Lisebelisoa tsa ho Sila tsa Laser

Na U ka Hlakola ka Laser?

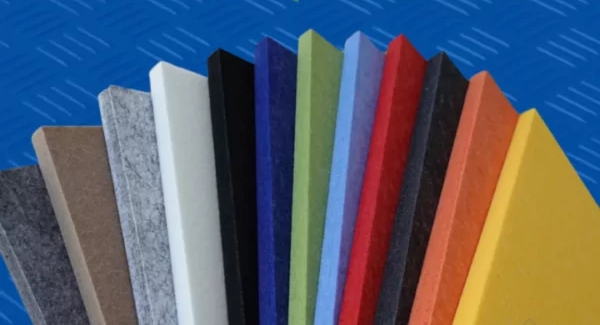

E, ho seha ka laser ke mokhoa o tloaelehileng le o sebetsang oa ho seha thepa ea ho thibela ho ruruha. Lisebelisoa tsa ho thibela ho ruruha tse kangbubblemapolanka,fiberglass, rabara, le dihlahiswa tse ding tsa ho kwahela mocheso le modumo di ka sehwa ka nepo ho sebediswa theknoloji ya laser.

Lisebelisoa tse Tloaelehileng tsa ho Sireletsa ka Laser:

Ho itšeha ka laserho thibela boea ba diminerale, laserho seha ulu ea majoe, boto ea ho seha ea laser, laserboto ea foam e pinki e sehiloeng, laserfoam ea ho thibela ho seha,polamo ea polyurethane e sehang ka laser,Styrofoam ea ho seha ka laser.

Tse ling:

Khalase ea Fiberglass, Ulu ea Mineral, Cellulose, Likhoele tsa Tlhaho, Polystyrene, Polyisocyanurate, Polyurethane, Vermiculite le Perlite, Foam ea Urea-formaldehyde, Foam ea Samente, Foam ea Phenolic, Lifahleho tsa Insulation

Sesebelisoa se Matla sa ho Seha - CO2 LASER

Lisebelisoa tsa ho thibela ho seha ka laser li fetola mokhoa ona, li fana ka ho nepahala, bokgabane le ho tenyetseha. Ka theknoloji ea laser, u ka seha ulu ea diminerale, ulu ea majoe, liboto tsa ho thibela ho seha, foam, fiberglass le tse ling ntle le mathata. Fumana melemo ea ho seha ho hloekileng, lerōle le fokotsehileng, le bophelo bo botle ba mosebelisi bo ntlafetseng. Boloka litšenyehelo ka ho felisa ho tsofala ha mahare le lintho tse sebelisoang. Mokhoa ona o loketse lits'ebetso tse kang likarolo tsa enjene, ho thibela ho seha ha liphaephe, ho thibela ho seha ha liindasteri le tsa leoatleng, merero ea lifofane le litharollo tsa molumo. Ntlafatsa ho seha ha laser bakeng sa liphetho tse ntle 'me u lule u le pele tšimong ea lisebelisoa tsa ho thibela ho seha.

Bohlokoa ba Bohlokoa ba Lisebelisoa tsa ho Thibela ho Seha ka Laser

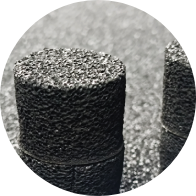

Moeli o Hlakileng le o Hloekileng

Ho Seha ka Libopeho tse ngata tse Tenyetsehang

Ho Seha ho Otlolohileng

✔ Ho nepahala le ho nepahala

Ho seha ka laser ho fana ka ho nepahala ho hoholo, ho dumella ho seha ho rarahaneng le ho nepahetseng, haholo-holo ka dipaterone tse rarahaneng kapa dibopeho tse ikgethileng bakeng sa dikarolo tsa ho kenya mocheso.

✔ Bokgoni

Ho seha ka laser ke ts'ebetso e potlakileng le e sebetsang hantle, e leng se etsang hore e lokele tlhahiso ea thepa ea ho thibela mocheso e nyane le e kholo.

✔ Hloekisa Meeli

Lehlasedi la laser le shebaneng le hlahisa mathoko a hloekileng le a koetsoeng, le fokotsa tlhoko ea ho qeta ka ho eketsehileng le ho netefatsa ponahalo e ntle bakeng sa lihlahisoa tsa ho thibela mocheso.

✔ Boiketsetso

Mechini ea ho seha ea laser e ka kopanngoa le lits'ebetso tsa tlhahiso tse iketsang, e nolofatsa mesebetsi ea tlhahiso bakeng sa katleho le botsitso.

✔ Ho feto-fetoha ha maemo

Ho seha ka laser ho na le mekhoa e mengata 'me ho ka sebelisoa le mefuta e fapaneng ea thepa ea ho futhumatsa, ho kenyeletsoa foam e thata, fiberglass, rabara, le tse ling.

