Nzira yeKusarudza Yakanakisisa Gasi Musanganiswa kune Yako Laser Welding?

Types, Benefits, uye Applications

Nhanganyaya:

Zvinhu Zvikuru Zvokuziva Usati Wanyura

Laser welding inzira yepamusoro-chaiyo welding inoshandisa danda relaser kunyungudutsa zvinhu zvechishandiso uye wozogadzira weld mushure mekutonhora. Mune laser welding, gasi inoita basa rakakosha.

Iyo gasi inodzivirira haingokanganise iyo welding seam kuumbwa, welding seam mhando, welding seam kupinza, uye hupamhi hwekupinda, asi zvakare inokanganisa zvakananga kunaka uye kugona kwelaser welding.

Ndeapi magasi anodiwa kuti laser welding?Ichi chinyorwa chichatarisa zvakadzamakukosha kwelaser welding magasi, magasi anoshandiswa, uye zvavanoita.

Tichakurudzirawoyakanakisa laser welding muchinanokuda kwezvido zvenyu.

Sei Gasi Richidiwa Kuti Laser Welding?

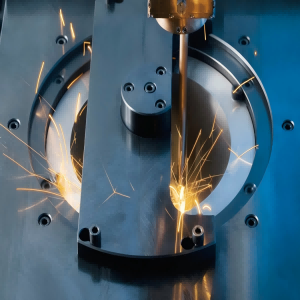

Laser Beam Welding

Munguva yelaser welding process, yakakwira-simba-density laser beam inotariswa pane welding nzvimbo yeworkpiece.

Kukonzera kunyunguduka kwepakarepo kwechinhu chepamusoro cheiyo workpiece.

Gasi rinodiwa panguva yekushongedza laser kuchengetedza nzvimbo yewelding.

Dzora tembiricha, vandudza mhando yeweld, uye chengetedza iyo optical system.

Kusarudza iyo yakakodzera gasi mhando uye maparamendi ekupa zvinhu zvakakosha pakuita kuti ishande.

Uye yakagadzikana laser welding process uye kuwana yepamusoro-mhando welding mhinduro.

1. Kudzivirirwa kweWelding Nzvimbo

Munguva ye laser welding process, iyo weld nzvimbo inoratidzwa kune yekunze nharaunda uye inokanganiswa nyore neokisijeni nemamwe magasi ari mumhepo.

Oxygen inokonzeresa oxidation reactions izvo zvinogona kutungamira mukuderedzwa weld quality, uye kusikwa kwepores uye inclusions. Iyo weld inogona kunyatsodzivirirwa kubva mukusvibiswa kweokisijeni nekupa gasi rakakodzera, kazhinji gasi inert senge argon, kunzvimbo yewelding.

2. Kudzora Kupisa

Gasi kusarudzwa uye kupa kunogona kubatsira kudzora tembiricha yenzvimbo yewelding. Nekugadzirisa chiyero chekuyerera uye rudzi rwegasi, kutonhora kwenzvimbo yewelding inogona kukanganiswa. Izvi zvakakosha kudzora nzvimbo inobatwa nekupisa (HAZ) panguva yekushongedza uye kuderedza kupisa kunokanganisa.

3. Kuvandudzwa kweWeld Quality

Mamwe magasi anobatsira, akadai seokisijeni kana nitrogen, anogona kuvandudza kunaka uye kushanda kwewelds. Semuenzaniso, kuwedzera okisijeni kunogona kuvandudza kupinda kweiyo weld uye kuwedzera kumhanya kwewelding, nepo ichikanganisa chimiro nekudzika kweweld.

4. Gasi Kutonhora

Mune laser welding, iyo welding nzvimbo inowanzokanganiswa nekupisa kwakanyanya. Kushandisa gasi kutonhora system kunogona kubatsira kudzora tembiricha yenzvimbo yewelding uye kudzivirira kupisa. Izvi zvakakosha kuti uderedze kushushikana kwekupisa munzvimbo yewelding uye kugadzirisa welding mhando.

Automated Laser Beam Welding

5. Gasi Kudzivirirwa kweOptical Systems

Iyo laser beam inotariswa pane welding nzvimbo kuburikidza neoptical system.

Munguva yekushambadzira, iyo yakanyungudutswa uye aerosols inogadzirwa inogona kusvibisa optical components.

Nekuunza magasi munzvimbo yewelding, njodzi yekusvibiswa inoderedzwa uye hupenyu hweiyo optical system hunowedzera.

Ndeapi Magasi Anoshandiswa MuLaser Welding?

