Simba reKunyatso: Kunzwisisa Laser Welding uye maApplication ayo

Zvese zvaunoda nezve laser welding

Welding nelaser inzira yakakosha mumaindasitiri mazhinji ekugadzira, uye kune nzira dzinoverengeka dziripo dzekujoinha zvinhu zvesimbi. Imwe yedzakanyanya uye yakanyatso dhizaini yewelding ndeye laser welding, iyo inoshandisa yakakwirira-powered laser kunyungudutsa uye kujoinha zvinhu zvesimbi. Muchikamu chino, tichaongorora kuti chii chinonzi laser welding, mashandisiro ayo, uye zvakanakira kushandisa laser welding muchina.

Chii chinonzi Laser Welding?

Kushandisa Laser welder inzira inoshandisa yakakwirira-simba Laser danda kupisa uye kunyungudutsa mipendero yezvikamu zvesimbi, ichibvumira kuti ibatanidzwe pamwechete. Iyo laser beam inotariswa pamusoro pesimbi, ichigadzira yakamanikana uye yakanyanya kupisa sosi inogona kukurumidza kunyungudika uye fuse simbi. Iko kurongeka kwelaser welding inobvumira kugadzirwa kwesimba rakasimba, rakanyatsojeka, uye remhando yepamusoro-soro mumhando dzakasiyana dzesimbi.

A Laser welding Machine inowanzoshandiswa mumaindasitiri akadai semotokari, aerospace, uye zvemagetsi, uko kurongeka uye kunaka kwakakosha. Iko kumhanya kwakanyanya uye kurongeka kwelaser welding inoita kuti ive yakanakira welding zvidiki kana zvakaomarara zvikamu, uko tsika dzechinyakare dzewelding dzinogona kunge dzisina kukodzera. Pamusoro pezvo, welding nelaser inogona kushandiswa kujoinha simbi dzakasiyana, izvo zvinonetsa kuwana nemaitiro echinyakare welding.

Mhando mbiri huru dzeLaser Welding:

Kune mhando mbiri huru dzelaser welding: conduction welding uye keyhole welding. Conduction welding inzira yakaderera-simba inobatanidza zvikamu zvesimbi nekunyungudutsa mativi epamusoro, ukuwo keyhole welding inzira ine simba guru inogadzira buri rekiyi musimbi, rinobva razadzwa nesimbi yakanyungudutswa kuita weld.

Zvakanakira Kushandisa Laser Welding Machine

• High Precision uye Kururama

Iyo laser beam inogona kutungamirwa kune yakatarwa nzvimbo yesimbi yepasi, iyo inobvumira kune chaiyo uye inodzorwa weld. Iyo yakanyanya kumhanya yelaser welding zvakare inoreva kuti zvikamu zvinogona kugadzirwa nekukurumidza, izvo zvinowedzera kugadzirwa uye kuderedza mutengo wekugadzira.

• High-mhando uye Aesthetically inofadza welds

Iyo yakatetepa uye yakanyanya kupisa sosi yelaser inogadzira diki-inokanganisa kupisa nzvimbo, izvo zvinoreva kuti pane kushoma kukanganisa, uye weld haina splatter, iyo inovimbisa kuchena uye kwakatsetseka kupera.

• Non-contact Process

laser welding inzira isingabatanidzi iyo inobvisa kudikanwa kwekubatana kwemuviri nesimbi yepasi, iyo inoderedza njodzi yekusvibiswa uye kukuvadzwa kwezvikamu zvesimbi. Izvi zvinoita kuti laser welding ive yakanakira welding zvinhu zvakapfava uye zvinhu zvinoda yakakosha kubata.

Mukupedzisa

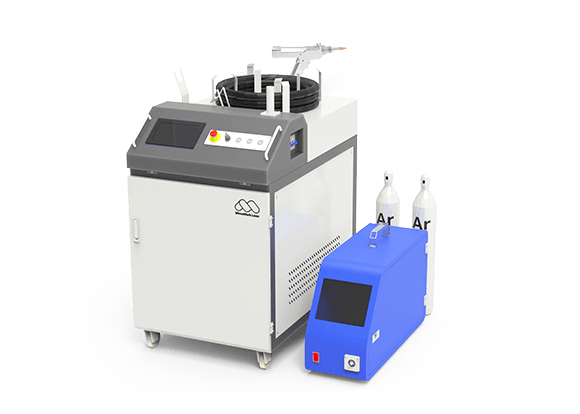

Welding neHandheld Laser Welder inzira yepamberi uye chaiyo yewelding inopa mabhenefiti akawanda kune akasiyana maindasitiri. Iyo chaiyo, kumhanya, uye emhando yepamusoro welds yaanopa inoita kuti ive sarudzo yakanaka yezvishandiso zvinoda mwero wepamusoro wekurongeka uye mhando. Kuisa mari mumuchina welaser welding inogona kuve sarudzo yehungwaru kune mabhizinesi anoda kukurumidza, chaiyo, uye yakavimbika welding nzira.

Yakakurudzirwa Laser welder muchina

Unoda kuisa mari muLaser welder muchina?

Nguva yekutumira: Mar-02-2023