Aluminium ea ho tjheseletsa ka laser

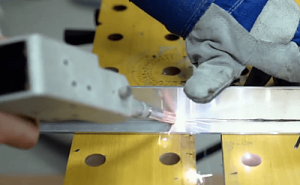

Ho weld aluminium ka laser ka mokhoa o sireletsehileng le ka katleho, ho bohlokoa ho latela mekhoa e nepahetseng le mehato ea tšireletso.

Sena se kenyeletsa ho hlwekisa bokaholimo ba aluminium ka botlalo,

ho sebelisa bolelele ba leqhubu le matla a laser a loketseng,

le ho fana ka tšireletso e lekaneng ea khase e sireletsang.

Ka mekhoa e nepahetseng, ho tjheseletsa aluminium ka laser ka letsoho e ka ba mokhoa o sebetsang le o molemo oa ho kopanya.

Ho Welding ka Laser e Tšoaroang ka Letsoho ke Eng?

Aluminium ea ho Wellisa ea Laser e Tšoareloang ka Motlakase

Ho tjheseletsa ka laser ka letsoho ke mokhoa o mocha o fumaneng matla a maholo tlhahisong ea tšepe lilemong tsa morao tjena.

Ho fapana le mekhoa ea ho tjheseletsa ea setso joalo ka MIG kapa TIG,

Ts'ebetso ena e sebelisa lehlaseli le tiileng la laser ho qhibilihisa le ho kopanya likarolo tsa tšepe ka ho nepahala ho ikhethang.

Melemo ea mantlha ea ho tjheseletsa ka laser e tšoaroang ka letsoho e kenyelletsa lebelo le tsotehang, ho nepahala ho phahameng, le ts'ebetso e bonolo ho e sebelisa.

Ha e le hantle, ho tjheseletsa ka laser ho ka fihlella lebelo le fihlang ho makgetlo a mane ka potlako ho feta ho tjheseletsa ka MIG kapa TIG ya setso,

ha laser e shebaneng haholo e netefatsa ho welds tse tsitsitseng le tsa boleng bo holimo.

Ka lebaka la tsoelo-pele theknolojing ea laser ea fiber,

Litsamaiso tsena li se li le theko e tlaase ebile li tšoarella nako e telele, li potlakisa ho amoheloa ha tsona ka bongata lefapheng la ts'ebetso ea tšepe.

Na Aluminium e ka Welded ka Laser?

Ho Welding ka Laser Aluminium ka Aluminium Laser Welder

E, aluminium e ka tjheselletsoa ka katleho ka laser, ho kenyeletsoa le litsamaiso tsa ho tjheseletsa ka laser tse tšoaroang ka letsoho.

Ho tjheseletsa ka laser ho fana ka melemo e 'maloa bakeng sa ho tjheseletsa aluminium ha ho bapisoa le mekhoa e meng ea ho tjheseletsa.

Melemo ea Aluminium ea ho Welding ka Laser

Manonyeletso a Moqotetsane le Libaka tse Nyenyane tse Amehileng ke Mocheso:

Sena se fokotsa ho sotha ha mocheso haholo ha ka nako e ts'oanang se boloka botsitso ba sebopeho sa likarolo tsa aluminium.

Taolo e Nepahetseng:

Ho tjheseletsa ka laser ho fana ka bokgoni bo ikgethang ba ho iketsetsa, ho nolofalletsa ho nepahala ho ka hlophiswang bakeng sa ho tjheseletsa ka ho tshwana, boleng bo hodimo.

Bokhoni ba ho Weld Likarolo tse Nyenyane tsa Aluminium:

Ho tjheseletsa ka laser ho ka kopanya aluminium ka katleho e tshesane ho fihlela ho 0.5 mm ntle le ho tjhesa ka hara thepa.

Liphephetso tse Ikhethang bakeng sa Aluminium ea ho Welding ka Laser

Ho bonahatsa ho Hoholo

Bokaholimo ba aluminium bo bonahatsang haholo bo baka tahlehelo e kholo ea matla a laser, e leng se bakang liphephetso bakeng sa ho hokahana ka katleho ha mahlasedi le thepa. Mekhoa e tsoetseng pele ea ts'ebetso ea bohlokoa ho ntlafatsa ho monngoa ha matla a laser.

Tloaelo ea ho ba le masoba le ho phatloha ho chesang

Ho qhalana ha mocheso ka potlako ha aluminium le litšobotsi tsa letamo le qhibilihisitsoeng ka mokelikeli hangata li fella ka ho se phethahale ha ho tjheseletsa tse kang masoba a khase le mapetso a chesang. Ka hona, taolo e nepahetseng ea liphetoho tsa ts'ebetso le tšireletso ea khase e sa sebetseng ke ea bohlokoa.

Aluminium ea ho Welding ka Laser e ka ba Bothata

Re ka u fa Litlhophiso tse Nepahetseng

Mokhoa oa ho Weld Aluminium ka Laser ka Polokeho?

