Ke Hobane'ng ha U Ipatlisisa ha Re se re U Entse?

Na u nahana ka sesebelisoa sa ho hloekisa ka laser bakeng sa khoebo ea hau kapa ts'ebeliso ea hau ea botho?

Ka botumo bo ntseng bo hola ba lisebelisoa tsena tse ncha, ho bohlokoa ho utloisisa seo u lokelang ho se batla pele u reka.

Sehloohong sena, re tla u tataisa ka lintlha tsa bohlokoa tseo u lokelang ho li nahana:

Ho kenyeletsoa mokhoa oa ho khetha mohloli o nepahetseng oa laser bakeng sa litlhoko tsa hau

Bohlokoa ba dikgetho tsa ho iketsetsa

Le seo u lokelang ho se hopola mabapi le ho paka.

Ebang o reka ka lekhetlo la pele kapa o batla ho ntlafatsa disebediswa tsa hao, tataiso ena e felletseng e tla o thusa ho etsa qeto e nang le tsebo.

Na u batla Pulsed Laser Cleaner ho Specific?

Re khothaletsa sengoloa sena homokhoa oa ho khetha sesebelisoa sa ho hloekisa laser se nang le pulsedmolemong oa hau!

Litšebeliso tsa Mochini oa ho Hloekisa oa Laser

Mechini ea ho hloekisa ka laser e tšoaroang ka letsoho e fana ka mefuta e fapaneng ea lits'ebetso tse sebetsang liindastering tse fapaneng.

Mona ke maemo a mang a tšebeliso a khethehileng moo mechine ena e ipabolang:

Pele ho penta kapa ho penta, libaka tse ka holimo li lokela ho hloeka 'me li se na litšila.

Li-laser tse tšoaroang ka letsoho li tlosa mafome, oli le pente ea khale ka katleho holim'a tšepe, li netefatsa hore li khomarela hantle bakeng sa liphetho tse ncha.

Ts'ebetso ena e thusa haholo libakeng tsa likoloi le tlhahiso.

Paballong ea bonono le ea nalane, ho hloekisa ka laser ka letsoho ho bohlokoa haholo bakeng sa ho tsosolosa liemahale, liemahale le lintho tsa khale.

Ho nepahala ha laser ho dumella di-conservator ho hlwekisa libaka tse bonolo ntle le ho senya thepa ya pele, e leng se tlosang ditshila le oxidation ka katleho.

Litsebi li sebelisa li-laser cleaners tse tšoaroang ka letsoho ho lokisa likarolo tsa tšepe bakeng sa ho tjheseletsa kapa ho lokisa.

Li ka felisa mafome le litšila kapele likarolong tse kang liforeimi le litsamaiso tsa mosi, tsa ntlafatsa boleng ba litokiso le ho atolosa nako ea bophelo ba likarolo.

Sebakeng sa lifofane, ho boloka botšepehi ba likarolo ho bohlokoa.

Mechini ea ho hloekisa ka laser e tšoaroang ka letsoho e sebelisetsoa ho tlosa litšila likarolong tsa lifofane ntle le mekhoa e khorofo e ka bakang tšenyo.

Sena se netefatsa polokeho le ho latela melao e tiileng ea indasteri.

Bakeng sa likarolo tsa elektroniki tse bonolo, li-laser cleaners tse tšoaroang ka letsoho li fana ka mokhoa o sa amaneng le ho tlosa lerōle, masalla le oxidation.

Sesebelisoa sena se bohlokoa bakeng sa ho boloka ts'ebetso le ts'epo ea lisebelisoa tsa elektroniki ntle le ho beha kotsing ea tšenyo e bakoang ke mekhoa ea setso ea ho hloekisa.

Indastering ea likepe, li-laser tse sebelisoang ka letsoho li sebelisoa ho tlosa li-barnacle, bolele le mafome likotopong tsa likepe.

Sena ha se ntlafatse ponahalo ea likepe feela empa se boetse se ntlafatsa ts'ebetso ea tsona ka ho fokotsa ho hula ha tsona ka metsing.

Tlhokomelo ea kamehla ea lisebelisoa tsa indasteri ke ea bohlokoa bakeng sa katleho.

Mechini ea ho hloekisa ka laser e tšoaroang ka letsoho e ka sebelisoa ho hloekisa mechine le lisebelisoa, e leng se tlosang pokello e ka amang ts'ebetso.

Sena se thusa ho fokotsa nako ea ho se sebetse le ho lelefatsa bophelo ba lisebelisoa.

Kahong, mechine ena e sebelisetsoa ho hloekisa libaka pele ho sebelisoa thepa e ncha kapa ho qeta.