Mune laser welding, gasi rinogona kuparadzanisa mhepo kubva kune welding plate uye kuidzivirira kubva pakusangana nemhepo. Nenzira iyi, iyo welding pamusoro peplate yesimbi ichave yakachena uye yakanyanya kunaka. Kushandisa gasi kunodzivirirawo malenzi kubva kuguruva rekushivirira. Kazhinji, zvinotevera magasi anoshandiswa:

1. Dziviriro Gasi:

Kudzivirira magasi, dzimwe nguva anonzi "inert magasi," anoita basa rakakosha mukugadzirisa laser welding. Laser welding maitiro anowanzo shandisa inert magasi kuchengetedza weld dziva. Iwo anowanzo shandiswa ekudzivirira magasi mune laser welding anonyanya kusanganisira argon uye neon. Zvimiro zvavo zvemuviri uye zvemakemikari zvakasiyana, saka mhedzisiro yavo pane weld zvakare yakasiyana.

Dziviriro Gasi:Argon

Argon ndeimwe yeanonyanya kushandiswa inert magasi.

Iyo ine yakakwira dhigirii yeionization pasi pechiito chelaser, iyo isingakodzeri kudzora kuumbwa kweplasma makore, ayo anozove nemhedzisiro pakushandiswa kunoshanda kwema lasers.

Iyo inert yemhando ye argon inoichengeta kunze kweiyo solder process, nepo ichibvisawo kupisa zvakanaka, ichibatsira kudzora tembiricha munzvimbo ye soldering.

Dziviriro Gasi:Neon

Neon inowanzoshandiswa seinert gasi, yakafanana neargon, uye inonyanya kushandiswa kuchengetedza nzvimbo yewelding kubva kuokisijeni uye zvimwe zvinosvibisa munzvimbo yekunze.

Izvo zvakakosha kuti uzive kuti neon haina kukodzera kune ese laser welding application.

Inonyanya kushandiswa kune mamwe akakosha ekuita mabasa, senge welding makobvu emidziyo kana kana yakadzika weld seams ichidikanwa.

2. Gasi rekubatsira:

Munguva yelaser welding process, mukuwedzera kune iyo huru yekudzivirira gasi, anobatsira magasi anogona zvakare kushandiswa kugadzirisa welding kuita uye mhando. Aya anotevera mamwe akajairika anobatsira magasi anoshandiswa mu laser welding.

Gasi rekubatsira:Okisijeni

Okisijeni inowanzoshandiswa segasi rekubatsira uye inogona kushandiswa kuwedzera kupisa uye kudzika kweweld panguva yekupisa.

Kuwedzera okisijeni kunogona kuwedzera welding kumhanya uye kupinda, asi inoda kunyatsodzorwa kudzivirira yakawandisa okisijeni ichikonzera oxidation matambudziko.

Gasi rekubatsira:Hydrogen / Hydrogen Musanganiswa

Hydrogen inovandudza kunaka kwewelds uye inoderedza kuumbwa kweporosity.

Misanganiswa yeargon nehydrogen inoshandiswa mune mamwe maapplication akakosha, senge welding simbi isina tsvina. Iyo hydrogen yemukati yemusanganiswa inowanzobva pa2% kusvika 15%.

Dziviriro Gasi:Nitrogen

Nitrogen inowanzo shandiswa segasi rinobatsira mune laser welding.

Iyo ionization simba renitrogen ine mwero, yakakwirira kupfuura argon uye yakaderera pane hydrogen.

Iyo ionization degree kazhinji iri pasi pechiito che laser. Inogona kuderedza zvirinani kuumbwa kwe plasma makore, kupa emhando yepamusoro welds uye kutaridzika, uye kuderedza kukanganiswa kweokisijeni pane welds.

Nitrogen inogona zvakare kushandiswa kudzora tembiricha yenzvimbo yewelding uye kuderedza kuumbwa kwemabhuru uye pores.

Dziviriro Gasi:Helium

Helium inowanzo shandiswa kune yakakwirira-simba laser welding nekuti ine yakaderera thermal conductivity uye haisi nyore ionized, ichibvumira laser kuti ipfuure zvakanaka uye danda simba kusvika kune workpiece pese pasina zvipingamupinyi.

Inobatsira kune yakakwirira simba welding. Helium inogona zvakare kushandiswa kuvandudza weld mhando uye kudzora tembiricha yewelding. Iri ndiro gasi rinonyanya kudzivirira rinoshandiswa mulaser welding, asi iri kudhura.

3. Kutonhodza Gasi:

Kutonhora gasi rinowanzo shandiswa panguva ye laser welding kudzora tembiricha yenzvimbo yewelding, kudzivirira kupisa, uye kuchengetedza welding mhando. Aya anotevera mamwe magasi ekutonhodza anowanzo shandiswa:

Gasi Rokutonhodza / Pakati:Mvura

Mvura yakajairika kutonhora svikiro inowanzo shandiswa kutonhorera laser jenareta uye laser welding optical masisitimu.

