uye simba; inochengetedza simba pane tembiricha dzakakwirira.

Shielding Gasi:100% Argon inoshanda.

Filler Wire:4045 kana 4047 filler waya yakakodzera.

Welding Tips:Chenesa kumusoro kuti ubvise chero tsvina. Chengetedza kumhanya kwakadzikama kuti uve nechokwadi chekugovera kupisa.

4000 Series Aluminium Alloys

Kuumbwa:Iine silicon, iyo inoderedza kunyungudika.

Properties:Kuwedzera ductility uye yakanakira kufa-kukanda; kusapisa kunorapika.

Shielding Gasi:Argon inosarudzwa.

Filler Wire:Shandisa 4047 filler waya kune yakakwana mhedzisiro.

Welding Tips:Preheating inogona kubatsira nekupinda. Nyatsoongorora zvinopinda zvekupisa kuti usapinda.

5000 Series Aluminium Alloys

Kuumbwa:Yakasanganiswa ne magnesium.

Properties:Simba repamusoro uye rakanakisa corrosion resistance; akakodzera mapepa uye ndiro.

Shielding Gasi:100% Argon inokurudzirwa.

Filler Wire:Shandisa 5356 filler waya kuti ienderane zvirinani.

Welding Tips:Preheating inobatsira kune zvikamu zvakakora. Shandisa nzira yekusundira kuvandudza chiito chekuchenesa uye kuderedza kusvibiswa.

6000 Series Aluminium Alloys

Kuumbwa:Iine zvose magnesium uye silicon.

Properties:Ductility yakanaka uye kupisa-kurapwa; yakanaka kune extrusions.

Shielding Gasi:Argon kana musanganiswa weArgon neHelium.

Filler Wire:4045 kana 5356 filler waya yakakodzera.

Welding Tips:Iva nechokwadi chekuchenesa kwakakodzera kwepamusoro. Shandisa kumhanya kwepamusoro kudzivirira kupisa.

7000 Series Aluminium Alloys

Kuumbwa:Kunyanya yakasanganiswa zinc.

Properties:Simba rakakwirira asi kazhinji harina kukodzera fusion welding nekuda kwekutsemuka nyaya.

Shielding Gasi:Argon ine Helium inogona kubatsira.

Filler Wire:Shandisa 7072 kana 7005 filler waya.

Welding Tips:Preheating yakakosha kuderedza njodzi yekutsemuka. Shandisa inodzorwa kupisa kwekuisa uye kudzivirira kumhanya kwakanyanya kwekufamba.

Nekufambira mberi kweTekinoroji Yemazuvano

Laser Welding Machine Mutengo hauna kumbobvira wave Uchidhura uyu!

2. Common Tips nokuti Laser Welding Aluminium

Kuti uwane Yakanaka Welding Mhedzisiro, Heano mamwe Mapoinzi Akakosha:

Kugadzirira Kwepamusoro

Gara uchichenesa nzvimbo yealuminium kubvisa maokisi uye zvinosvibisa.

Kudzora Kupisa

Chengetedza kupinza kwekushisa nekungwarira kudzivirira kutenderera uye kukanganisa, kunyanya pazvinhu zvitete.

Travel Speed

Rongedza kumhanya kwekufamba zvinoenderana neukobvu hwezvinhu kuti uenzanise kupinza uye kupisa kupinza.

Focal Point Adjustment

Tarisa iyo laser zvishoma pazasi pepamusoro pekupinda zvirinani uye kuderedzwa kutaridzika.

Kusarudza Pakati Akasiyana Mhando dzeLaser Welding Machine?

Tinogona Kubatsira Kuita Sarudzo Yakarurama Kubva pane Zvishandiso

3. Nzira yeKuwana Weld Yakanaka neAluminium Alloys

Kunzwisisa Material yako iri Half Way ipapo

Kunzwisisa zvakajairika aluminium alloy akateedzana kwakakosha kuti uwane yakanaka weld ine handheld laser welder nekuda kwezvikonzero zvakati:

Material Properties

Imwe neimwe aluminium alloy series ine yakasarudzika zvivakwa, zvinosanganisira simba, ductility, uye nzvimbo yekunyungudika.

Kuziva zvivakwa izvi kunobatsira pakusarudza akakodzera welding paramita, senge magetsi kuseta uye kumhanya kwekufamba, kuve nechokwadi chesimba, rinoshanda weld.

Welding Matambudziko

Yakasiyana alloy akateedzana inopa chaiwo matambudziko panguva yewelding.

Semuyenzaniso, 2000 akatevedzana alloys anowanzo kutsemuka, nepo 4000 akatevedzana alloys anogona kuyerera zviri nyore.

Kunzwisisa matambudziko aya kunoita kuti ma welders ashandise matekiniki ekudzikamisa nyaya, senge preheating kana kugadzirisa mafirita.

