Hagaha ugu dambeeya ee marada shaandhada goynta laser:

Noocyada, Faa'iidooyinka, iyo Codsiyada

Hordhac:

Waxyaabo Muhiim ah oo ay tahay inaad ogaato ka hor intaanad quusin

Dharka shaandhaynta ayaa door lama huraan ah ka ciyaara noocyo badan oo warshado ah, laga bilaabo biyaha iyo sifaynta hawada ilaa dawooyinka iyo habaynta cuntada. Sida ganacsiyadu u raadinayaan inay hagaajiyaan hufnaanta, saxnaanta, iyo habaynta wax soo saarka dharka shaandhada, maro shaandhaynta laysarka ayaa u soo baxday sidii xal la door biday. Si ka duwan hababka goynta dhaqameed, maro shaandhada goynta laser waxay bixisaa heer sare oo sax ah, xawaare, iyo qashinka walxaha ugu yar, taasoo ka dhigaysa doorasho ku habboon in la gooyo maro shaandhada laga sameeyay agabyo kala duwan sidapolyester-ka, nayloniyomaro aan tow lahayn.

Maqaalkan, waxaan si dhow u eegi doonaa noocyada kala duwan ee marada shaandhada iyo sida maro shaandhada goynta laysarka ay u qabato agab kala duwan. Waad arki doontaa sababta ay u noqotayxalka go-to-soo-saarka tayada sare leh, alaabta sifaynta gaarka ah. Waxaan sidoo kale la wadaagi doonaa fikradaha laga soo bilaabo tijaabooyinkeennii dhowaa agabka sida xumbo iyo polyester-ka, oo ku siinaya tusaalayaal adduunka dhabta ah oo ku saabsan sida laysarka jarista marada shaandhada ay kor ugu qaadi karto hufnaanta iyo joogtaynta wax soo saarka.

Sida Loo Jaro Dharka Filterka Laser-ka | Mashiinka Goynta Laser-ka ee Warshadaha sifaynta

U kaalay fiidiyowga si aad u sahamiso habka goynta laysarka shaandhada. Baahida sare ee goynta saxda ah waxay caan ku tahay mashiinka goynta laysarka ee warshadaha sifaynta.

Labada madax laser waxay sii kordhiyaan wax soo saarka, kor u qaadaan xawaaraha goynta iyadoo la hubinayo tayada.

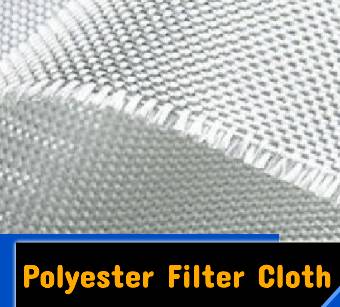

1. Maro Shaandheyn Polyester:

Isticmaalka:Maro filter polyester waa mid ka mid ah walxaha inta badan loo isticmaalo sifaynta sababtoo ah adkeysigeeda, caabbinta kiimikada, iyo awooda u adkeysiga heerkulka sare.

•Codsiyada:Inta badan waxaa loo isticmaalaa hababka sifaynta hawada, daaweynta biyaha, iyo hababka sifaynta warshadaha.

•Faa'iidooyinka Goynta Laser-ka:Polyester-ka ayaa aad ugu habboongoynta laser maro filtersababtoo ah waxay soo saartaa geeso nadiif ah oo sax ah. Laysku waxa kale oo uu xidhaa cidhifyada, isaga oo ka hortagaya jabka oo kor u qaadaya xoogga guud ee marada.

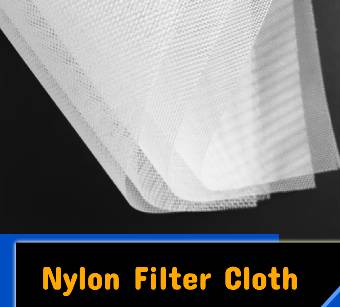

2. Maro Sifeeye Naylon:

Isticmaalka:Loo yaqaan dabacsanaan iyo adayggeeda, marada filter naylon waxay ku habboon tahay dalabka codsiyada sifaynta, sida warshadaha kiimikada ama qaybta cuntada iyo cabitaanka.