Aluminium e Bonahatsang Haholo ka Laser

Aluminium ea ho tjheseletsa ka laser e hlahisa liphephetso tse 'maloa tse ikhethang tse lokelang ho rarolloa ho netefatsa ho tjheseletsa ka mokhoa o sireletsehileng le o atlehileng.

Ho ya ka pono ya dintho tse bonahalang,

Ho khanna ha aluminium mochesong o phahameng,

Sebaka se tlaase sa ho qhibiliha,

Tloaelo ea ho theha likarolo tsa oxide

Kaofela li ka kenya letsoho mathateng a ho tjheseletsa.

U ka Hlōla Mathata Ana Joang? (Bakeng sa ho Weld ka Laser ea Aluminium)

Laola Mocheso o Kentsweng:

Ho tsamaisa mocheso ho phahameng ha aluminium ho bolela hore mocheso o ka ata kapele ho pholletsa le mosebetsi, e leng se lebisang ho qhibiliheng ho feteletseng kapa ho feto-fetoha ha oona.

Sebelisa mochini oa ho tjheseletsa oa laser o nang le matla a lekaneng ho kenella thepa, empa u laole ka hloko ho kenya mocheso ka ho fetola liparamente tse kang lebelo la ho tjheseletsa le matla a laser.

Tlosa Mealo ea Oxide

Lera la oxide le bopehang holim'a aluminium le na le ntlha e phahameng haholo ea ho qhibiliha ho feta tšepe ea motheo, e leng se ka lebisang ho porosity le liphoso tse ling.

Hloekisa bokaholimo ka botlalo pele o tjheseletsa, ebang ke ka mechine kapa ka lik'hemik'hale, ho netefatsa boleng bo botle ba tjheseletsa.

Thibela Tšilafalo ea Hydrocarbon

Litlolo kapa lintho tse silafatsang holim'a aluminium le tsona li ka baka mathata nakong ea ho tjheseletsa.

Netefatsa hore mosebetsi o hloekile ka botlalo ebile o omme pele o qala ts'ebetso ea ho tjheseletsa.

Mehopolo e Ikhethang ea Polokeho (Bakeng sa Aluminium ea ho Welding ka Laser)

Polokeho ea Laser

Ho reflectivity e phahameng ea aluminium ho bolela hore mahlaseli a laser a ka tlola ho potoloha sebaka sa mosebetsi, e leng se eketsang kotsi ea ho pepesehela mahlo le letlalo.

Netefatsa hore ho na le mekhoa e nepahetseng ea polokeho ea laser, ho kenyeletsoa le tšebeliso ea lieta tsa mahlo tse sireletsang le tse sireletsang mahlo.

Ho Ntša Mosi

Ho tjheseletsa aluminium ho ka hlahisa mosi o kotsi, ho kenyeletsoa le o tswang ho mouoane wa dielemente tse kopanyang tse kang magnesium le zinc.

Mekhoa e nepahetseng ea ho kenya moea le ho ntša mosi e bohlokoa ho sireletsa mochini o kopanyang le sebaka se haufi.

Thibelo ea Mollo

Ho kenella ha mocheso o phahameng le tšepe e qhibilihisitsoeng e amanang le aluminium ea ho welding ka laser ho ka baka kotsi ea mollo.

Nka mehato ea ho thibela ho hotetsoa ha lintho tse tukang tse haufi 'me u be le lisebelisoa tse loketseng tsa ho tima mollo haufi.

Litlhophiso tsa Aluminium tsa ho Welding ka Laser

Foreime ea Aluminium ea ho Welding ea Laser e Tšoaretsoeng ka Letsoho

Ha ho tluoa tabeng ea ho tjheseletsa aluminium ka laser, litlhophiso tse nepahetseng li ka etsa phapang e kholo.

Litlhophiso tse Akaretsang tsa Aluminium ea ho Welding ka Laser (Bakeng sa Litšupiso Feela)

Matla a Laser

Ho reflectivity e phahameng ea aluminium ho bolela hore matla a phahameng a laser a atisa ho hlokahala, ho tloha ho 1.5 kW ho isa ho 3 kW kapa ho feta, ho latela botenya ba thepa.

Ntlha ea Focal

Ho tsepamisa lehlaseli la laser hanyane ka tlase ho bokaholimo ba aluminium (hoo e ka bang 0.5 mm) ho ka thusa ho ntlafatsa ho kenella le ho fokotsa ho reflectivity.

Khase e Sireletsang

Argon ke khase e sireletsang e sebelisoang haholo bakeng sa aluminium ea ho tjheseletsa ka laser, kaha e thusa ho thibela oxidation le masoba ka har'a weld.

Bophara ba mahlasedi

Ho ntlafatsa bophara ba lehlasedi la laser, hangata pakeng tsa 0.2 le 0.5 mm, ho ka leka-lekanya ho kenella le ho kenya mocheso bakeng sa botenya bo itseng ba thepa.

