Tokiso ea Mabenyane a ho Wellisa ka Laser

Ho tjheseletsa ka laser ke mokhoa o mocha o fetotseng indasteri ya mabenyane.

Ha ba sebelisa mochini oa ho tjheseletsa mabenyane ka laser, baetsi ba mabenyane ba ka etsa li-weld tse nepahetseng le tsa boleng bo holimo holim'a mefuta e fapaneng ea litšepe, ho kenyeletsoa khauta, silevera le platinum, ntle le ho beha botšepehi kapa ponahalo ea mabenyane kotsing.

Mabenyane a ho Welding ka Laser ke eng?

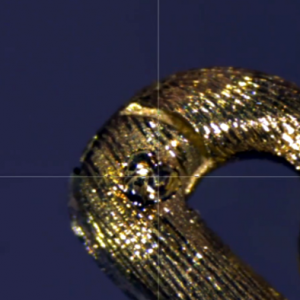

Mabenyane a ho tjheseletsa ka laser

Molemo o ka sehloohong oa ho tjheseletsa mabenyane ka laser ke ho nepahala le taolo ea eona.

Lehlaseli la laser le ka tsepamisoa sebakeng se senyenyane,

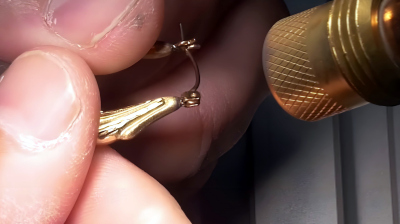

Ho lumella barekisi ba mabenyane ho tjheseletsa likarolo tse bonolo

Ntle le ho senya thepa e potolohileng.

Sena se etsa hore e be molemo haholo bakeng sa mesebetsi e kang ho beha mahakoe,

Ho lokisa litšoantšo tse rarahaneng tsa tšepe,

Le ho kopanya mabenyane a rarahaneng.

Ha ho bapisoa le Mekhoa ea Setso ea ho Welding:

Ho tjheseletsa ka laser ho hlahisa mocheso o fokolang, ho fokotsa kotsi ea ho fetoha kapa mokhathala oa thepa.

Sena se bohlokoa haholo ha o sebetsa ka majoe a nang le mocheso joalo ka emerald le opals.

Ho tjheseletsa ka laser ho boetse ho felisa tlhoko ea lisebelisoa tse ling tsa ho tjheseletsa,

Ho etsa qetello e hloekileng, e se nang sekoli.

Mechini ea ho tjheseletsa ea laser ea mabenyane e bonolo ho e sebelisa 'me e ka kopanngoa le lits'ebetso tsa tlhahiso tse iketsang,

Ho ntlafatsa bokgoni le botsitso.

Hape ba na le litšenyehelo tse tlase tsa tlhokomelo,

Ho ba etsa letsete le sebetsang bakeng sa lithupelo tsa mabenyane le bahlahisi.

Ke mofuta ofe oa ho tjheseletsa o sebelisoang bakeng sa mabenyane?

Tokiso ea Mabenyane a ho Wellisa ka Laser

Mefuta e tloaelehileng haholo ea ho tjheseletsa e sebelisoang bakeng sa mabenyane keho tjheseletsa ha microresistanceleho tjheseletsa ka laser.

Ho tjheseletsa ka laser:

Ho tjheseletsa ka laser ho boetse ho tumme haholo indastering ea mabenyane.

Ho tjheseletsa ka laser ho sebedisa lebone le matlafaditsweng ho etsa manonyeletso a sa bonahaleng mabenyaneng.

Mokhoa ona o tsebahala ka ho tenyetseha ha oona, ho tšepahala ha oona le lebelo la oona

Ho tjheseletsa ka laser ho ka sebediswa hodima mefuta e mengata ya ditshipi tsa bohlokwa,

Ho tloha silevera e ntle ho ea ho platinum,

Ntle le ho baka ho robeha kapa tshenyo.

Ho tjheseletsa ho hanyetsang hanyane:

Ho tjheseletsa ka microresistance ke khetho e tsebahalang bakeng sa lits'ebetso tsa mabenyane.

Mokhoa ona o sebelisa monyetla oa ho hanyetsa litšepe tse fapaneng ho theha matla,

Ho tjheseletsa ka nepo ntle le ho senya thepa e potolohileng.

Mocheso o laoloang le sebaka se senyenyane sa ho tjheseletsa li etsa ho tjheseletsa ho hanyetsang hanyane

E loketse hantle bakeng sa mabenyane a bonolo.

Mekhoa e meng ea ho tjheseletsa:

Ho tjheseletsa ka BrazingleHo Wellisa Pulse Arcka linako tse ling li sebelisetsoa mabenyane hape,

Empa ha li atile haholo ho feta ho hanyetsa hanyane le ho tjheseletsa ka laser.

