Sida Laser-ka loo gooyo Fabric nylon?

Naylon Laser Goynta

Mashiinnada goynta laser-ku waa hab wax ku ool ah oo hufan oo lagu gooyo laguna xardho qalabyo kala duwan, oo ay ku jiraan naylon. Goynta dharka naylon ee leh gooyaha laysarka waxay u baahan tahay tixgalin si loo hubiyo gooyn nadiif ah oo sax ah. Maqaalkan, waxaan ka wada hadli doonaa sida loo gooyo naylon leh amashiinka goynta laser dharkaoo sahamin faa'iidooyinka isticmaalka mishiinka goynta nylon ee tooska ah ee habka.

Tababarka Hawlgalka - Goynta Fabric nylon

1. Diyaari faylka Naqshadda

Talaabada ugu horeysa ee lagu goynayo dharka naylon leh gooyaha laser waa in la diyaariyo faylka naqshadeynta. Faylka naqshadeynta waa in la abuuraa iyadoo la adeegsanayo software-ku-saleysan vector sida Adobe Illustrator ama CorelDRAW. Naqshadeynta waa in lagu sameeyaa cabbirka saxda ah ee xaashida dharka nylon si loo hubiyo in si sax ah loo gooyo. OurMimoWork Laser Goynta Softwarewaxay taageertaa inta badan qaabka faylka naqshadeynta.

2. Dooro goobaha goynta laser saxda ah

Tallaabada xigta waa in la doorto goobaha goynta laser saxda ah. Habayntu way kala duwanaan doontaa iyadoo ku xidhan dhumucda dharka nylon iyo nooca laysarka la isticmaalayo. Guud ahaan, gooyaha laser CO2 oo leh awood 40 ilaa 120 watts ayaa ku habboon goynta dharka naylon. Waqti qaar ka mid ah marka aad rabto in aad goyso 1000D naylon dhar ah, 150W ama xataa awood laser sare ayaa loo baahan yahay. Markaa waxa ugu wanagsan in loo soo diro MimoWork Laser qalabkaaga tijaabada muunad.

Awoodda laysarka waa in la dejiyaa heer ka dhalaali doona marada nylon iyada oo aan guban. Xawaaraha laysarka waa in sidoo kale loo dejiyaa heer u oggolaanaya in leysku uu si habsami leh u gooyo dharka naylon iyada oo aan la abuurin geeso jeexan ama geeso jajaban.

Baro wax badan oo ku saabsan tilmaamaha goynta laser naylon

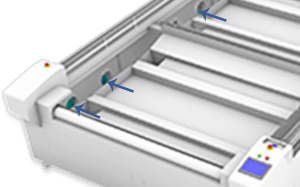

3. Sugso Wershadda nylon

Marka goobaha goynta laysarka la hagaajiyo, waa waqtigii lagu sugi lahaa dharka naylon sariirta goynta laysarka. Dharka naylon waa in lagu dhejiyaa sariirta goynta oo lagu xidho cajalado ama dhejisyo si looga hortago inay dhaqaaqdo inta lagu jiro habka goynta. Dhammaan mashiinka goynta laysarka ee MimoWork ayaa lehnidaamka vacuumhoostiisamiiska shaqadataasi waxay abuuri doontaa cadaadiska hawada si loo hagaajiyo dharkaaga.

Waxaan leenahay meelo kala duwan oo shaqo oo loogu talagalaymashiinka goynta laser fidsan, waxaad dooran kartaa mid ku habboon shuruudahaaga. Ama si toos ah ayaad noo soo waydiin kartaa.

4. Goynta Tijaabada

Ka hor inta aanad jarin naqshadda dhabta ah, waa fikrad wanaagsan in la sameeyo gooyo tijaabo ah oo ku saabsan gabal yar oo naylon ah. Tani waxay gacan ka geysan doontaa go'aaminta haddii goobaha goynta laysarka ay sax yihiin iyo haddii wax hagaajin ah loo baahan yahay in la sameeyo. Waa muhiim in la tijaabiyo gooyo la mid ah dharka naylon ee loo isticmaali doono mashruuca ugu dambeeya.

5. Bilow Goynta

Ka dib markii goynta tijaabada la dhammeeyo oo goobaha goynta laysarka la hagaajiyo, waa waqtigii la bilaabi lahaa jarista naqshadda dhabta ah. Goynta laysarka waa in la bilaabo, iyo faylka naqshadeynta waa in lagu shubaa software-ka.

