Ho Hloekisa ho Weld ka Laser

Ho Hloekisa ho Weld ka Laser ke Mokhoa o Sebedisetswang ho Tlosa Ditshila, Dioxide, le Dintho Tse Ding Tse sa Batleheng Bokahohleng ba WeldPele le KamoraTs'ebetso ea ho Chesetsa e Felletse. Tlhoekiso ena ke Mohato oa Bohlokoa Litšebelisong tse ngata tsa Liindasteri le tsa Tlhahiso hoNetefatsa Botšepehi le Ponahaloea Sehokelo se Welded.

Ho Hloekisa Tšepe ka Laser

Nakong ea ts'ebetso ea ho tjheseletsa, litšila tse fapaneng le lihlahisoa tse ling li ka lula holim'a weld, joalo kamafome, ho fafatsa le ho fetoha ha mmala.

Ha li silafalitsoe, tsena li kae ama hampe matla a weld, ho hanyetsa mafome, le botle ba pono.

Ho hlwekisa ka ho tjheseletsa ka laser ho sebedisa lehlasedi la laser le nang le matla a mangata ho tjhesa le ho tlosa di-deposit tsena tse sa batleheng tsa bokahodimo ka tsela e ikgethang.ntle le ho senyatšepe e ka tlase.

Melemo ea ho Hloekisa ka ho Weld ka Laser

1. Ho nepahala- Laser e ka shejwa hantle ho hlwekisa sebaka sa ho weld feela ntle le ho ama thepa e potileng.

2. Lebelo- Ho hlwekisa ka laser ke ts'ebetso e potlakileng, e iketsahallang e ka hlwekisang di-weld ka potlako ho feta mekgwa ya matsoho.

3. Ho tsitsa- Ho hlwekisa ka laser ho hlahisa sephetho se ts'oanang, se ka phetoang, ho netefatsa hore li-weld tsohle li hloekisoa ka maemo a tšoanang a holimo.

4. Ha ho na lintho tse ka sebelisoang- Ho hlwekisa ka laser ha ho hloke di-abrasives kapa dikhemikhale, e leng se fokotsang ditjeo tsa tshebetso le tshenyo.

Dikopo: Ho Hloekisa ka ho Weld ka Laser

Ho Hloekisa Lipoleiti tsa Tšepe tse Matla a Phahameng ka ho Fetisisa (HSLA) ho Weld ka Laser

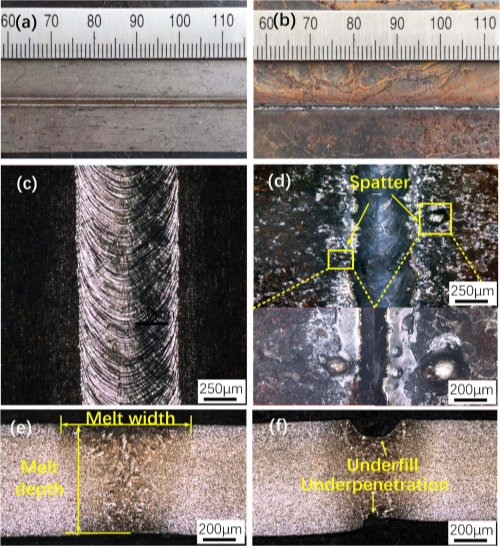

Ponahalo ea ho Welded ea e Phekotsoeng ka ho Hloekisa ka Laser (a, c, e) le e sa Phekoloang ka ho Hloekisa ka Laser (b, d, f)

Litekanyetso tse nepahetseng tsa ts'ebetso ea ho hloekisa ka laser li katlosamafome le mafura a tsoang holim'a mosebetsi.

Ho kenella ho hoholoho bonoe mehlala e hloekisitsoeng ha e bapisoa le e sa hloekisoang.

