Laser Welding Secrets: Gadzirisa Matambudziko Akawanda Zvino!

Nhanganyaya:

A Complete Guide to Troubleshooting

Handheld Laser Welding Machines

Handheld fiber laser welding muchina wakawana mukurumbira wakakura mumaindasitiri akasiyana nekuda kwekuita kwayo uye kushanda kwayo.

Nekudaro, senge chero imwe nzira yewelding, haina kudzivirirwa kumatambudziko uye nyaya dzinogona kumuka panguva yewelding process.

Izvi zvakakwanalaser welding kugadzirisa dambudzikoine chinangwa chekugadzirisa matambudziko akajairika anosanganisirwa nemaoko e-laser welding michina, matambudziko ane chekuita newelding, uye nyaya dzine chekuita nemhando yewelds.

Pre-Tanga Laser Welding Machine Kukanganisa & Solutions

1. Zvishandiso hazvigone kutanga (Simba)

Solution: Tarisa kana tambo yemagetsi switch ine simba.

2. Mwenje Haagone Kuvheneka

Mhinduro: Tarisa bhodhi rinotangira moto rine kana risina 220V voltage, tarisa bhodhi rechiedza; 3A fuse, rambi rexenon.

3. Chiedza Chakavhenekerwa, Hapana Laser

Solution: Tarisa ruoko rwakabata laser welding muchina chikamu chekuratidzira kunze kwechiedza chakajairika. Chekutanga pane zvese, tarisa iyo CNC chikamu chelaser bhatani yakavharwa, kana yakavharwa, wobva wavhura bhatani relaser. Kana bhatani relaser rakajairika, vhura iyo nhamba yekudzora kuratidza interface kuti uone kana kuseta kwechiedza chinoenderera, kana zvisiri, wobva wachinja kuita mwenje unoenderera.

Welding Phase Laser Welder Nyaya & Kugadzirisa

Iyo Weld Seam Yakasviba

Iyo gasi yekudzivirira haina kuvhurika, chero bedzi iyo nitrogen gasi yakavhurwa, inogona kugadziriswa.

Iyo yekufambisa mhepo yemhepo yekudzivirira gasi haina kunaka, kutungamira kwemhepo yekudzivirira gasi kunofanirwa kuitwa kunopesana nekufamba kwechigamba chebasa.

Kushaya Penetration In Welding

Kushaikwa kwelaser simba kunogona kuvandudza pulse hupamhi uye ikozvino.

Iyo lens inotarisisa haisi iyo chaiyo chiyero, kugadzirisa iyo inotarisisa huwandu padyo nenzvimbo yekutarisa.

Kupera simba kweLaser Beam

Kana mvura inotonhorera yakasvibiswa kana isina kutsiviwa kwenguva yakareba, inogona kugadziriswa nekutsiva mvura inotonhorera uye kuchenesa UV girazi chubhu uye xenon mwenje.

Iyo inotarisa lens kana resonant cavity diaphragm ye laser yakakuvadzwa kana kusvibiswa, inofanira kutsiviwa kana kucheneswa nenguva.

Fambisa iyo laser munzira huru yekuona, gadzirisa iyo yakazara ratidziro uye semi-reflection diaphragm munzira huru yekuona, tarisa uye kutenderedza nzvimbo nepepa remufananidzo.

Iyo laser haibudi kubva kumhangura yemhangura pazasi pemusoro unotarisisa. Rongedza iyo 45-degree inotaridza diaphragm kuitira kuti laser ibude kubva pakati pegasi muromo.

Laser Welding Quality Troubleshooting

1.Spatter

Mushure mekupedzwa kwelaser welding, zvidimbu zvesimbi zvakawanda zvinoonekwa pamusoro pechinhu kana chidimbu chebasa, chakasungirirwa pamusoro pechinhu kana chidimbu chebasa.

Chikonzero chekuparadzira: pamusoro pechinhu chakagadziriswa kana chidimbu chebasa hachina kuchena, pane mafuta kana zvinosvibisa, zvinogonawo kukonzerwa nekuputika kwegorofu.

