Malebela le Maqheka a ho Finyella Liphetho tse Phethahetseng ka Sehahi sa Laser sa Lesela

Lesela la ho seha ka laser le fetola lintho haholo bakeng sa baqapi, le fana ka mokhoa o nepahetseng oa ho phethahatsa mehopolo e rarahaneng.

Haeba o batla ho fumana diphetho tse se nang sekoli, ho fumana di-setting le maqheka a hao hantle ke ntho ya bohlokwa.

Sehloohong sena, re tla u tsamaisa ka sohle seo u hlokang ho se tseba ka lesela la ho seha ka laser. Ho tloha litlhophisong tse ntle ka ho fetisisa ho isa mekhoeng e lekiloeng le e nepahetseng, re na le malebela a ho u thusa ho phahamisa merero ea hau le ho fihlela liphetho tse ntle haholo. A re ke re kenelle!

Lethathamo la Dikahare:

Lesela la ho Seha la Laser ke eng?

Lesela la ho seha ka laser ke theknoloji e ncha e fetolang papali ea masela le moralo.

Ha e le hantle, e sebelisa lehlaseli la laser le matla a holimo ho seha mefuta e fapaneng ea masela ka ho nepahala ho makatsang.

Melemo ea eona ea khahla: u fumana mathoko a hloekileng, a koetsoeng a emisang ho taboha litseleng tsa eona, bokhoni ba ho etsa lipaterone tse rarahaneng le tse rarahaneng, le ho tenyetseha ha ho sebetsa le ntho e 'ngoe le e 'ngoe ho tloha ho silika e bonolo ho ea ho kanavase e tšoarellang. Ke tsela e ntle ea ho phethahatsa lipono tsa hau tsa boqapi!

>> Ho Etsa ka Botlalo ka Leseli<<

Lesela le sehang ka laser ha le lekanyetsoe ke lithibelo tsa lisebelisoa tsa setso tsa ho seha, tse lumellang ho thehoa hadipaterone tse rarahaneng tse kang tsa lesela.

Meralo e ikhethileng, esita le matshwao kapa di-monogram tse ikgethileng diaparong le disebedisweng tse ding.

Ho phaella moo, ke ts'ebetso e sa amaneng le batho, ho bolelang hore ho na leha ho amehe ka ho toba 'melengka lesela,ho fokotsakotsi ea tšenyo kapa ho sotha.

Litlhophiso tse Molemohali tsa Laser bakeng sa Laser Cut holim'a Lesela

Ho fumana di-setting tse nepahetseng tsa laser ho bohlokwa bakeng sa ho fihlella diphetho tse ntle haholo ha o seha lesela. Di-setting tse ntle ka ho fetisisa di ka fapana ho latela mabaka a mmalwa, ho kenyeletswa botenya le mofuta wa lesela, moralo wa hao, le seha se ikgethang sa laser seo o se sebedisang.

Mona ke litataiso tse akaretsang tse tla u thusa ho seta laser ea hau bakeng sa ho seha lesela:

▶ Matla a Laser bakeng sa Lesela le Sehiloeng ka Laser:

Matla a laser ao u a khethang a lokela ho lumellana le botenya ba lesela la hao.

>> Bakeng sa masela a masesaane le a bonolo, ikemisetse ho beha matla a tlase a ka bang 10-20%.

>> Bakeng sa masela a teteaneng, eketsa matla ho fihla ho hoo e ka bang 50-60%.

Ka tsela ena, o tla netefatsa hore o kgaola hantle ntle le ho senya thepa ya hao!

Tube ea Laser bakeng sa Seha sa Laser

Ho seha ka laser ea CO2 ke mokhoa o sebelisoang haholo le o sebetsang hantle o loketseng masela a fapaneng, ho kenyeletsoa polyester, k'hothone, nylon, felt, Cordura, silika le tse ling.

Ka tloaelo, tube ea laser ea 100W e sebetsa hantle bakeng sa lits'ebetso tse ngata.

Leha ho le jwalo, haeba o na le ditlhoko tse ikgethang—jwalo ka ho seha masela a mangata kapa thepa e ikgethang e kopaneng—ho bohlokwa ho nahana ka ditlhoko tseo.

Kamehla re khothaletsa ho etsa teko ea laser pele re qala tlhahiso ea masela. Sena se thusa ho netefatsa hore u fihlela liphetho tse lakatsehang ntle le lintho tse makatsang!