Filler Material Kuenderana

Yakasiyana aruminiyamu alloys inoda inoenderana filler zvinhu kuti ive nechokwadi chisungo chakasimba.

Semuenzaniso, kushandisa waya chaiyo yekuzadza kunogona kudzivirira nyaya senge porosity kana kusakwana fusion.

Kuziva kweiyo alloy nhevedzano inobatsira mukusarudza iyo chaiyo yekuzadza waya kuti uwedzere kunaka weld.

Kudzivirira Gasi Kusarudzwa

Sarudzo yekudzivirira gasi inogona kukanganisa zvakanyanya weld mhando.

Imwe neimwe alloy akatevedzana angangoda chaiwo ekudzivirira magasi kudzivirira oxidation uye kunatsiridza kupinda.

Kunzwisisa kuumbwa kwealloy kunobatsira velders kusarudza yakanakisa kudzivirira gasi kune yakanyanya mhedzisiro.

Heat Management

Alloys akasiyana anoita zvakasiyana nekupisa.

Zvimwe zvingada preheating kana post-weld marapirwo kuti abvise kushushikana.

Kunzwisisa iyo alloy akatevedzana inobvumira welders kuti vatore kupisa kwekuisa zvinobudirira, kuderedza njodzi yekurwa kana kutsemuka.

Application Kukodzera

Mamwe maaluminium alloys anokodzera zvirinani kune chaiwo maapplication, senge aerospace kana mota.

Kuziva maitiro ega ega akatevedzana kunobatsira pakusarudza alloy chaiyo yebasa, kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nekuita uye kuchengetedza zviyero.

Kubudirira Kwemari

Kushandisa alloy akakodzera uye welding paramita kunogona kutungamira kune yakanyatsoita welding maitiro, kuderedza marara emidziyo uye kushandazve.

Kunzwisisa alloy zvivakwa kunobatsira kuronga zvirinani uye kuita, pakupedzisira kuchengetedza nguva uye mutengo.

Hunhu Hwakanaka

Kuziva kweakasiyana aluminium akatevedzana kunobatsira mukumisikidza maitiro ekudzora emhando.

Welders anogona kutora chaiwo matekiniki uye zviyero zvinoenderana nerudzi rwealloy, zvichitungamira kune anowirirana uye emhando yepamusoro welds.

Welding Aluminium Yakaoma neTraditional Welding

Laser Welding Rerutsa Maitiro aya

Unoda Kuziva Zvakawanda nezve Laser Welding Aluminium?

Welding Aluminium is Tricker pane Welding Zvimwe Zvishandiso.

Naizvozvo Takanyora Chinyorwa zvese nezve Maitiro eKuwana Akanaka Welds neAluminium.

Kubva kuSettings kuenda kuMaitiro.

NeVhidhiyo uye Rumwe Ruzivo.

Kufarira Laser Welding Zvimwe Zvishandiso?

Unoda Kutanga paLaser Welding Nekukurumidza?

Unoda Kuzorodza Ruzivo rwako rweLaser Welding?

Iyi Yakazara Reference Guide Yakagadzirirwa iwe chete!

Yakakwira-Capacity & Wattage kune Akasiyana Welding Application

Iyo 2000W handheld laser welding muchina inoratidzwa nediki muchina saizi asi inopenya welding mhando.

Iyo yakagadzikana fiber laser sosi uye yakabatana fiber tambo inopa yakachengeteka uye yakatsiga laser beam kuburitsa.

Nesimba repamusoro, iyo laser welding keyhole inokwana uye inogonesa iyo welding joint firmer kunyangwe kune gobvu simbi.

Portability for Flexibility

Iine compact uye diki muchina chitarisiko, inotakurika laser welder muchina wakashongedzerwa neinofambika handheld laser welder pfuti iyo isingaremi uye yakanakira akawanda-laser welding application pane chero kona uye pamusoro.

Optional marudzi akasiyana-siyana e laser welder nozzles uye otomatiki waya yekudyisa masisitimu anoita kuti laser welding kushanda kuve nyore uye zvine hushamwari kune vanotanga.

Yakakwira-kumhanya laser welding inowedzera zvakanyanya kugadzirwa kwako uye kubuda uku uchigonesa yakanakisa laser welding maitiro.

Zvinhu Zvaunofanirwa Kuziva Nezve: Handheld Laser Welding

Kana wakanakidzwa nevhidhiyo iyi, wadii kufunga nezvazvokunyorera kune yedu Youtube Channel?

Zvishandiso Zvinoenderana Unogona Kufarira:

Kutenga Kwese Kunofanira Kuziviswa Zvakanaka

Tinogona Kubatsira Neruzivo rwakadzama uye Kubvunza!

Nguva yekutumira: Zvita-20-2024