•Codsiyada:Caadi ahaan loo isticmaalo sifaynta kiimikada, daaweynta biyaha, iyo sifaynta habaynta cuntada.

•Faa'iidooyinka Goynta Laser-ka:Xoogga naylon iyo iska caabbinta xirashada ayaa ka dhigaya musharax aad u fiicangoynta laser maro filter. Laysarku wuxuu xaqiijiyaa siman, cidhifyada xidhan ee ilaalinaya adkeysiga walxaha iyo sifooyinka sifaynta.

3. Maro Sifeeye Polypropylene:

Isticmaalka:Polypropylene waxay caan ku tahay iska caabbinta kiimikaad ee heer sare ah, taasoo ka dhigaysa mid ku habboon shaandhaynta kiimikooyinka gardarrada leh ama walxaha heerkulka sare leh.

•Codsiyada:Waxa loo isticmaalaa sifaynta dawooyinka, sifaynta warshadaha, iyo sifaynta dareeraha.

•Faa'iidooyinka Goynta Laser-ka: Goynta laser maro filterSida polypropylene waxay u oggolaaneysaa goyn sax ah iyo naqshado qallafsan oo aan waxyeello u geysan walxaha. Cidhifyada xiran waxay bixiyaan qaabdhismeed ka wanaagsan, taas oo ka dhigaysa mid ku habboon codsiyada muhiimka ah.

4. Maro sifeeya oo aan duubnayn:

Isticmaalka:Maro shaandhada aan togan waa mid fudud, dabacsan, iyo kharash-ool ah. Waxaa loo adeegsadaa codsiyada halka fududeynta isticmaalka iyo cadaadiska hooseeya ay muhiim yihiin.

•Codsiyada:Loo isticmaalo sifaynta baabuurta, hawada, iyo boodhka, iyo sidoo kale alaabta shaandhada la tuuri karo.

•Faa'iidooyinka Goynta Laser-ka:Maro aan tow lahayn ayaa noqon karagoynta lasersi degdeg ah oo hufan.Goynta laser maro filterwaa mid aad ugu wanagsan baahiyaha kala duwan ee shaandhaynta, taas oo u ogolaanaysa daloolo fiican iyo goyn goob wayn.

Maro shaandhada laser-ka-goynta waxay isticmaashaa laysar diiradda saaraya, tamarta sare leh oo dhalaaliya ama ka soo saara dharka isla goobta xidhiidhka. Waxaa haga nidaamka CNC (Kombuyuutarka Koontaroolka), laysarka wuxuu ku dhaqaaqaa si sax ah oo cajiib ah, taasoo suurtogal ka dhigaysa in la gooyo ama xitaa xardho noocyo kala duwan oo maro shaandho ah oo sax ah oo heer sare ah.

Dabcan, dhammaan walxaha shaandhada shaandhada isku mid maaha. Mid kasta oo ka mid ah wuxuu u baahan yahay habayn si fiican loo hagaajiyay si loo gaaro natiijooyinka goynta ugu fiican. Aynu kala jebinno sida maro shaandhada goynta laysarka ay ugu shaqeyso qaar ka mid ah agabka inta badan la isticmaalo.

Polyester-ka Laser-ka ah:

Maro filter polyester waa mid adkeysi leh oo adkaysi u leh iskala bixinta, taas oo mararka qaarkood adkeyn karta in lagu gooyo qalab dhaqameed. Goynta laser-ku waxay ku siinaysaa faa'iido cad halkan, maadaama ay bixiso si siman, cidhifyo xiran oo ka hortagaya jabka iyadoo la ilaalinayo xoogga dharka. Saxnimadan ayaa si gaar ah muhiim ugu ah warshadaha sida daaweynta biyaha ama habaynta cuntada, halkaas oo waxqabadka shaandhada joogtada ah looga baahan yahay.