Mvura inotonhorera masisitimu inogona kubatsira kuchengetedza yakagadzikana tembiricha yelaser jenareta uye optical components kuti ive nechokwadi chelaser beam kugadzikana uye kuita.

Gasi Rokutonhodza / Pakati:Atmospheric magasi

Mune mamwe laser welding process, ambient atmospheric magasi anogona kushandiswa kutonhora.

Semuenzaniso, mune optical system yelaser jenareta, iyo yakatenderedza gasi gasi inogona kupa kutonhora mhedzisiro.

Gasi Rokutonhodza / Pakati:Inert magasi

Inert magasi akadai seargon uye nitrogen anogonawo kushandiswa semagasi ekutonhodza.

Ivo vane yakaderera thermal conductivity uye inogona kushandiswa kudzora tembiricha yenzvimbo yewelding uye kuderedza kupisa-kukanganisa zone (HAZ).

Gasi Rokutonhodza / Pakati:Liquid Nitrogen

Liquid nitrogen yakanyanya kudzika-tembiricha kutonhora svikiro inogona kushandiswa kune yakanyanyisa-simba laser welding.

Iyo inopa inoshanda kwazvo kutonhora mhedzisiro uye inova nechokwadi chekudzora tembiricha munzvimbo yewelding.

4. Yakasanganiswa Gasi:

Musanganiswa wegasi unowanzo shandiswa muwelding kukwirisa akasiyana siyana ekuita, senge welding kumhanya, kudzika kwekupinda, uye kugadzikana kwearc. Kune mhando mbiri huru dzegasi musanganiswa: mabhinari uye ternary musanganiswa.

Binary Gasi Misanganiswa:Argon + Okisijeni

Kuwedzera huwandu hushoma hweokisijeni kune argon kunovandudza kugadzikana kwearc, kunatsa dziva re weld, uye kunowedzera kumhanya kwewelding. Musanganiswa uyu unowanzo shandiswa kugadzira kabhoni simbi, yakaderera-alloy simbi, uye simbi isina tsvina.

Binary Gasi Misanganiswa:Argon + Carbon Dioxide

Kuwedzerwa kweCO₂ kune argon kunowedzera simba rekutsvaira uye kuramba kwekuora uku ichideredza spatter. Musanganiswa uyu unowanzo shandiswa kugadzira kabhoni simbi uye simbi isina tsvina.

Binary Gasi Misanganiswa:Argon + Hydrogen

Hydrogen inowedzera tembiricha yearc, inonatsiridza kumhanya kwewelding, uye inoderedza hurema hwewelding. Inonyanya kukosha kune welding nickel-based alloys uye Stainless simbi.

Ternary Gasi Misanganiswa:Argon + Oxygen + Carbon Dioxide

Musanganiswa uyu unosanganisa mabhenefiti ezvose argon-oxygen uye argon-CO₂ musanganiswa. Iyo inoderedza spatter, inovandudza weld pool fluidity, uye inosimudzira weld mhando. Inoshandiswa zvakanyanya kugadzira simbi dzakasiyana-siyana dzekabhoni simbi, yakaderera-alloy simbi, uye simbi isina tsvina.

Ternary Gasi Misanganiswa:Argon + Helium + Carbon Dioxide

Musanganiswa uyu unobatsira kuvandudza arc kugadzikana, inowedzera weld pool tembiricha, uye inosimudzira welding kumhanya. Inoshandiswa mupfupi-yedunhu arc welding uye inorema welding application, ichipa zvirinani kutonga pamusoro peoxidation.

Kusarudzwa kweGasi MuMashandisirwo Akasiyana

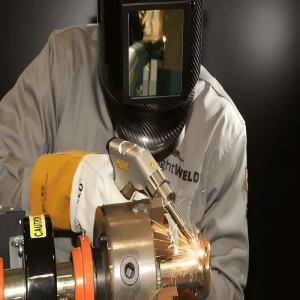

Handheld Laser Welding

Mumashandisirwo akasiyana elaser welding, kusarudza gasi rakakodzera kwakakosha, nekuti musanganiswa wegasi wakasiyana unogona kuburitsa mhando dzakasiyana welding, kumhanya, uye kushanda nesimba. Heano mamwe mazano ekukubatsira iwe kusarudza gasi rakakodzera kune yako chaiyo application:

Mhando yeWelding Material:

Simbi isina ngurakazhinji anoshandisaArgon kana Argon/Hydrogen Musanganiswa.

Aluminium uye Aluminium Alloyskazhinji kushandisaArgon yakachena.

