Laser-ka-soo-baxa Polyester-ka

Polyester-ka goynta laser-ka waa caan waana caadi.Tani ma aha oo kaliya in ay sabab u tahay iswaafajinta CO2 laser (kaas oo si fiican u nuugaya walxaha polyesterka) laakiin sidoo kale waxaa mahad leh heerka sare ee otomatiga mashiinka goynta laser.

Waxaan ognahay in dharka polyester-ka uu leeyahay sifooyin aad u wanaagsan qoyaan-qoritaan, qallajin degdeg ah, caabbinta laalaabtay iyo adkeysiga. Kuwani waxay polyester-ka ka dhigaan qayb muhiim ah oo ka mid ah dharka isboortiga, dharka maalinlaha ah, dharka guriga iyo qalabka dibadda. Si loo waafajiyo kor u kaca alaabta polyesterka, mashiinka goynta laysarka dharka ayaa la hagaajiyay oo la cusboonaysiiyay.

Waxaa jira laba nooc oo aasaasi ah oo goynta laysarka polyester-ka ah oo loogu talagalay adigadhar polyester adag iyo dhar polyester-ka dheeha-sublimated. Ka sokow goynta laysarka dharka polyester-ka, laser CO2 wuxuu leeyahay waxqabad aan caadi ahayn oo ku saabsan filimka goynta laysarka ee polyester-ka iyo goynta laysarka la dareemay. Hadda nala soco, sahamiso adduunka polyester-ka goynta laysarka.

Shaxda Tusmada:

◼ Qalabaynta Laser ee Polyester-ka

1. Laysarka Goynta Polyester-ka

Ma jari kartaa polyester-ka adoon jabin? Jawaabta ka timid laser cutter waa HAA!

Laser goynta polyesterka gaar ahaan dharka polyesterka ayaa si weyn loo isticmaalaa. Iyada oo leh barta laser-ka fiican iyo dariiqa goynta saxda ah ee laysarka, mashiinka goynta laysarka wuxuu si sax ah u gooyn karaa dharka polyesterka qaybo loo isticmaalo dharka, dharka isboortiga, ama boodhadhka.

Saxnimada sare ee polyester-ka goynta laysarka waxay keenaysaa gees nadiif ah oo siman. Kulaylka ka imanaya laser CO2 ayaa awood u leh inuu xidho cidhifka isla markiiba, isagoo ka takhalusaya hab-socodka ka dib.

Gooyaha laysarka, si ka sii saxan, laydhka laysarka, ayaa ku yaal meel lala xidhiidho oo la gooyo polyesterka. Taasi waa sababta aysan u xaddidnayn goynta qaababka, qaababka, iyo cabbirrada. Waxaad isticmaali kartaa gooyaha laser-ka ee polyester-ka si aad u xaqiijiso naqshado-dawaarle, oo leh saameyn goyn oo qumman.

2. Daloolinta Laser ee Polyester-ka

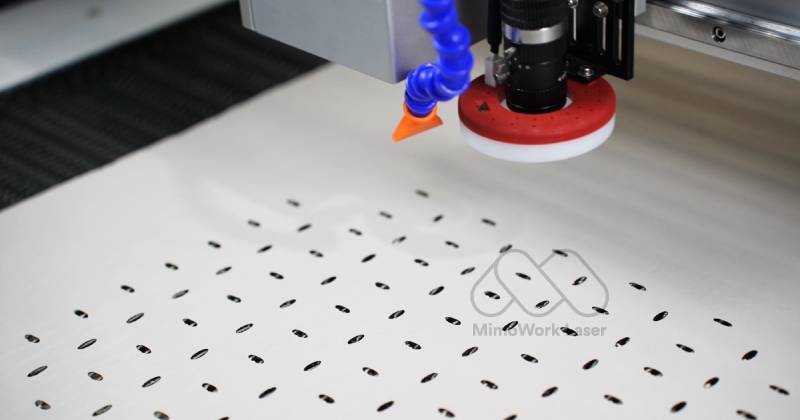

Daloolinta Laser-ku waa sida laysarka goynta polyesterka, laakiin faraqa u dhexeeya waa laser godadka yar yar ee polyester-ka.Waxaan ognahay in barta laysarka ay aad u dhuuban tahay ay gaari karto 0.3mm, taas oo macnaheedu yahay goynta laysarka godadka yaryar waa suurtagal.