Ba ka tlosa masela, likhomaretsi le litšila tse ling tse tsoang konkreite, tšepe le libaka tse ling ka katleho, ba netefatsa motheo o hloekileng bakeng sa lits'ebetso tse ncha.

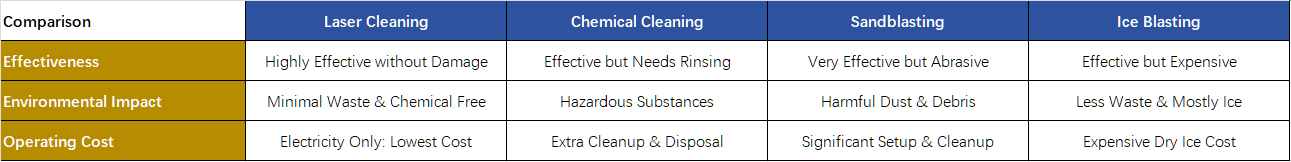

Papiso Pakeng tsa Mekhoa e Fapaneng ea ho Hloekisa

Mechini ea ho hloekisa ka laser e tšoaroang ka letsoho e fana ka mokhoa o mong oa sejoale-joale ho fapana le mekhoa ea setso ea ho hloekisa joalo ka ho hloekisa ka lik'hemik'hale, ho phatloha ka lehlabathe le ho phatloha ka leqhoa.

Mona ke papiso e hlakileng ea mekhoa ena:

Chate e Bontšang Papiso Pakeng tsa Mekhoa e Fapaneng ea ho Hloekisa

Na u batla ho tseba haholoanyane ka mechini ea ho hloekisa ka laser?

Qala ho Buisana le Rona Kajeno!