Kalafo ea pele ea ho hloekisa ka laser e thusa ka katlehoqobaho hlaha ha masoba le mapetso ka har'a weld lee ntlafatsaboleng ba ho bopa ha weld.

Ho hlwekisa Weld ka laser pele ho kalafo ho fokotsa diphoso tse ngata tse kang masoba le mapetso ka hare ho weld, ka honaho ntlafatsathepa ea ho thaepa ea weld.

Matla a tloaelehileng a ho thapolla a sampole ka kalafo ea pele ea ho hloekisa ka laser ke 510 MPa, e lengHodimo ka 30%ho feta moo ntle le kalafo ea pele ho tlhoekiso ea laser.

Ho lelefala ha lenonyeletso la weld le hlwekisitsoeng ka laser ke 36%, e lengmakhetlo a 3ea lenonyello le sa hloekang la weld (12%).

Sheba Pampiri ea Pele ea Lipatlisiso mabapi le Heke ea Lipatlisiso Mona.

Ho Hloekisa ho Weld ka Laser ea Aluminium ea Khoebo ea 5A06

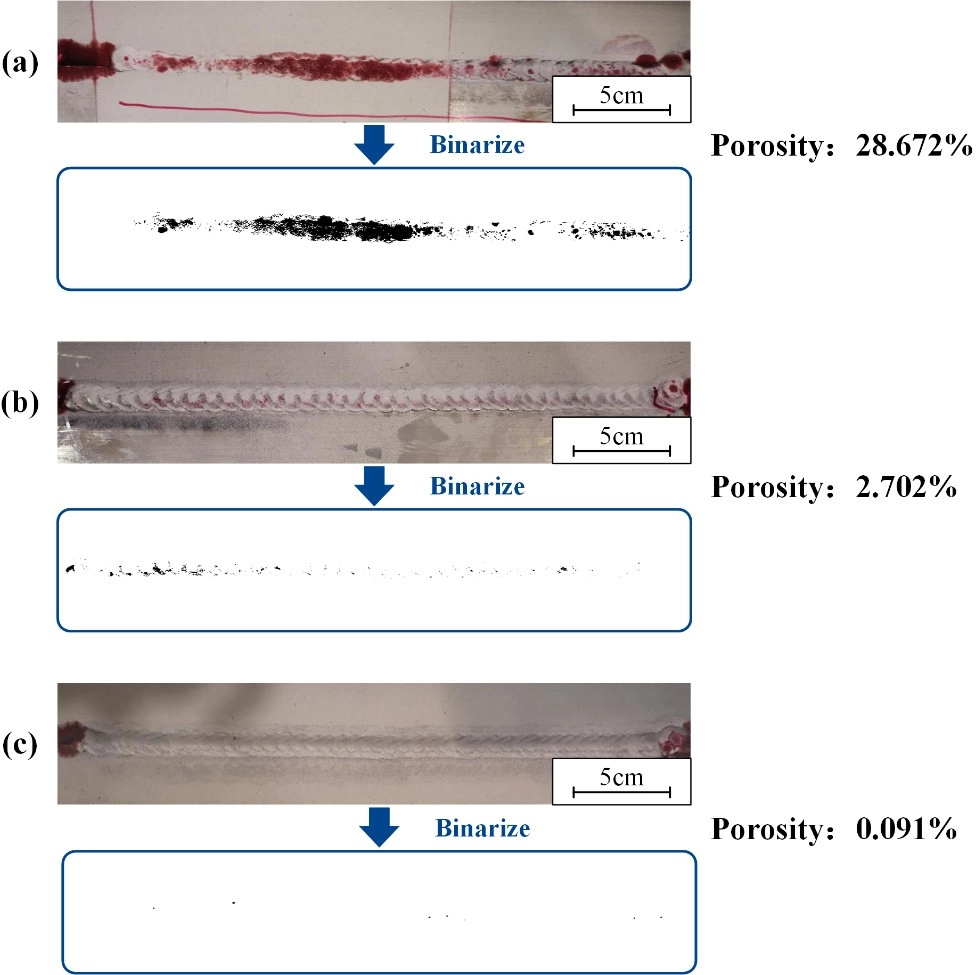

Sephetho sa Teko ea ho Pepeta le Metsi Sampole ka: (a) Oli; (b) Metsi; (c) Ho Hloekisa ka Laser.

