Xalka Laser-ka Xirfadlayaasha ah ee Goynta & Qorista

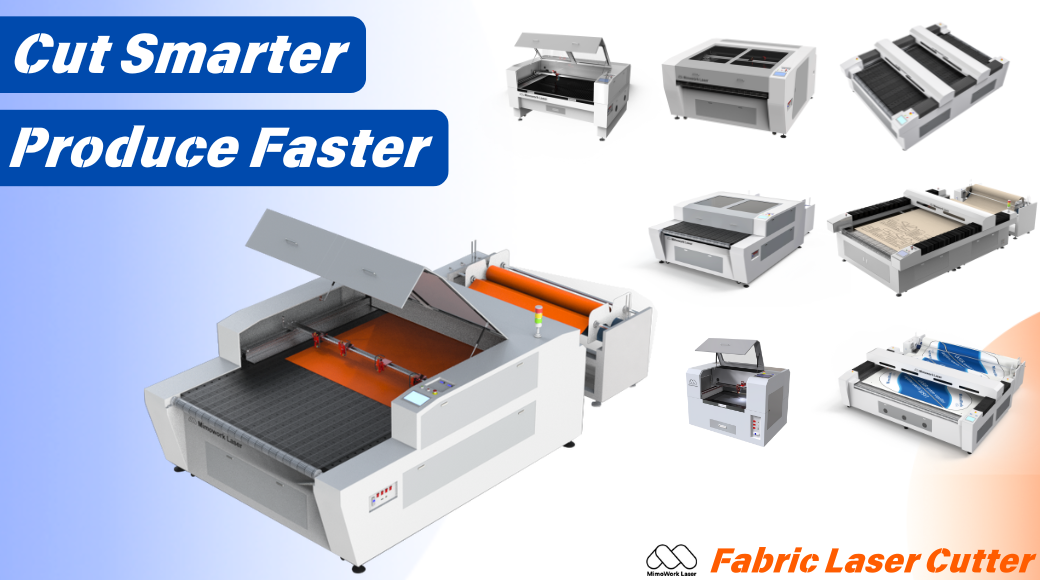

Marka lagu daro nidaamka CNC (Kombuyuutar Tiro-koobeedka) iyo tignoolajiyada sare ee laysarka, gooyaha laysarka dharka ayaa la siiyaa faa'iidooyin aad u wanaagsan, waxay ku guuleysan kartaa habayn toos ah oo sax ah & nadiif ah oo nadiif ah laser iyo xardho la taaban karo oo leysarka ah oo ku saabsan dhar kala duwan. MimoWork Laser waxay soo saartay 4 ugu caansan uguna caansan mashiinnada goynta laser CO2 ee dharka iyo maqaarka. Cabbirrada miiska shaqada waa 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm, iyo 1800mm * 3000mm.

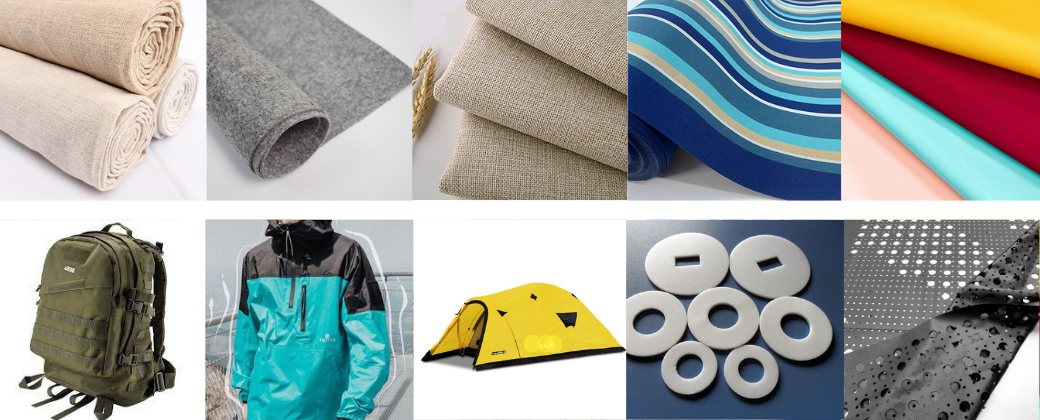

Thanks to auto-feeder iyo miiska gudbinta, mashiinka goynta laser CO2 oo leh nidaamka quudinta auto-quudinta ayaa ku habboon inta badan goynta dharka duubka. Mashiinka goynta laysarka ee dharka ayaa sidoo kale xardhay kara dhar, dun, iyo maqaar isagoo hagaajinaya awoodda laysarka iyo xawaaraha. Qalabka ku habboon waa suuf, Cordura, Kevlar, dhar shiraac ah, naylon, xariir, dhogorta, dareemay, filim, xumbo, Alancantra, maqaar dhab ah, maqaar PU ah iyo kuwa kale.

