Chii chauri KuedzaDo?

Tsvaga MaitiroIzvo zvinofananidza Kugadzira kwako & Zvinodiwa

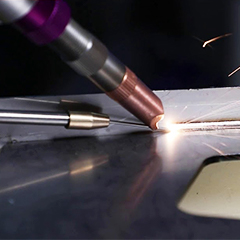

Laser Kucheka

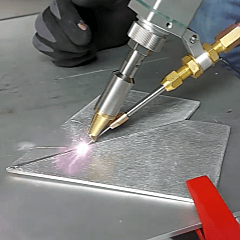

Laser Welding & Kuchenesa

Kusunungura Simba reChiedza

Kuongorora Zvakavanzwa Zvinoshamisa zveLaser Technology

Muhupenyu hwedu hwemazuva ese, kuvepo kwakapararira kwelaser tekinoroji hakuonekwe.

Asi usatya!Isu takagadzira zvine hungwaru chinyorwa chinokwezva chinoburitsa zviuru nezviuru zvekushandisa kwema lasers.

Kubva pahunyanzvi hwekunyatsocheka laser kucheka kusvika kune yakaoma nyika yelaser engraving, iyo enchanting nzvimbo yekumaka yelaser, uye nekuchenjera kudhirowa kwelaser, ngatitange rwendo runoshamisa.

Gadzirira kushamiswa apo isu tinoburitsa zvakavanzika uye nekufumura hunyanzvi hunoshamisa hune lasers.

Pamwe chete, ngativhenekere nzira yekuwana nekusingaperi mukana we laser tekinoroji.

Revolutionizing Material Processing neSimba reLaser

Skupinda mukatiiyo inoshamisa nzvimbo yelaser processing tekinoroji, uko kushamwaridzana kunonakidza pakati pematanda emalasi uye zvinhu (simbi nezvisiri-simbi) inogadzirisa nhanho yekugona-kumucheto.

Bmhanya iwe pachakorwendo rwunonakidza runosanganisira kuchekwa, welding, kurapwa pamusoro, perforation, micro processing, uye kunyangwe kugona kunoshamisa kushanda sechiedza chechiedza chekuzivikanwa kwechinhu.

Pgadzirira kushamiswaapo isu tinonyura mukati memoyo welaser yakanyanya tsika uye inotonga domain: laser processing tekinoroji.

Luye isu tivhure zvakavanzikayelaser tekinoroji, mubatanidzwa we optical finesse, hunyanzvi hwemagetsi, wizardry yemagetsi, hunyanzvi hwezvinhu, uye hunyanzvi hwekuona.

Sezvo isu tichienzanisa laser kucheka nedzimwe nzira dzekucheka dzinopisa, chizaruro chakadzama chakamirira-nhongonya yekumhanyisa uye nemazvo.

1. Kunyatsotsanangurwa Patsva:

Yakashambidzwa mukupenya kwelaserdanda diki, rakananganauyeyakanyanya simba density, hunyanzvi hwekucheka laser hunobuda,kuzivisa nguva itsva yekunyatsojeka.

Pupurira kugona kwakanaka kweiyo laser'sakacheka, akatetepa uye akaenzanirana, akanyatsoenderana nepamusoro, kuwana inofema yedimensional yechokwadi inosvika ± 0.05mm. Tarisa uone kutsvedzereka kwenzvimbo dzakachekwa,vachizvitutumadza nekazevezeve twehasha-makumi mashoma emamicrometer.

Gadzirira kunakidzwa sezvo laser yekucheka inotonga seyekupedzisira yekupedzisira, kupfuura kudiwa kwekupindira kwemuchina, uyeinopa zvikamu zvinogona kushandiswa nyore nyore.Pupurira mashiripiti ekubata kwelaser, uchiendanzvimbo shoma-dzinokanganisa kupisa, kuchengetedza zvimisikidzo zvezvinhu zvakavakidzana, uye kuderedza deformation.

Kudimburwa kwese kuri achirevo chechokwadi chisingaenzaniswi, ine mucherechedzo weiyo geometric symphony, inopa zvisina mhosva nguva dzose rectangular cross-section.

2. Kutamba Kwekubudirira:

Tanga nekutamba kunokatyamadza kwachorwa nelaser's transmission prowess.

Iyo nhanho yakaiswa ine zviuru zveCNC worktables inoshongedza laser yekucheka muchina, ichigonesa symphony yenhamba kutonga.Nekungochinja kweiyo CNC chirongwa, inoyevedza metamorphosis inoitika, kusashanda kuchinjika kune contours yeakasiyana-siyana workpiece, kuwiriranisa humambo hweaviri-dimensional uye matatu-dimensional yekucheka.

3. Kumbundira Iyo Isingabatanidzi Wonder:

Simudza fungidziro yako kunzvimbo yezvisingabatanidzi zvinoshamisa, uko laser's ethereal touch inozvidza magungano.

Haisisiri yakasungwa nemiganhu yekupfeka uye kubvarura, pupurira zvinoshamisa zvekugadzira akasiyana maworkpiece pasina maketani ekutsiva maturusi. Kungogadziridzwa kweiyo laser's inopenya kubuda paramita inoisa nhanho yeshanduko.

Kunakidzwa neruzha rweruzha rwakaderera, ruzha runyoro rwekuzunguzika kushoma, uye kusavapo kunofadza kwekusvibiswa.

4. Kuongorora Izvo Zvisingaverengeki Material Horizons:

Tanga pane odyssey kuburikidza ne cosmos yezvinhu zvakamirira kumbundirwa nelaser yekushandura.

Kubva pamatepi akaomarara esimbi matrix anosanganisirwa kusvika pakunaka kwematehwe, kuzevezera kwakasimba kwehuni, uye shinda dzakasimba dzechisikigo, kugona kwelaser kunosvika kure nekure.

Chinhu chega chega, chirevo cheyakasarudzika yekupisa uye yemuviri tapestry, inotamba inoenderana neiyo laser's affinity, ichiratidza bespoke inogadziriswa kune hunyanzvi hwekucheka laser.

Gadzirira kukwezvwa neyakajeka saga yehunyanzvi hwelaser, sezvo ichiisa mucherechedzo wayo pane zvinyorwa zvekugadzirisa zvinhu, kudarika miganho, uye kubatidza nguva nyowani yekurongeka, kunyatsoita, uye kusingaperi mikana.

Tauya Kubatsira!

Kana iwe ukazviwana uchifungisisa kana laser processing ndiyo yakakodzera chigadzirwa chako, tiri pano kuti tikubatsire!

Kunze kwekuona kana zvinhu zvako zvakakodzera laser yekucheka, pane zvimwe zvakakosha zvekufunga nezvazvo:

1. Precision zvinodiwa

2. Kubudirira kwekugadzira

3. Kudzora mari

Usanetseke, isu tinofara kugovera ruzivo urwu rwakakosha newe.

Rega michina yedu inoshamisa laser ive inokonzeresa yekubudirira kwako kugadzira!