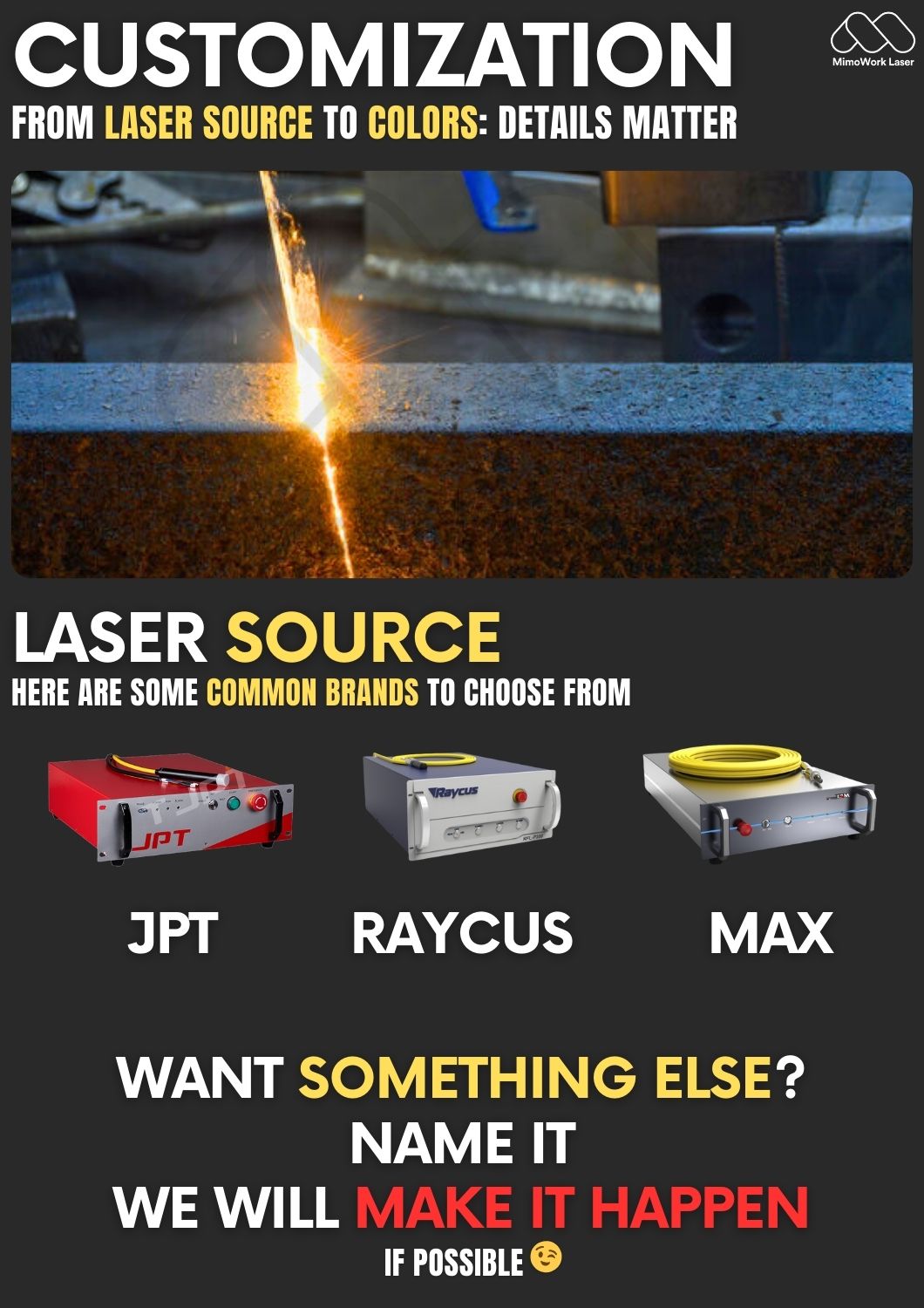

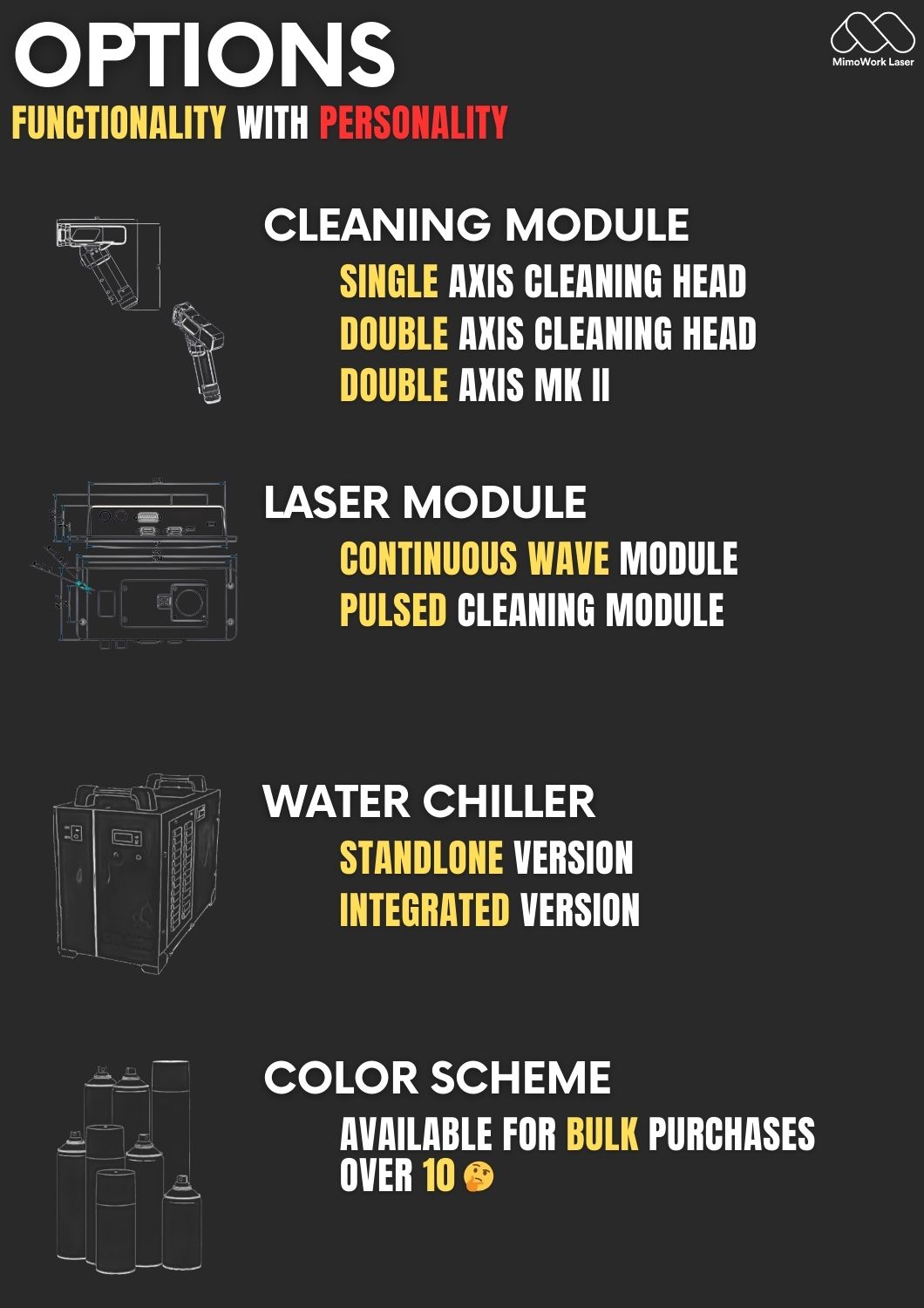

Ho iketsetsa le ho khetha

Re fana ka mefuta e mengata ea likhetho tsa ho iketsetsa bakeng sa bareki ba rona.