Ho betla ho kenyelletsa ho sebelisa thepa ea ho tlatsa ho kopanya litšepe,

Ha ho ntse ho sebediswa pulse arc welding ho kopanya dikotwana ka motlakase.

Leha ho le jwalo, mekgwa ena e kanna ya se fane ka boemo bo tshwanang ba ho nepahala le taolo

E hlokahala bakeng sa meralo e rarahaneng ea mabenyane.

Na U Batla ho Tseba Haholoanyane ka Mabenyane a ho Welding ka Laser?

Re ka Thusa!

Sesepa sa ho Welder sa Mabenyane sa Laser se Nepahetse Hakae?

Tokiso ea Mabenyane a ho Wellisa ka Laser

Bahoebi ba mabenyane ba laser ba tsebahala ka ho nepahala le ho nepahala ha bona ho ikhethang.

Lehlaseli la laser le shebaneng le lumella barekisi ba mabenyane ho etsa litokiso tse rarahaneng le tse bonolo ka ho nepahala ho totobetseng.

Tsohle ka ho Nepahala le Taolo:

Mocheso o matla oa laser le bokhoni ba ho fetoloa ho tloha ho 0.2mm ho isa ho 2mm ka bophara

E fana ka barekisi ba mabenyanetaolo e felletsengmoo laser e sebediswang teng.

Sena se ba dumella ho sebetsa haufi haholo le majoe a tshabang mocheso.

Ntle le ho baka tshenyo efe kapa efe.

Barekisi ba mabenyane joale ba ka etsa mesebetsi e neng e etsoa khafetsa

Pele ho ne ho sa khonehe kapa ho ja nako e ngata haholo ho sebelisoa mekhoa ea setso ea ho kopanya.

Phetoho ea Lipapali bakeng sa Indasteri ea Mabenyane:

Ho nepahala ha ho tjheseletsa ka laser ho fetola indasteri ea mabenyane.

E nolofalletsa barekisi ba mabenyane ho boloka botšepehi le ponahalo ea pele ea lintho tsa khale nakong ea tokiso,

Ntle le ho tlosa majoe kapa ho ipeha kotsing ea ho senya tšepe e bonolo.

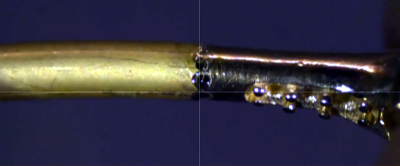

Laser e ka kopanya tšepe hammoho.

Ntle le ho fetola patina kapa ho oxidating sengoathoana sa pele.

Ho Finyella se sa Kgoneheng:

Bakeng sa meralo e mecha ea mabenyane, ho nepahala ha laser ho bohlokoa haholo.

Barekisi ba mabenyane ba ka kopanya likotoana tse rarahaneng, tse nang le taemane e ngata ha ba ntse ba boloka lintlha tse rarahaneng li sa senyeha,

Ntho e ka bang thata haholo ka toche ea setso.

Laser e ka boela ea sebelisoa ho potlakisa

'Me u lokise liphoso tse kang masoba a masoba ka nepo ntle le ho ama karolo e setseng ea karolo.

Na o ka Welded ka Laser Mabenyane a Khauta?

Mabenyane a Khauta a ho Wellisa ka Laser

E, o ka tjheseletsa khauta ka laser bakeng sa mabenyane.

Ho tjheseletsa ka laser ke mokhoa o sebetsang haholo le o nepahetseng

Bakeng sa ho sebetsa ka khauta le litšepe tse ling tsa bohlokoa ho etseng le ho lokisa mabenyane.

Melemo ea Bohlokoa ea ho Sebelisa ho Welding ka Laser bakeng sa Mabenyane a Khauta:

Ho feto-fetoha ha maemo- Basebelisi ba laser ba ka sebetsana le mefuta e mengata ea litšepe tsa khauta, ho tloha ho 10K ho isa ho 24K, hammoho le litšepe tse ling tsa bohlokoa tse kang platinum le silevera.

Tšenyo e Fokolang ea Mocheso -Ho tjheseletsa ka laser ho hlahisa mocheso o sebakeng se itseng haholo, ho fokotsa "sebaka se amehileng ke mocheso" le ho fokotsa kotsi ea ho sotha kapa ho fetola 'mala oa khauta.

Ho nepahala -Lehlaseli la laser le ka shejoa ka nepo ho tjheseletsa libaka tse nyane, tse rarahaneng ntle le ho ama karolo e setseng.

Sena se etsa hore ho tjheseletsa ka laser e be ntho e loketseng mesebetsi e kang ho beha mahakoe a bohlokwa, ho lokisa dinoko, le ho kopanya meralo e rarahaneng ya mabenyane.

Lebelo le Bokgoni -Ho tjheseletsa ka laser ke ts'ebetso e potlakileng, e lumellang barekisi ba mabenyane ho qeta litokiso le mesebetsi ea ho kopanya kapele ho feta ka mekhoa ea setso joalo ka ho kopanya.