1) Teerera kuchenesa zvinhu kana chidimbu chebasa pamberi pelaser welding;

2) Spatter yakabatana zvakananga nemasimba emagetsi. Kudzikiswa kwakakodzera kwesimba rewelding kunogona kuderedza spatter.

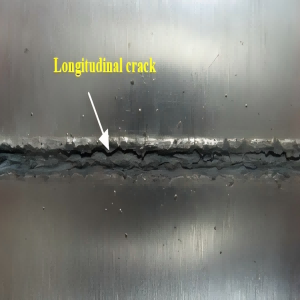

2. Mitswe

Kana iyo inotonhora yekumhanya yeworkpiece inokurumidza, tembiricha yemvura inotonhorera inofanira kugadziridzwa pachigadziro kuti iwedzere tembiricha yemvura.

Kana iyo workpiece yakakodzera gap yakakura kwazvo kana paine burr, iyo machining chaiyo yeworkpiece inofanira kuvandudzwa.

Iyo workpiece haina kucheneswa. Muchiitiko ichi, workpiece inoda kucheneswa zvakare.

Kuyerera kwegasi rinodzivirira rakakura kwazvo, iro rinogona kugadziriswa nekuderedza kuyerera kwegasi rinodzivirira.

3. Pore On The Weld Surface

Zvikonzero zvekugadzirwa kweporosity:

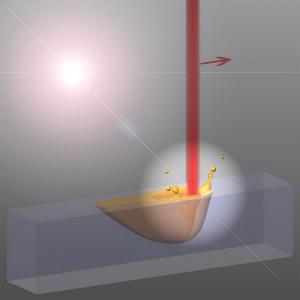

1) Iyo laser welding pool yakanyungudutswa yakadzika uye nhete, uye mwero wekutonhora unokurumidza. Iyo gasi inogadzirwa mudziva rakanyungudutswa yakanonoka kupfachukira, izvo zvinogona kutungamira nyore pakuumbwa kweporosity.

2) Nzvimbo ye weld haina kucheneswa, kana zinc mhute ye galvanized sheet inoputika.

Chenesa pamusoro pechishandiso chebasa uye nepamusoro peiyo weld isati yatungidzirwa kuti uvandudze volatilization ye zinc kana yapisa.

4. Welding Kutsauka

Iyo weld simbi haigone kusimba pakati peiyo yakabatana chimiro.

Chikonzero chekutsauka: Nzvimbo isina kurongeka panguva yewelding, kana nguva isina kururama yekuzadza uye kurongeka kwewaya.

Solution: Gadzirisa nzvimbo yewelding, kana nguva yekuzadza uye nzvimbo yewaya, pamwe nenzvimbo yemwenje, waya uye weld.

5. Surface Slag Entrapment, Iyo Inonyanya Kuonekwa Pakati Pematanho

Surface slag kubatwa kunokonzera:

1) Kana ma-multi-layer multi-pass welding, kuvhara pakati pezvikamu hakuna kuchena; kana pamusoro peiyo yapfuura weld haina kufuratira kana iyo yekumusoro yeweld haina kusangana nezvinodiwa.

2) Maitiro ekushandisa welding asina kunaka, senge yakaderera welding yekupinza simba, welding yekumhanyisa inokurumidza.

Solution: Sarudza inonzwisisika welding ikozvino uye welding kumhanya, uye interlayer coating inofanira kucheneswa kana multi-layer multi-pass welding. Gaya uye bvisa weld ne slag pamusoro, uye gadzira weld kana zvichidikanwa.

Zvimwe Zvishandiso - Handheld Laser Welder Common Matambudziko uye Solutions

1. Kukundikana kweChengetedzo Yekudzivirira Chishandiso

Zvidziviriro zvekuchengetedza zvemuchina welaser welding, senge musuwo wekamuri yekubatira, gasi kuyerera, uye tembiricha sensor, yakakosha pakushanda kwayo. Kukundikana kwezvishandiso izvi hazvigoni kungovhiringidza kushanda kwechigadzirwa chacho chete asiwo kunoisa njodzi yekukuvara kune anoshanda.