Iteanye le ronabakeng sa likeletso tse ling tsa litsebi haeba u na le mathata ka lesela la ho seha ka laser.

▶ Lebelo la Lesela la ho Seha ka Laser:

Lebelo la ho seha la laser ke ntlha e 'ngoe ea bohlokoa e fapaneng ho latela botenya ba lesela:

>> Bakeng sa masela a masesaane le a bonolo, sebelisa lebelo le liehang la hoo e ka bang 10-15 mm/s.

>> Bakeng sa masela a teteaneng, o ka eketsa lebelo ho fihla ho hoo e ka bang 20-25 mm/s.

Ho lokisa lebelo ka nepo ho netefatsa ho seha ho hloekileng ha ka nako e ts'oanang ho boloka botšepehi ba lesela!

▶ Makgetlo:

Beha maqhubu a laser ho boleng bo phahameng ba 1000-2000 Hz.

Sena se netefatsa ho seha ho hloekileng le ho nepahetseng, ho fokotsa kotsi ea mathoko a masesaane.

▶ Thuso ea Moea:

Ho sebelisa tšobotsi ea thuso ea moea ho molemo.

E thusa ho tlosa lithōle sebakeng seo ho sehiloeng ho sona,ho e boloka e hloekile le ho thibela tšenyo e ka bang teng leselang nakong ea ts'ebetso ea ho seha.

▶ Sesebelisoa sa ho ntša mosi:

Ho Hloekisa ka Laser bakeng sa ho Tlosa Mosi

Ha o seha thepa e itseng e kopaneng, o ka kopana le monko o sa thabiseng.

Sesebelisoa sa ho ntša mosi se bohlokoa bakeng sa ho boloka tikoloho e hloekile, haholo-holo bakeng sa bareki ba sebetsang mererong e bonolo, joalo ka mekotla ea moea.

Sena se thusa ho netefatsa tikoloho e sireletsehileng le e monate ea ho sebetsa.

Thesesebelisoa sa ho ntša mosie ka u thusa ho rarolla tsena.

Ha re ntse re se na leseli ka ho beha lesela la ho itšeha ka laser, ikopanye le rona bakeng sa likeletso tse qaqileng haholoanyane

Mekhoa le Malebela a ho Seha Lesela ka Laser

Ho fihlela diphetho tse ntle ka ho fetisisa ha lesela la ho seha ka laser,nahana ka mekhoa le malebela a latelang:

1. Ho Lokisa Lesela

Hlatsoa le ho Aena:Kamehla hlatsoa le ho aena lesela ho tlosa matheba le litšila.

Sehatsetsi se Tsitsitseng:Tlotsa sesebelisoa se tsitsitseng sa fusible ka morao ho lesela. Sena se thusa ho thibela ho sutha nakong ea ts'ebetso ea ho seha.

2. Mehopolo ea Moralo

Ho rarahana le Lintlha tse qaqileng:Hopola ho rarahana ha moralo oa hau.

Qoba dintlha tse nyane haholo kapa dikhutlo tse bohale, kaha tsena e ka ba phephetso ho di seha ka nepo ka seha sa laser sa lesela.

3. Likhao tsa Teko

Etsa Sekhahla sa Teko:Kamehla etsa teko ea ho seha lesela le sa qaloang pele u seha moralo oa hau oa ho qetela.

Sena se tla u thusa ho khetholla litlhophiso tse ntle ka ho fetisisa tsa laser bakeng sa lesela le moralo oa hau o ikhethileng.

4. Ho Hloekisa Mochini oa ho Seha oa Laser oa Lesela

Tlhokomelo ea Kamehla:Kamora ho seha, hlwekisa seha sa laser ho thibela hore ditshila di se ke tsa bokellana, e leng se ka senyang mochini.

Tlhokomelo e tloaelehileng e netefatsa ts'ebetso e ntle le nako e telele.

Pontšo ea Video | Mokhoa oa ho Seha Lesela la Canvas ka Laser

Pontšo ea Video | Na Laser e ka Seha Lesela la Mela e Mengata?

Hobaneng Sehahi sa Laser sa Lesela e le Sesebelisoa se Molemohali sa ho Seha Lesela

Leha li-cutter tse fapaneng tsa laser li ka seha lesela, se-cutter sa laser se inehetseng ke khetho e ntle ka mabaka a 'maloa:

1. Ho nepahala le ho nepahala

Moralo o Ikhethileng: Lisehi tsa laser tsa lesela li etselitsoe ka ho khetheha ho seha lesela, li na le software e lumellang taolo e nepahetseng holim'a ts'ebetso ea ho seha. Sena se netefatsa hore lesela le sehiloe ho latela litlhaloso tse nepahetseng tsa moralo oa hau.