Dharka Laysarka Goyn ee Aan-xidhka Lahayn:

Dharka aan toliyaha lahayn waa kuwo khafiif ah oo jilicsan, taas oo ka dhigaysa mid aad u fiican goynta laysarka. Tiknoolajiyadan, maaddada si dhakhso ah ayaa loo farsamayn karaa iyada oo aan la dhimin qaabdhismeedkeeda, taas oo keenta nadiif ah, gooyo sax ah oo muhiim u ah qaabeynta filtarrada. Habkani waxa uu si gaar ah u qiimo badan yahay marka lagu shaqaynayo maro aan dun lahayn oo sifaynta caafimaadka ama baabuurta, halkaas oo saxnaanta iyo joogtaynta ay fure u yihiin.

Laser-goynta nylon:

Dharka nylon waxaa lagu yaqaan dabacsanaantooda iyo adkaantooda, laakiin waxay noqon karaan kuwo aad u adag in lagu maareeyo hababka goynta farsamada. Habka laser-ku wuxuu xalliyaa caqabadan isagoo soo saaraya gooyn fiiqan, sax ah oo aan sababin qallooc. Natiijadu waa filtarrada xajiya qaabkooda oo keena waxqabad la isku halayn karo, taas oo muhiim u ah baahida bay'ada sida codsiyada kiimikada ama daawooyinka.

Xumbo Goynta Laser:

Xumbadu waa shay jilicsan oo dalool leh oo si fudud u jeexjeexi kara ama u qallali kara marka la gooyo garbaha. Tiknoolajiyada Laser-ku waxay bixisaa xal nadiif ah oo la isku halleyn karo, maadaama ay si habsami leh u gooyso xumbo iyada oo aan burburin unugyada ama aan wax u dhimayn qaabdhismeedkeeda. Tani waxay hubinaysaa filtarrada laga sameeyay xumbo-xumada inay ilaashadaan sinnaanta iyo shaqayntooda, taasoo ka dhigaysa inay si gaar ah faa'iido ugu yeeshaan codsiyada sida nadiifinta hawada iyo dahaarka acoustic.

Waa maxay sababta u dooro goynta laser-ka ee marada shaandhaynta?

Goynta laser maro filterwaxay bixisaa faa'iidooyin badan oo ku saabsan hababka goynta dhaqameed, gaar ahaan qalabka shaandhada. Waa kuwan qaar ka mid ah faa'iidooyinka muhiimka ah:

1. Saxnaanta iyo Nadiifinta Edge

Goynta laser maro filterWaxay hubisaa goynta saxda ah ee leh cidhifyo nadiif ah oo xidhan, taas oo muhiim u ah ilaalinta sharafta qaab dhismeedka marada shaandhada. Tani waxay si gaar ah muhiim ugu tahay nidaamyada sifeynta halkaasoo maaddadu ay tahay inay ilaaliso awoodda ay u leedahay inay si hufan u shaandheyso.

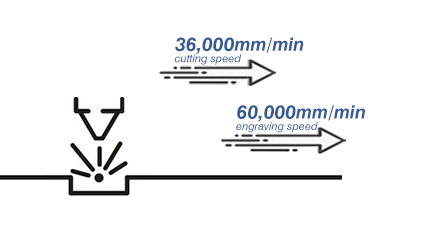

2. Xawaaraha dheereeya & Hufnaanta Sare

Goynta laser maro filterwuu ka dhaqso badan yahay oo ka waxtar badan yahay hababka farsamada ama dhimista, gaar ahaan kuwa qallafsan ama naqshadaha gaarka ah. Thenidaamka goynta laser maro filterWaxa kale oo si toos ah loo samayn karaa, taas oo yaraynaysa baahida faragelinta gacanta iyo dedejinta wakhtiyada wax soo saarka.

3. Qashinka ugu yar

Hababka goynta dhaqameedku waxay inta badan abuuraan qashinka alaabta xad-dhaafka ah, gaar ahaan marka la jarayo qaabab adag.Goynta laser maro filterwaxay bixisaa saxnaanta sare iyo qashinka ugu yar, taas oo ka dhigaysa ikhtiyaar qiimo leh oo wax soo saar yar iyo mid weyn labadaba.