O ka kgetha ntho e nngwe le e nngwe ho tloha mohloding wa laser le mojuleng wa ho hlwekisa ho ya ho mojuleng wa laser le sehatsetsi sa metsi.

Ho feta moo, haeba o odara ka bongata (diyuniti tse 10 kapa ho feta), o ka kgetha le moralo wa mebala oo o o ratang!

Ha o tsebe hantle hore na o khethe eng? Ha ho na matšoenyeho!

Re tsebise feela hore na u tla be u hloekisa thepa efe, botenya ba hao le mofuta oa setshelo, le lebelo leo u le batlang la ho hloekisa.

Re mona ho u thusa ho theha setaele se phethahetseng bakeng sa litlhoko tsa hau!

Lisebelisoa tsa Sesepa sa Laser

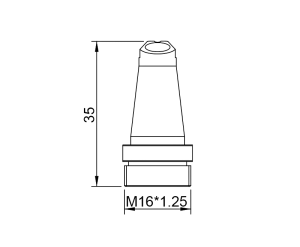

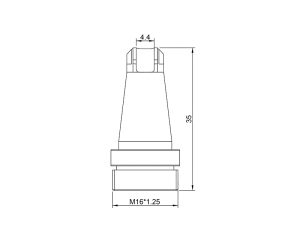

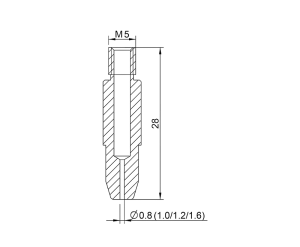

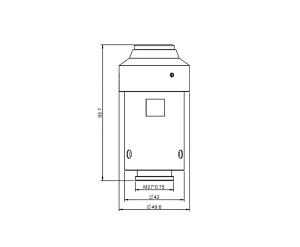

Bakeng sa lisebelisoa, re fana ka lilense tse ling tse sireletsang le mefuta e fapaneng ea li-nozzle tse etselitsoeng lits'ebetso tse fapaneng tsa ho tjheseletsa le ho hloekisa.

Haeba o hloka tlhahisoleseding e qaqileng kapa o batla ho reka disebediswa tse ding, ikutloe u lokolohile ho qoqa le rona!

Khetho ea Linotlolo tse Fapaneng bakeng sa Mochini oa ho Hloekisa/ho Wellisa ka Laser

Tlhahisoleseding e Eketsehileng ka Sesepa sa Laser

Laser ea fiber e nang le pulsed e nang le ho nepahala ho phahameng le sebaka se se nang mocheso hangata e ka fihlela phello e ntle ea ho hloekisa leha e le ka tlas'a phepelo e tlase ea motlakase

| Khetho ea Matla | 100w/ 200w/ 300w/ 500w |

| Maqhubu a ho otla ha pelo | 20kHz - 2000kHz |

| Phetoho ea Bolelele ba Pulse | 10ns - 350ns |

| Mofuta oa Laser | Laser ea Faeba e Pulsed |

| Letšoao la khoebo | Laser ea MimoWork |

Ho fapana le sehlatsoi sa laser sa pulse, mochini o hlwekisang wa laser o nang le maqhubu a sa kgaotseng o ka fihlella tlhahiso e matla haholo e bolelang lebelo le phahameng le sebaka se seholo sa ho hlwekisa.

| Khetho ea Matla | 1000w/ 1500w/ 2000w/ 3000w |

| Bophara ba mahlasedi | 10-200nm |

| Lebelo le Phahameng la ho Sekena | 7000mm/s |

| Mofuta oa Laser | Leqhubu le Tsoelang Pele |

| Letšoao la khoebo | Laser ea MimoWork |

Livideo tse mabapi le ho Hloekisa ka Laser

Mechini ea ho hloekisa ka laser e tšoaroang ka letsoho ke lisebelisoa tse tsoetseng pele tse etselitsoeng ho tlosa litšila, mafome le masela a khale holim'a libaka tse sebelisang theknoloji ea laser.

Li sebetsa ka ho lebisa lehlaseli la laser le shebaneng le thepa, e leng se etsang hore lintho tse sa batleheng li fetohe mouoane kapa li ntše ka katleho ntle le ho senya bokaholimo bo ka tlase.

Nako ea poso: Pulungoana-05-2024