| Qaabka | Cabbirka Shaxda Shaqada (W * L) | Awoodda leysarka | Cabbirka Mashiinka (W*L*H) |

| F-6040 | 600mm * 400mm | 60W | 1400mm*915mm*1200mm |

| F-1060 | 1000mm * 600mm | 60W/80W/100W | 1700mm*1150mm*1200mm |

| F-1390 | 1300mm * 900mm | 80W/100W/130W/150W/300W | 1900mm*1450mm*1200mm |

| F-1325 | 1300mm * 2500mm | 150W/300W/450W/600W | 2050mm*3555mm*1130mm |

| F-1530 | 1500mm * 3000mm | 150W/300W/450W/600W | 2250mm*4055mm*1130mm |

| F-1610 | 1600mm * 1000mm | 100W/130W/150W/300W | 2210mm*2120mm*1200mm |

| F-1810 | 1800mm * 1000mm | 100W/130W/150W/300W | 2410mm*2120mm*1200mm |

| F-1630 | 1600mm * 3000mm | 150W/300W | 2110mm*4352mm*1223mm |

| F-1830 | 1800mm * 3000mm | 150W/300W | 2280mm*4352mm*1223mm |

| C-1612 | 1600mm * 1200mm | 100W/130W/150W | 2300mm*2180*2500mm |

| C-1814 | 1800mm * 1400mm | 100W/130W/150W | 2500mm*2380*2500mm |

| Nooca Laser | CO2 Tube Laser Glass / CO2 RF Laser Tube |

| Xawaaraha Goynta ugu badan | 36,000mm/daqiiqo |

| Xawaaraha ugu badan ee xardho | 64,000mm/daqiiqo |

| Nidaamka Mooshinka | Servo Motor/Hybrid Servo Motor/Tallaabada Matoorka |

| Nidaamka Gudbinta | Gudbinta suunka Gudbinta Gear & Rack / Gudbinta Isku-xidhka Kubbada |

| Nooca Shaxda Shaqada | Miiska Shaqada Qaadista Biraha Fudud /Shaxda Goynta Laser-ka Malabka /Miiska Goynta Laser Strip Mindi /Miiska Shuttle |

| Tirada Madaxa Laser | Shardi ah 1/2/3/4/6/8 |

| Dhererka Focal | 38.1 / 50.8 / 63.5 / 101.6mm |

| Xaqiijinta Goobta | ± 0.015mm |

| Balaadhka khadka Min | 0.15-0.3mm |

| Qaabka qaboojinta | Nidaamka qaboojinta iyo ilaalinta biyaha |

| Nidaamka Hawlgalka | Daaqadaha |

| Nidaamka Xakamaynta | Xawaaraha Sare ee DSP |

| Taageerada Qaab Sawireedka | AI, PLT, BMP, DXF, DST, TGA, iwm |

| Isha Korontada | 110V/220V(±10%), 50HZ/60HZ |

| Awoodda Guud | <1250W |

| Heerkulka shaqada | 0-35℃/32-95℉ (22℃/72℉ lagu taliyay) |

| Qoyaanka shaqaynaysa | 20% ~ 80% (aan-buuxin) qoyaan qaraabo leh oo 50% lagu taliyay waxqabadka ugu fiican |

| Heerka Mashiinka | CE, FDA, ROHS, ISO-9001 |

Sida loo doorto CO2 Laser Cutter-ka kugu habboon?

Marka aynu nidhaahno CO2 mashiinka goynta laser-ka ee dharka iyo maqaar, kama hadlayno mishiinka goynta laser-ka oo goyn kara dharka, waxaanu ula jeednaa gooyaha laser-ka ee la socda suunka gudbinta, feederiyaha auto iyo dhammaan qaybaha kale ee lagama maarmaanka ah waxay kaa caawinayaan inaad si toos ah uga jarto dharka duubista.