Titanium Alloyskazhinji kushandisaNitrogen.

High-Carbon Steelskazhinji kushandisaOkisijeni seGasi Rinobatsira.

Welding Speed uye Pentration:

Kana yakakwira welding kumhanya kana yakadzika welding kupinda ichidikanwa, musanganiswa wegasi unogona kugadziriswa. Kuwedzera okisijeni kazhinji kunonatsiridza kukurumidza uye kupinda, asi inoda kunyatsodzorwa kudzivirira matambudziko oxidation.

Kudzora Kwenzvimbo Yakabatwa Nekupisa (HAZ):

Zvichienderana nechinhu chiri kucheneswa, tsvina ine ngozi inoda maitirwo akasarudzika inogona kugadzirwa panguva yekuchenesa. Izvi zvinogona kuwedzera kumutengo wakazara weiyo laser yekuchenesa maitiro.

Weld Quality:

Mamwe gasi musanganiswa anogona kuvandudza kunaka uye kutaridzika kwewelds. Semuenzaniso, nitrogen inogona kupa chimiro chiri nani uye chimiro chepamusoro.

Pore uye Bubble Kudzora:

Kune maapplication anoda emhando yepamusoro welds, kutarisisa kwakanyanya kunoda kubhadharwa pakuumbwa kwemapores uye mabhuru. Kusarudzwa kwegasi kwakakodzera kunogona kuderedza njodzi yekuremara uku.

Zvishandiso uye Mutengo Zvinotarisirwa:

Kusarudzwa kwegasi kunokanganiswawo nemhando yemidziyo uye mutengo. Mamwe magasi angangoda masisitimu ekupa akakosha kana mitengo yakakwira.

Kune chaiwo maapplication, zvinokurudzirwa kushanda neanjiniya welding kana nyanzvi yekugadzira laser welding michina kuti uwane zano rehunyanzvi uye nekugonesa maitirwo ewelding.

Kumwe kuyedza nekugadzirisa kunowanzo kudiwa musanganiswa wekupedzisira gasi usati wasarudzwa.

Zvichienderana neiyo chaiyo application, akasiyana gasi musanganiswa uye ma parameter anogona kuyedzwa kuti awane akanakisa welding mamiriro.

Zvinhu Zvaunofanira Kuziva Nezve: Handheld Laser Welding

Yakakurudzirwa Laser Welding Machine

Kuti ukwidze mabasa ako esimbi uye ekugadzirisa zvinhu, kusarudza michina yakakodzera kwakakosha. MimoWork Laser inokurudzira iyoHandheld Laser Welding Machineyekubatanidza simbi chaiyo uye inoshanda.

Yakakwira-Capacity & Wattage kune Akasiyana Welding Application

Iyo 2000W handheld laser welding muchina inoratidzwa nediki muchina saizi asi inopenya welding mhando.

Iyo yakagadzikana fiber laser sosi uye yakabatana fiber tambo inopa yakachengeteka uye yakatsiga laser beam kuburitsa.

Nesimba repamusoro, iyo laser welding keyhole inokwana uye inogonesa iyo welding joint firmer kunyangwe kune gobvu simbi.

Iine compact uye diki muchina chitarisiko, inotakurika laser welder muchina wakashongedzerwa neinofambika handheld laser welder pfuti iyo isingaremi uye yakanakira akawanda-laser welding application pane chero kona uye pamusoro.

Optional marudzi akasiyana-siyana e laser welder nozzles uye otomatiki waya yekudyisa masisitimu anoita kuti laser welding kushanda kuve nyore uye zvine hushamwari kune vanotanga.

Yakakwira-kumhanya laser welding inowedzera zvakanyanya kugadzirwa kwako uye kubuda uku uchigonesa yakanakisa laser welding maitiro.

Pfupisa

Muchidimbu, laser welding inoda kushandisa gasi kuchengetedza nzvimbo dzekubatira, kutonga tembiricha, kunatsiridza weld mhando, uye kuchengetedza optical masisitimu. Kusarudza marudzi egasi akakodzera uye maparamendi ekupa chinhu chakakosha pakuona kuti inoshanda uye yakagadzikana laser welding process uye kuwana yepamusoro-mhando welding mhinduro. Zvishandiso zvakasiyana uye mashandisirwo angangoda marudzi akasiyana uye zvikamu zvakasanganiswa kuti zvisangane nezvinodiwa zvewelding.

Svika kwatiri nhasikuti udzidze zvakawanda nezve edu laser cutters uye maitiro avanogona optimize yako yekucheka maitiro ekugadzira.

Related Links

Chero Mazano Nezve Laser Welding Machines?

Nguva yekutumira: Jan-13-2025