✔ Litšila tse Fokolitsoeng

Tsela eo ho seha ka laser ho sa amaneng le yona e fokotsa tshenyo ya thepa, kaha lehlasedi la laser le shebana hantle le libaka tse hlokahalang bakeng sa ho seha.

• Sebaka sa ho Sebetsa: 1600mm*1000mm(62.9” *39.3”)

• Matla a Laser: 100W/150W/300W

• Sebaka sa ho Sebetsa: 1600mm * 3000mm (62.9'' *118'')

• Matla a Laser: 100W/150W/300W

• Sebaka sa ho Sebetsa: 2500mm * 3000mm (98.4'' *118'')

• Matla a Laser: 150W/300W/500W

Livideo | Lisebelisoa tsa ho Sila ka Laser

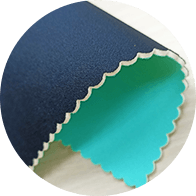

Ho kenya Fiberglass ka Laser Cut

Sehahi sa laser se sireletsang ke khetho e ntle bakeng sa ho seha fiberglass. Video ena e bonts'a ho seha ha fiberglass le fiber ea ceramic ka laser le disampole tse felileng. Ho sa tsotelehe botenya, sehahi sa laser sa CO2 se na le bokhoni ba ho seha thepa ea ho sireletsa 'mele' me se lebisa pheletsong e hloekileng le e boreleli. Ke ka lebaka leo mochini oa laser oa co2 o ratoang ho seheng fiberglass le fiber ea ceramic.

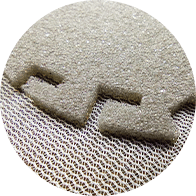

Ho Thibela Foam ka Laser - E Sebetsa Joang?

Re sebelisitse:

• Foam e teteaneng ea 10mm

• Foam e teteaneng ea 20mm

* Ka teko, laser e na le ts'ebetso e ntle ea ho seha bakeng sa ho kenya foam e teteaneng. Moeli oa ho seha o hloekile ebile o boreleli, 'me ho nepahala ha ho seha ho holimo ho fihlela maemo a indasteri.

Seha foam ka katleho bakeng sa ho kenya mocheso ka sehatsetsi sa laser sa CO2! Sesebelisoa sena se feto-fetohang se netefatsa ho seha ho nepahetseng le ho hloekileng ha thepa ea foam, e leng se etsang hore e be e loketseng merero ea ho kenya mocheso. Ts'ebetso e sa amaneng le laser ea CO2 e fokotsa ho tsofala le tšenyo, e netefatsa boleng bo botle ba ho seha le mahlakore a boreleli.

Hore na o sireletsa matlo kapa libaka tsa khoebo ka mocheso o phahameng, sehahi sa laser sa CO2 se fana ka tharollo e tšepahalang le e sebetsang hantle bakeng sa ho fihlela liphetho tsa boleng bo holimo mererong ea ho sireletsa foam, ho netefatsa ho nepahala le katleho.

Thepa ea Hao ea ho Sireletsa ke Eng? Ho thoe'ng ka Ts'ebetso ea Laser ho Thepa?

Romela Boitsebiso ba Hao Bakeng sa Teko ea Mahala!

Likopo tse Tloaelehileng tsa ho Sila ka Laser

Lienjene tse Buellang, Li-turbine tsa Khase le Mouoane, Mekhoa ea ho Futhumatsa Mosi, Likarolo tsa Enjene, Ho Thibela Liphaephe, Ho Thibela Liindasteri, Ho Thibela Likepe, Ho Thibela Lifofane, Ho Thibela Lifofane, Ho Thibela Molumo

Lisebelisoa tsa ho thibela ho ruruha li sebelisoa haholo bakeng sa lits'ebetso tse fapaneng: lienjine tse kopanyang, liturbine tsa khase le mouoane le ho thibela liphaephe le ho thibela liindasteri le ho thibela likepe le ho thibela likepe le ho thibela lifofane le ho thibela likoloi; ho na le mefuta e fapaneng ea lisebelisoa tsa ho thibela ho ruruha, masela, lesela la asbestos, foil. Mochini oa ho seha thipa ka laser o nkela sebaka sa ho seha thipa ea setso butle-butle.

Sehahi se Teteaneng sa Ceramic & Fiberglass Insulation

✔Tšireletso ea tikoloho, ha ho na lerōle le sehiloeng le ho qhibilihisoa

✔Sireletsa bophelo ba mosebelisi, fokotsa lerōle le kotsi ka ho seha thipa

✔Boloka litšenyehelo/lijo tse sebelisoang, litšenyehelo tsa ho roala ha mahare