Botenya ba lera la oxide la motsoako oa Aluminium 5A06 ke 1–2 lm, 'me ho hloekisa ka laser ho bontšaphello e tšepisangmabapi le ho tlosoa ha oxide bakeng sa ho tjheseletsa TIG.

Ho fumanoe masobasebakeng sa ho kopanya sa li-weld tsa TIGkamora mobu o tloaelehileng, 'me likarolo tse kenyellelitsoeng tse nang le sebopeho se hlakileng le tsona li ile tsa hlahlojoa.

Kamora ho hlwekiswa ka laser,ho ne ho se na masoba a tengsebakeng sa ho kopana.

Ho feta moo, tekanyo ea oksijenee fokotsehile haholo, e leng se dumellanang le diphetho tse fetileng.

Ho phaella moo, lera le lesesaane la ho qhibiliha ha mocheso le etsahetse nakong ea ho hloekisa ka laser, e leng se ileng sa fella kasebopeho se senyenyane se hloekisitsoengsebakeng sa ho kopana.

Sheba Pampiri ea Pele ea Lipatlisiso mabapi le Heke ea Lipatlisiso Mona.

Kapa Sheba Sengoloa sena seo re se phatlalalitseng ho:Aluminium ea ho Hloekisa ka Laser (Kamoo Bafuputsi ba e Etsisitseng Kateng)

Na U Batla ho Tseba ka ho Hloekisa ho Weld ka Laser?

Re ka Thusa!

Nka Sebelisa Eng ho Hloekisa Li-Weld tsa Ka?

Ho Hloekisa Li-Welds ho Fana kaLitlamo tse MatlaleHo Thibela ho Tshala

Tse ling ke tsenaMekhoa ea SetsoBakeng sa ho Hloekisa Li-Weld:

Tlhaloso:Sebelisa borashe ba terata kapa lebili ho tlosa litšila, matheba le li-oxide.

Melemo:Ha e theko e tlase ebile e sebetsa hantle bakeng sa ho hlwekisa bokaholimo.

Mathata:E ka ba mosebetsi o boima haholo 'me e kanna ea se ke ea fihla libakeng tse thata.

Tlhaloso:Sebelisa grinder ho otlolla di-weld le ho tlosa diphoso.

Melemo:E sebetsa hantle bakeng sa ho hlwekisa le ho bopa dintho ka bongata.

Mathata:E ka fetola boemo ba ho weld mme e ka hlahisa mocheso.

Tlhaloso:Sebelisa litharollo tse thehiloeng ho asiti kapa li-solvent ho qhala litšila.

Melemo:E sebetsa hantle bakeng sa masalla a thata mme e ka sebediswa ditshebedisong tse fapaneng.

Mathata:E hloka mehato ea tšireletso le ho lahla lintho hantle.

Tlhaloso:Sutumelletsa thepa e khorofo ka lebelo le phahameng ho tlosa litšila.

Melemo:E potlakile ebile e sebetsa hantle bakeng sa libaka tse kholo.

Mathata:E ka baka khoholeho ea bokaholimo haeba e sa laoloe.

Tlhaloso:Sebelisa maqhubu a molumo a maqhubu a phahameng ka har'a tharollo ea ho hloekisa ho tlosa lithōle.

Melemo:E fihlella dibopeho tse rarahaneng mme e tlosa ditshila ka botlalo.

Mathata:Lisebelisoa li ka bitsa chelete e ngata 'me boholo ba ho hloekisa bo ka lekanyetsoa.