Waxaad habayn kartaa qaababka, iyo cabbirrada godadka, oo ay ku jiraan meelaha bannaan ee u dhexeeya godadka kala duwan. Codsiga godadka goynta laser-ka ee polyester-ka ayaa si weyn loogu isticmaalaa dharka isboortiga, si loo xaqiijiyo neefsashada weyn. Intaa waxaa dheer, dalool laysarka wuxuu leeyahay xawaare degdeg ah, kaas oo si heer sare ah waxtar ugu leh farsamaynta polyesterka.

3. Calaamadaynta Laser ee Polyester-ka

Calaamadaynta laser-ka ee polyester-ka (sidoo kale loo yaqaan polyester xaradhka laser) waa tignoolajiyada calaamadaynta gaarka ah. Haddi lagu xardho shaadhka polyesterka, bacaha, ama tuwaalada, mishiinka laysarka ayaa samayn kara. Meesha laysarka ee fiican iyo awoodda saxda ah iyo xakamaynta xawaaraha, waxay ka dhigaysaa xaradhka ama calaamadaynta saamaynta fantastik ah. Waxaad ku xarri kartaa calaamad, garaaf, qoraal, magac, ama nashqad kasta oo ku taal marada polyesterka ama la dareemo. Calaamadda joogtada ahi ma xidhnayn mana baaba'in. Waxaad qurxin kartaa dharka guriga ama waxaad ku dhejin kartaa calaamado si aad u aqoonsato dharka gaarka ah.

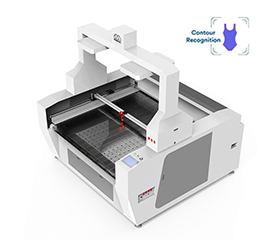

Furitaanka siraha si degdeg ah oo toos ah goynta dharka isboortiga sublimation, ahMimoWork vision laser cutteru soo ifbaxa sida ciyaarta-beddelka ugu dambeeya ee dharka sareeyo, oo ay ku jiraan dharka isboortiga, lugaha, dharka dabaasha, iyo in ka badan. Mashiinkan goynta ah wuxuu soo bandhigayaa waa cusub oo adduunka ah ee wax soo saarka dharka, taas oo ay ugu wacan tahay aqoonsiga qaabka saxda ah iyo awoodaha goynta saxda ah.

U dhex gal goobta dharka isboorti ee daabacan oo tayo sare leh, halkaas oo naqshado qallafsan ay nolosha ku yimaadaan si sax ah oo aan la barbar dhigi karin. Laakiin taasi dhammaanteed ma aha – MimoWork vision laser cutter ayaa kor iyo dhaafsiisan si toos ah u quudinaysa, gudbinta, iyo sifooyinka goynta.

Gooyaha Laser-ka ee Kaamerada ee Dharka Ciyaaraha & Dharka

Waxaan ku dhex quuseynaa hababka horumarsan iyo hababka tooska ah, anagoo sahameynayna waxyaabaha yaabka leh ee goynta laysarka ee dharka daabacan iyo kuwa firfircoon. Ku qalabaysan kamarad gees-goyn ah iyo iskaanka, mishiinkeena goynta laysarka waxa uu qaataa hufnaan wuxuuna wax-soosaaraa heerar aan hore loo arag. Fiidiyowgayaga xiisaha badan, markhaati ka noqo sixirka laysarka aragga si toos ah oo toos ah oo loogu talagalay adduunka dharka.

