Ha ho tluoa tabeng ea ho sebetsa le masela, ho hlekefe e ka ba hlooho ea hau ea sebele, hangata e senya mosebetsi oa hao o boima.

Empa seke oa tšoenyeha!

Sehloohong sena, re tla arolelana malebela le maqheka a sebetsang bakeng sa ho fihlela lintho tse imetsoeng ntle le litšila, 'me re tla hlahloba merero ea hau ea lesela ho boemo bo bocha. Ha re inehele!

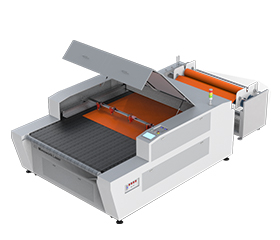

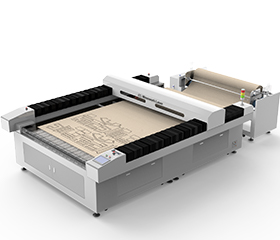

Sebelisa mohloa oa lesela laser

E 'ngoe ea mekhoa e metle ka ho fetisisa ea ho khaola lesela ntle le hore e ka senyeha ke ka ho sebelisa mochini o sehiloeng oa fabric. Mahlale ana a tsofetseng a sebelisa molamu o matla o phahameng ho fokotsa lesela ka mokhoa o hlakileng le ho nepahala, o tlohela bohale bo hloekileng le bo sa hloeka nako le nako.

Ho fapana le mekhoa ea setso ea ho seha, mohloa oa lesela la laser o nka mehato ea lesela ha le khaotsoe, e e tiisa ka mokhoa o atlehileng ka ho thibela ho qhekella.

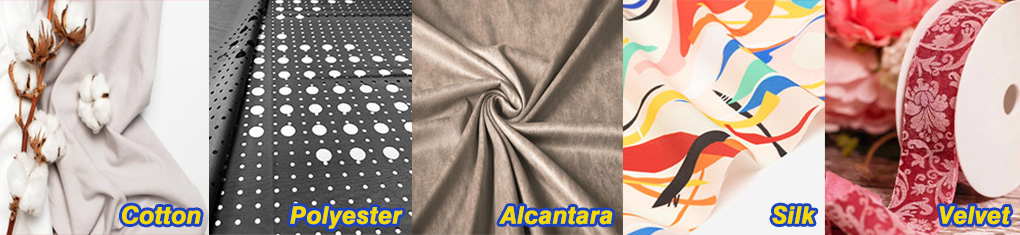

Khetha lesela le nepahetseng ho ba laser

Ha ho chechisa lesela le nang le mochini oa masela o sehiloeng oa laser,Ho bohlokoa ho khetha mofuta o nepahetseng oa lesela.

Masela a entsoe ka likhoele tsa tlhaho tse kangCottonMmeLinenka kakaretso ho bonolo ho e fokotsa mme e tla hlahisa mekhahlelo e hloekisitsoeng.

Ka lehlakoreng le leng, masela a maiketsetso a kang nylon le polyester a ka thatafalloa ho khaola mme a ka hloka liphetho tse tobileng tsa laser ho fihlela liphetho tse lakatsehang.

Lokisetsa lesela bakeng sa laser

Pele o kena ka laser ho roala lesela la hau,Mosebetsi o monyane oa pele o ea hole haholo ho fumana litholoana tse ntle.

1. Qala ka ho hlatsoa le ho omisa lesela la hau ho tlosa lerōle kapa maloanlahla a ka u sitisang ho itšeha.

2. Ha e etsoa, e fane ka tšepe e ntle ea ho kokobetsa likotsi kapa ho kopuoa - sena se thusa ho hlakoloa.

Theha faele ea vector

Ka mor'a moo, u tla hloka faele ea vector ea moralo oa hau. Faele ena ea dijithale e fana ka likarolo tse tonanse le sebopeho sa seo u batlang ho se fokotsa.

Ho ba le konopo ea Vector ho bohlokoa hobane e tataisa laser, e netefatsa hore o latela litlatsetso tse hloekileng, tse nepahetseng.

Lekola litlhophiso

This way, you can make sure the laser is cutting at the right power and speed. Don't hesitate to tweak the settings as needed to get the perfect results. It's also a good idea to try out different settings on various fabric types to find what works best for each material. Ho senyeha ho monate!

Pontšo ea Video | How to Laser Cut Fabric without Fraying

Ho seha lesela ntle le ho fofa ho tlameha ho ba le tsebo ea mang kapa mang ea ratang ho sebetsa le masela.

Le ha mekhoa ea setso e ka etsoa mosebetsing, hangata ba nka nako e eketsehileng 'me ho ka lebisa liphellong tse sa bonahaleng. Kenya mochini oa feshene oa lesela! This game-changing tool allows you to achieve perfect cuts effortlessly every single time.

Ha thekenoloji ea ho fetoha ea masela, ho sebelisa mohloa oa lesela o ntse o fumaneha ebile e theko e tlase, ebang o rala morero oa day kapa o tsamaisa ts'ebetso ea mofuta oa lapeng.

Ka lisebelisoa tse nepahetseng, mekhoa le theknoloji e nepahetseng ea Savy, o ka theha lihlahisoa tse ntle, tse shebahalang hantle habonolo. Happy crafting!

Glance | Mochini o sehiloeng oa Fabric Laser

Khetha e lumellanang le tlhoko ea hau

Ho ferekana le lipotso tsa hore na tlala ea Laser se feletsoe joang lesela ntle le ho qhekella

Nako ea poso: Feb-21-2023