Lebelo la ho tjheseletsa

Lebelo la ho tjheseletsa le lokela ho leka-lekana ho thibela ho se kenelle (ka potlako haholo) le ho kenella mochesong o feteletseng (ho lieha haholo).

Lebelo le kgothaletswang hangata le tloha ho di-inchi tse 20 ho isa ho tse 60 ka motsotso.

Likopo tsa Aluminium ea ho Welding ka Laser

Aluminium ea ho Wellisa ka Laser e nang le Laser Welder e Tšoaretsoeng ka Motlakase

Ho tjheseletsa ka laser e se e le mokhoa o tsebahalang oa ho kopanya likarolo tsa aluminium liindastering tse fapaneng ka lebaka la melemo ea eona e ikhethang.

Indasteri ea Likoloi

Li-welder tsa aluminium laser li sebelisoa haholo indastering ea likoloi ho kopanya liphanele tsa aluminium, mamati le likarolo tse ling tsa sebopeho.

Sena se thusa ho fokotsa boima ba koloi, ho ntlafatsa ts'ebeliso e ntle ea mafura, le ho ntlafatsa matla le ho tiea ha 'mele oa koloi ka kakaretso.

Indasteri ea Lifofane

Lefapheng la lifofane, ho tjheseletsa ka laser ho sebediswa ho kopanya di-blade tsa enjene, di-disc tsa turbine, mabota a dikhabini le mamati a entsweng ka di-alloy tsa aluminium.

Taolo e nepahetseng le sebaka se fokolang se amehileng ke mocheso sa ho welding ka laser li netefatsa botšepehi ba sebopeho le ho tšoarella ha likarolo tsena tsa bohlokoa tsa lifofane.

Lisebelisoa tsa Elektroniki le Puisano

Ho tjheseletsa ka laser ho sebediswa ho tjheseletsa dikarolo tsa aluminium disebedisweng tsa elektroniki, tse kang diboto tsa potoloho, disensara le dipontsho.

Ho nepahala ho hoholo le ho iketsetsa ha welding ea laser ho nolofalletsa likhokahano tse tšepahalang le tse tsitsitseng, tsa bohlokoa bakeng sa ts'ebetso le botsitso ba lihlahisoa tsa elektroniki.

Lisebelisoa tsa Bongaka

Ho tjheseletsa ka laser ya aluminium ho sebediswa tlhahisong ya disebediswa tsa bongaka, ho kenyeletswa disebediswa tsa ho buoa, dinalete, di-stents le disebediswa tsa meno.

Tlhaho ea ho tjheseletsa ka laser e hloekileng le e se nang tšenyo ke ea bohlokoa bakeng sa ho netefatsa polokeho le bohloeki ba lihlahisoa tsena tsa bongaka.

Ho Sebetsa ka Hlobo

Ho tjheseletsa ka laser ho sebediswa indastering ya ho sebetsana le hlobo ho lokisa le ho fetola hlobo ya aluminium,

Tse kang ho hatakela hlobo, hlobo ea ente, le hlobo ea forging.

Ho eketsa thepa ka nepo le bokgoni ba ho lokisa ka potlako ba ho tjheseletsa ka laser

Thusa ho atolosa nako ea bophelo le ts'ebetso ea lisebelisoa tsena tsa bohlokoa tsa tlhahiso.

Ka ponahalo ea mochini o monyane le o monyenyane, mochini oa ho welder oa laser o nkehang habobebe o na le sethunya sa ho welder sa laser se ka tsamaisoang ka letsoho, se bobebe ebile se loketse lits'ebetso tsa ho welder tsa laser tse ngata ka likhutlo le libaka life kapa life.

Matla a Laser:1000W - 1500W

Boholo ba sephutheloana (mm):500*980*720

Mokhoa oa ho Pholisa:Ho Pholisa Metsi

E Theko e Tlase le e nkehang habobebe

Mochini oa ho tjheseletsa oa laser oa faeba oa 3000W o na le tlhahiso ea matla a maholo, e o nolofalletsang ho tjheseletsa lipoleiti tsa tšepe tse teteaneng ka laser ka lebelo le potlakileng.

E hlomelitsoe ka sesebelisoa sa ho futhumatsa metsi se nang le matla a mangata ho pholisa mocheso oa sesebelisoa sa ho futhumatsa ka laser hang-hang, sesebelisoa sa ho futhumatsa ka laser se nang le matla a maholo se ka sebetsa hantle 'me sa hlahisa boleng bo phahameng ba ho tjheseletsa bo sa fetoheng.

Tlhahiso e Phahameng ea Matlabakeng sa Tikoloho ea Liindasteri

Bokgoni bo PhahamengBakeng sa Boitsebiso bo Botenya

Ho Pholisa Metsi a Liindasteribakeng sa Tshebetso e Ikhethang