Muchiitiko chekusashanda nemidziyo yekudzivirira, zvakakosha kumisa kuvhiyiwa kamwechete uye kubata nyanzvi dzekugadzirisa uye kutsiva.

2. Wire Feeder Jamming

Kana paine waya yekudyisa jam iyi mamiriro, chinhu chekutanga chatinofanira kuita kutarisa kana pfuti yepfuti yakavharwa, danho rechipiri nderekutarisa kana waya yekudyisa yakavharwa uye kune sirika disk kutenderera kwakajairika.

Pfupisa

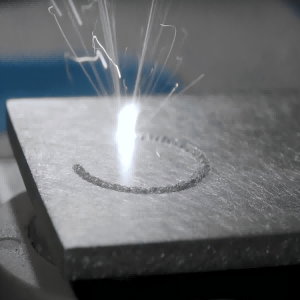

Nekurongeka kusingaenzaniswi, kumhanya uye kuita zvakasiyana-siyana, laser welding tekinoroji yakakosha mumaindasitiri akadai semotokari, aerospace uye zvemagetsi.

Zvisinei, kukanganisa kwakasiyana-siyana kunogona kuitika panguva yekugadzira, kusanganisira porosity, kuputika, kuputika, bhiza risina kujairika, kupisa-kunze, deformation, uye oxidation.

Chirema chega chega chine chikonzero chaicho, senge isina kurongeka Laser Settings, kusvibiswa kwezvinhu, kusakwana kwemagasi ekudzivirira, kana majoini asina kurongeka.

Nekunzwisisa kukanganisa uku uye midzi yazvo zvinokonzeresa, vagadziri vanogona kuita mhinduro dzakanangwa, senge optimize laser paramita, kuve nechokwadi chekubatana kwakaringana, kushandisa emhando yepamusoro magasi ekudzivirira, uye kushandisa pre - uye post-weld kurapwa.

Kudzidziswa kwakakodzera kwevashandisi, kugadzirisa kwemidziyo yemazuva ese uye chaiyo-nguva yekutarisa maitiro inowedzera kunatsiridza welding mhando uye kuderedza kuremara.

Iine yakazara nzira yekudzivirira kuremara uye maitiro ekugadzirisa, laser welding inogara ichiburitsa yakasimba, yakavimbika uye yepamusoro-mhando welds inosangana neyakaomesesa indasitiri zviyero.

Hauzive kuti ndeupi rudzi rwe laser welding muchina wekusarudza?

Iwe unofanirwa kuziva: Maitiro ekusarudza ruoko rwakabata laser muchina

Yakakwira-Capacity & Wattage kune Akasiyana Welding Application

Iyo 2000W handheld laser welding muchina inoratidzwa nediki muchina saizi asi inopenya welding mhando.

Iyo yakagadzikana fiber laser sosi uye yakabatana fiber tambo inopa yakachengeteka uye yakatsiga laser beam kuburitsa.

Nesimba repamusoro, iyo laser welding keyhole inokwana uye inogonesa iyo welding joint firmer kunyangwe kune gobvu simbi.

Portability for Flexibility

Iine compact uye diki muchina chitarisiko, inotakurika laser welder muchina wakashongedzerwa neinofambika handheld laser welder pfuti iyo isingaremi uye yakanakira akawanda-laser welding application pane chero kona uye pamusoro.

Optional marudzi akasiyana-siyana e laser welder nozzles uye otomatiki waya yekudyisa masisitimu anoita kuti laser welding kushanda kuve nyore uye zvine hushamwari kune vanotanga.

Yakakwira-kumhanya laser welding inowedzera zvakanyanya kugadzirwa kwako uye kubuda uku uchigonesa yakanakisa laser welding maitiro.

Zvinhu Zvaunofanira Kuziva Nezve: Handheld Laser Welding

Kana wakanakidzwa nevhidhiyo iyi, wadii kufunga nezvazvokunyorera kune yedu Youtube Channel?

Zvishandiso Zvinoenderana Unogona Kufarira:

Kutenga Kwese Kunofanira Kuziviswa Zvakanaka

Tinogona Kubatsira Neruzivo rwakadzama uye Kubvunza!

Nguva yekutumira: Jan-16-2025