Gooyaha laysarka ayaa markaa gooyn doona dharka naylon sida ku cad faylka naqshadeynta. Waxaa muhiim ah in la kormeero habka goynta si loo hubiyo in maradu aanay kululayn, iyo laysarka ayaa si habsami leh u jaraya. Xusuusnow inaad shidmarawaxada qiiqa iyo bamka hawadasi loo hagaajiyo natiijada goynta.

6. Dhamaystirka

Qaybaha la gooyey ee dharka naylon waxa laga yaabaa inay u baahdaan taabasho dhammays tir ah si loo khafiifiyo gees kasta oo qallafsan ama in meesha laga saaro midab kasta oo uu keeno habka goynta laysarka. Iyadoo ku xiran codsiga, qaybaha la gooyay waxay u baahan karaan in la isku tolo ama loo isticmaalo sida qaybo gaar ah.

Faa'iidooyinka Mashiinnada Goynta Nayloon ee Toogta ah

Isticmaalka mashiinka goynta naylon ee tooska ah wuxuu hagaajin karaa habka goynta dharka naylon. Mashiinadan waxaa loogu talagalay inay si toos ah ugu shubaan oo ay u gooyaan tiro badan oo dharka nylon si dhakhso ah oo sax ah. Mashiinnada goynta naylon ee tooska ah ayaa si gaar ah faa'iido u leh warshadaha u baahan wax soo saar ballaaran oo naylon ah, sida warshadaha baabuurta iyo hawada sare.

FAQ

Haa, waxaad ku gooyn kartaa naylon leh CO₂ laser, waxayna bixisaa nadiif, geeso xiran iyo saxsanaan sare, taasoo ka dhigaysa mid ku habboon dunta iyo dharka warshadaha. Si kastaba ha ahaatee, naylon waxay soo saartaa qiiq xoog leh oo suurtagal ah marka laysarka la gooyo, sidaas darteed hawo ku habboon ama soo saarista qiiqa waa lagama maarmaan. Mar haddii naylon si sahal ah u dhalaalto, goobaha laysarka waa in si taxadar leh loo hagaajiyaa si looga fogaado gubasho ama qallooc. Iyada oo la raacayo habka saxda ah iyo tallaabooyinka badbaadada, goynta CO₂ laser waa hab wax ku ool ah oo wax ku ool ah oo lagu farsameeyo walxaha naylon.

Naylon waa badbaado in leysarka la gooyo marka qiiq sax ah la soo saaro. Goynta naylon waxa ay sii deysaa ur xoogan iyo gaasas khatar ah, sidaa awgeed aad ayaa loogu talinayaa in la isticmaalo mishiin ku xidhan oo hawo leh.

Laser jarida nylon waxay bixisaa sax aan xiriir la lahayn, geesaha shaabadaysan, hoos u jajaban, iyo awoodda lagu abuuro qaabab adag. Waxa kale oo ay wanaajisaa wax soo saarka iyada oo meesha ka saaraysa baahida loo qabo habaynta ka dib.

Gooyaha Laser-ka ee lagu taliyay

Qalabka la xidhiidha goynta laysarka

Gabagabo

Dharka naylon goynta laser waa hab sax ah oo hufan oo lagu gooyo naqshadaha qalafsan ee walxaha. Nidaamku wuxuu u baahan yahay in si taxadar leh loo tixgeliyo goobaha goynta laysarka, iyo sidoo kale diyaarinta faylka naqshadeynta iyo ilaalinta dharka sariirta goynta. Mashiinka goynta laser-ka saxda ah iyo goobaha, goynta dharka nylon ee goynta laysarka waxay soo saari kartaa natiijooyin nadiif ah oo sax ah. Intaa waxaa dheer, isticmaalka mashiinka goynta naylon ee tooska ah wuxuu hagaajin karaa habka wax soo saarka ballaaran. Haddii loo isticmaalodharka & moodada, baabuurta, ama codsiyada hawada, Goynta dharka naylon leh gooyo laser waa xal wax ku ool ah oo waxtar leh.

Baro macluumaad dheeraad ah oo ku saabsan mashiinka goynta laser naylon?

Waqtiga boostada: Meey-12-2023