2. Likarolo tse Ikhethileng

Thuso ea Moea: Li-cutter tse ngata tsa laser tsa lesela li na le likarolo tsa thuso ea moea tse fefolang lithōle sebakeng sa ho seha. Sena se boloka lesela le hloekile 'me se fokotsa kotsi ea tšenyo nakong ea ts'ebetso ea ho seha.

3. Bokhoni ba Moralo o Rarahaneng

Mehlala e Rarahaneng: Ho nepahala ha ho seha ka laser ea lesela ho nolofalletsa baqapi ho etsa meralo e rarahaneng le e qaqileng eo ho ka bang thata ho e fihlela ka mekhoa ea setso ea ho seha.

Ha re phethela,lesela la ho seha ka laserkeboqapi le bo nepahetsengmokhoa oa ho seha lesela o fang baqapi bokhoni ba ho etsameralo e rarahaneng ka ho nepahala le ho nepahala.

Ka ho sebelisaeka ho le letonaLitlhophiso tsa laser, mekhoa.

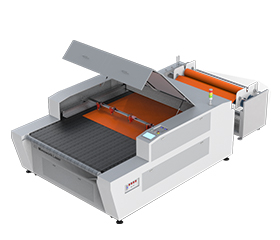

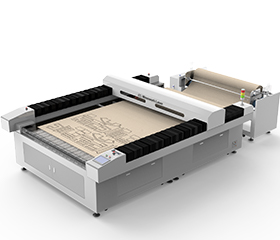

Mochini oa ho Seha oa Laser oa Lesela

Khetha e lumellanang le litlhoko tsa hau

Mokhoa oa ho Seha Lesela ka Laser Lapeng kapa Fekthering?

Haufinyane re fumane litlhoko tse ngata mabapi le li-cutter tsa lesela tsa laser bakeng sa tšebeliso ea lapeng kapa workshop, re nkile qeto ea ho hlakisa le ho otloloha.

E, lesela le sehiloeng ka laser lapenghoa khonehaempa o hloka ho nahana ka boholo ba lesela la hao le boholo ba bethe ea laser.

Hangata, sehahi se senyenyane sa laser se tla ba setle haholo joalokaseha sa laser 6040leseha sa laser 9060.

'Mesistimi ea moea e hlokahalang, ho molemo haeba o na le phaephe ya ho kenya moya kapa sokete.

Bakeng sa fektheri,tlhahiso e ngata ea hlokahala, kahoo re khothaletsa tekanyetsosehahi sa laser sa lesela1610lemochini o moholo oa ho itšeha oa laser oa fomate1630.

Sesebelisoa sa ho fepa ka bohonaletafole ea phetisetsoba ka sebetsa 'moho, ba hlokomelaothomathikiho seha lesela ka laser.

Hase feela seo, re entse lipatlisiso le ho hlahisa litharollo tse feto-fetohang bakeng sa katleho e phahameng, basebetsi ba fokolang, le litlhoko tse ling tse khethehileng.

Mohlala: Lihlooho tse ngata tsa Laser bakeng sa ho Seha Lesela

◼Hlooho ea Laser e nang le Letšoao la Enke: Ho Tšoaea le ho Seha

Mofepi oa mekhahlelo e 'meli:Lesela la Lera la Li-Layers tse 2 le Sehiloeng ka Laser

Ho thoe'ng ka ho Ngola ka Laser ho Lesela?

Karolong ea mantlha ea ho betla ka laser ea CO2 ho na le laser ea CO2 ka boeona, e hlahisang khanya e matla haholo ho bolelele ba leqhubu bo itseng. Bophahamo bona ba leqhubu bo sebetsa haholo bakeng sa ho betla le ho seha thepa e fapaneng, ho kenyeletsoa le lesela.

Ha lehlaseli la laser le kopana le lesela, le futhumatsa bokaholimo, e leng se bakang mouoane o fumanehang sebakeng seo. Ts'ebetso ena e hlahisa dipaterone tse nepahetseng le tse rarahaneng, e leng se lumellang meralo e qaqileng eo ho leng thata ho e fihlela ka mekhoa ea setso.