Bakeng saHo tlosoa ha laser & Litokisetso tsa Bokaholimo ba Laser:

Ho tlosoa ha laser

Tlhaloso:Sebelisa mahlaseli a laser a matla a mangata ho fetola litšila hore li fetohe mouoane ntle le ho ama thepa ea motheo.

Melemo:E nepahetse, e mosa tikolohong, 'me e sebetsa hantle bakeng sa lits'ebetso tse bonolo.

Mathata:Lisebelisoa li ka bitsa chelete e ngata, 'me li hloka ts'ebetso e nang le boiphihlelo.

Litokisetso tsa Bokaholimo ba Laser

Tlhaloso:Sebelisa laser ho lokisa libaka ka ho tlosa li-oxide le litšila pele o li tjheseletsa.

Melemo:E ntlafatsa boleng ba ho tjheseletsa le ho fokotsa diphoso.

Mathata:Lisebelisoa le tsona li ka bitsa chelete e ngata, 'me li hloka ts'ebetso e nang le boiphihlelo.

Mokhoa oa ho Hloekisa Tšepe ka Laser?

Ho Hloekisa ka Laser ke Mokhoa o Sebetsang oa ho Tlosa Litšila

Apara PPE e loketseng, ho kenyeletsoa le likhalase tsa tšireletso, liatlana le liaparo tse sireletsang.

Tiisa karolo ea tšepe sebakeng se tsitsitseng ho thibela motsamao nakong ea ho hloekisa. Lokisa hlooho ea laser ho ea sebakeng se khothaletsoang ho tloha holim'a metsi, hangata pakeng tsa10-30 mm.

Lekola ts'ebetso ea ho hloekisa ka linako tsohleBatla diphetoho bokaholimong, tse kang ho tloswa ha ditshila kapa tshenyo efe kapa efe tshepeng.

Kamora ho hlwekisa, hlahloba sebaka seo ho tjheselletswang ho sona bakeng sa bohloeki le ditshila tse setseng. Ho itshetlehile ka tshebediso, nahana kaho sebelisa sekoahelo se sireletsangho thibela ho bola nakong e tlang.

Sesebelisoa se Molemohali sa ho Hloekisa Li-Weld ke sefe?

Ho Hloekisa ka Laser ho Ikhetha e le E 'ngoe ea Lisebelisoa tse Molemohali tse Fumanehang

Bakeng sa mang kapa mang ea amehang tlhahisong kapa tlhokomelong ea tšepe, ho hloekisa ka laser kesesebelisoa sa bohlokoa sa ho hloekisa li-weld.

Ho nepahala ha eona, katleho le melemo ea tikoloho ho etsa hore e be khetho e ntle ka ho fetisisa bakeng saho fihlella liphetho tsa boleng bo holimoha ka nako e tšoanang ho fokotsa likotsi le nako ea ho phomola.

Haeba o batla ho ntlafatsa mekhoa ea hau ea ho hloekisa, nahana ka ho tsetela theknolojing ea ho hloekisa ka laser.

U Etsa Joang Hore Li-weld li shebahale li Hloekile?

Ho Hloekisa ka Laser ho Thusa ho Finyella Li-weld tse Hloekileng le tse shebahalang li le tsa Setsebi

Ho Lokisetsa Bokaholimo

Tlhoekiso ea Pele:Pele o tjheseletsa, etsa bonnete ba hore tšepe ea motheo ha e na litšila tse kang mafome, oli le litšila. Mohato ona kebohlokoa bakeng sa ho fihlela ho chesetsoa ho hloekileng.

Ho Hloekisa ka Laser:Sebelisa sistimi ea ho hloekisa ka laser ho tlosa litšila life kapa life tse holim'a metsi ka katleho. Mokhoa o reretsoeng o netefatsa hore ke litšila feela tse tlosoang.ntle le ho senya tšepe.