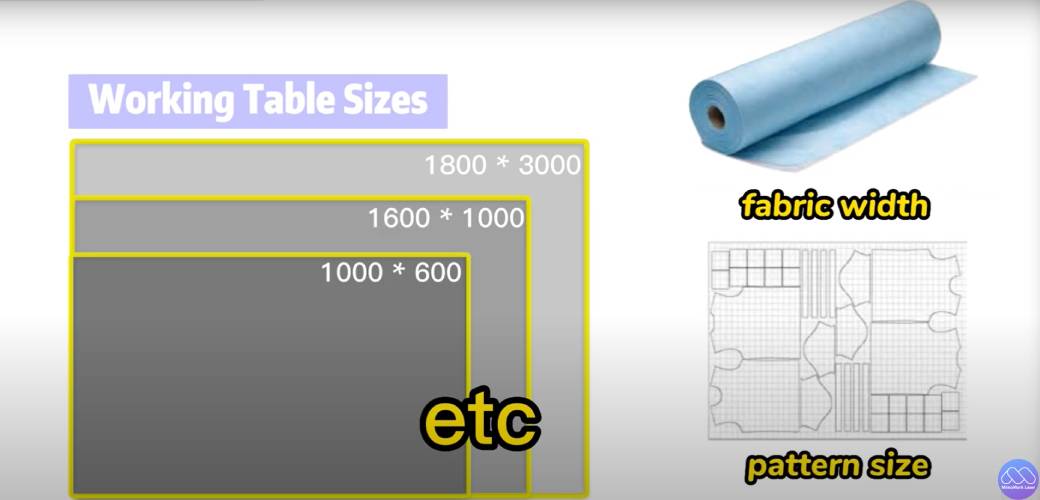

1. Cabbirka miiska shaqada

| Qalabka & Codsiyada | Khadka dharka, sida lebbiska, buluugga | Dharka warshadaha sida Cordura, nylon, Kevlar | Agabka Dharka, Sida Xarkaha iyo Calaamadda Tolman | Shuruudaha Gaarka ah ee Kale |

| Cabbirka Shaxda Shaqada | 1600*1000,1800*1000 | 1600*3000, 1800*3000 | 1000*600 | La habeeyay |

2. Awoodda leysarka

| Noocyada Qalabka | suuf, dareemo, linen, shiraac iyo dhar polyester | Haragga | Cordura, Kevlar, Nylon | Dharka Muraayadaha Fiber |

| Awood lagu taliyay | 100W | 100W ilaa 150W | 150W ilaa 300W | 300W ilaa 600W |

3. Waxtarka Goynta

Dharka goynta laysarka iyo dunta, habka ugu wanaagsan ee lagu kordhin karo waxtarka goynta waa in la qalabeeyo madaxyada laser-ka badan.

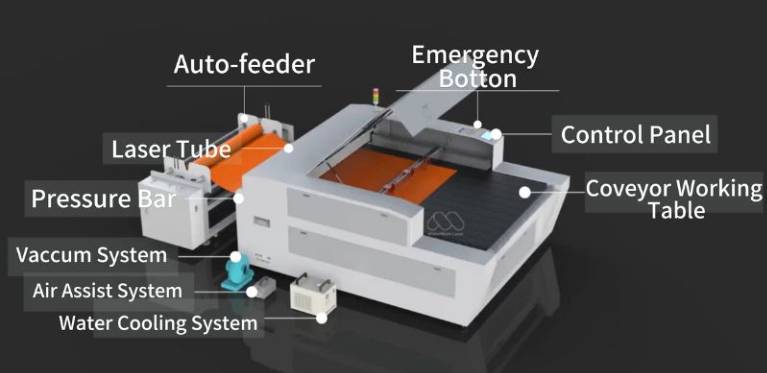

Features Machine Laser

1. Jidka toosan

Tilmaamaha tareenada tooska ah waa qaybo lagama maarmaan ah oo fududeeya socodka siman, toosan ee mashiinada kala duwan. Waxaa loo qorsheeyay in ay qaadaan culeys marka ay yareynayaan khilaafka, hubinta xasilloonida iyo saxnaanta dhaqdhaqaaqa.