Labada dhidibka laysarka ee Y-axis waxay bixiyaan wax-ku-oolnimo aan la barbar dhigi karin, taasoo ka dhigaysa mashiinka laser-goynta kamaradda mid soo jiidasho leh oo goynta laser-ka ah ee dharka hoos-u-dhigga, oo ay ku jiraan adduunka qallafsan ee alaabta funaanadaha. U diyaargarow inaad wax ka beddesho habkaaga goynta laysarka si hufan iyo qaab!

Sida Laser-ka loo gooyo Ilmada Sublimation-ka

Sidee si sax ah loo gooyaa calanka sublimated? Mashiinka goynta laser-ka weyn ee dharka ayaa ah aaladda ugu fudud ee lagu xaqiijin karo wax soo saarka tooska ah ee warshadaha xayeysiinta sublimation. Sida calamada ilmada, boodhadhka, bandhigyada bandhigyada, gadaasha, iwm.

Fiidiyowgaan wuxuu soo bandhigayaa sida loo shaqeeyo kamarad gooyaha laserwaxayna muujinaysaa habka goynta laysarka calanka ilmada. Goynta saxda ah ee la socota koontoroolka qaabka daabacan, iyo xawaaraha goynta degdega ah.

◼ Faa'iidooyinka laga helo Polyester-ka Goynta Laser-ka

Sidee loo gooyaa dharka polyester-ka si degdeg ah & si sax ah? Iyada oo la adeegsanayo gooyaha laser-ka, waxaad heli kartaa qaybaha ugu fiican ee polyester-ka ee polyester-ka sublimation ama polyester adag. Waxtarka sare wuxuu la yimaadaa tayada ugu sareysa.

Kala duwanShaxda shaqadaiyo ikhtiyaariNidaamyada Aqoonsiga Kontourgacan ka geysanaya goynta laysarka noocyo kala duwan oo alaabta poliesterka cabbir kasta, qaab kasta, iyo qaab daabacan.

Ma aha oo kaliya, gooyaha laser ayaa karaka saar werwerka ku saabsan qalloocinta shay iyo dhaawaca iyada oo ay ugu wacan tahay habaynta aan la xidhiidhin.

Iyada oo qaabeyn macquul ah iyo goyn sax ah, ahpolyester-ka-gooyaha laser-kawaxay ka caawisaa in la kordhiyokaydinta kharashka eealaabta ceeriin iyo farsamaynta.

Quudinta tooska ah, gudbinta, iyo goynta ayaa si weyn kor ugu qaadi karta waxtarkaaga wax soo saarka.

Nadiifi oo gees siman

Goynta wareeg kasta-xagal

Waxtarka sare & wax soo saarka

✔Cidhifyada nadiifka ah iyo kuwa fidsan ma jiraan wax waxyeelo ah

✔ Goynta saxan saxan oo leh Nidaamka Aqoonsiga Kontour

✔ Waxtarka sare oo joogto ah auto-quudinta

✔ Ku habboon jarida qaab kasta oo daabacan iyo qaab

✔ Nidaamka xakamaynta tooska ah ee CNC, badbaadinta shaqada iyo kharashka waqtiga

✔ Saxnaanta sare ee soo noqnoqda, hubinta tayada sare ee joogtada ah

✔ Ma jiro qalab ciribtirka iyo beddelka

✔ Habka habaynta deegaanka-saaxiibtinimo

Waxaan ognahay in dharka polyesterka uu leeyahay codsiyo kala duwan oo kala duwan laga bilaabo dharka ilaa alaabta warshadaha. Codsiyada dharka polyesterka ee kala duwan waxay la yimaadaan sifooyin kala duwan oo walxaha iyo shuruudaha habaynta. Qalabka laser-ka, sida saxda ah ee CO2 laser cutter, waa qalab goynta ugu fiican ee alaabooyinka kala duwan ee polyester-ka.