Melemo ea ho betla ka laser ea CO2:

1. Ho nepahala:Bokhoni ba ho etsa dipaterone tse rarahaneng le tse qaqileng ka ho nepahala ho hoholo.

2. Ho feto-fetoha ha maemo:E loketse mefuta e mengata ea masela, ho kenyeletsoa k'hothone, polyester le metsoako.

3. Botsitso:Mokhoa o hloekileng ha o bapisoa le ho betla ka mokhoa oa setso, o fokotsang litšila le tšebeliso ea lik'hemik'hale.

Ho Matlafatsa Boqapi

Ho betla ka laser ea CO2 ke theknoloji e ncha e fetolang tsela eo masela a raliloeng le ho hlahisoa ka eona. E fana ka sesebelisoa se matla bakeng sa litsebi tsa mesebetsi ea matsoho, bo-rakhoebo le baqapi, se ba nolofalletsang ho sutumelletsa meeli ea boqapi.

Lesela la ho Ngola ka Laser Joaloka Alcantara, Boea bo Koetsoeng, Felt

Hlahloba Setaele sa Lesela la ho Ngola ka Laser

1. Ho Khetha Lesela le Nepahetseng

2. Mohlala oa ho Ngola Moralo (Bitmap vs Vector)

3. Liparamithara tse ntle ka ho fetisisa tsa Laser

4. Apara Lesela 'me U Qale ho le Fata

Ebang o rata feshene, setsebi sa mesebetsi ea matsoho, kapa moetsi ea hlokomelang tikoloho, mongolo oa CO2 laser o fatiloeng leselang o bula lefatše la menyetla e emetseng ho hlahlojoa. Ho tloha ho pōpo ea lesela e ikhethang, e etselitsoeng motho ka mong ho ea ho lits'ebetso tsa meralo e mecha, bokhoni ha bo na moeli!

Mehlala ea Lesela la ho Ngola ka Laser

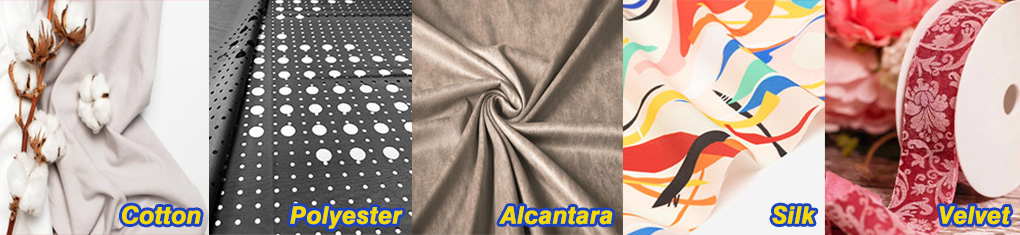

Hase masela ohle a loketseng ho betla ka laser. Mona ke tlhaloso ea mefuta ea masela a sebetsang hantle:

Masela a Molemohali bakeng sa ho Ngola ka Laser

Polyester: Masela a nang le tekanyo e phahameng ea polyester ke a molemo ka ho fetisisa bakeng sa ho betla ka laser. Karolo ea polymer e sebelisana hantle le mocheso oa laser, e leng se lumellang ho betla ka nepo le ho hlaka. Polyester e sebelisoa hangata liaparong tsa lipapali le liaparong tse mafolofolo ka lebaka la ho tšoarella ha eona le thepa ea eona e tlosang mongobo.

Masela a Phephetsang

Lisebelisoa tsa Tlhaho le tsa Lintho tse Hloekileng: Masela a entsoeng ka k'hothone, silika, ulu, kapa lintho tse ling tse hloekileng a ka ba thata ho a betla. Lisebelisoa tsena li kanna tsa se hlahise litholoana tse hlakileng ka lebaka la sebopeho sa tsona le tsela eo li arabelang mochesong ka eona.

Qetello

Bakeng sa liphetho tse ntle ka ho fetisisa tsa ho betla ka laser, tsepamisa maikutlo masela a thehiloeng ho polyester. Thepa ea 'ona ha e nolofatse feela ho betla ka nepo empa hape e ntlafatsa ho tšoarella le ts'ebetso lits'ebetsong tse fapaneng.

Lisebelisoa tse Tloaelehileng tsa Lesela la ho Ngola ka Laser:

boea ba nku, ikutloa, bubble, denim,neoprene, naelone, lesela la kanavase, velvet, jj.

Pherekano efe kapa efe le Lipotso tsa Mokhoa oa ho Beha Laser Cutting bakeng sa Masela

Nako ea poso: Loetse-05-2023