2. Control Panel

Shaashadda taabashada waxay sahlaysaa in la hagaajiyo cabbirrada. Waxaad si toos ah ula socon kartaa amperage (mA) iyo heerkulka biyaha isla markiiba shaashadda shaashadda.

3. Lens Focus Lens ee Maraykanka

CO2 USA leeser lenses waa qaybo indhaha ah oo sax ah oo loogu talagalay nidaamyada laser CO2. Muraayadahani waxay door muhiim ah ka ciyaaraan jihaynta iyo diiradda saaraya laydhka laysarka ee alaabta la farsamaynayo, hubinta goynta ugu fican, xardhitaanka, ama calaamadaynta waxqabadka. Laga sameeyay alaab tayo sare leh sida zinc selenide ama galaas, muraayadaha diirada CO2 ayaa loo farsameeyay inay u adkeystaan kulaylka xooggan ee ka dhasha hawlgallada laysarka iyadoo la ilaalinayo caddaynta iyo cimri dhererka.

4. Servo Motor

Matoorada Servo waxay xaqiijinayaan xawaaraha sare iyo saxnaanta sare ee goynta laysarka iyo xaradhka. Seromotor-ku waa servomechanism-loop-xidhan kaas oo isticmaala jawaab celinta booska si uu u xakameeyo dhaqdhaqaaqiisa iyo booskiisa ugu dambeeya.

5. Taageeraha daalka

Taageerayaasha daaqu waa qaybo muhiim ah oo ka mid ah mashiinnada goynta laysarka dharka, looguna talagalay in lagu ilaaliyo jawi shaqo oo ammaan ah oo hufan. Shaqadooda aasaasiga ah waa inay ka saaraan qiiqa, qiiqa, iyo walxaha qayb ka ah ee ka dhasha habka goynta laysarka.

6. Burburiyaha hawada

Caawimada hawadu aad ayay muhiim kuugu tahay si aad u hubiso wax soo saarka siman. Waxaanu dhignay caawinta hawada dhinaca madaxa laysarka, waxay nadiifin kartaa qiiqa iyo qaybaha inta lagu jiro jarida laysarka.

Mid kale, caawinta hawadu waxay hoos u dhigi kartaa heerkulka aagga habaynta (oo loo yaqaan aagga kulaylku saameeyay), taasoo u horseedaysa gees nadiif ah oo siman.

7. Laser Software(ikhtiyaar)

Doorashada software laser ku haboon waxay cusboonaysiin kartaa wax soo saarkaaga. Software-kayada MimoNEST waa doorasho wanaagsan oo loogu talagalay jarista qaababka qaababka iyo cabbirrada kala duwan, si otomaatig ah buul u dhejinta qaababka si loo kordhiyo isticmaalka alaabta iyo goynta waxtarka, macluumaad dheeraad ah oo ku saabsan software laser, fadlan la hadal khabiirkayaga laser.

Faahfaahinta Machine Laser

Nidaamka Gaadhida: waxa uu si toos ah ugu gudbiyaa dunta duuban miiska oo leh miis-qaade toos ah.

• Tuubada Laser: ilayska laysarka ayaa halkan lagu soo saaray. Iyo CO2 tube dhalo galaas ah iyo tuubada RF waa ikhtiyaari marka loo eego baahidaada.

Nidaamka faakuumka: marka lagu daro marawaxada qiiqa, miiska faakuumku waxa uu nuugi karaa marada si uu u siman yahay.

• Nidaamka Caawinta Hawada: hawo-qabooyaha ayaa wakhti ku habboon ka saari kara qiiqa iyo boodhka inta lagu jiro goynta laysarka ama alaabta kale.

Nidaamka qaboojinta biyaha: nidaamka wareegga biyaha ayaa qaboojin kara tuubada laysarka iyo qaybaha kale ee laysarka si ay u badbaadiyaan oo ay u dheereeyaan nolosha adeegga.

• Baarka Cadaadiska: waa qalab caawiya oo ka caawiya inay maradu fidsanto oo si habsami leh u gudbiso.

MimoWork Laser - Macluumaadka Shirkadda

Mimowork waa soo saaraha laser-ku-jeedka natiijooyinka, oo ku saleysan Shanghai iyo Dongguan Shiinaha.