Maxaa sidaa loo yidhi? Laser CO2 waxay leedahay faa'iido dabiici ah oo ku saabsan jarista dharka, sababtoo ah dhar aad u weyn oo lagu dhejiyo CO2 laser, oo ay ku jiraan polyesterka. Sidoo kale, goynta laysarka ma laha xaddidaad goynta naqshadeynta, sidaas darteed qaab kasta, cabbir kasta wuxuu noqon karaa gooyn laser. Taasi waxay siisaa kala duwanaansho ballaaran oo loogu talagalay jarista laysarka ee alaabooyinka kala duwan ee polyester-ka. Sida dharka-ciyaaraha, bacaha, maryaha shaandhada, boodhadhka, iwm.

• Shandado & Boorsooyin

• Faashada

◼ Codsiyada Goynta Laser Polyester Dareen

Polyester-ka goynta laser-ka dareemaywaxay soo bandhigtaa codsiyo kala duwan.

Oo ay ku jiraan farsamada gacanta iyo mashaariicda DIY, alaabta guriga lagu qurxiyo sida farshaxanka gidaarka iyo xeebaha, qalabka moodada sida koofiyadaha iyo bacaha, sahayda xafiisyada sida qabanqaabiyeyaasha iyo suufka jiirka, gudaha baabuurta, xalalka ilaalinta codka, iyo alaabta xayaysiinta.

Saxnaanta iyo kala-duwanaanta goynta laysarka ayaa ka dhigaysa mid ku habboon abuurista naqshado adag iyo qaabab gaar ah.

Isticmaalka laser CO2 si loo gooyo dareemada polyesterka ayaa si gaar ah faa'iido u leh sababtoo ah waxay soo saartaa cidhifyo nadiif ah oo siman oo aan jajabnayn.

Wax ku oolnimada ay ku goyso qaababka adag, iyo dabeecadeeda aan la xiriirin, waxay yareysaa qallooca walxaha waxayna hubisaa natiijooyin tayo sare leh.

◼ Codsiyada Filimka Polyester-ka ee Goynta Laser-ka

Filimka polyester-ka laser-ka-goynta ayaa si weyn loogu isticmaalaa warshado kala duwan iyadoo ay ugu wacan tahay saxnaanta iyo kala-duwanaanta. Codsiyada waxaa ka mid ah abuurista wareegyada dabacsan, stencils, daabacaadda shaashadda, dusha sare ee ilaalinta, alaabta baakadaha, sumadaha, iyo golayaasha.

Goynta laser-ku waxay bixisaa gooyn nadiif ah oo sax ah iyada oo aan la keenin wax qallafsan. Taasi waxay lagama maarmaan u tahay ilaalinta sharafta iyo shaqeynta polyesterkafilimalaabta. Nidaamku waa mid aad waxtar u leh, oo u oggolaanaya naqshado qallafsan iyo is-beddelid, taas oo ka dhigaysa mid ku habboon labadaba prototyping iyo wax soo saarka ballaaran.

◼ Gooyaha Laser Polyester ee lagu taliyay

• Awoodda leysarka: 100W/150W/ 3000W

• Goobta Shaqada: 1800mm * 1300mm (70.87'' * 51.18'')

• Awoodda leysarka: 100W/150W/300W

• Goobta Shaqada: 1600mm*1000mm (62.9" *39.3")

•Aagga aruurinta fidsan: 1600mm * 500mm

• Awoodda leysarka: 150W/300W/500W

• Goobta Shaqada: 1600mm * 3000mm (62.9'' *118'')

◼ Macluumaadka Agabka ee Dharka Polyester-ka ee Goynta Laser-ka

Sida ereyga guud ee polymer-ka macmalka ah, polyester (PET) hadda inta badan waxaa loo arkaa mid shaqaynaysa walxaha synthetic, ku dhaca warshadaha iyo alaabta badeecadaha. Ka samaysan dunta polyester-ka iyo fiilooyinka, suufka tolan iyo tolan waxaa lagu gartaasifooyinka soo jireenka ah ee iska caabbinta yaraynta iyo kala bixinta, iska caabinta laalaabka, adkeysiga, nadiifinta fudud, iyo dhimashada.