Sena se ka eketsa tlhahiso mosebetsing oa ho etsa mabenyane.

Na o ka kgona ho weld mabenyane a silevera ka laser?

Mabenyane a Khauta a ho Wellisa ka Laser

E, o ka tjheseletsa silevera ka laser bakeng sa ho etsa mabenyane.

Silevera e hloka maemo a phahameng a matla a laser ha e bapisoa le litšepe tse ling tse kang khauta kapa platinum.

Motjhini oa laser o hloka ho ba le bonyane li-kilowatts tse 6 tsa matla a ho otla ha peak ho tjheseletsa silevera ka katleho.

Ts'ebetso ea ho tjheseletsa silevera hangata e nka nako e telele ho feta litšepe tse ling tsa bohlokoa.

Sena se bakoa ke kgatello e phahameng ya bokahodimo ba silivera.

Ho sebelisa khase e sa sebetseng joalo ka argon kapa naetrojene nakong ea ts'ebetso ea ho tjheseletsa ka laser

E ka thusa ho ntlafatsa boleng ba ho weld le ho fokotsa litšila.

Khase e sa sebetseng e hlahisa "leru" le sireletsang ho potoloha sebaka sa ho tjheseletsa.

E qala "tlase", E fella "molemo":

Ha o kenya silevera ka ho tjheseletsa ka laser, ho molemo ho sebedisa terata e tlatsitseng ya silefera e tlase hanyane,

Joalo ka terata e thata ea "ho tjheseletsa silevera", ho fapana le silevera e hloekileng ea 925.

Boleng bo tlase ba silevera bo dumella terata ho phalla hantle maemong a tlase a motlakase,

Ho fokotsa kotsi ea ho petsoha kapa ho petsoha ha lesoba.

Ho bohlokoa hoqala ka di-setting tse tlase tsa motlakase mme o sebetse butle-butle ha o kenya silevera ka welding ya laser.

Sena se thusa ho fumana mocheso o motle bakeng sa sengoathoana se seng le se seng mme se hlahisa di-weld tse matla le tse tsitsitseng haholoanyane.

Sehokelo sa ho Welder sa Laser sa Mabenyane

E ikhetha ka boholo ba mochini oa eona o monyane le ho sebetsa habonolo ho lokiseng mabenyane le tlhahisong ea mekhabiso.

Bakeng sa dipaterone tse ntle le dintlha tse qaqileng tsa mabenyane. O ka sebetsana le tsona ka sesebelisoa se senyenyane sa ho welder ka laser kamora ho itloaetsa hanyane.

Moralo o Monyenyanebakeng sa Phihlello.

Tšireletso ea Sefahla sa Elektronikibakeng sa Polokeho ea Mahlo.

E na le kutloisisoSistimi ea Taolo ea Dijithale.

LitšehetsoHo Pholisa Moea kapa Metsi.

Na ho Lokisa Mabenyane a ho Welding ka Laser ho Molemo ho Feta ho Soldering?

Ha ho tluoa tabeng ea ho lokisa mabenyane, barekisi ba mabenyane ba na le likhetho tse peli tse ka sehloohong:

Ho tjheseletsa ka laserleHo kopanya toche.

Mekhoa ena ka bobeli e na le melemo le mathata a eona,

'Me khetho qetellong e itšetlehile ka litlhoko tse khethehileng tsa sekhechana sa mabenyane.

Bakeng sa ho Welding ka Laser:

Ho tjheseletsa ka laser hangata ho nahanoamokhoa o motle oa ho lokisa mabenyane.

Ho fapana le ho kopanya mabenyane ka tsela ea setso, ho tjheseletsa ka laser ho lumella barekisi ba mabenyane ho lokisa mabenyane ka katleho le ka katleho.

Ntle le ho tlosa majoe a utloang mocheso

Hape ntle le tšebeliso ea flux kapa loto solder.

Mokhoa oa ho tjheseletsa ka laser o hloekile haholo, ha o na 'mala o sootho,

'Me ho hloka nako e nyane ho ntlafatsa sengoathoana.

Matla a ho Wellisa le ho Feto-fetoha ha Lintho:

Ho tjheseletsa ka laser ho boetse ho etsa tlamo e matla ho feta ho tjheseletsa.

Ho tjheseletsa hantle ka laser ho matla a fetang tšepe e sa tsoakoang hararo,

Kapa matla a 260 ho feta lenonyeletso la solder.

Sena se etsa hore litokiso tse entsoeng ka laser li tšoarelle haholoanyane 'me ho se be bonolo hore li hlōlehe ha nako e ntse e ea.

Molemo o mong oa ho tjheseletsa ka laser ke hore e ka sebelisoa holim'a mefuta e mengata ea thepa,

Ho kenyeletsoa mabenyane a tletseng khauta le a koahetsoeng ka khauta,

E leng se ka bang thata ho se lokisa ka ho sebedisa mekgwa ya setso ya ho kopanya dikotwana.