Iyada oo leh khibrad qoto dheer oo 20-sano ah, waxaan soo saareynaa nidaamyada laser-ka waxaanan bixinnaa xalal wax-soo-saar dhammaystiran iyo xallinta SMEs (shirkadaha yaryar iyo kuwa dhexdhexaadka ah) ee warshado badan oo kala duwan.

Waxaan bixinaa:

✔ Noocyo Balaadhan oo ah Mashiinada Laser-ka oo loogu talagalay Maro, Akril, Alwaax, Harag, iwm.

✔ Xalka Laser-ka la habeeyey

✔ Hagitaan Xirfadeed oo ka timid La-taliyaha Iibka Kahor ilaa Tababarka Hawlgalka

✔ Kulan Video Online ah

✔ Tijaabinta Qalabka

✔ Ikhtiyaarada iyo Qaybaha Hadhaaga ee Mashiinada Laser-ka

✔ Ku daba gal qof gaar ah oo Ingiriisi ah

✔ Tixraaca Macmiilka Adduunka oo dhan

✔ Casharka Fiidiyowga ee YouTube

✔ Buugga hawlgalka

Shahaadada & Patentka

FAQ

• Waa maxay maroyaal badbaado u ah goynta laysarka?

Inta badan Dharka.

Dharka badbaadada u leh goynta laysarka waxaa ka mid ah alaabta dabiiciga ah sida suufka, xariirta, iyo linenka, iyo sidoo kale dharka synthetic sida polyester iyo naylon. Qalabkani sida caadiga ah si fiican ayey u gooyaan iyaga oo aan soo saarin qiiq waxyeello leh. Si kastaba ha ahaatee, dharka leh maadada synthetic sare, sida vinyl ama kuwa ay ku jirto koloriin, waxaad u baahan tahay inaad taxaddar dheeraad ah yeelato si aad u nadiifiso qiiqa adigoo isticmaalaya qiiqa soosaarayaasha xirfadlayaasha ah, sababtoo ah waxay sii deyn karaan gaasaska sunta ah marka la gubo. Had iyo jeer hubi hawo-siin habboon oo tixraac tilmaamaha soo-saareyaasha ee hab-dhaqannada badbaadada-goynta ah.

• Waa imisa mishiinka goynta laysarka?

Goynta laser-ka aasaasiga ah ee CO2 waxay ku kala duwan yihiin qiimo ka hooseeya $2,000 ilaa in ka badan $200,000. Farqiga qiimaha ayaa aad u weyn marka ay timaado qaabeynta kala duwan ee CO2 laser cutters. Si aad u fahamto qiimaha mashiinka laysarka, waxaad u baahan tahay inaad tixgeliso wax ka badan qiimaha bilowga ah. Waa inaad sidoo kale tixgelisaa qiimaha guud ee lahaanshaha mashiinka laysarka inta uu nool yahay, si aad si fiican u qiimeyso inay mudan tahay in la maalgeliyo qayb ka mid ah qalabka laysarka. Faahfaahinta ku saabsan qiimaha mashiinka goynta laser si aad u hubiso bogga:Waa imisa Qiimaha Mashiinka Laser-ka?

• Sidee u shaqeeyaa mashiinka goynta laysarka?

Laydhka laysarka wuxuu ka bilaabmaa isha laysarka, waxaana haga oo diiradda saaraya muraayadaha iyo lenska diiradda saaraya madaxa laysarka, ka dibna lagu toogtay walxaha. Nidaamka CNC wuxuu xakameynayaa jiilka iftiinka laysarka, awoodda iyo garaaca laysarka, iyo dariiqa goynta madaxa laserka. Isku darka hawo-mareenka, marawaxada qiiqa, qalabka dhaqdhaqaaqa iyo miiska shaqada, habka goynta laysarka aasaasiga ah ayaa loo dhammeyn karaa si habsami leh.

• Gaaskee loo isticmaalaa mashiinka goynta laysarka?

Waxaa jira laba qaybood oo u baahan gaaska: resonator-ka iyo madaxa goynta laysarka. Resonator-ka, gaaska ay ku jiraan nadiif-sare (fasalka 5 ama ka wanaagsan) CO2, nitrogen, iyo helium ayaa looga baahan yahay inay soo saaraan laydhka laysarka. Laakiin sida caadiga ah, uma baahnid inaad bedesho gaasaskan. Madaxa goynta, nitrogen ama ogsijiinta caawinta gaasta ayaa loo baahan yahay si ay uga caawiso ilaalinta walxaha la farsameeyo iyo hagaajinta iftiinka laysarka si loo gaaro saamaynta goynta ugu fiican.