4. Habaynta iyo dabacsanaanta

Goynta laser maro filterwaxay u ogolaataa in si buuxda loo habeeyo maryaha shaandhada. Haddii aad u baahan tahay daloolin yaryar, qaabab gaar ah, ama naqshado faahfaahsan,goynta laser maro filterwaxay si fudud u dabooli kartaa baahiyahaaga, taasoo ku siinaysa dabacsanaan si aad u soo saarto noocyo kala duwan oo alaabooyin maro shaandho ah.

5. Qalab la'aan

Si ka duwan goynta dhimista ama goynta farsamada,goynta laser maro filterkuma lug laha taabashada jirka ee walxaha, taasoo la micno ah in aanay jirin wax xidhid ah oo ku saabsan daab ama qalab. Tani waxay yaraynaysaa kharashka dayactirka iyo wakhtiga dhimista, taas oo ka dhigaysa xal wakhti dheer ah oo la isku halleyn karo.

Mashiinnada Goynta Laser-ka ee Shaandhaynta ee lagu taliyay

Si loo gaaro natiijooyinka ugu fiican marka la jarayo maro filter, doorashada saxda ahmashiinka goynta laysarka maro filterwaa muhiim. MimoWork Laser waxay bixisaa mashiinno kala duwan oo ku habboongoynta laser maro filter, oo ay ku jiraan:

• Goobta Shaqada (W *L): 1000mm * 600mm

• Awoodda leysarka: 60W/80W/100W

• Goobta Shaqada (W *L): 1300mm * 900mm

• Awoodda leysarka: 100W/150W/300W

• Goobta Shaqada (W *L): 1800mm * 1000mm

• Awoodda leysarka: 100W/150W/300W

Gabagabadii

Goynta laser maro filterwaxa la caddeeyey in uu yahay hab aad u wanaagsan oo lagu goynayo maryaha shaandhada, isagoo bixinaya faa'iidooyin badan sida saxnaanta, xawaaraha, iyo qashinka ugu yar. Haddii aad jarayso polyester-ka, xumbo, naylon, ama marado aan togan ahayn, maro shaandhada goynta laysarka waxay hubisaa natiijooyin tayo sare leh oo leh cidhifyo xidhan iyo naqshado la habeeyey. MimoWork Laser's noocyada kala duwan ee hababka goynta laysarka shaandhada ayaa siinaya xalka ugu fiican ee ganacsiyada nooc kasta leh ee raadinaya inay wanaajiyaan habka wax soo saarka marada shaandhada.

Nala soo xidhiidh maanta si aad wax badan uga barato sida aanu nahaymashiinnada goynta laser-ka shaandhayntawaxay wanaajin kartaa hawlaha goynta maro shaandhaynta waxayna wanaajin kartaa tayada alaabtaada.

Marka ay timaado doorashada amashiinka goynta laysarka maro filter, tixgeli kuwan soo socda:

Noocyada Mashiinnada:

Qalabka laser CO2 ayaa guud ahaan lagula talinayaa in la gooyo maro filter sababtoo ah laysarka ayaa jari kara qaabab iyo cabbirro kala duwan. Waxaad u baahan tahay inaad doorato cabbirka mashiinka laysarka ee ku habboon iyo awoodda iyadoo loo eegayo noocyada alaabtaada iyo sifooyinkaaga. La tasho khabiirka laysarka si aad u hesho talo-bixin xirfadeed.

Imtixaanku waa Kow:

Kahor intaadan maalgelin mashiinka goynta laysarka, habka ugu fiican ayaa ah in la sameeyo tijaabada walxaha iyadoo la adeegsanayo laser. Waxaad isticmaali kartaa qashinka shaandhada oo aad isku daydo awoodo kala duwan oo laysarka iyo xawaaraha si aad u hubiso saamaynta goynta.

Waxaa laga yaabaa inaad xiiseyneyso

Fikrad kasta oo ku saabsan Maro Filter Goynta Laser-ka, Ku Soo Dhawoow inaad nala hadasho!

Ma jiraan wax su'aalo ah oo ku saabsan mashiinka goynta laser-ka ee marada sifaynta?

Markii ugu dambeysay ee la cusbooneysiiyay: Sebtember 9, 2025

Waqtiga boostada: Nov-14-2024