Polyester-ka waxaa la siiyaa sifooyin badan si kor loogu qaado waayo-aragnimada xidhashada macaamiisha, ballaariyo hawlaha dhar warshadaha. Sida suuf-polyester-ka waxaa lagu soo bandhigay awood sare, iska caabin cimilo, neefsasho iyo anti-static, taas oo ka dhigaysa alaabta ceeriin ee caadiga ah ee maalin kasta. dharka iyo ciyaaraha. Sidoo kale, codsiyada warshadahaaad bay u badan yihiin, sida dharka suunka qaada, suumanka kursiga, dareemada polyesterka.

Tiknoolajiyada farsamaynta ku habboon waxay siin kartaa ciyaar buuxda si ay u sifeeyaan sifooyinka wanaagsan ee polyesterka. Thenidaamka laysarkahad iyo jeer waxay ahayd doorashada koowaad ee farsamaynta polyester-ka, haddii ay tahay warshadaha dharka, warshadaha dharka guriga, qurxinta gudaha jilicsan, warshadaha walxaha kabaha, ama farsamaynta farsamada, warshadaha tignoolajiyada-dhamaadka sare,goynta laser, calaamadaynta laysarka iyo daloolinta laysarkaon polyester kaMimoWork Laser Cuttergacan ka geysata hagaajinta hufnaanta habaynta iyo sahaminta fursado badan oo ku saabsan codsiga alaabta iyo habaynta adiga.

◼ FAQ ee Polyester-ka Goynta Laser-ka

# Ma jari kartaa Laser-ka Polyester-ka?

Haa, dharka polyester-ka ayaa noqon kara laysarka.

CO2 lasers ayaa inta badan loo isticmaalaa in lagu gooyo dharka polyesterka sababtoo ah kala duwanaanshahooda iyo awooda ay ku gooyaan qalabyo kala duwan.

Adigoo isticmaalaya goobaha iyo farsamooyinka saxda ah ee laysarka, dharka polyester-ka ayaa si wax ku ool ah u goyn kara laser si loo gaaro gooyn sax ah oo nadiif ah,

taas oo ka dhigaysa mid ku habboon codsiyada kala duwan ee soo saarista dharka, dunta, iyo warshadaha kale.

Sida Loo Jaro Dharka Laser-ka?

Dharka goynta laser-ka sida polyester-ka iyo naylon waa mid fudud oo toos ah.

Waxa kaliya oo aad u baahan tahay fayl goynta dhijitaalka ah, duubka polyester-ka, iyo gooyaha laysarka dharka.

Soo rar faylka goynta oo deji jaangooyooyinka laser-ka ee ku habboon, inta ka hartay farsamaynta waxaa dhammayn doona gooyaha laysarka.

Qalabka laysarka ayaa awood u leh inuu si toos ah u quudiyo dharka oo si toos ah u gooyo dharka.

# Ammaan ma tahay in Laysarka la gooyo Polyester-ka?

Haa, polyester-ka goynta laysarka guud ahaan waa badbaado marka taxaddarrada habboon ee badbaadada la qaado.

Polyester-ka waa wax caadi ah oo loogu talagalay goynta laysarka sababtoo ah waxay soo saari kartaa gooyn sax ah oo nadiif ah.

Caadi ahaan, waxaan u baahanahay inaan qalabeyno qalab hawo-qaadasho oo si wanaagsan loo sameeyay,

oo deji xawaaraha laser saxda ah & awoodda ku salaysan dhumucda alaabta iyo miisaanka garaam.

Si aad u hesho talo dejin faahfaahsan oo laser ah, waxaan kugula talineynaa inaad la tashato khabiiradayada laser-ka ee khibradda leh.