Ho Hloekisa Kamora ho Weld

Tlhoekiso ea Kamora ho Weld:Kamora ho tjheseletsa, hlwekisa sebaka sa ho tjheseletsa ka leisara kapele ho tlosa mafome, matheba le oxidation tse ka sitisang ponahalo ya tjheseletsa.

Ho tsitsa:Mokhoa oa ho hloekisa ka laser o fana ka liphetho tse ts'oanang, ho netefatsa hore li-weld tsohle li na le qetello e tsitsitseng le e hloekileng.

Lipontšo tsa Video: Ho Hloekisa Tšepe ka Laser

Ho Hloekisa ka Laser ke Eng le Hore na e Sebetsa Joang?

E 'ngoe ea melemo e meholo ea ho hloekisa ka laser ke hore kemokhoa o omileng.

Ho bolelang hore ha ho hlokahale hore ho tlosoe lithōle ka mor'a ho hloekisoa.

Lebisa feela lehlaseli la laser holim'a sebaka seo u batlang ho se hloekisa.ntle le ho ama thepa e ka tlase.

Li-laser cleaners le tsona lia sebetsa.e nyane ebile e nkeha habonolo, ho lumellabakeng sa ho hlwekisa hantle sebakeng seo.

Hangata e hlokalisebelisoa tsa mantlha tsa tšireletso ea botho feela, tse kang likhalase tsa tšireletso le li-respirator.

Ho tlosa mafome ka laser ho molemo ho hloekisa mafome

Ho qhaqha lehlabathe ho ka bakalerōle le lengata 'me le hloka tlhoekiso e kholo.

Ho hlwekisa leqhoa ka omileng kee ka bang theko e boima ebile e sa lokele mesebetsi e meholo.

Ho hlwekisa ka lik'hemik'hale ho kaho kenyeletsa dintho tse kotsi le mathata a ho lahla dintho.

Ka papiso,Ho hloekisa ka laser ho hlaha e le khetho e ikhethang.

E na le mekhoa e mengata haholo, e sebetsana le mefuta e fapaneng ea lintho tse silafatsang ka nepo

Ts'ebetso ena e boloka litšenyehelo ka nako e telele ka lebaka lanotšebeliso ea thepa le litlhoko tse tlase tsa tlhokomelo.

Mochini oa ho Hloekisa Laser o Tšoaroang ka Letsoho: Ho Hloekisa ho Weld ka Laser

Sehloekisi sa Laser se Pulsed(100W, 200W, 300W, 400W)

Li-purse tsa laser tse nang le pulsed fiber li loketse haholo ho hloekisabonolo,e bonolo ho e utloisisakapakotsing e phahameng ea mochesolibaka, moo tlhaho e nepahetseng le e laoloang ea laser e nang le pulsed e leng ea bohlokoa bakeng sa ho hloekisa ka katleho le ntle le tšenyo.

Matla a Laser:100-500W

Ho Fetola Bolelele ba Pulse:10-350ns

Bolelele ba Cable ea Faeba:3-10m

Bolelele ba maqhubu:1064nm

Mohloli oa Laser:Laser ea Faeba e Pulsed

Mochini oa ho Tlosa Mafome ka Laser(Ho Hloekisa Pele le Kamora ho Weld ka Laser)

Ho hlwekisa ka weld ka laser ho sebediswa haholo diindastering tse kangsefofane,likoloi,kaho ea likepeletlhahiso ea lisebelisoa tsa elektronikimooli-weld tsa boleng bo holimo, tse se nang sekolili bohlokoa bakeng sa polokeho, ts'ebetso le ponahalo.

Matla a Laser:100-3000W

Maqhubu a Pulse ea Laser e Fetohang:Ho fihlela ho 1000KHz

Bolelele ba Cable ea Faeba:3-20m

Bolelele ba maqhubu:1064nm, 1070nm

TšehetsoTse fapanengLipuo