HAWLGALKA

Sidee Loo Isticmaalaa Mashiinka Goynta Laser?

Mashiinka Goynta Laser waa mashiin caqli-gal ah oo toos ah, iyadoo la kaashanayo nidaamka CNC iyo software goynta laser-ka, mashiinka laysarka wuxuu wax ka qaban karaa sawirro adag oo si toos ah u qorsheeya waddada goynta ugu habboon. Kaliya waxaad u baahan tahay inaad soo dejiso faylka goynta nidaamka laysarka, dooro ama dejiso cabirrada goynta laysarka sida xawaaraha iyo awoodda, oo riix badhanka bilowga. Gooyaha laysarka ayaa dhammayn doona inta ka hadhay habka goynta. Waad ku mahadsan tahay cidhifka goynta qumman ee leh cidhif siman iyo dusha nadiifka ah, uma baahnid inaad jarto ama nadiifiso qaybaha la dhammeeyey. Habka goynta laysarka waa mid degdeg ah, hawlgalkuna waa mid fudud oo saaxiibtinimo bilowga ah.

▶ Tusaale: Warshad duubista goynta leysarka

Talaabada 1. Dusha Duubka Duubka Quudinta

Diyaari Maradda:Dusha marada duuban nidaamka quudinta otomaatiga ah, dharka ka dhig mid siman oo gees ah, oo bilow feedhiyaha otomaatiga ah, dulsaar dunta duubka miiska beddelka.

Mashiinka laser:Dooro mashiinka goynta laysarka ee dharka leh feediyaha otomaatiga ah iyo miiska qaade. Goobta shaqada ee mishiinku waxay u baahan tahay inay la mid noqoto qaabka dharka.

▶

Talaabada 2. Soo rar faylka Goynta & Deji Halbeegyada Laser-ka

Naqshad File:Soo deji faylka goynta software goynta laysarka.

Deji Halbeegyada:Guud ahaan, waxaad u baahan tahay inaad dejiso awoodda laysarka iyo xawaaraha laser si waafaqsan dhumucda alaabta, cufnaanta, iyo shuruudaha goynta saxda ah. Qalabka khafiifka ah waxay u baahan yihiin awood hoose, waxaad tijaabin kartaa xawaaraha laser si aad u hesho saameyn goynta ugu fiican.

▶

Talaabada 3. Bilow Dhar-goynta Laser-ka

Goynta laser:Waxay diyaar u tahay madax goynta laser badan, waxaad dooran kartaa laba madax laser hal gantry, ama laba madax laser laba gantry madax banaan. Taasi way ka duwan tahay wax soo saarka goynta laser. Waxaad u baahan tahay inaad kala hadasho khabiirkayaga laysarka qaabka goyntaada.

Mashiinka Goynta Laser-ka ee Qaab-weyn waxaa loogu talagalay dhar-dheer iyo dun. Miis shaqo oo dhererkeedu yahay 10 mitir iyo 1.5-mitir oo ballac ah, gooyaha laser-ka ee qaabka weyn wuxuu ku habboon yahay inta badan go'yaasha dharka iyo duubabka sida teendhada, baarashuudka, kitesurfing, rooga duulista, boodhka xayeysiiska iyo calaamadaynta, marada shiraaca iyo iwm.

Mashiinka goynta laser CO2 wuxuu ku qalabaysan yahay nidaam mashruuc leh oo leh shaqo meeleyn sax ah. Aragtida hore ee qalabka shaqada ee la jarayo ama lagu xardhay ayaa kaa caawinaysa inaad dhigto agabka meesha saxda ah, taasoo awood u siinaysa goynta laser-ka-dambe iyo xaradhka laysarka inay u socoto si habsami leh oo saxnaan sare leh.

Waa maxay macluumaadka aad u baahan tahay inaad bixiso?

> Macluumaadka xiriirkayaga

Degdeg wax badan u baro:

U dhex gal Dunida Sixirka ee CO2 Laser Goynta Mashiinka,

Kala hadal Khabiirkayaga Laser-ka!

Waqtiga boostada: Nov-04-2024